Исследование неравномерности линейной плотности нити и выбор единичных показателей качества нити

Автор: Ф.Ф. Казаков, Н.Н. Саттарова, M. Аслонова, З. Мухторова

Журнал: Современные инновации, системы и технологии.

Рубрика: Машиностроение, металлургия и материаловедение

Статья в выпуске: 2 (2), 2022 года.

Бесплатный доступ

В статье рассмотрены вопросы повышения качества пряжи и снижения ее обрывности, которые тесно связаны с неравномерностью полуфабрикатов, возникающей при их вытяжке. Представлены табличные результаты сравнительного анализа контрольных и лабораторных (исследовательских) показателей технологических расстояний модифицированного вытяжного прибора Q-Packe кольцепрядильной машины.

Вытяжной прибор, волокно, продукт, вытяжка, сила трения, эффективность, пряжа, ткань, экономическая эффективность

Короткий адрес: https://sciup.org/14123385

IDR: 14123385 | DOI: 10.47813/2782-2818-2022-2-2-0162-0168

Текст статьи Исследование неравномерности линейной плотности нити и выбор единичных показателей качества нити

The textile industry is one of the branches of the national economy. Textile industry enterprises produce a variety of consumer goods - fabrics, yarn, cotton fiber, knitwear and others. Improving the design of equipment is relevant today. The interaction of individual mechanisms should be taken into account when designing textile machines. The analysis of modern technologies allows us to conclude that a number of problems have not yet been fully solved, in particular, the purchase of equivalent products and the elimination of failures in the production process [1]. The issues of improving the quality of yarn and reducing its discontinuity are closely related to unevenness semi-finished products that occur during their extraction. Therefore, special attention should be paid to the study of the extraction process, improvement of exhaust devices (belts, roving frames, spinning machines) and optimization of technological parameters of the extraction process [2].

MATERIALS AND METHODS

The unevenness of the elongation process is mainly due to the transition of the fibers to the speed of the average pair. This applies not only to floating, but also to controlled fibers, but shorter fibers are more susceptible to this effect. Therefore, the front ends of the fibers require premature transition of the cylinder to forward speed. Under the strong influence of neighboring fibers that move slowly, the rear ends of the fibers lengthen and therefore they move the fibers at their own speed. However, the friction force transmitting motion from one fiber to another depends not only on the number of fibers and the length of their contact area, but also on the field strength of the friction forces. At the speed of the front cylinder, it is necessary to strengthen the braking of the rear clamp at the rear ends of the fibers to prevent premature connection of the fibers [3].

The creation of such a field of friction forces that would keep the fibers from prematurely switching to the previous pair of speeds would solve the problem of unevenness of products formed during elongation. The calculation of the economic efficiency of modern spinning machines was carried out in accordance with the "Methodology for determining the economic efficiency of the use of new technologies, inventions and innovation proposals [4].

The economic efficiency of the production and use of new tools of improved quality is determined by the following formula. Currently, the introduction of the process of modification of the spinning machine G35 Q-Packe exhaust device increases economic efficiency [5].

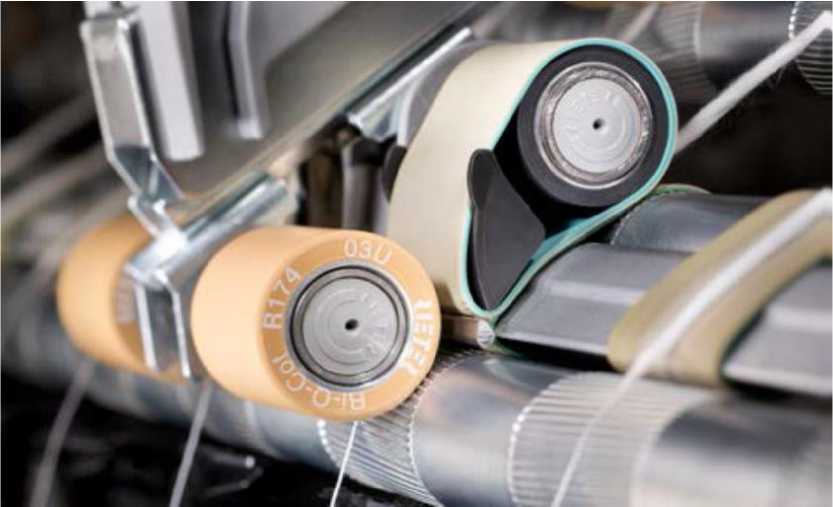

Figure 1. Modified exhaust device.

RESULTS AND DISCUSSION

Table 1. Indicators of the distance between the modified exhaust device Q-Packe ring

|

spinning machine. |

|||||

|

№ |

Indicators |

First Strap |

Second Strap |

Third Strap |

|

|

1 |

Modified Daily distance of the |

Control 20 mm |

45 mm |

39.2mm |

x |

|

2 |

Q-Packe exhaust device of the spinning machine (Laboratory) research Modified Daily distance of the 16 mm |

51 mm |

30.0mm 1.0mm 39.2mm |

x x |

|

|

Q - Packe exhaust device of the spinning machine |

30.0mm 1.0mm |

x |

|||

Table 2. Results of the modified Q-Packe exhaust device on a ring spinning machine.

|

№ |

Indicators |

Before the study |

After the study |

According to GOST |

|

400 |

380 |

360 |

||

|

280 |

250 |

230 |

||

|

1 |

Nepsa number: |

200 |

180 |

160 |

|

140 |

120 |

100 |

||

|

14 |

12 |

12 |

||

|

66 |

62 |

60 |

||

|

2 |

Number of breaks: |

214 |

210 |

200 |

|

887 |

878 |

850 |

||

|

14 |

12 |

12 |

||

|

66 |

62 |

60 |

||

|

3 |

Stop the spindles |

214 |

210 |

200 |

|

887 |

878 |

850 |

We evaluate the effectiveness of solving the task by improving the process of improving the quality of products, changing individual yarn quality indicators, as well as changing quality indicators [6].

The product quality indicator is a quantitative description of one or more characteristics that make up a product, taking into account the specific conditions of its creation and operation or consumption [7].

If the numerical value of the quality indicator increases with the improvement of the quality of the material, it is called positive, and if it decreases, it is called negative. As indicators of yarn, unique indicators of the quality of the material are used, characterizing one of its properties [8, 9].

-Selection of individual yarn quality indicators listed in the table Requirements of the regulatory document.

Table 3. Selection of individual yarn quality indicators given in the table.

|

Number name |

Single indicators of yarn quality |

Pointing at the pointer |

|

1 |

Linear density, tex |

Neutral |

|

2 |

Relative deviation of the actual linear density from the nominal, % |

Negative |

|

3 |

Absolute breaking load, cH |

Positive |

|

4 |

Relative breaking load cH/tex Coefficient of variation of linear density, % |

Positive |

|

5 |

Coefficient of variation of breaking load, % |

Neutral |

|

6 |

Coefficient of variation in twist, % |

Negative |

As can be seen from Table 3, the yarn quality is characterized by several single indicators. At the same time, it is necessary and advisable to use a generalized quantitative assessment of quality, when the complex of the most important features of the product is combined into a single indicator.

As research methods, qualimetry methods are used, consistently implementing a complex algorithm for determining quality indicators [10, 11].

CONCLUSION

The method of constructing a complex yarn quality indicator consists in the selection, sorting, measurement, normalization of quality indicators, followed by their transformation into a complex indicator.