Investigation of surfacing technological opportunities by the indirect three-phase arc with consumable electrodes

Автор: Bezrukih A.A., Meister R.A., Lubnin M.A., Gotovko S.A.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 7 (33), 2010 года.

Бесплатный доступ

This paper is devoted to the high-effective process of surfacing by the indirect three-phase arc with covered electrodes. The share of the parent metal in the surfaced one does not exceed 10 % which is infeasible for one-arc surfacing.

Surfacing, indirect three-phase arc, consumable electrodes

Короткий адрес: https://sciup.org/148176438

IDR: 148176438

Текст научной статьи Investigation of surfacing technological opportunities by the indirect three-phase arc with consumable electrodes

Operating conditions of technical systems, including the space machinery, require manufacturing of units and parts with specific properties of working surfaces, such as: heat resistance and thermal stability, wear resistance, corrosion resistance, etc. Thus, economical use of expensive materials is necessary. The problem is solved by using surfacing processes. However, widespread one-arc method of surfacing with consumable electrodes has grave disadvantages such as low productivity and necessity of coating with four or five layers for required structure of surfaced metal.

Application of alternating current in surfacing processes allows using simple and cheap power supplies that have higher efficiency in comparison with rectifiers. The alternating current arc doesn’t have such a disadvantage as magnetic blowout. Therefore, using welding transformers, especially-three-phase ones, is rather perspective in surfacing processes.

Three-phase arc has the following advantages: high efficiency of the process reached due to simultaneous melting of three electrodes at once; considerable decrease of fusion penetration in the absence of current in part being surfaced; intensive stirring of molten metal in the pool providing homogeneous structure of rollers. The distinguishing feature of the method is the following: the product being surfaced is not included in a circuit, the three-phase arc is located between three cores, i. e. three one-phase arcs are simultaneously on fire in one general torch, mutually influencing each other and electrodes. Such interaction considerably increases productivity of surfacing operations, reduces the specific consumption of the electric power and strengthens ionization of arc space. Thus, the fusion penetration of the parent metal considerably decreases in comparison with one-phase surfacing processes. It occurs only due to the thermal influence of three-phase arc and molten electrode metal. As a result of 1,6–3,0 mm diameter electrode manufacturing, it is possible to reduce the weight of electrode holders and current-carrying wires for three-phase arc processes that has solved a problem of the method realization [1].

However, in references there is no practically information about application of surfacing by indirect three-phase arc with three electrodes. As a result, investigations have been carried out on three-phase surfacing with consumable electrodes for the purpose of roller formation with the minimum share of the parent metal in the surfaced one by optimization of process parameters.

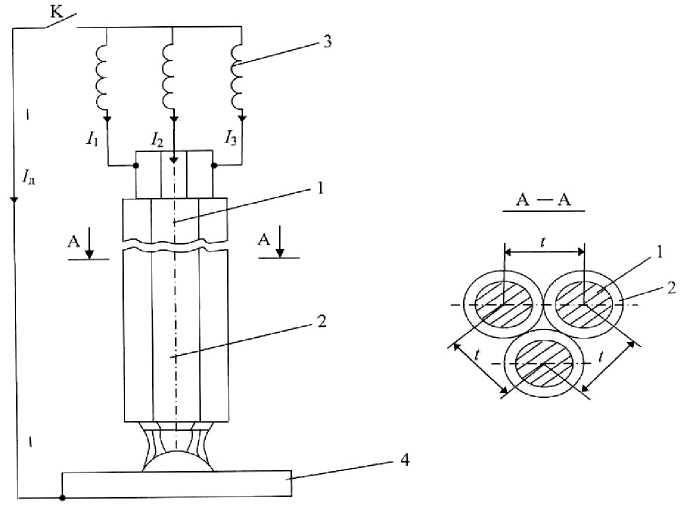

For the experiments with three-phase processes, a special plant with TSHS-1000-3 transformer has been assembled. The surfacing scheme is presented in fig. 1. Dropping characteristic was provided with single throttles with ring magnetic conductors. It gives the chance to regulate and equalize current in each phase that provides uniformity of burning-off.

