Influence of chromium-containing Al2О3 nanopowders on structural modifications in aluminum oxide micropowders

Автор: Lyamkina Nina E., Chiganova Galina А., Sokolov Аndrey S.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 4 т.11, 2018 года.

Бесплатный доступ

Influence of an additive of chromium-containing Al2O3 nanopowders on phase transitions in aluminum oxide micropowder (a waste from alumina production) is investigated. Aluminum oxide nanopowders were synthesized by shock-wave method. Chromium compounds were introduced during the synthesis as well as following annealing of powders. Main difference between obtained chromium-containing Al2O3 nanopowders was their phase composition. Mixtures of nanopowders and alumina macropowders were pressed and sintered. The additive of the Al2O3 nanopowder that was dopped with chromium ions during the synthesis and is characterized by the prevalence of θ-phase is demonstrated to be the most perspective for ceramics fabrication on the alumina base.

Aluminum oxide nanopowders, phase transition, corundum ceramics

Короткий адрес: https://sciup.org/146279374

IDR: 146279374 | УДК: 544.015.4:546.62-31 | DOI: 10.17516/1999494X-0068

Текст научной статьи Influence of chromium-containing Al2О3 nanopowders on structural modifications in aluminum oxide micropowders

mixtures that were used in our experiments (0.18%), we presume that phase transitions in NPs and their influence on processes taking place during alumina sintering play a key role. However, the influence of the chromium oxide presence on the corundum formation in alumina can not be excluded as e.g. in [6] it was shown that the addition of 0.2% Cr 2 O 3 to aluminum hydroxide accelerates the corundum formation (though it does not affect the temperature range of the phase transition).

We also obtained chromium-containing shock-wave synthesized NPs of aluminum oxide by the thermal processing of its mixture with ammonium dichromate. When such NPs are heated up to 1000°С δ-Al 2 О 3 prevails, chromium partially incorporates to the lattice of α-phase and solid solution in θ-Al 2 О 3 does not form. Therefore, the phase composition of Al2О3 and the chromium state in NPs differ for NPs that are dopped by Cr ions during synthesis and obtained by thermal processing of Al 2 О 3 mixture with ammonium dichromate. The influence of additives of different chromium-containing NPs on phase transitions of alumina and properties of obtained ceramics have not been studied before.

The relevant issue of the rational usage of alumina production waste combined with a high efficiency of shock-wave synthesis of aluminum oxide nanopowders calls for studies focusing on the detection of factors that would enable to fabricate NP-based ceramics with improved properties.

In this work we investigated phase transitions in Al 2 O 3 during annealing of chromium-containing shock-wave synthesized NPs and their mixtures with alumina micropowder that is a waste from alumina production (Achinsk alumina refinery).

Methods

Shock-wave synthesized nanopowders of aluminum oxide were studied: chromium-free NP-1, NP-2 with an additive of ammonium dichromate, NP-3 that was doped with chromium(III) ions during the explosion and their mixtures with alumina micropowders (an average particle radius of 2.6 micron). Mixtures of micropowders with 10% mass NP (a NP content is equivalent to the one used in [4]) were obtained by the ultrasonic dispersion of an ethanol suspension (UZDN-А, frequency of 22 kHz) followed by desiccation. Derivatographs Q-1500 и Netzsch STA 449 were used for differential thermal analysis (DTA). X-ray diffraction (XRD) was carried out at the powder diffractometer DRON-4 with monochromatic CuK α emission. Data from [7] and the ASTM catalogue were used to identify phases. When a maximum intensity peak of one phase coincided with some reflexes of a different phase, the relative phase content was estimated by intensity values of single peaks as described in [5].

Compression of powder mixtures was carried out at a hydraulic press at the pressure of 1 GPa. 3% solution of polyvinyl alcohol was used as plasticizer. High-temperature furnace SVTP–1650 was used for thermal processing of powders and sintering. Ceramics microhardness was measured by Vickers hardness test (PMT-3M). The reported results were averaged by 3-5 parallel experiments.

