Influence of carbon nanotubes on the durability and permeability of foam concrete

Автор: Nasimi Shahin, Ehsani Armin, Shambina Svetlana Lvovna, Gebre Tesfaldet Hadgembes

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 3 (117), 2025 года.

Бесплатный доступ

The research object is foam concrete modified with carbon nanotubes (CNTs). The aim is to investigate how CNT incorporation and dispersion affect the material’s permeability and durability, addressing key limitations of conventional lightweight concrete. through adding a range of additives into the mixing process. Foam concrete is one of the types of light concrete that is prepared by mixing sand, cement, water and foam. In general, one of the ways to improve the mechanical properties of concrete is to add a variety of additives to the mixing plan. Method. The mechanical properties are considered for the investigation by adding carbon nanotubes and considering the latest advancements in the field of nanomaterials in the manufacturing of concrete additives and their compatibility with foam and cement types that are accessible in the market. It is hoped that conducting this research will be a start for the next steps in the field of optimizing the production of fiber concrete with high elastic properties. In this project, by using different percentages of carbon nanotubes in the design, favorable results can be obtained. Results. These results show that with the increase in the percentage of carbon nanotubes in foam concrete, the penetration of chlorine ions has decreased by 9.7% compared to the control sample, the depth of water penetration has decreased by 4.8% compared to the control sample, and the water absorption has decreased by 5.5% compared to the control sample.

Carbon nanotube, Lightweight concrete, Permeability, Durability, Foam concrete, Nanotechnology

Короткий адрес: https://sciup.org/143184929

IDR: 143184929 | УДК: 69 | DOI: 10.4123/CUBS.117.5

Текст научной статьи Influence of carbon nanotubes on the durability and permeability of foam concrete

-

1 Introduction

One of the important problems in the design and implementation of structures, especially tall buildings and large concrete bridges, is the significant dead weight of their members. If the production of lightweight concrete with sufficient formability and strength is achieved, in addition to reducing the dead load of the structures, the construction cost will be significantly reduced. An advantage of using lightweight concrete is reducing the dead load of the structure. The construction industry has relied heavily on concrete, and because of their remarkable mechanical properties, nanoparticles can be used to improve cementitious composite performance and create high-strength concrete with strong binding and self-healing qualities. Lightweight concrete was first introduced by the Romans in the second century where the Pantheon has been constructed using pumice. [1]. The main preferred properties of lightweight concrete are its low density and thermal conductivity. So, its main advantages are reduction of deadload, faster building construction and lower haulage and handling costs [2]. Lightweight concrete is lighter than conventional concrete with a dry density between 300Kg/m3 and1840 Kg/m3 [3].

Most predominant practical challenges in the construction industry are to execute the robust design in the field. Even if it is implemented with great difficulties, the cost has reached a higher degree, since Nasimi, S.; Ehsani, A.; Shambina, S; Gebre T. H.

Influence of carbon nanotubes on the durability and permeability of foam concrete;

the materials requirement is very great. Many researches, have attempted to arrive at a unique solution for addressing robust design and construction difficulties, procuring large volume of materials with high cost with the lightweight concrete material. Through a variety of destructive and non-destructive testing, the mechanical and durability characteristics of conventional concrete and pumice lightweight aggregate concrete is evaluated, and a suitable substitute is discovered [4]. It demonstrates that adding more pumice aggregate will reduce the concrete's density and produce lightweight aggregate concrete. By substituting class C fly ash and silica fume for cement, the compressive strength of concretes made from expanded perlite and pumice aggregate mixtures was examined [5]. The workability and sample weight will be impacted if silica fume and class C fly ash are substituted for cement. To create environmentally friendly concrete, a cement mortar slurry including foam was studied as a new and highly beneficial material for the construction industry [6]. One of the primary drawbacks of foam concrete is the extensive use of river sand as a filler. For structural applications, lightweight concrete with polyethylene beads for thermal insulation was taken into consideration [7]. To determine mechanical characteristics, thermal resistance, and durability, mixtures exhibiting low unit weight and adequate compressive strength were chosen for in-depth analysis. Lightweight concrete is made with low density aggregates [8] rather than traditional natural aggregates, like perlite, pumice [9], vermiculite [10], expanded clay [11], thermo cole beads [12], coke breeze [13], artificial cinders [14], shale [15], slate [16], Cement Clinker aggregate [17], fly ash aggregate [18], and scoria etc. The typical normal weight aggregate has a density of around 2250 to 2400 kg/m3 whereas the lightweight concrete has density in the range of 1440 to 1850 kg/m3 [19]. The density variations are mainly due to the lightweight aggregate’s density nature and non-porous characteristics [20]. Because of the density reduction, the lightweight concrete has wide applications in manufacturing precast elements such as blocks, slabs and panels, as well as in the ready mixture applications with on-site additive [21].

