Investigation of the rheological properties of PVC compositions containing phthalate plasticizers

Автор: Maskova Albina Rafitovna, Mazitova Aliya Karamovna, Aminova Guliya Karamovna, Rolnik Lyubov Zelihovna, Faizullina Galiya Fatyhovna

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Статья в выпуске: 3 т.10, 2018 года.

Бесплатный доступ

Polymer materials based on polyvinyl chloride (PVC) are processed in the form of multitudinous compositions. One of the main indicators in the processing of polymer compositions is manufacturability. It is known that in the processing of polyvinyl chloride compositions manufacturability is estimated by rheology of melts. The determine polymer processability the melt flow index (MFI) is the most widespread and almost universally used value. The melt flow index of the polymer material is the mass of polymer in grams extruded through the capillary at a certain temperature and pressure overfall in 10 minutes. It allows us to take decisions on the necessary conditions of processing the polymer composition and to determine the temperature limits of converting. In fact, PVC compositions are characterized by high viscosity and various chemical additives. For example, plasticizers are used to improve the processing conditions. This research studied how oxyalkylated alcohol phthalates developed by the authors influence on the MFI polymer. The results show that the synthesized esters, in a greater degree respect to the industrial plasticizer di- octylphthalate (DOP), increase the fluidity of the melt of the PVC composition and reduce its processing temperature thus improving the effectiveness of the plastic production.

Oxyethylated alcohol, oxypropylated alcohol, pvc, melt flow index, flow temperature, oxyalkylated alcohol phthalates

Короткий адрес: https://sciup.org/142212199

IDR: 142212199 | УДК: 678 | DOI: 10.15828/2075-8545-2018-10-3-127-137

Текст научной статьи Investigation of the rheological properties of PVC compositions containing phthalate plasticizers

Additives of various functional purposes – plasticizers, stabilizers, fillers, fire retardants, etc. – allow achieving the meaningful change in the characteristics of polymers. The choice of the type and dosage of the initial components is determined by the conditions of processing the polymer composition and the necessary complex of operational properties of the products obtained.

Plasticizers have great impact on the structure and properties of polymers. Physical, mechanical and rheological properties of polymeric materials can be changed in a guided way with help of plasticizers. Successful selection of plasticizer expands the polymers scope of use and extends their lifespan. Most plasticizers produced in industry are used for plasticizing of polyvinylchloride (PVC).

The widely used method for analysis of rheological properties of polyvinylchloride melt is capillary viscometry, which helps to determine melt

RESULTS OF THE RESEARCH ON THE PROPERTIES AND CHARACTERISTICS OF THE NEW PLASTICIZERS flow index (MFI), that characterizes the speed of flowing of melt through the standard size capillary at given temperature and pressure. The value of MFI is the parameter, which largely determines the choice of processing conditions of polymer compositions. In addition, MFI can be used for the quality control of raw materials (components) of polymeric compositions. Thus, the melt flow index of composition is the important parameter, which determines the processability of PVC-compositions [1–7].

The aim of the work was to study properties of PVC-compositions containing proposed plasticizers and to estimate efficiency of plasticizers in comparison with commercial prototype.

Previously we described phthalates of oxyalkylated alcohol, especially: symmetrical and unsymmetrical phthalates of oxyethylated and oxy-propylated butanol and phenol. In the papers [8-18] the results of investigation of methods of their obtaining and some physico-chemical properties are presented. In the present case we focused on investigation of the influence of developed compounds on the technological properties of PVC-materials.

Experimental part

We used model PVC compositions containing a thermal stabilizer (calcium and zinc stearates – 3 parts by weight of PVC / 100 parts by weight of PVC) and a plasticizer – prototypes of esters of oxyethylated alcohol – butoxyethylphenoxyethylphthalate (compound I), mixed esters of oxyethylated and oxypropylated alcohol – butoxyethylphenoxypropylphthalate (compound II), esters of oxypropylated alcohol – butoxypropylphenoxypropylphthalate (compound III) or commercially available analogue of dioctylphthalate (DOP) in the experiments.

The influence of oxyalkylated alcohol phthalates on the melt flow index was determined by capillary viscometry at 195оС and at the load 2.16 kg on the apparatus IIRT-AM according to the GOST 11645-73 [19].

