Исследование отходов волокна, образующихся в технологических процессах прядильного производства

Автор: К. Жуманиязов, Д. Анорбоев

Журнал: Современные инновации, системы и технологии.

Рубрика: Прикладные вопросы и задачи применения систем и технологий

Статья в выпуске: 5 (1), 2025 года.

Бесплатный доступ

На основании результатов анализа проведенных исследований показано, что, используя в отделенных отходах пригодные для прядения волокна, можно добиться эффективного использования сырья на предприятии прядильного производства. Соответственно, рекомендуется использовать годные волокна из отходов кардочесальных машин в качестве сырья для прядения пряжи высокой линейной плотности. В результате экспериментов установлено, что очистительно-гребнечесальные машины, выпускаемые ведущими фирмами развитых стран, при своей эффективной работе сбрасывают определенную часть сырья в отходы. Известно, что факторы, влияющие на степень измельчения и очистки сырья, зависят от скорости рабочих органов очистки, формы колосниковых решет, типов рабочих органов очистки, расстояния между барабаном очистки и разделительными ножами, формы и расположения обшивок рабочих органов очистки. Обобщая результаты эксперимента, следует отметить, что при прядении нитей линейной плотностью 29 текс и выше рекомендуется добавлять в смесь 10-12 процентов гребенчатого ореха и таранда. В результате добавления в смесь 10-12 процентов чесальных орехов и таранда использование сырья дает хороший эффект, а прядущиеся нити соответствуют требованиям стандарта. В результате экспериментов установлено, что в отходах содержатся древесные опилки, орехи, короткие волокна, оболочки семян, липкие волокна, камни и т. д., а также некоторое количество волокон, пригодных для прядения.

Волокно, пряжа, машина, барабан

Короткий адрес: https://sciup.org/14133013

IDR: 14133013 | УДК: 677.022 | DOI: 10.47813/2782-2818-2025-5-1-2040-2045

Текст статьи Исследование отходов волокна, образующихся в технологических процессах прядильного производства

DOI:

The main task in the production of textile products is to ensure the quality of the received products. In order to ensure the quality of the finished product used for various purposes, the main technological processes of spinning enterprises are the grindingcleaning, mixing and carding processes. In recent years, as a result of the improvement and modernization of cleaning units and carding machines, significant progress has been made.

In the production of textile and light industrial products, the consumption of raw materials is the main factor determining the cost. It has been observed in experiments that its share goes up to 90%. Therefore, it is an important and urgent issue to find all the possibilities of full and effective use of raw materials in the industry, their scientific justification and correct use.

It is known that the main part of fiber waste suitable for spinning is used for the production of non-woven fabrics, and a part is used in spinning enterprises. Non-woven fabrics for technical purposes are mainly made from low-grade fibers and waste. The existing aggregates for the most efficient grinding and cleaning of fibers lead to an increase in the amount of waste in the processing of such mixtures. When the qualitative composition of the waste called savash nut and fluff produced in the used aggregates was studied, it was found that up to 70% of it contains fibers of different lengths and soft defects.

It is necessary to rapidly master modern techniques and technologies that have been successfully tested on a global scale in enterprises. To further increase the competitiveness of the products produced by the enterprises of our country, in this way, to ensure the stable development of industrial sectors and the growth of export potential, is to develop the sector and achieve high-quality products.

Effective use of low-cost fiber waste and installation of specialized equipment play an important role in increasing the economic potential of the enterprise. This research work is also aimed at studying this issue.

ANALYSIS OF SCIENTIFIC PAPERS

It is known that the main part of fiber waste suitable for spinning is used for the production of non-woven fabrics, and a part is used in spinning enterprises. Non-woven fabrics for technical purposes are mainly made from low-grade fibers and waste. The existing aggregates for the most efficient grinding and cleaning of fibers lead to an increase in the amount of waste in the processing of such mixtures. It follows that one of the main indicators affecting the quality of the product, reducing the amount of waste and improving the quality of the product is one of the urgent problems of today.

The problem of reducing the amount of waste generated in production enterprises is one of the important issues, and the process of its implementation is limited in terms of possibilities. Because the generation of waste is an objective necessity and technological inevitability, and it is related to the nature of the process. This need arises during the process of pre-treatment of seed cotton, cleaning of fiber raw materials, binding of semifinished products, forming a package, cutting the fabric to a specified size for making a product, and similar requirements [1].