Different purposes behind picking LWC as a development material are turning out to be progressively essential and more consideration is taken to vitality preservation and to utilization of industrial waste materials to supplant modest normal sources [22]. Due to decrease in dead weight of the material there is a possibility of reduction in size of the members in structure this helps in construction of lightweight structures in low seismic zones. LWC made with regular or from simulated total is characterized by the ACI Committee 213 into three classifications as per its quality and thickness [23].

Nanotechnology is not a new field, but a new approach in all fields. A lot of research has been done on adding nanoparticles to cement. Nanotechnology has wide applications in various fields such as food, pharmaceutical, medical, biotechnology, electronics, computer, communication, transportation, energy, environment, air, space, etc. In road and construction, this technology plays a role in the private sector. The applications of this phenomenon in the building industry and in construction in general have received very little attention due to the rapid growth of scientific and practical research of Nano sciences and techniques in all sciences and industries, but from 2010-2015 regarding Nano reinforcements. With the construction industry's growing impetus, a new wave in building materials has emerged [24].

The production of foam concrete with good quality depends on several factors such as suitable foaming material, method of foam production, proper distribution of it in the mixture, quality materials, mixer design, compliance with production principles and proper performance with fresh and hardened concrete. According to the need for and use of lightweight concrete in structural components, lightweight concrete is divided into load-bearing and non-load-bearing structures. According to the regulations of ACI 213 (Guide for Structural Lightweight-Aggregate Concrete) lightweight concrete is concrete whose 28-day strength is more than 17 MPa and its dry weight is not more than 1850 kg/m3. Non-structural light concrete is concrete that is not responsible for bearing and transferring force, and this category of concrete is mainly used as heat and sound insulation, decorating ceilings, filling foam slabs, as roof leveler and fireproof coating for steel beams. The dry specific gravity of this type of concrete varies from 240 kg/m3 to 800 kg/m3, and their 28-day compressive strength generally varies between 0.7 and 7 MPa. Foam concrete was first invented in Sweden in 1923 and is used due to the desirable properties mentioned [25], [26], [27]

Conventional concrete has several disadvantages, including the potential for porosity and cracking, which reduce the mechanical properties and durability of the material. To improve the durability and resistance to cracking of concrete, the concept of properly dispersing nanoparticles in the structure has become popular. Carbon nanotubes (CNTs) are an attractive material due to their remarkable functional properties and can enhance the mechanical performance of cement-based composites.

The tiny size of this nanomaterial makes it extremely difficult to disperse it uniformly throughout the cement-based composite, according to Van Der Waals' attraction hypothesis. Because of the materials' Nasimi, S.; Ehsani, A.; Shambina, S; Gebre T. H.

Influence of carbon nanotubes on the durability and permeability of foam concrete;

strong agglomeration tendency at the nanoscale, cementitious composites can have a major impact on their mechanical and microstructural performance. Achieving a uniform dispersion of carbon nanotube material in foam concrete is more difficult. Because of their remarkable mechanical properties, carbon nanotubes (CNTs) are one of the promising nanomaterials that can be used to improve the performance of cementitious composites. The ongoing difficulty of dispersion inside the cementitious structure complicates the homogeneous distribution of CNTs. While carbon nanotubes (CNTs) reduce the durability and permeability of foam concrete, their uniform distribution throughout the composite structure can improve the mechanical performance of CNT-cement composites. Considering the above drawbacks, this study investigated how carbon nanotubes affected the permeability and durability of foam concrete.