Results and discussion

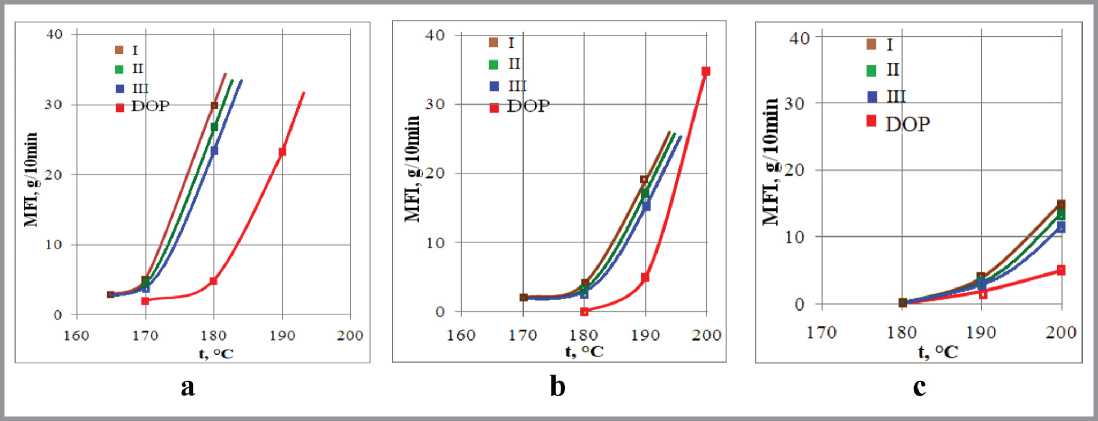

From the experimental results one can see (fig. 1) that with increasing of temperature and quantity of introduced plasticizer the melt flow index of PVC-composition increases.

RESULTS OF THE RESEARCH ON THE PROPERTIES AND CHARACTERISTICS OF THE NEW PLASTICIZERS

Fig. 1. The influence of quantity of oxyalkylated alcohol phthalates (1, 3, 5) and DOP (2, 4, 6) on MFI of PVC-compositions.

The content of plasticizer, weight part of PVC: 1,2 – 80; 3,4 – 60; 5,6 – 40 (I–III – symbols of oxyalkylated alcohol phthalates)

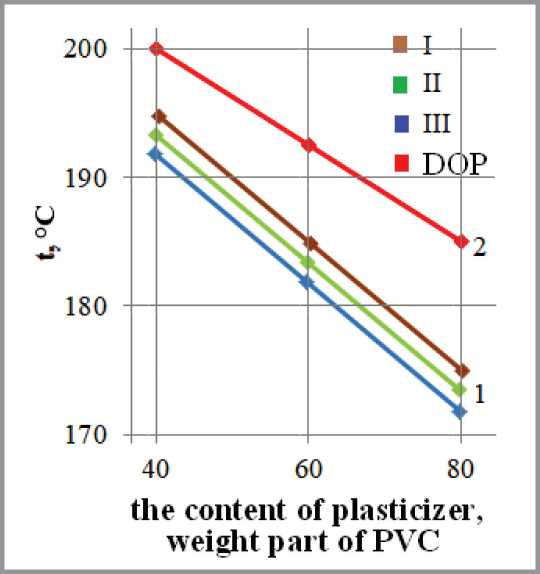

It was found out that for PVC-compositions with same amount of plasticizer at the same value of MFI the main parameters that influence on the rheological properties, namely, temperature and content of plasticizer are linked linearly (fig. 2).

Fig. 2. The dependence of flow temperature of PVC-composition from the content of plasticizer in mixture:

-

1 – oxyalkylated alcohol phthalates;

-

2 – DOP) at constant value of MFI, 5g/10 min

(I–III – symbols of oxyalkylated alcohol phthalates)

RESULTS OF THE RESEARCH ON THE PROPERTIES AND CHARACTERISTICS OF THE NEW PLASTICIZERS

For quantity estimation of influence of plasticizer on the flow of polymer melt, the index of effectivenes θ , which equal to the slope ratio of the obtained experimental straights to the x – axis, was used. The value of index θ corresponds to changing of flow temperature of PVC-composition when in its formulation 1 weight part of plasticizer is introduced in case of constant value of the melt index of composition. From the experimental results (fig. 1) follow that proposed plasticizers in a greater degree than DOP increase the flow of melt of PVC-composition and decrease its processing temperature.

It is found that the flow of the melt of PVC somewhat depends from chemical nature of used plasticizer. According to the obtained results due to the influence on the flow of melt of polymer, phthalates of oxyalkylated alcohol can be arranged in the following series: esters of oxyethylated alcohol > mixed esters of oxyethylated and oxypropylated alcohol > esters of oxypropylated alcohol. In the case of introduction of developed plasticizers within compatibility with PVC, the flow of the melt increases proportionally that indicates on better compatibility with PVC.

Conclusion

Thus, the nature of plasticizer influences on the melt index. The presence of the plasticizer with specific structure to a greater or lesser degree increases the flow of the melt of PVC-composition, this allow us to suppose that their using in the composition of PVC-compounds improves their processing characteristics.

The performed research has been funded through the government grant «Syn-thesis and investigation of the modern polyvinyl chloride plasticizers» according to the Decree of the Government of the Republic of Bashkortostan of 07.02.2018 № 56 «On providing grants of the Republic of Bashkortostan to young scientists and groups of young researchers in 2018».