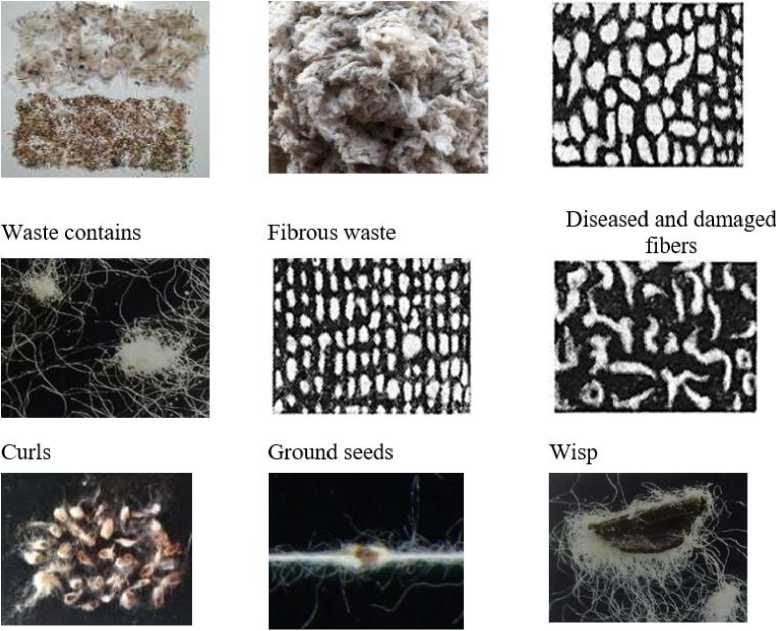

If we take a sample of a certain amount of cotton fiber and analyze its composition, we can see that there are different characteristics and defective fibers in addition to normal mature fibers [2-4]. Such defects are biological and mechanical, and they appear during the growth and development of cotton, during the initial processing of seed cotton in cotton gins, and during the extraction of yarn from cotton fibers in spinning enterprises [5]. The greater the number of such defects, the lower the quality of the cotton fiber, the more complicated the technological processes of processing it, the more the amount of waste, and the less the output of the yarn. As a result, the quality of the spun yarn decreases, its cost increases, and the number of yarn breaks during the spinning process increases. This, in turn, leads to a decrease in the productivity of spinning machines. The types of waste affecting product quality are shown in Figure 1 [6-9].

METHODS

The quality indicators of finished products and semi-finished products at spinning enterprises are carried out in the laboratory facilities for product quality control located at the enterprise. Currently, the laboratory facilities of the spinning mills are equipped with complete laboratory equipment. Product quality indicators are controlled by laboratory staff at each plant. At present, the equipment of Riter (Switzerland) and Truetzschler (Germany) firms, which are developed in the world, are at the forefront of the production and processing of waste at spinning mills, they are shown in Table 1.

The peel stuck to the fiber Harmful defect Seed bark

Figure 1. Properties and defects in cotton fiber.

Table 1. Existing waste treatment machines in the enterprise.

|

№ |

The name of the machines |

«Riter» (Switzerland) |

«Truetzschler» (Germany) |

|

1 |

Automatic thread cutter |

Unifloc A 11 |

BLENDOMAT BO-A |

|

2 |

Cleaner of heavy compounds |

A48 |

- |

|

3 |

The shuffle provider |

V 25 |

BO – R |

|

4 |

Multi-function separator |

- |

SP – MF |

|

5 |

Initial cleaner |

UNIciean B 11 |

CLEANER CL-C 3-1 |

|

6 |

Universal mixer |

UNImix B 70 |

MULTI MIXER MX-1 10 -1 |

|

7 |

Fiber cleaner |

UNIflex B 60 |

|

|

8 |

Separator of foreign impurities |

- |

JOSSI |

|

9 |

Dust cleaning unit |

A 21 |

SP – DX |

|

10 |

The shuffler and provider machine |

UNIStone A 79 |

DO 2 |

|

11 |

Condenser |

A21 |

LVSA |

|

12 |

Distribution transfer case |

Aerofeed –A 70 |

TWO WAY DISTRIBUTOR |

|

13 |

Combing machine |

S-60 |

TC 6 |

The sample taken in the supply device of this equipment is placed in the specified order. The Uster Afis Pro 2 analyzer cleans the sample from waste and separates its fibers. The degree of pollution is determined by weighing the amount of waste extracted from the sample using a scale. This process is checked three times and evaluated against their average value. An image of the Uster Afis Pro 2 analyzer is shown below (Fig. 2).