-

2 Materials and Methods

2.1 Specifications of consumables 2.1.1 Cement

-

2.1.2 Aggregates:

The cement used in this study is Portland Type II, whose physical and chemical characteristics are given in Tables 1 and 2:

Table 1. Physical characteristics of cement

|

Physical properties |

value |

|

|

Specific area of 1 cm²/gr |

2800 |

|

|

Expansion of autoclave test (%) |

0,8 |

|

|

hydration heat (Cal/gr) |

Initial (min) |

45 |

|

final (hour) |

6 |

|

|

Compressive strength (kg/cm²) |

3 day |

100 |

|

7 day |

175 |

|

|

28 day |

315 |

|

|

Hydration heat (Cal/gr) |

70 |

|

Table 2. Chemical characteristics of cement

|

Chemical elements |

SIO 2 |

AL 2 O 3 |

Fe 2 O 3 |

MgO |

SO 3 |

C 3 A |

IR |

LOI |

|

Content (%) |

20 |

6 |

6 |

5 |

3 |

8 |

0.75 |

3 |

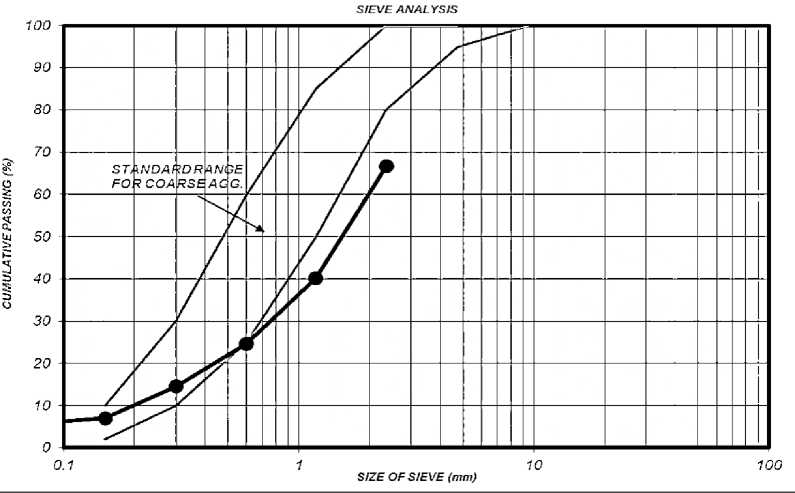

The ASTM test techniques (C136, C128, C127, C33, and C29) are used to determine the properties of fine and coarse aggregates, and the aggregates' maximum diameter is 19 mm. Table No. 3 displays the aggregates' physical and chemical properties. Additionally, Chart No. 1 displays the aggregate grading results.

Table 3: Fine (sand) and coarse (gravel) aggregates' physical and chemical properties

|

Aggregate type |

Apparent specific gravity Kg/m3 |

Relative humidity (%) |

Saturated humidity with dry surface (%) |

Modulus of softness F.M |

|

Sand |

1450 |

3 |

6 |

3.72 |

Fig. 1 - Fine-grained and coarse-grained materials with the permissible limits of the ASTM-C136-84a standard

2.1.3 Carbon nanotube particles:

2.2 Concrete mixing plan:

2.3 Test methods:

It is suggested that the two primary nanotechnology possibilities for reinforcing cements are carbon nanotubes (CNTS) and carbon nanofibers (CNFS). These nanoparticles' exceptional tensile strength, distinct electrical and chemical properties, and extremely high modulus of elasticity and resistance demonstrate their attractive potential to develop a new generation of construction materials. The application of these nanoparticles improves cement materials' mechanical properties, resistance to fracture propagation, electromagnetic wave protection, and capacity for self-healing. Carbon nanofibers are simpler to disperse in the cement mixture than nanotubes. They are also less expensive and easier to produce [28]. One of the primary issues with these nanomaterials is that their high internal gravity and extreme hydrophobicity make it impossible for them to be distributed uniformly in the cement mixture. Another issue is that they don't properly adhere to the cement paste. [29]. The specifications of carbon nanotubes are presented according to table number 4:

Table 4. Characteristics of carbon nanotubes used

|

OD |

length |

Purity |

Ash |

SSA |

True Density |

|

10-20 nm |

~ 30 µm |

≥95 wt % |

≤1.5 wt% |

200 m2/g |

2.1 g/cm3 |

In this research, the trial and error method has been used to plan the mixing. In this research, a control design with a 0.45 water-to-cement ratio with three grades of cement, 350, 400, and 450 kg/m3 was used, and the details of the sample mixing plan for durability, permeability, and compressive strength tests are according to Table 5.

