Investigation of physical-mechanical and electric properties of conducting SnO2-based ceramics

Автор: Dobrosmislov Sergey S., Kirko Vladimir I., Nagibin Gennadiy E., Resinkina Oksana A., Stepanov Egor I.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 3 т.3, 2010 года.

Бесплатный доступ

In our paper there are presented results of the investigation of physical-mechanical and electric properties of conducting ceramics based on SnO2-Sb2O3-CuO-system with superdispersed additives of metal oxides produced by pyrolysis of their water-soluble salts.

Ceramics, tin dioxide, superdispersed additives of metal oxides, mechanical properties

Короткий адрес: https://sciup.org/146114543

IDR: 146114543 | УДК: 538.9

Текст научной статьи Investigation of physical-mechanical and electric properties of conducting SnO2-based ceramics

Results of the investigation of physical-mechanical and electrophysical properties of SnO 2 – and Sb2O3-based ceramics with various types of metal oxide additives including CuO are presented in papers [1-10]. A peculiar feature of the materials of this class is their unique high temperature properties at 900-1300 °С such as simultaneously high strength, electroconductivity and resistance to corrosion in corrosive media. The latter makes it possible to apply them as perspective electrode materials particularly for non-consumable anodes in the aluminium production. In papers [11-12] there is suggested the following ceramics composition SnO 2 + 1.0-1.5 wt. % Sb 2 O 3 + 0.1-0.5 wt. % CuO whose density approaches 6600 kg∕m3 and electroconductivity 0.25 10 -4 Ohm m at 970 °С.

It is known that physical-mechanical and electrophysical properties of ceramics depend on many factors such as chemical and granulometric composition of the initial charge, time and method of its preparation, pressing and burning conditions, etc. In papers [13-14] it has been shown that doping of the initial charge with 5% superdispersed metal oxide powder makes it possible to enhance ceramics strength, density, as well as decrease its porosity and sintering temperature. The addition of superdispersed powder into electroconducting ceramics has to influence their conducting properties.

The aim of the present work is to investigate an influence of the superdispersed metal oxide additives on physical-mechanical and electrophysical properties of ceramics based on the composition SnO 2 + 2 wt. % Sb 2 O 3 + 2 wt. % CuO.

Experimental technique

The ceramic specimens were prepared according to the following technique: grinding and mixing initial powders in an aqueous solution of metal salts to produce the initial charge SnO2 + 2 wt. % Sb2O3 + 2 wt. % CuO, prebaking at 1100 °С, grinding and preparing the press bodies with polyvinyl alcohol of 5% content, pressing, drying, sintering at 1300 °С for 2 hours. The ceramic specimens of 15 mm in diameter and 10 mm high were prepared for physical-mechanical tests. And cubic specimens 5×4×50 mm were used for electrophysical measurements.

The specimens’ density was measured with hydrostatic weighing technique in alcohol, the open porosity according to the State Standard 2409-95. The resistivity within the temperature range 20950 °С was done with the four-probe technique described in [15]. Mechanical properties (compression strength) were measured with the device Instron 3369. The crystal structure of the synthesized ceramics was checked by the X-ray structure analysis with XRD 6000.

Experimental results

The experimental results are presented in table 1.

Columns 2 – 5 contain the charge compositions made by the pyrolysis of water-soluble metal salts during their prebaking at 1100 °С. The corresponding salts used in the work are presented in the column 6. Columns 7 – 10 contain measurement results of the ceramics’ density, open porosity, strength and resistivity at 950 °С, respectively. Ceramics compositions of the strength less than 300 MPa were not included into the table.

As follows from the table all specimens’ density exceeds 6000 kg/m3. The specimen № 4 (92.76 % SnO 2 – 1.93 % Sb 2 O 3 – 1.93 % CuO – 3.38 % MnO 2 ) possesses the highest density 6630 kg/m3 and therefore the lowest open porosity 0.11 %. The specimen №1 (94.12 % SnO2 – 1.96 % Sb2O3 – 1.96 % CuO – 1.96 CoO) having sufficiently low open porosity (3.75 %), high strength and density (463 MPa and 6400 kg/m3, respectively) revealed the lowest resistivity (0.15·10-3 Ohm m at 950 °С). To make a comparison in table 1 there are presented the properties of the basic ceramics SnO 2 – 1.5 % Sb 2 O 3 – 1.5 % CuO [16] without superdispersed additives (№13). The table shows that the superdispersed additives of practically all metal oxides decrease electrical characteristics of the ceramics except the cobalt oxide (№1). But in some cases the additives allow to decrease the porosity and increase strength as it takes place with MnO 2 (№4-5).

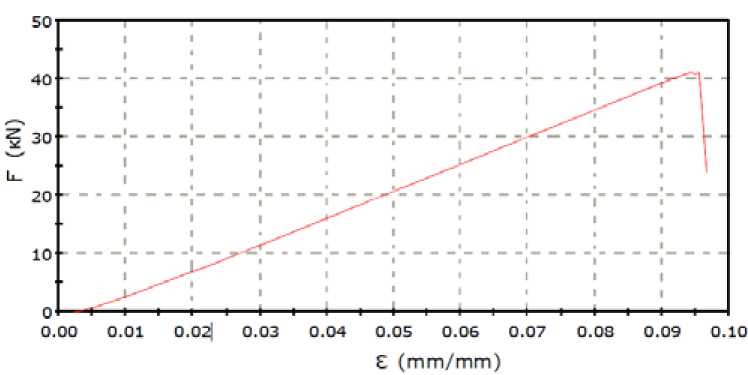

A typical relationship of compressive load and degree of deformation for the ceramics under investigation is shown in Fig. 1.

