Innovative technology to reduce fracture of large steel castings which are essential to railway transport

Автор: Toirov O.T., Tursunov N.Q., Qochqorov L.A., Valiyeva D.Sh.

Журнал: Теория и практика современной науки @modern-j

Рубрика: Основной раздел

Статья в выпуске: 1 (91), 2023 года.

Бесплатный доступ

Using the ProCast software, an analysis was made of the manufacturability of the gating system used in the existing production in the manufacture of the casting "Side frame" of railway cars. A special feature is the presence of an extended horizontal collector and underwater metal to the end parts of the casting. The disadvantage of such a gating system is that the filling of the entire mold with liquid metal is carried out through the end parts of the casting prone to cracking. At the same time, two counter flows accumulate in the intended form, their merging in the middle parts of the casting in a cooled and highly contaminated state, since the process in filling part of the flow is collected along the path of sand inclusions, oxidized and saturated with hydrogen. These factors are a prerequisite for the formation of various defects in castings. Due to problems, a new gating system technology was proposed, which was analyzed in the ProCast program. In the process of analysis, the most optimal solution for the gating system was deduced.

Короткий адрес: https://sciup.org/140297167

IDR: 140297167

Текст научной статьи Innovative technology to reduce fracture of large steel castings which are essential to railway transport

Sanoat mahsulotlarining ekspluatatsion va texnologik xususiyatlarini yaxshilash, ishlab chiqarilayotgan mahsulotlarning texnik darajasi va sifatini oshirish fan va texnikaning asosiy vazifalaridan biridir. Yuk vagonlarining asosiy qismlaridan biri yon ramasi, po'latdan qumli qoliplarda quyma olish usulida tayorlanadi. Yuk tashish jarayonida bu quymalar eng katta yuklanishlar ostida harakat qiladi. Yon ramalar bilan bog'liq muammolardan biri bu ularning sinishidir. Ekspluatatsiya paytida yon ramaning sinishi iqtisodiy yo'qotishlarga olib keladi.

20ГЛ po'latdan (1-jadval) quyma olish usulida tayorlangan yon ramalarning sinish sabablariga bir qancha sabablarni keltirish mumkin. Masalan: ichki quyma nuqsonlar (g’ovaklar, qisqarish natijasida bo’ladigan bo’shliqlar, issiq yoriqlar), quymaning quyish jarayonida suyuq metallning yetmay qolishi, to’lqin simon ko’rinishdagi nuqsonlar, kuchlanishlar[1].

1-jadval

|

Po’lat tarkibiga kiruvchi elementlar |

C |

Si |

Mn |

P, S |

Cr, Ni |

Cu |

Al |

|

Miqdori, % |

0,17…0,25 |

0,30…0,50 |

1,10…1,40 |

≤ 0,02 |

≤ 0,03 |

≤ 0,06 |

0,02…0,06 |

Sinishning oldini olish uchun asosan po'lat quymalardagi issiq yoriqlarni kamaytirish, metall tarkibidagi zararli aralashmalar miqdorini tartibga solish va quyishning harorat oralig'iga rioya qilishdir.

Issiq yoriq - bu kristallanish jarayonida yuzaga keladigan, quymaning qisqarishidan kelib chiqadigan quyma tanasidagi yirtiq yoki yoriq shaklida nuqson. U kuchli oksidlangan sirtga ega.

Issiq yoriqning vujudga kelish sabablari quyidagilardir:

-

- quyma konstruksiyasining noto’g’riligi;

-

- quymaning alohida qismlarini notekis sovushi;

-

- suyuq metall ta'minotini noto'g'ri tanlash;

-

- o’zak va qoliplarning sovush va qisqarish jarayonlariga qarshilik qilishi;

-

- quyilayotgan metallning harorati baland bo’lib ketishi;

-

- oltingugurt, fosfor, vodorod va aralashmalarning ko'payishi;

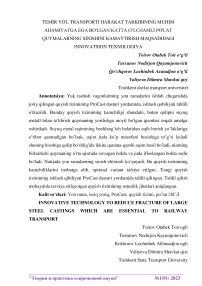

Yon rama devorlari har xil o’lchamga ega ichki qismi bo’shliq bo’lgan murakkab quymadir. (1-rasm).

