Investigation of ultrasound waves on pretreatment of osmotic dehydration of carrot slices

Автор: Tahmasebi Soheila, Mirzaee Somaye, Kaviyani Mehdi, Tabrizi Mahsa, Shariati Mohammad Ali

Журнал: Вестник аграрной науки @vestnikogau

Статья в выпуске: 1 (46), 2014 года.

Бесплатный доступ

In this study, carrot slices were put in glucose osmotic 50% at 1, 2 and 3 hr. Ultrasound waves, frequency 40 kH power 30 w/l, passed through container of osmotic solution and carrot slices. The results revealed that significant increasing of dry matter of sample by using ultrasound waves.pre osmotic time had a significant on dry material by increasing from 1to 3 hr.sample treated by ultrasound waves lost water faster and their final dry solid was significantly more than control (without ultrasound treatment).

Ultrasound wave, carrot slice, osmotic dehydration

Короткий адрес: https://sciup.org/147124151

IDR: 147124151 | УДК: 635.132:581.188.3:534-8

Текст научной статьи Investigation of ultrasound waves on pretreatment of osmotic dehydration of carrot slices

Osmotic dehydration is one the new processing of food stuffs which uses in combination of hot air as preprocess of dehydration or as dehydrating method (Bayat Tork et al., 2011; Rahmanand Perera, 2007). In this method, food slices put in an osmotic solution more than product (salty or sweet solutions).Osmotic pressure cause to gradually removing of cell wall’s water, penetrating a few of salts or minerals from solution to food stuff texture, finally it observed that moisture has been decreased and dry solid increased( Amidi Fazli et al, 2008).

Application of osmotic drying on apricot in Saccharose or saline solution showed that fruit drying is for their preserving , base on model increasing volume leads to increase quick mass transfer, quick increasing of dry solid and increasing total solution amount, increased mass transferred, the best results observed in 5:1 ratio of fruit solution (Manafi et al . 2010).

In investigations of combination effects of ultrasound waves and alkaline on decreasing drying time of grape and producing raisins , it was revealed that these waves weren’t effective individual, only having the most significant in 40 and 60 min ,however combined treated samples decreased significantly dry solid of raisins(Maskoki et al., 2007).

The other innovations in food dehydration , drying using sound waves with high intensity and low frequency, is being dried in low range 140-200 ˚F via increasing heat transfer and mass transfer in boundary of products. This phenomenon leads to separate liquid phase of solid phase. Their drying race is 3-10 folded of regular dryers (Simal et al., 2003).

In this study, to perform osmotic dehydration carrot slices put in the glucose (50%) osmotic solution 1, 2 and3 hr, and ultra sound waves 28KH power 30w/L passed of container of carrot slices. After pretreatment, slices let to be removed their water, their surfaces dried, weighed and dried at 50˚c. Drying continued that weight reach to less than 0.5g weight difference after 2 consecutive weighing. Half of the sample applied for sensory and rehydrating experiments and rest for drying at 105˚c to a constant weight. Drying curve plot in 50 ˚c designed, by weighting dry solid at ˚c, moisture content of samples determined before and after pre osmotic process (Fito et al., 1998). All treatments perform in 3 repetitions and results analyzed by Results showed that increasing dehydration time from 1to 3 hr led to more removing of water , in samples treated by ultra sounds, dehydrating was better , less moisture in the end of pre osmotic process , significant differences with control (without ultra sound treatment).

In this study , to perform pre osmotic treatment carrot slices put in glucose solution (50%), ultrasound waves being passed of them (40KH, 30 w/L) in 1,2and 3 hr, finally let the samples’ water removed , their surface dried weighed and dried at 50˚C.

MATERIAL AND METHODS

Required carrot bout freshly of fruit vegetable market, required glucose BX 80 bout from Shadineh Co Isfahan, Iran. Carrots diameter 2 cm were selected to perform experiments .first of all their head and tail which didn’t have suitable thickness cut , the middle part cut into slices with 2 cm diameter and Their size, shape uniformed.

To prepare this solution glucose solution 50 % w/w with BX 80 % applied, diluted with distilled in ration 10:6 to produce a 50% w/w solution. To apply this treatment, ultrasound bath produced by pars nahand co equipped with 3 ultrasound generator with 50 w power (150w together) used, carrot slices with osmotic solution in with 1:4 ratio (200 g slices and 800 g osmotic solution) mixed, put in an 1L beaker in ultrasound bath filled by 5 L water as a waves transferring medium and temperature moderating, samples treated for 1-3 hr. Samples were shook every 1 min equally by glass during this time.

Water temperature controlled during process, fixed in range 38-40 ˚c by removing some hot water. In the end, slices sank by a meal, dried by straw paper. After osmotic pretreatment, samples were put in oven 50 ˚c, weighed every 30 min .drying continued to reach a less than 5 g difference in 2 weighing, then dried in oven at 105 ˚c, weighed again and their moisture measured by formulation.

RESULT AND DISCUSSION

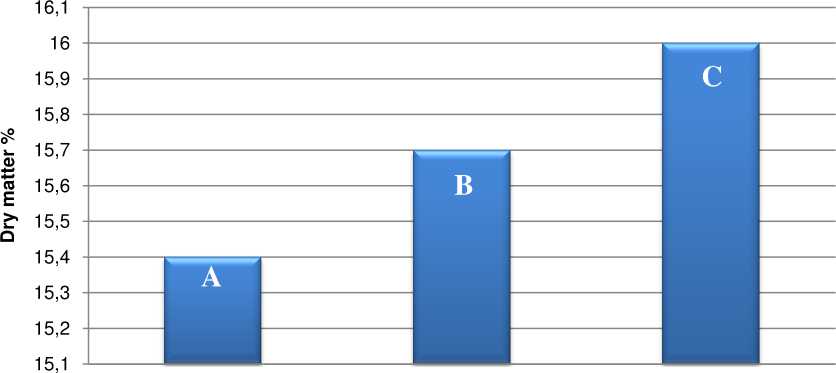

After drying at 105 ˚c, dry solid percent measured, the least and the most were related to osmotic pretreated samples in 1 and 3 hr respectively. Comparing results of 3 applied times with Duncan test revealed a significant difference .Fig 1 shows the effect of osmotic pretreatment on dry solid of carrots.

