Improving the quality of polymer-modified asphalt coating binder by settling resin of pyrolysis

Автор: Kiselev Vladimir P., Filimonov Vladimir S., Bugaenko Maksim B., Kemenev Nikolay V., Ivanova Luidmila A.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 8 т.6, 2013 года.

Бесплатный доступ

The quality of binder in asphalt mixes largely determines the characteristics of road surface. In the present study the possibility of modifying the binder by introducing the settling resin of pyrolysis of wood raw material into bitumen is considered in order to improve adhesion of bitumen to stone materials and to improve the quality of asphalt concrete.

Road surface, asphalt, resin pyrolysis, adhesion, bitumen, stone materials

Короткий адрес: https://sciup.org/146114804

IDR: 146114804 | УДК: 691.327:666.964.3

Текст научной статьи Improving the quality of polymer-modified asphalt coating binder by settling resin of pyrolysis

Modern quality of pavements in Russia leaves to desire their significant improvement [1]. Due to the large amount of spending materials needed for production of road surface in the form of crushed stone, gravel, binder composition and the presence of substantial quantities of various dead-end waste of various industries, such as legnina, rubber, wood waste, etc. there is a need to use them in road construction. Problems that arise therewith attract the attention of researchers and experts. Creation of asphalt mixtures that satisfy the consumers for their operational characteristics results in the long-term use of road surface, in reducing repair works, also in using the waste of various productions and, consequently, in significant reduce of road construction costs. One of important aspects in improving the quality of pavements is bettering the characteristics of the binder. From the literature [2-14] it is known that the use of block co-polymers such as styrene-butadiene-styrene (SBS), also known as bivinyl- styrene thermoplastic elastomer (DST-30-01 in RF, Kraton D 1101 in the Netherlands, Finapren in Belgium) enables to improve the properties of a polymer-bitumen binder: to expand plastic range when reducing the temperature of brittleness and increasing the temperature of softening, and also to increase the strength characteristics of asphalt concrete, its fracture strength, stability to shears etc. The thermoplastic polymers such as polyethylene are used for producing a polymer-bitumen binder. As the authors of papers [4-7, 1315] assert, the adhesive ability of a polymer-bitumen binder is higher than the initial bitumen. The

In our opinion, adding the butadiene to blocks of aromatic units of styrene really promotes to hardening the binder while improving its elasticity, i.e. increases the cohesive energy (W c ). However, the following should be considered. As a rule, the finished rubber products based on rubber and thermoplastic elastoplasts have a small quantity of adhesion. That would suggest that even uncured elastoplasts being added to the mass of bitumen are not able to increase the adhesion of the modified binder to the mineral materials significantly.

In this case the nature of the mineral material is irrelevant since in the majority of thermoplastic reactive groups are not included. To test this hypothesis the experiments were conducted to study the adhesive properties of modified bitumen. It is of a great interest to study the effect of introducing the sediment resin of pyrolysis of wood raw material into the bitumen on increasing the adhesion of bitumen to stone materials and improving the quality of asphalt concrete.

Experimental procedure

In a mixture the crushed stone is used obtained in the result of breaking the massive rocks and which meets the requirements of the State standard (the StSt) 8267-82, StSt 10260-82, StSt 8268-82. Natural and crushed sands, meeting the requirements of the StSt 8736-85, were used to prepare the mixture. The mineral powder used for making to asphalt is a product of crushed limestone, dolomites and other carbonate rocks with limited clay impurities (not more than 5 % by mass). The total amount of sesquioxides Al 2 O 3 + Fe 2 O 3 in the rock did not exceed 1.7 % by mass.

We used sediment resin of pyrolysis by humidity 7-12 % obtained upon thermal destruction of hydrolysis lignin (HL) or the pine nut shells (PNS) at the temperature of 450-500 °C in an inert atmosphere. Modification of bitumen of Achinsk petroleum refinery, brands BND 90/130 the StSt 22245-90 was carried out at the temperature of technology of asphalt production – 170 °C

At studying the composition of the original bitumen and modified binders the standard test methods were used:

– the temperature of softening by the “ring and sphere” method was determined according to the StSt 11506-73; the adhesion of bitumen with the sand and marble was defined by the StSt 11508-74; the temperature of brittleness by Fraas was determined according to the StSt 11507-78; extensibility at +25 °C and 0 °C was measured in accordance with the StSt 11505-75; penetration was determined according to the StSt 11502-82; elasticity, characterized by the ability of modified bitumen binder (MBB) to reversible deformation, was determined by reduce of the sample length, pre-stretched up to the rupture. Elasticity of binder was calculated by the formula

Е = ( D 25 + 3) - L1 -100%, (1)

D 25 + 3

where D25 – extensibility at 25 0C, cm; L1 – the sum of two parts of the sample (the final measurement), cm; 3 – the constant of the instrument.