1-rasm - Yon rama quymasining umumiy ko'rinishi.

L shaklga ega radiusi 55 mm bo’lgan quti teshiklariga etibor qarataylik. Aynan shu qismda issiq yoriqlar hosil bo’lishi, juda ko’p sinishlarga sabab bolishi amaliyotda o’z natijasini ko’rsatdi.

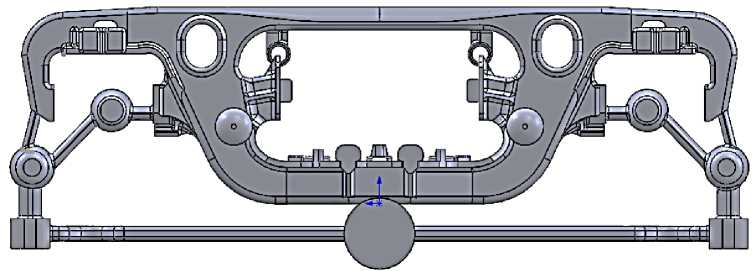

Quyma-mexanika zavodida amaldagi texnologiyasiga ko'ra, yon rama gorizontal ko’rinishda quymaning 4 qismidan suyuq metal bilan ta’minlab beruvchi quyma tizimi yordamida qum qoliplariga quyiladi (2-rasm)

2-rasm - Yon ramaning quyish tizimi bilan umumiy ko'rinishi

Bunday tizimining kamchiligi shundaki, butun qolipni suyuq metall bilan to'ldirish issiq yorilishga moyil bo'lgan quyma qismlari orqali oqib o’tadi. Shu bilan birga, qolip bo'shlig'ida ikkita qarama-qarshi oqim hosil bo'ladi, bu oqimlarning birlashishi quymaning o'rta qismida sovugan va juda ifloslangan holatda birlashadi, chunki oqimning boshlang’ich holatidan quymaning o’ziga qadar juda uzoq masofa bosib o’tadi natijada suyuq metal oksidlanadi va vodorod bilan to'yingan. Bu omillar to'qimalarda turli nuqsonlar, qum va gaz g’ovaklari, shuningdek, yoriqlar vujudga kelishi uchun bir imkondir. Shu sababli, yuqoridagi kamchiliklarni kamaytirish maqsadida yon ramaning quyish tizimining dizaynini o'zgartirish dolzarb vazifalardan biri hisoblanadi.

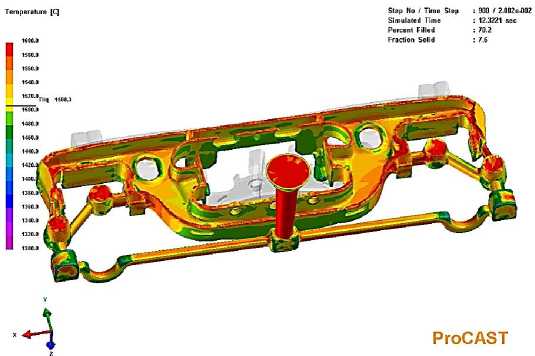

Amaldagi joriy quyush tizimining kamchiliklarini tahlil qilish natijalarini hisobga olgan holda, uning yanada oqilona dizaynini izlash maqsadida yon rama quyishning 3D modeli ishlab chiqildi. 3D model ProCast dasturidan foydalanib quyish jarayoni harakatlantirildi(simulyatsiya), qolip bo'shlig'ini suyuq metal bilan to'ldirish, suyuq metalning turli qismlarida qotib qolishi va kristallanish jarayonlari ko'rib chiqildi. Ushbu jarayonlar quyish tizimining tavsiya etilgan variantlarida ham simulyatsiya qilingan. Qolib bo'shlig'i tez va bir meyorda suyuq metall oqimi bilan to'ldirishni ta'minlovchi eng yaxshi variant sifatida yangi quyish tizimi innovatsion g’oya sifatida tanlandi.