The following demands, besides standard ones, are made of electrode covering for surfacing by three-phase arc: electroconductivity and slag viscosity. Their violation may cause short circuits between cores on the inetrelectrode covering layer, complicating a process schedule. Electrodes with three cores in general coating are not produced in industry. They are assembled in laboratory environment from normal 1.6–3 mm diameter electrodes of МР-3, ОЗС-12 marks, etc. Bundle manufacturing includes coating of the cores tied up by threads with silicate glue, after its drying they are fastened through equal intervals with a thin wire and are dried at 200 °С [2]. Conglutination prevents a divergence of electrodes at bundle burning. The identical distance I between cores (fig. 1) provides them with equal electric parameters of modes; that promotes their uniform melting. Assembled bundle was fixed in a simple electrode holder with three mutually isolated copper plates.

The initiation of the indirect arc is carried out by contact of the product with three electrodes while connecting a neutral main to the product. After initiation of the arc and the part warming up, the neutral main is disconnected from the part. It is impossible to turn off the arcs without power cutting; it is a disadvantage of the process. Unlike one-arc welding it is impossible to change arc voltage during surfacing process in this case. Voltage on the arcs depends on the distance between electrodes and the thickness of their covering.

Fig. 1. Scheme of surfacing by indirect three-phase arc:

1 – electrode core; 2 – coating on electrode; 3 – secondary windings of three-phase transformer; 4 – part; I 1 , I 2 , I 3 – currents in electrodes; I д – current in neutral main; К – contact of neutral main switching off; I – distance between electrodes

The most important indices of independent three-phase arc burning stability include simultaneous initiation of three arcs, uniformity of three electrodes melting, burning and spitting losses, stability on fusion penetration depth and roller formation, distance from an independent three-phase arc to the part, absence of three electrodes meltback during breaks in arc burning [3].

Surfacing factor Q н (g/(А·h)) in experiments was defined as follows:

Qн = Gн·3600/(3·I·t), where Qн – surfaced metal mass, g; t – time of arc burning, s; I – linear current in electrodes, А (I1 = I2 = I3).

Percent of burning and spitting losses – ψ was defined according to the formula:

ψ = Gбр/ Gн·100 %, where Gбр – spark mass, g.

Surfacing was made on scraped bright to metallic luster plates of low-carbon steel of 3–5 mm thickness at following parameters: I 3 = 55–60 A; U д = 30–32 В; U хх = 80. Metal deposit factor was 6.23–6.37 g/(a·hour), burning and spitting losses – 15–10 %. Thus, efficiency of this process is higher, than at single-phase surfacing as energy is consumed only for electrode bundle melting.

The difference between traditional one-arc process and surfacing by indirect three-phase arc is in considerably greater productivity. It is provided with simultaneous burning of three electrodes at once. Moreover, according to the experiments, on identical current modes three electrodes at surfacing by indirect three-phase arc are melt 20 % faster, than one electrode at usual one-arc surfacing. High efficiency is provided also due to the parent metal fusion penetration reduction. At surfacing with one electrode, the value of parent metal share in surfaced one usually is 30–40 %. As a result, most of the surfacing metal penetrates the parent one, and pure surfaced metal may be provided only in 4th or 5th layer. During surfacing using the method being investigated, samples with share of parent metal in surfaced one less than 10 % have been obtained.

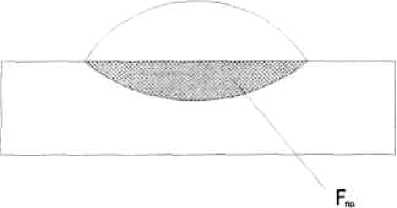

After surfacing samples with rollers were cut across, polished with subsequent etching in the 30 % solution of nitric acid for meltback limit revealing. The share of parent metal in surfaced one was defined by means of digital pictures under the following formula:

λ = Fпр /Fп, where Fпр – fusion area of the parent metal; Fп – total cross-section area of the roller (fig. 2).