Results and discussion

According to XRD data NP-1 contains only δ- and θ-Al2O3 with a ratio of 7:1. The same phase ratio is observed for NP-2 that differs only by chemical composition with 1.2% of chromium. The same amount of chromium is presented in NP-3 where θ-Al2O3 prevails and α-phase is observed: the ratio of θ-, δ- and α-Al2O3 is 13:7:1. According to the most wide spread literature data corundum formation with annealing of δ -Al2O3 that is presented in all NP samples goes via an intermediate stage of θ-phase (at 1050°С) and subsequent transition θ→α takes place at 1200°С [8]. Nevertheless, at – 455 – nonisothermic heating conditions with the rate of 15°C/min DTA curves for all NPs under investigation are characterized with the presence of the only peak with the maximum at temperatures above 1200°С with the narrowest one being observed for NP-3. Characteristic points of derivatogramms and calculated values of activation energies of Al2O3 phase transitions are listed in Table 1.

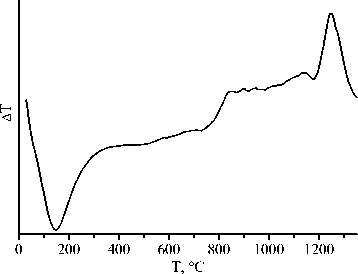

Calculated values of activation energies coincide within error limits for all the samples and they are close to the average one for the transition δ→θ-Al 2 O 3 when overlapped with the transition θ→α: 669 kJ/mole [9]. Obviously, same overlapping is observed in our experiments as well. Comparison of DTA data for NP-1 and NP-2 (Table 1) demonstrates the Cr 2 O 3 influence on the acceleration of corundum formation. A narrower exo-effect peak at the NP-3 DTA curve corresponds to the NP phase composition: prevailing of 9 -phase and presence of a -AHL DTA data for alumina micropowder are presented in Fig. 1.

Low- and high-temperature peaks on the DTA curve agree well with literature data for aluminum hydroxides: endothermic effects at 130–160°С are due to unbounded water [10], up to 400°С bounded or structural water is removed [11] and exothermic effect at temperatures above 1200°С is due to α-Al2O3 crystallization [10]. According to NMR-spectroscopical data [11] for temperatures of 400– 600°С y -ALO 3 forms and at 700°С 5- and 9-Al 2 O 3 appear that are transformed to corundum under following heating.

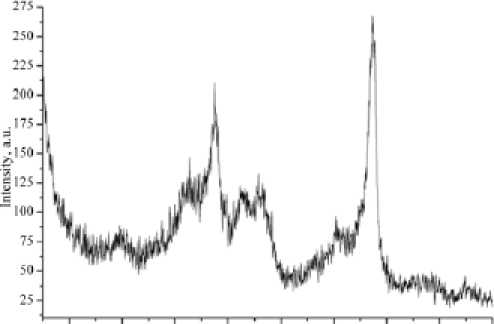

A diffractogram of alumina powder demonstrated its low degree of crystallinity. The most pronounced peak corresponds to 2 9 ~ 67.3°, but for this angle reflexes of у -, к -, 9 -, 5 -Al 2 O3 can be observed. Only presence of к- phase can be reliably identified with a maximum at 2 9 ~ 42.6°, as there is no overlapping with other phases.

Exo-effects at the DTA curve for temperatures above 800°С (Fig. 1) are due to phase transitions of Al2O3. XRD data (Fig. 2) shows that annealing of alumina micropowder at 800°С during 2 hours

Table 1. DTA results for NPs

|

Sample number |

Т init , °С |

Т fin , °С |

Т max , °С |

E act. , kJ/mole |

|

NP-1 |

— 1262 |

— 1397 |

1300 |

— 686±25 |

|

NP-2 |

1150 |

1300 |

1225 |

685±31 |

|

NP-3 |

1150 |

1260 |

1220 |

689±36 |

Fig. 1. DTA curve for alumina micropowder

S 10 15 20 25 30 35 40 45 50 55 60 65 TO 75 80 85 «0 26, degree

Fig. 2. Diffractogram of alumina micropowder after annealing at 800°С results in a higher degree of crystallinity of the sample and arising of γ-phase that is identified by a reflex at 2θ ≈ 60.9°. Calculated ratio of κ- and γ-Al2O3 was approximately 1:1.