\

RESULTS AND DISCUSSION

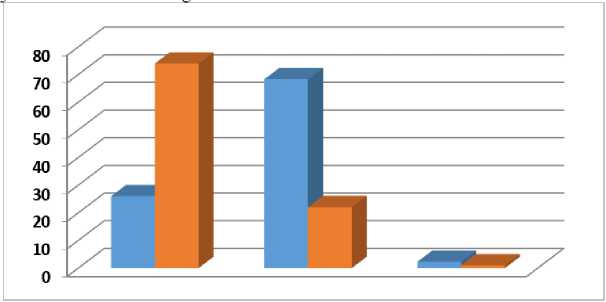

The conducted researches investigated the types and amounts of waste coming out of the “Jizzakh textil” yarn spinning enterprise located in the Jizzakh region. The composition of the waste coming out of the equipment in the production process was taken using the laboratory equipment Uster Afis Pro 2, a sample of one hundred grams was taken from the waste from the cleaning and combing machines, and their composition was checked. Experiments were carried out on fiber waste samples obtained from cotton fiber and their mixtures of good grade 4-type I and II varieties of the selection variety Porloq. The results obtained on the basis of the conducted experiments are presented in Table 2 below.

Figure 2. Uster Afis Pro 2.

Table 2. Percentage of fiber and waste in cotton fiber processing.

|

Firms |

Waste mass, gram |

Fibrous waste, gram |

Herbs and foreign compounds, gram |

Dust and invisible waste, gram |

Waste standards |

|

Truetzschler |

100 |

26 |

68.3 |

2.3 |

ST 3 |

|

100 |

74 |

22 |

1 |

ST 7 |

|

|

Rieter |

100 |

63.7 |

33.1 |

1.0 |

ST 3 |

|

100 |

70.4 |

24.5 |

2.6 |

ST 7 |

As it can be seen from the analysis of the results presented in the tables, the amount of fiber waste (ST3 standard) is 26% of fiber waste (ST3 standard) was found to exist when using machines of the German “Truetzschler” company, and 63.7% of fiber waste was found to exist when using the machines of the Swiss “Rieter” company. It was also determined based on experiments that 63%, 75%, and 72.5% of the tarandi (standard ST7) separated from the carding machine is fiber waste. In order to compare the obtained results, the following histogram shows the data in Figure 3.

Fibrous Herbs and foreign Dust and invisible waste waste compounds

ST 3 ■ ST 7

Figure 3. Waste composition fraction.

Cleaning and carding processes in textile enterprises are one of the main processes in the production of quality products. Because as a result of the cleaning and combing process, the fibers, fiber waste and other foreign impurities are separated from the fiber products. As a result of these processes, along with waste, fibers suitable for spinning are separated as waste [10-14].

CONCLUSION

In conclusion, it should be noted that it is advisable to use the combing-cleaning unit and carding machines of the German company "Truetzschler", because the amount of fibers suitable for spinning in the oreshka and tarandi is the least, and the amount of product output is that of combing-cleaning units and combing of other brands. It was found out from the analysis of the results of the research conducted that it is possible to achieve efficient use of raw materials in the enterprise by using the fibers suitable for spinning in the separated waste. From the results of the research, it became known that the cleaning and combing machines produced by the leading companies of developed countries, together with their efficient operation, release a certain part of the raw materials into waste. One of the important tasks is to prevent the release of fibers suitable for the production of this product as waste and to determine the factors affecting it. As a result of the experiments, it was found that the waste contains sticks, nuts (oreshki), short fibers, seed husks, sticky fibers, stones and a certain amount of fibers suitable for spinning. It was determined that the product contained in the waste is suitable for production.