Fig. 2. Cross-section area of the roller

It is established that fusion penetration of the parent metal is minimal; the share of the parent metal in surfaced one has reached 10 %. It is obvious, that the method of three-phase surfacing by indirect arc allows solving a problem of parent metal fusion penetration. Producing of pure surfaced metal without impurities of parent metal is possible from the first or the second layers that is inaccessible with standard one-arc methods of surfacing. It is revealed, that current increasing considerably improves weld forming, initiation of arc, and stability of its burning. However, fusion penetration increases from 2–7 to 8–10 %.

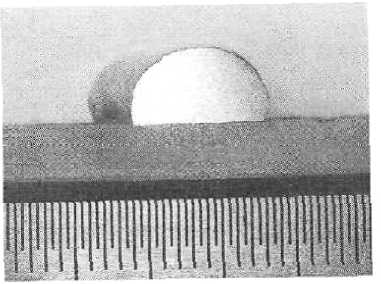

Surfacing on simple steel with electrodes of austenitic class has shown also good results. 2.5 mm diameter electrodes ОК 61,30 of ESAB were used for surfacing. Minimal fusion penetration of parent metal has been obtained at the following modes: I эл = 50 А, U л = 32–34 В, Uхх = 75 В. The share of the parent metal in the surfaced one does not exceed 5 % (fig. 3).

Fig. 3. Outward appearance of the sample surfaced with electrodes of austenitic class in cross-section

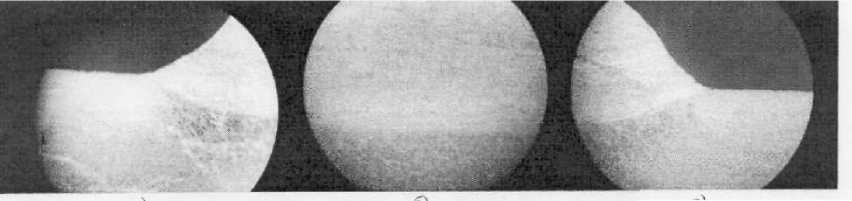

Micro section metallographic specimens are made from surfacing samples with electrodes МР-3 for microstructure character revealing (fig. 4). Reagent of the following composition was used for micro section metallographic specimen etching by means of rubbing in: HCl – 60 cm3, CuSO 4 – 12 g, H 2 O – 60 cm3. Examination was carried out using METAM ЛВ-31 microscope with × 50 and × 100 magnification.

The micro section analysis has revealed the structure lamination of the surfaced roller (fig. 5), relating probably to the specific character of the electrode bundle. The dendrite structure typical for melting processes is well visualized. The boundary between the parent metal and the surfaced one is distinguished.

Fig. 4. Cross-section of the roller surfaced with 2 mm diameter МР-3 electrodes

The transitional area (fig. 6), from which a growth of columnar crystallite blocks begins, consists of the parent metal and the surfaced one. Heat-affected zone has a coarse-grained structure, as a result of overheating of the parent metal during surfacing. It is evidence of high efficiency of thermal source. Overcoming coarse-grained structure of the parent metal near meltback boundary is possible by forced cooling of a part back side with running water, by means of surfacing speed increasing, and the subsequent thermal processing (normalization).

Conclusions

– the minimum current of steady-state combustion of indirect three-phase arc for 2 mm diameter electrodes is 55 A. At reduced values the initiation of the arc becomes difficult;

– the optimal interval of currents is 60–70 А. Exceeding these values causes excessive depth of the parent metal fusion penetration;

– one has obtained samples of surfacing by indirect three-phase arc in which the share of the parent metal in surfaced one is less than 10 %.

High efficiency of surfacing technological process by indirect three-phase arc with covered electrodes is confirmed.

Surfaced roller lamination, related to electrode bundle, and dendrite structure are revealed by metallographic method. The boundary between the parent metal and the surfaced one is distinguished, it relates, probably, to reduced influence of indirect arc on the parent metal.

b

c

Fig. 5. General view of microstructure in surfaced metal zone (х 50): a , c – roller edges; b – the middle

Fig. 6. Transitional area, × 100