Table 5. Mixing design

|

cement content (kg/m³) |

Material weight (kg) |

Foam volume (Lit) |

||

|

cement |

sand |

water |

||

|

450 |

450 |

1286 |

162 |

246 |

|

400 |

400 |

1121 |

144 |

316 |

|

350 |

350 |

750 |

136 |

361 |

In this research, concrete tests at the age of 90 days to test durability and permeability are in three plans with 350, 400 and 450 kilograms per cubic meter of cement and five percent of 0, 1, 2, 3, 4 and 5 carbon nanotube particles. , of which 12 samples were taken to test chlorine ion penetration, 12 samples to test water penetration depth, 12 samples to test surface water absorption.

-

2.3.1 Chlorine ion penetration test

One of the tests to determine the permeability of concrete is the chlorine ion permeability test according to the ASTM C1202 standard. In order to perform this test, first, it should be done from 15x15x15 cm cubic samples. The resulting concrete sample has a diameter of 100 mm and a thickness of 50 mm. The concrete sample is placed in a special cell of a permeable device, which contains a three percent sodium chloride solution on one side and a three percent caustic soda solution on the other side, and since one of the solutions are acidic and the other is open, the solution has found a polar state and an electric current flow in it, which has a potential difference of 60 volts. After 6 hours of the flow establishment, the intensity of the flow passing through the saturated concrete is obtained, which can be read from the computer connected to it. The higher the flow rate, the higher the permeability of concrete. In addition, it is the unit of permeability of concrete against chloride ions of Coulomb.

-

2.3.2 Testing the penetration depth of water under pressure

-

2.3.3 Short-term water absorption tests

We perform short-term water absorption test according to BS 1881 Part 12 standard. First, we put the concrete sample in the heater and set the temperature to 105±5 ºC until it is completely dry, then we weigh it and record the number, now the sample is placed in distilled water for half an hour so that Put 54.2 cm of water on the sample. After half an hour, we take the sample out of the water and dry its surface completely, then weigh it and record the number. Now, formula 1 is used to get the percentage of water absorption:

Another concrete test to determine permeability is the test to determine the depth of water penetration according to the standard. In order to perform this test, we place a 15x15x15 cm cubic sample in the machine cell, then open the pump valve and adjust the pressure to 5 bar. When the water pressure reaches 5 bar, the valve is closed and after 72 hours, we break the sample and read the three infiltration heights and record the average. The above device has three cells that can take three samples each time. Put it in the device. Also, there is a valve under each of the guards, which is used to regulate the pressure under the sample.

P=(W-D)/D

D= Dry weight of the sample in grams

W=Wet weight of the sample in grams

P= Percentage of water absorption

This test is also a good standard to determine the surface quality of concrete. Another use of this test is to control the quality of prefabricated concrete tables.

3 Results and Discussion

3.1 Penetration of chlorine ion

3.2 Short-term water absorption

3.3 Depth of water penetration

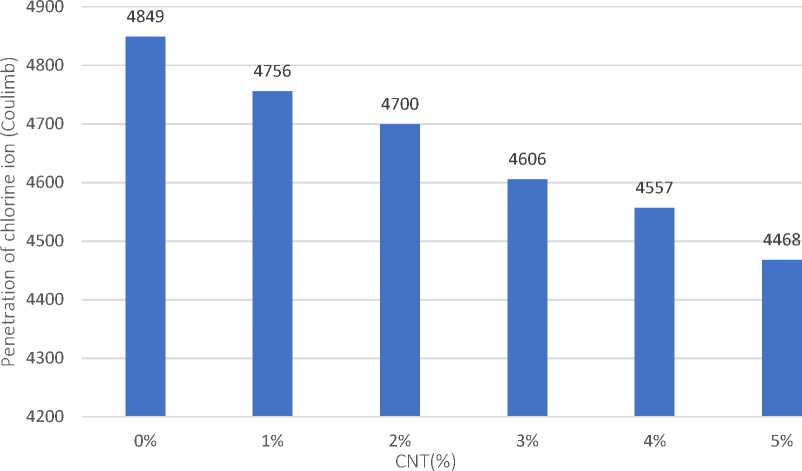

According to Figure 2, the lowest amount of chlorine ion penetration is in the sample made with 450 gauge and containing 5% of carbon nanotubes, which is the alternative of the chained nature of nano particles, which reduces the voids in the sample.