Investigations of samples of organic compounds were carried out according to the StSt 12801-98 “Materials based on organic binders for road and airfield construction. Test methods.” The content – 896 – of asphalt in the mixture made 6.5 % from the weight of the mineral (over 100). Samples of asphalt concrete mixtures studied in the paper agreed with the requirements of the StSt 9128-97.

Results and discussion

Increasing the adhesion of the hydrophobic binder bitumen to sufficiently water-soaked stone materials of acid (granite) and basic (marble, limestone, dolomite) rocks can be achieved by introducing the asphalt binder into the composition binder of surface-active substances. Potential modifiers of oil bitumen are resins of pyrolysis of the plant or wood raw material being formed in the amount of about 10 % at obtaining charcoal. Phenolic substances in the settling pyrolysis tar, as it is shown in previous papers [16,17], are able to slow the processes of thermooxidative destruction of tars and bitumen what predetermines their use as inhibitors. Availability of functional groups in the settling pyrolysis tar which are characteristic of surface-active material [SAM] supposes also a demonstration of surface – active properties in this type of resins. All the above listed factors make for successful use of this product as an effective modifier, modifying properties of which are practically not studied.

An important indicator which determines the suitability of any additive into the binder is its impact on adhesion with the stone components of the asphalt. Studying the adhesion of modified by crude settling resin of pyrolysis (SRP), of hydrolysis lignin (HL) and pine (cedar) nutshells (PNS) of bitumen with stone material by the method according to Technical requirements (TQ) RosdorNII 5718-004052044773-95 showed a rather weak adhesion degree.

Adhesion of the initial bitumen as well as of the composition: bitumen BND 90/130 + SRP from HL; bitumen BND 90/130 + SRP from the SNH was rather weak:

A B = 38 %; A B+SRP from HL = 58 %; A B+SPR of CPN = 53 %;

where A – the surface share of mineral material covered with bitumen after boiling in a soda solution. According to the method RosdorNII TQ 5718-004-052044773-95 the A-value <50 % corresponds to the unsatisfactory adhesion of a binder to the surface of the mineral material, the value of A = 51-70 % corresponds to the satisfactory adhesion, the value of A = 71-90 % agrees with a good adhesion and the value of A = 91 – 100 % – with an excellent one.

When warming up the SRP at 170 C ° (the temperature of the cooking process of asphalt) for 1 hour in the oven the results of complex thermal analysis show that the bound water and volatile components are removed. Using the heated up to 170° C tars of pyrolysis of HL and SRP we prepared samples of the modified binder. Testing of adhesion to the surface of the mineral material has shown that it is assessed practically as a very good one:

A/ B + SRP from HL = 91 %; A/ B + SRP of CPN = 85 %

Thus, these results clearly show that using SRP for the preparation of the modified binder it is needed to remove remnants of water and volatile organic compounds from it which reduce the quality of the road coating. Since the adhesion of a binder modified by settling resin pyrolysis HL was higher later in the experiments then the SPR HL was used as the surface-active additive the SPR HL.

Indicators of physical and mechanical properties of the original bitumen BND 90/130 and bitumen, a modified by SRP HL are shown in the Table 1. As it can be seen from the Table 1, the adding the tar of pyrolysis (a more a liquid component) to the bitumen results in reducing its viscosity, what is – 897 –