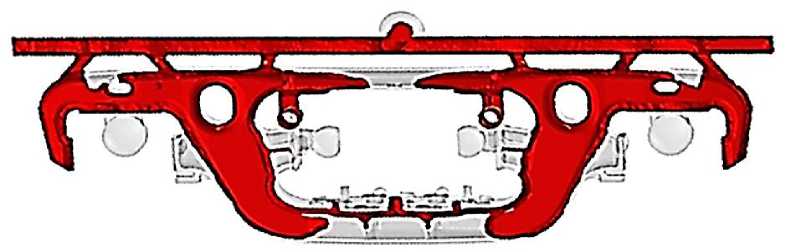

Suyuq metall bilan qolipni quyish tizimi orqali to'ldirish jarayonini kompyuter simulyatsiyasini o'rganish natijalari 4-rasmda keltirilgan[4].

Quyish tizimining yuqoridagi kamchiliklarini bartaraf etish uchun, amaldagi texnologiyaga o’zgartirishlar kiritilib quyish tizimining yangi dizayni ishlab chiqildi.

Shu bilan bir qatorda quyish tizimining tavsiya etilgan yangi ko’rinishi ProCast dasturida simulyatsilashtirilib chiqildi (4-rasm)

-

4 -rasm. Qolib bo'shlig'ini yangi quyish tizimi orqali suyuq po'lat bilan to'ldirilishi

Yon rama uchun tavsiya etilgan yangi quyish tizimi bir qancha afzalliklarga ega. Juda qisqa vaqtda quymani suyuq metal bilan to’lish imkonini beradi, bir meyorda qolipning suyuq metal bilan to’lishini taminlab beradi, suyuq metal oqimini kerakli qismlarga yo’naltiradi shu bilan birga kristallanish jarayonini bir maromda bo’lishini taminlab beradi. Bu quyish tizimi metall sarfini kamaytiradi. Bunday texnik yechim, shubhasiz, quyma yon ramalarning nuqsonlarini sezilarli darajada kamaytirishni va ularni ishlab chiqarish samaradorligini oshirishni ta'minlaydi.

Foydalanilgan adabiyotlar

-

1. Турсунов, Н. К., & Тоиров, О. Т. (2021). Снижение дефектности рам по трещинам за счёт применения конструкции литниковой системы.

-

2. Тен, Э. Б., & Тоиров, О. Т. (2020). Оптимизация литиковой системы для отливки «Рама боковая» с помощью компьютерного моделирования. In Прогрессивные литейные технологии (pp. 57-63).

-

3. Toirov, O. T., Tursunov, N. Q., Nigmatova, D. I., & Qo’chqorov, L. A. (2022). Using of exothermic inserts in the large steel castings production of a particularly. Web of Scientist: International Scientific Research Journal, 3(1), 250-256.

-

4. Toirov, O. T., Tursunov, N. Q., & Nigmatova, D. I. (2022, January). Reduction of defects in large steel castings on the example of" side frame". In International Conference on Multidimensional Research and Innovative Technological Analyses (pp. 19-23).

-

5. Toirov, O., & Tursunov, N. (2021). Development of production technology of rolling stock cast parts. In E3S Web of Conferences (Vol. 264, p. 05013). EDP Sciences.

-

6. Кучкоров, Л. А. У., Турсунов, Н. К., & Тоиров, О. Т. У. (2021). Исследование стержневых смесей для повышения газопроницаемости. Oriental renaissance: Innovative, educational, natural and social sciences, 1(8), 831-836.

-

7. Турсунов, Н. К., Тоиров, О. Т., Железняков, А. А., & Комиссаров, В. В. (2021). Снижение дефектности крупных литых деталей подвижного состава железнодорожного транспорта за счет выполнения мощных упрочняющих рёбер.

-

8. Boburbek Toiro’g’li, T., Saminjonovich, J. T., & Otabek Toiro’g’li, T. (2021). Ob’yektlarni Tanib Olishda Neyron Tarmoqning O’rni. Барқарорлик ва Етакчи Тадқиқотлар онлайн илмий журнали, 1(6), 681-684.