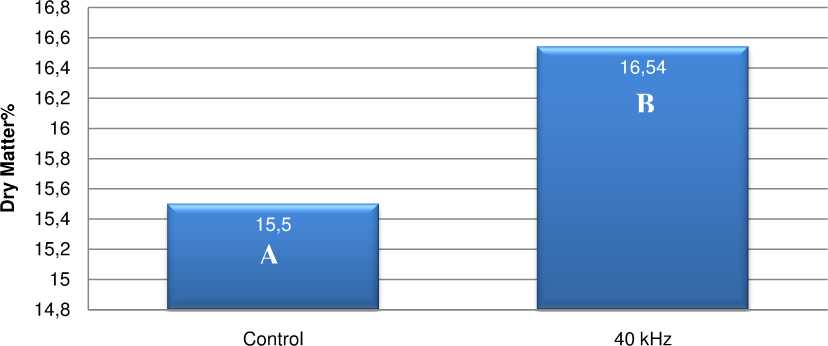

Comparing average of ultrasound waves treated and control samples displayed a significant differences between samples cause to a significant increasing in samples’ dry solid .It might be due to transmitting of ultra sound waves, increasing movement of liquid surrounded samples , improving osmotic between carrots and osmotic solution.

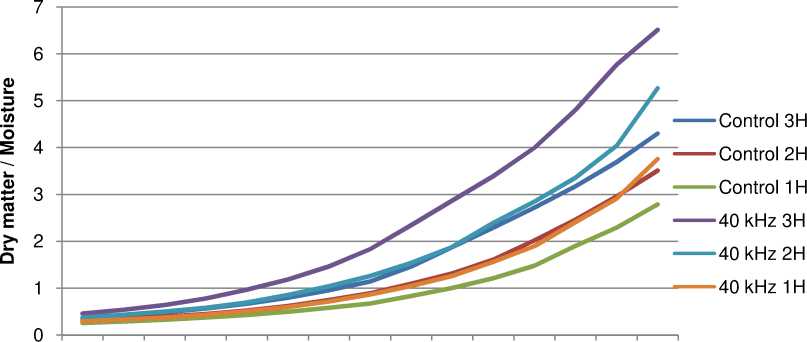

Samples weighed every 30 min after osmotic pretreatment at 50 ˚c. Figure 3 showed the ration of dry solid to moisture during dehydration time.

our time of osmosis pretreatment

Figure 1 - The effects of ultrasound on samples’ moisture and dry solid

Ultrasonic treatment

Figure 2 - Effect of Ultrasonic waves on Dry matter after osmosis pretreatment

0 30 60 90 120 150 180 210 240 270 300 330 360 390 420

Drying time at 50 C

Figure 3 - Dry matter/Moisture in drying time

As it shown in fig 3 this ratio is more in samples treated using ultrasound , 9 times more in treatment at 2-3 hr , however without using ultrasound this ration is 4.5 ultimately, thus using ultrasound caused to improve better and more glucose has been penetrated in samples.

CONCLUSION

In osmotic pretreatment of carrot slices time has been a significant relationship on samples’ dry solid, moisture decreased their dry solid increased during 1-3 hr. Using ultrasound waves 28KH F and power 30 W/L led to significant changes in moisture and dry solid contents in the end of processing.

Список литературы Investigation of ultrasound waves on pretreatment of osmotic dehydration of carrot slices

- Rahman, M.S., and Perera, C.O. 2007.Drying and Food Preservation. pp. 412. In Rahman M.S., Handbook of food preservation, 2nd ed., CRC Press

- Manafi, M. Hesari, J. Peighambardoust, H. and. RahimzadeKhoyi, M. 2010 Osmotic Dehydration of Apricot using Saltsucrose Solutions. World Academy of Science, Engineering and Technology. 1088-1091

- Bidaisee, G. & Badrie, N. (2001). Osmotic dehydration of cashewapple (Anacardiumoc-cidentale L.): quality evaluation of candiedcashew apples. International Journal of Food Science and Techonology, 36, 71-78

- Fito, P.; Chiralt, A, Barat, J.; Salvatori, D and Andrés, A. 1998. «Some advances in osmotic dehydration of fruit». Food Science and Technology International, 4, 329-338

- Bidaisee, G. &Badrie, N. (2001). Osmotic dehydration of cashewapple (Anacardiumoccidentale L.): International Journal of Food Science and Techonology, 36, 71-78

- Norma I., Fairley, P. 1992. Analysis of the sugar content of fruit juices and drinks using ultrasonic velocity measurements.International Journal of Food Science & Technology. 1992: 7 (5) 515-529

- Schuett, A. I. 1992. Ultrasonics in sterilizatoin sinks. Application of ultrasonics in equipment for cleaning and disinfection of knives at the workplace in slaughter and meat cutting plants.Fleischwirtschaft; 72(6) 864-867

- Zheng, L& Sun, D.W. (2006). Innovative applications of power ultrasound during food freezing processes -a review.Trends in Food Science & Technology, Volume 17, Issue 1, pp. 16-23

- Simal S., Benedito J., Clemente G., Femenia A., Rosselló C., 2003. Ultrasonic determination of Sonochem. 3, pp. 253-260