Table 1. Physical and mechanical properties of the original bitumen and the bitumen modified by SRP

|

о нА А А о fl у о 5 и | .5 1 та " S е |

A А 1 1 ‘5 । ‘5 3 • 3 |

Е со та |

й 1 1 S та Л (Z) |

Е '^ та со та |

Е i t со та |

‘s f 1 § г| Q 5 |

|

О 0> Ан н та й $ ° Е 1 £ та |

об i 5 Е о Z |

^ |

Я |

S |

Я |

|

|

и СЧ 3 0 щ |

fl s i и Е о Z |

о |

л |

л |

||

|

о II О а 1 |

। та Е Z |

^ |

40 |

9 |

о |

|

|

§5 s ° Ан |

<54 |

2 |

40 |

S |

о |

ОО |

|

1^ СО § |

40 |

|||||

|

о ^ та й 3 та Е g 5 ° Н о |

S а Z а й Е й 'Е |

Ан (Z) Е й Е й S |

Ан (Z) Е + й Е Й S |

Ан (Z) Е + й Е Й S |

Ан (Z) Е + й Е Й S |

Ан G^ (Z) Е + й Е Й S |

|

Е о О |

2 |

ОО |

40" |

|

|

fl fl Он Он Е св Й та н |

fl О 3 N 2 СТ Е о S о •та g 1 8 й 'О1 и 2 |

о 75 1 75 й О |

* Он 3 S § |

О, ,fl i ад 6 |

As a mineral powder the limestone powder was used.

* The organic binder – bitumen modified by additives used in this study.

characterized by the deeper penetration of the needle into the asphalt (penetration) – at 25 °C., and also by a lower temperature of softening. Apparently, due to the presence of tars and oils in SRP it plays the role of a plasticizer. It should be noted that with SRP increasing in the bitumen in the sample № 1 – sample № 6 series the penetration and temperature of softening of the modified binder changes to a greater extent, but these changes do not go beyond the StSt 22245-90. The positive fact is that at modifying the bitumen by settling resin of pyrolysis in the frames of studying its extensibility somewhat increases at the temperature 25oC, i.e, the modified bitumen has a better plasticity.

Brittleness temperature of bitumen at adding SRP decreases within limits regulated by the StSt 22245-90. This is a quite natural phenomenon at adding the plasticizing agents to the binder. The results in the Table 1 show that the optimal number of settling resin of pyrolysis for modification of bitumen should be not more than 5 %. With increasing it up to 10 % the adhesion of a binder with marble gravel which is determined by the photograph of the sample number 2 does not meet the standard. In order to evaluate the impact of SRP in the binder on the quality of asphalt concrete the samples of asphalt concrete mixtures were prepared according to the recipe of the Table 2. The properties of the samples are given in the Table 3.

The data in the Table 3 shows that the samples of asphalt concrete mixtures prepared with a modified SRP binder, including also the sample number 5, for the preparation of which the bitumen with 5 % SRP was used correspond to the StSt 9198-97. However, the strength characteristics in the dry and water-saturated condition (after a brief – 1 day, and prolonged saturation by water – 14 days) exceed the requirements of the StSt 9128-97 and the respective indices of the ideal sample № 1 which is based on the original bitumen. Rather good quality indicators have the sample number 6 with 10 % SRP. He has only one slightly reduced parameter, it is the coefficient of a long-term water saturation which influences the frost resistance of the asphalt concrete. Its decline is evident from the introducing a large number of plasticizing additive the role of which in the mixture the SRP realizes. An appropriate loosening of the material structure takes place here. This is seen by reducing density, by increasing swelling and volumetric water saturation of road material. Presence of compounds in SRP, containing active functional groups, apparently, promotes a better adhesion of the asphalt binder to stone materials of asphalt and effects on the mechanical properties of asphalt concrete. This effect shows itself when the SRP amount in the bitumen makes up to 5 % wt.

In the exploitation course of roads the destruction of composite materials happens. An organic binder is exposed to corrosion, the stone materials, however, are practically not destroyed. Stability of properties after heating the 4 mm thick layer at the temperature 163 oC during 5 hours is an indirect characteristics of the organic binder resistance to the “aging”, it means to the thermal-oxidative destruction caused by impact of temperature fluctuations, solar radiation, weather conditions.