-

9. Тoirov, B. Т., Jumaev, Т. S., & Toirov, O. T. (2021). Obyektlarni tanib olishda python dasturidan foydalanishning afzalliklari. Scientific progress, 2(7), 165-168. 10. ТУРСУНОВ, Н., & ТОИРОВ, О. (2021). Снижение дефектности рам по трещинам за счет изменения конструкции литниковой системы. in проблемы безопасности на транспорте (pp. 162-165).

-

11. Турсунов, Н. К., & Тоиров, О. Т. (2021). Снижение дефектности рам по трещинам за счёт применения конструкции литниковой системы.

-

12. Тоиров, О. Т., Кучкоров, Л. А., & Валиева, Д. Ш. (2021). Влияние режима термической обработки на микроструктуру стали гадфильда. Scientific progress , 2 (2), 1202-1205.

-

13. Kayumjonovich, T. N. (2022). DEVELOPMENT OF A METHOD FOR SELECTING THE COMPOSITIONS OF MOLDING SANDS FOR CRITICAL PARTS OF THE ROLLING STOCK. Web of Scientist: International Scientific Research Journal, 3(5), 1840-1847.

-

14. Kayumjonovich, T. N. (2022). NON-METALLIC INCLUSIONS IN STEEL PROCESSED WITH MODIFIERS. Web of Scientist: International Scientific Research Journal, 3(5), 1848-1853.

-

15. Мелибоева, М. А., Валиева, Д. Ш., Эркинов, С. M., & Кучкоров, Л. А. (2022). СОВЕРШЕНСТВОВАНИЕ ТЕХНОЛОГИИ ИЗГОТОВЛЕНИЯ ДЕТАЛИ ДЛЯ СНИЖЕНИЯ СЕБЕСТОИМОСТИ. Oriental renaissance: Innovative, educational, natural and social sciences, 2(5-2), 796-802.

-

16. Sharifxodjaeva, X. A., Erkinov, S. M., Sh, V. D., & Kuchkorov, L. A. (2022). ON THE BASIS OF COMPUTER SIMULATION OF THE DESIGN OF RIFTS FOR STEEL CASTINGS OF COMPLEX CONFIGURATION. Web of Scientist: International Scientific Research Journal, 3(5), 1991-1995.

-

17. Sh, V. D., Erkinov, S. M., Kh, O. I., Zh, A. S., & Toirov, O. T. (2022). IMPROVING THE TECHNOLOGY OF MANUFACTURING PARTS TO REDUCE COSTS. Web of Scientist: International Scientific Research Journal, 3(5), 1834-1839.

-

18. Urazbayev, T. T., Tursunov, N. Q., Yusupova, D. B., Sh, V. D., Erkinov, S. M., & Maturaev, M. O. (2022). RESEARCH AND IMPROVEMENT OF THE PRODUCTION TECHNOLOGY OF HIGH-MANGANESE STEEL 110G13L FOR RAILWAY FROGS. Web of Scientist: International Scientific Research Journal, 3(6), 10-19.

-

19. Ruzmetov, Y., & Valieva, D. (2021). Specialized railway carriage for grain. In E3S Web of Conferences (Vol. 264, p. 05059). EDP Sciences.

Список литературы Innovative technology to reduce fracture of large steel castings which are essential to railway transport

- Турсунов, Н. К., & Тоиров, О. Т. (2021). Снижение дефектности рам по трещинам за счёт применения конструкции литниковой системы.

- Тен, Э. Б., & Тоиров, О. Т. (2020). Оптимизация литиковой системы для отливки «Рама боковая» с помощью компьютерного моделирования. In Прогрессивные литейные технологии (pp. 57-63).

- Toirov, O. T., Tursunov, N. Q., Nigmatova, D. I., & Qo’chqorov, L. A. (2022). Using of exothermic inserts in the large steel castings production of a particularly. Web of Scientist: International Scientific Research Journal, 3(1), 250-256.

- Toirov, O. T., Tursunov, N. Q., & Nigmatova, D. I. (2022, January). Reduction of defects in large steel castings on the example of" side frame". In International Conference on Multidimensional Research and Innovative Technological Analyses (pp. 19-23).