The curve is characterized with a little plasticity region at the stress 425 MPa (for the composition №4) and a uniform linear one witnessing a well sintering of the ceramics made in the present work.

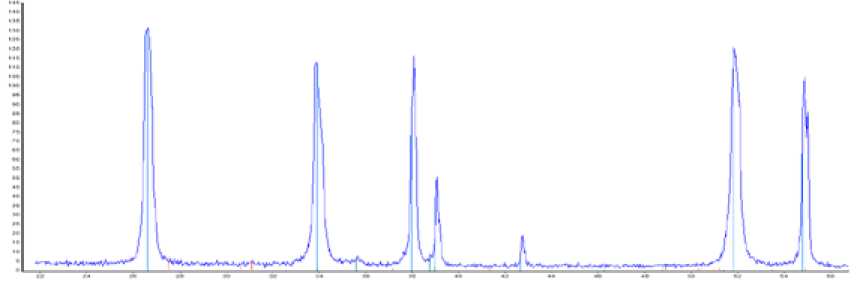

A typical X-ray pattern for all specimens synthesized is shown in Fig. 2.

As follows from the X-ray patterns all ceramics possesses the crystal structure of cassiterite SnO 2 . This witnesses a practically complete solution of the metal oxides formed as a result of the thermal decomposition inside the host lattice (SnO 2 ).

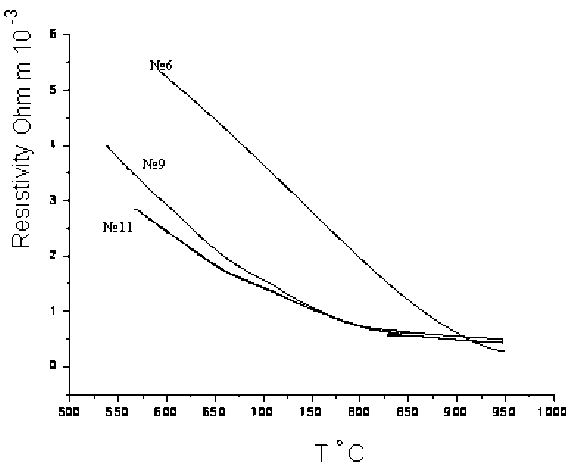

Temperature dependences of the ceramics’ resistivity (specimen’s №№ 6, 9, 11) are shown in figure 3.

As is seen from the figure, within the temperature range being considered there takes place a significant resistivity drop. In the low temperature range (Т≤900 °С) a great difference of the – 317 –

Table 1. The composition and properties of the SnO 2 -based ceramics

|

6 62 > ° X S § a V II s c=i н 5 О |

о |

m —; m 64 m fl- IT) fl- —; |

|

|

й & И s |

04 |

ri ro, r| ir, _ fl- V-, M 0C' ir, O' О fl- го, M M _ M O fl- _ ir, O IC, |

|

|

sb О О |

ОО |

b 6 cc o 6 Ь r- ^ OO -H 40 fl; -H 04 ^ СЧ OO IT) OO м м о d m a- oo o^ m m -h |

|

|

Й 60 2 44 Q |

г- |

— О M А M О ^н04 40тт04 00т*оо^н04<х>т А о A O м м ri ri A 6 4O4O4O4O4O4O4O4O4O4O4O4O4O |

|

|

о ад о |

fl § |

40 |

О о О О б£ Ж Щ N “ Р о ^м; о о ® z 2 О N О !Z сч Рн О о О О О о о б б б б б (5с^ооО(5(5^^^^^ ^^^^^ । । । । 1>—1>—1>—1>—। unSSSuuSSSSS . |

|

< |

2?22о n и z а £ । । । । । . 2 2 2 04 $ мГ бГ бГ бГ ббОООооООООО ^4flflfl^^flflflflfl unSSSuuSSSSS 1 1 1 1 1 1 1 1 1 1 1 1 40 40 40 СС 40 СС 40 61 61 61 61 61 О4О4О4Сбб^Сбб^О4О4О4О4О4 |

||

|

о о |

fl- |

40 40 40 Сб Сб 61 61 61 61 61 04 04 04 04 04 04 04 04 04 04 04 0410 |

|

|

о |

m |

40 40 40 Сб Сб 61 61 61 61 61 O4O4O4O4O4O4O4O4O4O4O4O4V*) |

|

|

б й со |

61 |

61 61 61x0 "М- ^О fl- 6J 6J 6J 6I 6I fl- fl- fl-" 61 ^4 61 ^4 61 61 61 61 61 г-O4O4O4O4O4O4O4O4O4O4O4O4O4 |

|

|

б — 61 fl- V-, \O г- СУС' 0х — — — — |

|||

Fig. 1. A typical relationship of compressive load and degree of deformation for the ceramics under investigation

Fig. 2. A typical X-ray pattern for all specimens (№ 1-13)

Fig. 3. Temperature dependences of the ceramics’ resistivity (specimen’s №№ 6, 9, 11)

temperature dependences occurs because of the difference in the composition of the decomposed water-soluble additives. In the high temperature range the resistivity is practically independent of the composition.

Conclusions

-

1. The influence of the water-soluble metal salt additives on the physical-mechanical and electrophysical properties of the ceramics synthesized on the base of the composition SnO2 + 2 wt. % Sb 2 O 3 + 2 wt. % CuO has been investigated in the work.

-

2. It has been shown that the additives make it possible to increase the ceramics’ strength to 530 MPa and decrease the open porosity to 0.11 % at sufficiently low resistivity value (0.15∙10-3 Ohm m). This is important when using ceramics as anodes operating at high temperatures in corrosive media.

The paper is published under the aegis of the Siberian Federal University Development Programme.