RESULTS OF THE RESEARCH ON THE PROPERTIES AND CHARACTERISTICS OF THE NEW PLASTICIZERS

Список литературы Investigation of the rheological properties of PVC compositions containing phthalate plasticizers

- Тиниус К. Пластификаторы. -М.: Химия, 1964. -915 с.

- Барштейн Р.С., Кириллович В.И., Носовский Ю.Е. Пластификаторы для полимеров. -М.: Химия, 1982. -196 с.

- Мазитова А.К., Аминова Г.К., Нафикова Р.Ф., Дебердеев Р.Я. Основные поливинилхлоридные композиции строительного назначения. -Уфа, 2013. -130 с.

- Мазитова А.К., Нафикова Р.Ф., Аминова Г.К. Пластификаторы поливинилхлорида//Наука и эпоха: монография. -под общей ред. проф. О.И. Кирикова. -Воронеж, 2011. -С. 276-296.

- Маскова А.Р. Поливинилхлоридные композиции строительного назначения, пластифицированные фталатами оксиалкилированных спиртов: дис.. канд. техн. наук. -Уфа, 2012. -143 c.

- Уилки Ч., Саммерс Дж., Д.А.ниелс Ч. Поливинилхлорид. -СПб.: Профессия, 2007. -728 с.

- Власов С.В., Кандырин Л.Б., Кулезнев В.Н. и др. Основы технологии переработки пластмасс: Учебник для ВУЗов. -2-е изд., испр. и доп. -М.: Химия, 2004. -600 с.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Cабитов И.Н., Недосеко И.В. Новые пластификаторы поливинилхлорида//Нанотехнологии в строительстве. -2017. -Том 9, № 6. -С. 168-180. -DOI: dx.doi.org/10.15828/2075-8545-2017-9-6-168-180.

- Файзуллина Г.Ф., Габитов А.И., Маскова А.Р., Ахметова И.И. Пластификация поливинилхлорида новыми пластификаторами//Нефтегазовое дело. -2017. -Т. 15, № 3. -С. 106-111.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Ягафарова Г. Г., Мазитов Р.М. Новые пластификаторы для ПВХ-композиций строительного назначения//Нанотехнологии в строительстве. -2017. -Том 9, № 4. -С. 48-63. -DOI: dx.doi. org/10.15828/2075-8545-2017-9-4-48-63.

- Mazitova A.K., Aminova G.K., Maskova A.R., Zentsov V.N., Nedopekin D.V. and Rayzer Ju.S. 2017. Development of Oil-Benzen-Resistant PVC-Plastics. Journal of Engineering and Applied Sciences, 12: 7865-7869 DOI: 10.3923/jeas-ci.2017.7865.7869

- Мазитова А.К., Аминова Г.К., Габитов А.И., Маскова А.Р., Рахматуллина Р.Г. Новые пластификаторы ПВХ-композиций специального назначения//Башкирский химический журнал. -2015. -Т. 22, № 3. -С. 23-26.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Буйлова Е.А., Недопекин Д.В. Дифеноксиэтилфталаты и бутоксиэтилфеноксиэтилфталаты -новые пластификаторы поливинилхлорида//Нефтегазовое дело. -2015. -№ 5. -С. 376-397.

- Мазитова А.К., Степанова Л.Б., Аминова Г.Ф., Маскова А.Р. Разработка функциональных добавок для поливинилхлоридных композиций строительного назначения//Промышленное производство и использование эластомеров. -2015. -№ 2. -С. 27-31.

- Aminova G.F., Gabitov A.I., Maskova A.R., Yagafarova G.G., Rolnik L.Z., Klyavlin M.S. New composite PVC-material for finishing purposes, plasticized by butoxyalkylphen oxyalkylphthalates//Electronic scientific journal «Oil and gas business». -2013. -№ 5. -P. 353-362.

- Мазитова А.К., Аминова Г.Ф., Габитов А.И., Маскова А.Р., Хуснутдинов Б.Р., Фаттахова А.М. Разработка новых пластификаторов поливинилхлорида//Нефтегазовое дело. -2014. -Т. 12, № 1. -С. 120-127.

- Аминова Г.Ф., Габитов А.И., Маскова А.Р., Горелов В.С. Пластификаторы на основе оксиалкилированных фенолов//В сборнике: Проблемы строительного комплекса России. XVIII Международная научно-техническая конференция. -2014. -С. 271-273.

- Габитов А.И., Маскова А.Р., Буйлова Е.А., Аминова Г.Ф. Бутоксиэтилфеноксипропилфталаты -новые пластификаторы поливинилхлорида//В сборнике: Проблемы строительного комплекса России. XVIII Международная научно-техническая конференция. -2014. -С. 267-268.

- ГОСТ 11645-73 Пластмассы. Метод определения показателя текучести расплава термопластов.