Fig. 2 - Chlorine ion penetration test results of samples made with a grade of 450 kg/m3

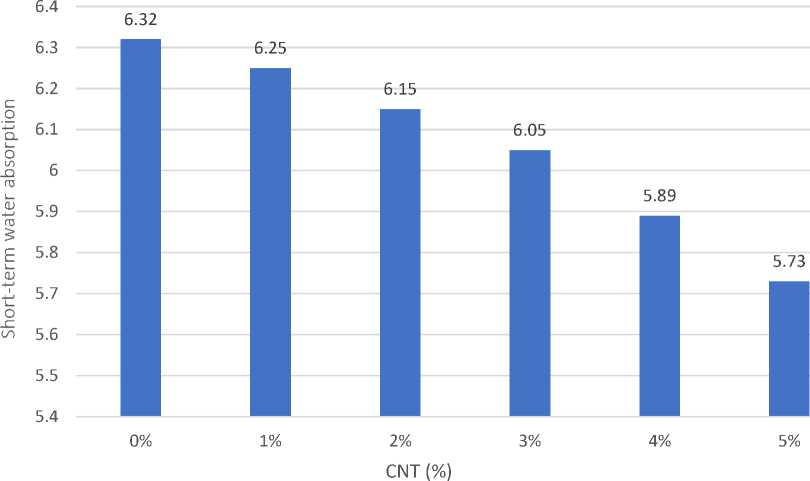

According to Figure 3, the lowest amount of short-term water absorption is in the sample made with 450 grade and containing 5% of carbon nanotubes, which is the alternative to the chain-like nature of nano particles, which causes a reduction in the size and thickness of the sample.

Fig. 3 - Results of short-term water absorption test of samples made with 450 kg/m3

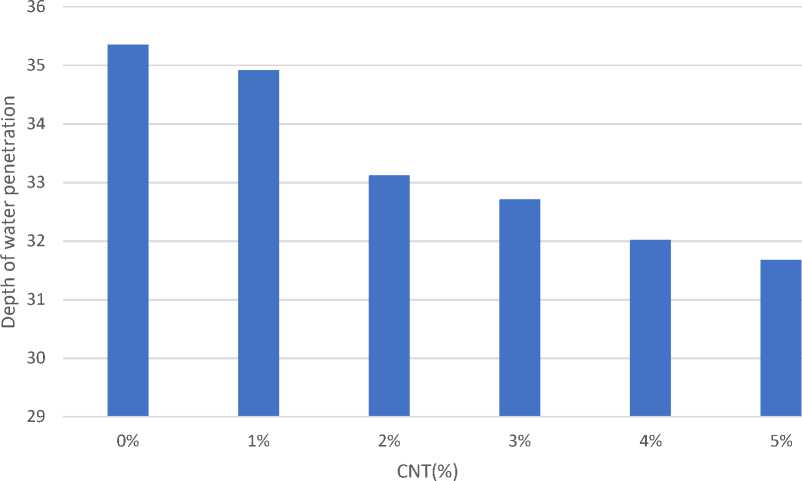

According to Figure 4, the lowest amount of water penetration is in the sample made with 450 gauge and containing 5% of carbon nanotubes, which is the alternative of the chain-like nature of nano particles, which reduces the voids in the sample.

Fig. 4 - The results of testing the depth of water penetration under the pressure of samples made with a grade of 450 kg/m3

-

4 Conclusions

This study examined the impact of carbon nanotubes on the permeability and durability of foam concrete by creating 15 cm cubic samples with carbon nanotubes. The samples' depth of water penetration, chlorine ion penetration, and short-term water absorption were compared. As summed up below, this comparison demonstrates that adding carbon nanotubes to concrete significantly improves its qualities.

-

1. The use of carbon nanotubes reduces the penetration of chlorine ions in the samples, which is about 9.7% less than the control sample.

-

2. The use of carbon nanotubes reduces the depth of water penetration in the samples, which is about 8.4% less than the control sample.

-

3. The use of carbon nanotubes reduces the percentage of short-term water absorption in the samples, which is about 5.5% lower than the control sample.