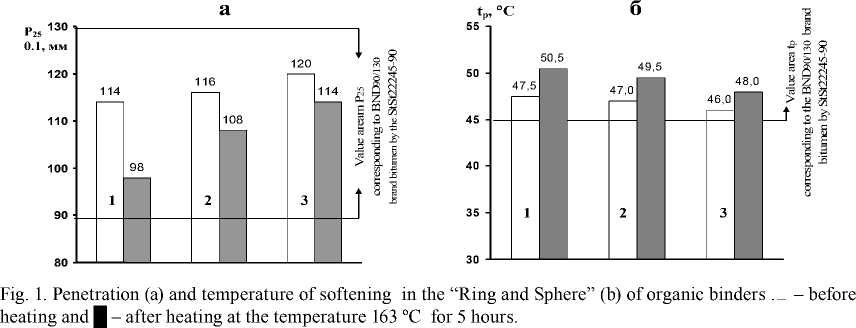

As it can be seen from the Table 1 and the Figure 1 (a & b), the difference in the temperature of softening before and after the test, also the bitumen modified by SRP in the amount of 0,5 % and 1,0 and 1,5 % by mass make respectively 3; 2,5; 2 ° C, what confirms the inhibiting role of the SRP in the

Table 3. Physical and mechanical parameters of organic compounds on the basis of bitumen, modified SRP identified by the StSt 12801-98 methods

|

о ■s § 8 |

° ^ о О V й |

8 о _ ^ ад >. < -о |

„ 8 v 5 Я g 5 |

(D S 8 S "о |

Breaking point at compressing the dry specimens, MPa |

Factors of water resistance |

|||

|

R 20 o C |

R o |

R o |

K w. |

K w. prot. |

|||||

|

1 |

6,5 |

2,44 |

1,69 1,5 + 4,0 |

0,39 |

3,20 --------- Not more than 2,20 |

1,15 -------- Not more than 1,0 |

7,0 ------- Not more than 12,0 |

0,87 ------- Not more than 0,85 |

0,77 ------- Not more than 0,7 |

|

2 |

6,5 |

2,44 |

1,86 |

0,39 |

3,00 |

1,38 |

7,2 |

0,95 |

0,77 |

|

3 |

6,5 |

2,45 |

2,01 |

0,42 |

3,62 |

1,40 |

7,6 |

0,98 |

0,76 |

|

4 |

6,5 |

2,43 |

2,15 |

0,56 |

3,64 |

1,42 |

8,2 |

0,99 |

0,78 |

|

5 |

6,5 |

2,40 |

2,75 |

0,59 |

4,12 |

1,48 |

7,9 |

0,88 |

0,76 |

|

6 |

6,5 |

2,36 |

3,15 |

0,98 |

223,34 |

1,35 |

8,8 |

0,85 |

0,57 |

* The numerator shows the physical and mechanical parameters of prepared asphalt based on the BND 90/130 bitumen, the denominator shows the requirements of the StSt 9128-97 for asphalt of the type B, of the brand 2 for the second road-climatic zone.

1 – bitumen of the BND 90/130 brand, containing 0.5 % wt. of SRP.

-

2 – bitumen, containing 1.0 % wt of. SRP.

-

3 – bitumen, containing 1.5 % wt. of SRP.

oxidative process of «aging» of a binder. The bitumen used in this study (Tables 1 and 5) fails in the test for “ageing” (Δ t soft. = 7 оС).

Changes in penetration tested for “aging” of bitumen samples also do not go beyond the BND 90/130 bitumen brand of the StSt 22245-90. It should be noted that at the “aging” of bitumen the complex chemical and physical diffusion processes take place. The processes of surface evaporation in existing or being formed at the “aging” of low-boiling components of petroleum bitumen run, the structure of the bitumen is compacted due to the formation of asphaltenes from resins and oils. The loss of mass is an important characteristic of the bitumen resistance to destruction at its heating under test conditions. The weight loss of samples of initial bitumen and modified bitumen with 0,5 %, 1 %, 1.5 % by mass, 5 % and 10 % by mass of SRP was determined during the test. It made 1,10 % 0,88 % 0,75 % 0,68 % 1,15 % and 2,28 %, respectively. As it can be seen from the data of dependence of weight loss of organic binders with different SRP amounts on heating time under the test conditions the adding the 5 and 10 % mass of resins result in a greater weight loss after heating than in the original bitumen. Probably after the addition of such an amount (5 % and especially 10 %) of resin the bitumen is diluted and the processes of evaporation of low-boiling fractions such as bitumen and tar are dominating.

Conclusion

Thus, the addition of settling resin of pyrolysis (SRP) into the asphalt in order to modify its properties enables to obtain the asphalt of the required by StSt 9128-97 quality, increases the adhesion of oil bitumen to the surface of mineral components of asphalt concrete, reduces the intensity of “ageing” of the bitumen under road coating exploitation. Optimal SRP amount in the modified asphalt binder must be not more than 5 % by mass.