DTA analysis reveals that the influence of additive of the aluminum oxide nanopowder NP-1 on alumina phase transition mainly results in a more pronounced exo-effect in the range between 730–1000°С, some decrease of the temperature of the maximum related to α-Al 2 O 3 formation and a significant drop of the enthalpy of this process from 19 to 4 kJ/mole. According to XRD data after annealing at 800°С during 2 hours such mixture contains δ-Al 2 O 3 (a peak at 2θ ≈ 34.5°) and α-Al2O3 (2θ ≈ 43.3°) with the ratio of 5:1. We believe that the presence of δ-phase is related to the NP-1 phase composition (with prevailing δ-Al 2 O 3 ) and corresponding stimulation of the transition from γ-Al2O3 to δ-phase in alumina. Heat release from this transition initiates corundum formation mostly from κ-Al 2 O 3 that is characterized by a direct transition κ→α-Al 2 O 3 [8]. Decrease of heat release above 1200°С is explained with the fact that a significant part of corundum has already formed before.

Presence of ammonium dichromate in this mixture (alumina with NP-2) results in a pronounced peak at DTA curves that corresponds to exo-effect in the temperature range 735–930°С with a maximum at 836°С. Apart from δ- and α-Al2O3 diffractogramms of these samples reveal the presence of θ-phase (2θ ≈ 38.7°) and traces of γ-Al 2 O 3 . The ratio of δ-, θ - и α -Al 2 O 3 is around 6:3:1. We suggest that the presence of chromium oxide facilitates the crystallization of γ-Al2O3 from an amorphous alumina phase. This agrees well with data from [12] about influence of Cr 2 O 3 on the decrease of crystallization temperature of γ-Al2O3 in powders that were obtained by thermal decomposition of aluminum hydroxide. Stimulating effect of Cr 2 O 3 on formation of δ - и θ-Al 2 O 3 under annealing of γ-Al2O3 was indicated in [13].

When compared with DTA data for these samples the mixture of alumina with NP-3 demonstrates less pronounced exo-effects in the medium-temperature range and there is no distinct peak with a maximum at 836°С. In the high-temperature range significant differences were not observed for characteristic points. For 750–950°С exo-effects are less pronounced also when compared with the alumina mixture with NP-1.

The main difference of phase composition of this powder mixture after annealing at 800°С and the alumina mixture with NP-2 is a slight increase of α-phase relative content when compared with other phases that is explained with the presence of α-Al2O3 in NP-3.

It is obvious that less pronounced exo-effects at 750–950°С are caused by significant decrease of δ -Al2O3 fraction in an original mixture: from ∼ 9% in mixtures with NP-1 and NP-2 down to 3%. This decrease of δ-phase that stimulates the transition γ → δ-Al 2 O 3 in alumina results in corresponding decrease of γ-oxide that was transformed in this temperature range.

A stepped sintering regime was used for ceramics fabrication from mixtures of alumina micropowders with Al2O3 NPs according to DTA data. It included a linear heating with a rate of 15°С/min and isothermic stages: annealing at 400°С during 2 hours to remove unbounded and structural water completely, annealing at 800 and 1200°С during one hour for transformation accompanying phase transitions and one hour annealing at 1600°С. Microhardness measurements have shown practically identical (within the limits of experimental error) values of this property for sintered samples fabricated with NP-1 and NP-2 additives. Microhardness of NP-3 sample was higher by factor of 1.4–1.5.