- Toirov, O., & Tursunov, N. (2021). Development of production technology of rolling stock cast parts. In E3S Web of Conferences (Vol. 264, p. 05013). EDP Sciences.

- Кучкоров, Л. А. У., Турсунов, Н. К., & Тоиров, О. Т. У. (2021). Исследование стержневых смесей для повышения газопроницаемости. Oriental renaissance: Innovative, educational, natural and social sciences, 1(8), 831-836.

- Турсунов, Н. К., Тоиров, О. Т., Железняков, А. А., & Комиссаров, В. В. (2021). Снижение дефектности крупных литых деталей подвижного состава железнодорожного транспорта за счет выполнения мощных упрочняющих рёбер.

- Boburbek Toiro’g’li, T., Saminjonovich, J. T., & Otabek Toiro’g’li, T. (2021). Ob’yektlarni Tanib Olishda Neyron Tarmoqning O’rni. Барқарорлик ва Етакчи Тадқиқотлар онлайн илмий журнали, 1(6), 681-684.

- Тoirov, B. Т., Jumaev, Т. S., & Toirov, O. T. (2021). Obyektlarni tanib olishda python dasturidan foydalanishning afzalliklari. Scientific progress, 2(7), 165-168.

- ТУРСУНОВ, Н., & ТОИРОВ, О. (2021). Снижение дефектности рам по трещинам за счет изменения конструкции литниковой системы. in проблемы безопасности на транспорте (pp. 162-165).

- Турсунов, Н. К., & Тоиров, О. Т. (2021). Снижение дефектности рам по трещинам за счёт применения конструкции литниковой системы.

- Тоиров, О. Т., Кучкоров, Л. А., & Валиева, Д. Ш. (2021). Влияние режима термической обработки на микроструктуру стали гадфильда. Scientific progress, 2(2), 1202-1205.

- Kayumjonovich, T. N. (2022). DEVELOPMENT OF A METHOD FOR SELECTING THE COMPOSITIONS OF MOLDING SANDS FOR CRITICAL PARTS OF THE ROLLING STOCK. Web of Scientist: International Scientific Research Journal, 3(5), 1840-1847.

- Kayumjonovich, T. N. (2022). NON-METALLIC INCLUSIONS IN STEEL PROCESSED WITH MODIFIERS. Web of Scientist: International Scientific Research Journal, 3(5), 1848-1853.

- Мелибоева, М. А., Валиева, Д. Ш., Эркинов, С. M., & Кучкоров, Л. А. (2022). СОВЕРШЕНСТВОВАНИЕ ТЕХНОЛОГИИ ИЗГОТОВЛЕНИЯ ДЕТАЛИ ДЛЯ СНИЖЕНИЯ СЕБЕСТОИМОСТИ. Oriental renaissance: Innovative, educational, natural and social sciences, 2(5-2), 796-802.

- Sharifxodjaeva, X. A., Erkinov, S. M., Sh, V. D., & Kuchkorov, L. A. (2022). ON THE BASIS OF COMPUTER SIMULATION OF THE DESIGN OF RIFTS FOR STEEL CASTINGS OF COMPLEX CONFIGURATION. Web of Scientist: International Scientific Research Journal, 3(5), 1991-1995.

- Sh, V. D., Erkinov, S. M., Kh, O. I., Zh, A. S., & Toirov, O. T. (2022). IMPROVING THE TECHNOLOGY OF MANUFACTURING PARTS TO REDUCE COSTS. Web of Scientist: International Scientific Research Journal, 3(5), 1834-1839.

- Urazbayev, T. T., Tursunov, N. Q., Yusupova, D. B., Sh, V. D., Erkinov, S. M., & Maturaev, M. O. (2022). RESEARCH AND IMPROVEMENT OF THE PRODUCTION TECHNOLOGY OF HIGH-MANGANESE STEEL 110G13L FOR RAILWAY FROGS. Web of Scientist: International Scientific Research Journal, 3(6), 10-19.

- Ruzmetov, Y., & Valieva, D. (2021). Specialized railway carriage for grain. In E3S Web of Conferences (Vol. 264, p. 05059). EDP Sciences.