Thus, the presence of small amount of chromium oxide in NP-2 additive nearly did not influenced microhardness of fabricated ceramics. The main factor of the microhardness increase for samples produced with NP-3 was a lower intensity of phase transitions at early sintering stages. Respectively, the local heating caused by their exo-effects was less steep. It could reduce the formation of closed pores that are “trapped” when particles are “baked”. The density increase for samples with NP-3 additive when compared with sintered mixtures of alumina with NP-1 and NP-2 confirms this suggestion.

Conclusion

The additive of ammonium dichromate (precursor of Cr 2 O 3 ) in amount that was considered in this work to shock-wave synthesized nanopowder of aluminum oxide practically does not influence microhardeness and density of ceramics that was sintered from alumina mixture with Al 2 O 3 nanopowders. The increase of ceramics microhardeness and density that was obtained when aluminum oxide was dopped by chromium ions during shock-wave synthesis are mainly caused by differences of its phase composition and corresponding influence on alumina phase transition.

Список литературы Influence of chromium-containing Al2О3 nanopowders on structural modifications in aluminum oxide micropowders

- Гордеев Ю.И., Зеер Г.М., Зеленкова Е.Г. Плотность упаковки и кинетика спекания керамики из порошковых смесей с бимодальным распределением частиц по размерам. Сборник трудов II межрегиональной конференции «Ультрадисперсные порошки, материалы и наноструктуры». Красноярск, ИПЦ КГТУ, 1999, 199-205.

- Лефевр С., Монсо Д., Федорова Е.Н. Получение керамики на основе оксида алюминия с использованием микроволнового нагрева. Сборник трудов Всероссийской. научно-технической конференции «Ультрадисперсные порошки, наноструктуры и материалы». Красноярск: ИПЦ КГТУ, 2003, 172-174.

- Букаемский А.А., Тарасова Л.С., Федорова Е.Н. Исследование особенностей фазового состава и стабильности ультрадисперсного Al2O3 взрывного синтеза. Известия ВУЗов: Цветная металлургия, 2000, 5, 60-63

- Лямкина Н.Э., Чиганова Г.А., Зеер Г.М. Применение ультрадисперсных порошков Al2O3-Cr2O3 ударно-волнового синтеза для получения корундовой керамики. Фундаментальные проблемы современного материаловедения, 2007, 4(2), 87-89

- Лямкина Н.Э., Чиганова Г.А., Слабко В.В., Воротынов А.М., Таранова М.А. Легированный хромом ультрадисперсный Al2O3 взрывного синтеза. Неорганические материалы, 2005, 41(8), 948-954

- Рябов А.Н., Кожина И.И., Козлов И.Л. Влияние условий получения окиси алюминия на ее полиморфные превращения. Журнал неорганической химии, 1970, 15(3), 602-606

- Липпенс Б.К., Стеггерда Й.Й. Строение и свойства адсорбентов и катализаторов: Активная окись алюминия, под ред. В.Г. Линсена. М.: Мир. 1973, 190-203

- Химическая энциклопедия, под ред. Кнунянц И.Л. и др. Т. 1. М.: Советская энциклопедия. 1988, 623 с.

- Козлова И.Р. Структурные превращения в напыленной окиси алюминия. Неорганические материалы, 1971, 7(8), 1372-1376

- Иванова А.С., Литвак Г.С., Крюкова Г.Н. Реальная структура метастабильных форм оксида алюминия. Кинетика и катализ, 2000, 41(1), 137-141

- Дудкин Б.Н., Канева С.И., Мастихин В.М., Плетнев Р.Н. Трансформация структуры малых частиц оксида алюминия, полученного золь-гель-способом из различных прекурсоров при термообработке. Журнал общей химии, 2000, 70(12), 1949-1955

- Бондарь И.А., Глушкова В.Б., Цейтлин П.А. и др. Исследование фазовых переходов в Al2O3. Неорганические материалы, 1971, 7(8), 1367-1371

- Гавриш А.М., Карякин Э.Л., Лысак С.В. и др. Влияние добавок на фазовые превращения в алюмооксидных волокнах. Огнеупоры, 1988, 10, 15-20