Электронный умный текстиль: новые возможности в текстильной промышленности Бангладеш

Автор: Омар Фарук, Сайма Махаджабин, Нараян Чандра Натх , Прианка Кабирадж

Журнал: Современные инновации, системы и технологии.

Рубрика: Электроника, измерительная техника, радиотехника и связь

Статья в выпуске: 4 (4), 2024 года.

Бесплатный доступ

Производствои технологии развиваются в настоящее время достаточно интенсивно во многих отраслях, включая текстильную промышленность. Одним из инновационных направлений развития в текстильной и швейной отраслях является создание электронного умного текстиля. Такой интеллектуальный текстиль способен воспринимать, обрабатывать и интерпретировать широкий спектр импульсов и воздействия от электрических, химических, биологических, магнитных или других источников. Уровень интеллектуальности зависит от категории текстиля: яркие материалы, динамичная креативная одежда и пассивно интеллектуальная одежда. Выделяют пять уникальных элементов инновационного текстиля, используемых для его интеллектуализации. Это встраиваемые устройства, элементы удержания, сетевое взаимодействие, обработка данных и детекторы. Использование данных элементов должно отвечать всем (в том числе, и традиционным) функциям одежды, включая прочность, повседневное использование и устойчивость к традиционным методам ухода за текстилем. Это уже не ограничивается только теоретическими разработками, так как теперь умный текстиль обладает большим практическим потенциалом и является частью нашей повседневной жизни. Уже в наши дни он широко используется во многих областях, таких как одежда для аварино-спасательных работ, специальная и армейская одежда, а также снаряжение для защиты здоровья и безопасности. Кроме того, следует отметить биологические применения умного текстиля, его использование в спортивной одежде, защитном снаряжении, в разработках в области ракетостроения и т.д. Таким образом, электронный умный текстиль важной инновационной разработкой для создания одежды следующего поколения. Данное исследование направлено на обзор и анализ результатов исследований в области интеллектуального текстиля, включая рассмотрение его различных типов и функций. Рассматриваются ассортимент предметов умной одежды, а также современные интеллектуальные текстильные продукты и их актуальные применения.

Электронный текстиль, умный текстиль, интерактивный текстиль, датчики, одежда следующего поколения.

Короткий адрес: https://sciup.org/14131318

IDR: 14131318 | DOI: 10.47813/2782-2818-2024-4-4-0401-0425

Текст статьи Электронный умный текстиль: новые возможности в текстильной промышленности Бангладеш

DOI:

Smart materials, or smart textiles, are a growing field that focuses on the ability of textiles to detect and respond to environmental cues. These materials can be electrical, thermal, chemical, magnetic, or other sources, and can be used in various applications such as clothing, medical, aerospace, military, ecology, and environmental protection. Smart clothing, for example, is a novel garment feature that allows for interactive reactions by detecting signals, analyzing data, and triggering responses. Smart textiles are systems that combine sensors, actuators, and electrical devices to detect and respond to external stimuli [1]. Examples of such materials include textiles and dyes that react to changes in temperature to change color, clothing composed of conductive polymers that glow in response to electromagnetic signals, and materials that control surface temperature to maintain physiological comfort [2].

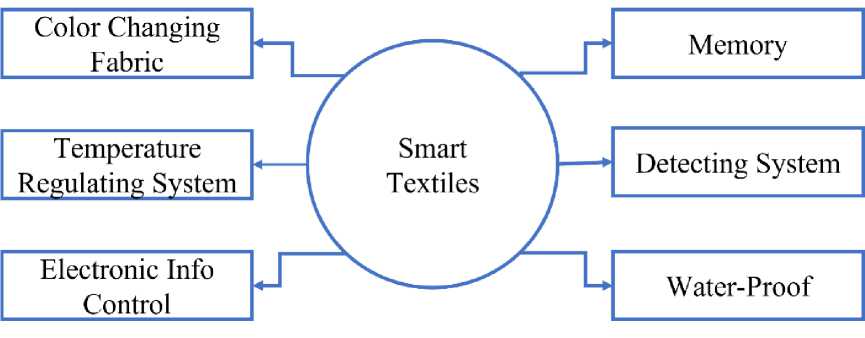

In recent years, there has been a significant increase in interest in wearable textile-based personal systems that provide health monitoring, safety, and protection. The need for intelligent materials that can change color and shape or include interactive aspects has never been higher, with applications in medical, health, aerospace, military, ecology, and life apparel industries [3]. The primary uses of smart fabric textiles are outlined in Figure 1.

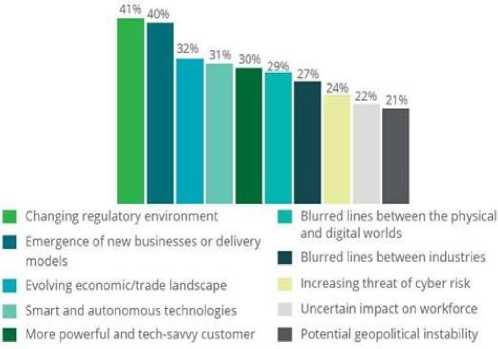

By establishing a smart economy, smart society, smart government, and smart citizens simultaneously by 2041, Bangladesh can achieve its goal of establishing a smart economy, smart society, smart government, and smart citizens. Adopting technology, promoting industry-oriented education, embracing circularity, pursuing man-made products, and fostering innovation are key elements in achieving this goal. By focusing on Smart Textile, the government has already started to respond to the growing demand for smart textiles and the impact of the fourth industrial revolution on the global economy [6].

Bangladesh's ready-made garment (RMG) industry is embracing automation and cuttingedge technology to improve its operations and competitiveness. The country's garment manufacturing sector has shifted from industrialized to developing nations to lower production costs, leveraging automation as a competitive advantage. Countries like China, Vietnam, and India are integrating Apparel 4.0 technology in their factories, with Chinese garment makers implementing 3D printing, augmented reality, and smart clothes, while Indian garment maker Raymond is utilizing sewbot technology. Vietnam has made significant advancements in ERP, additive manufacturing, and RFID [7, 8]

Automation may eliminate 800 million jobs by 2030, according to McKinsey Global Institute. Sector 4.0 is anticipated to decimate Bangladesh's garment sector, displacing 5 million workers, or 60% of all employment, within 15 years [9]. Bangladeshi garment companies leverage robotic autocontractors, automated knitting machines, chemical dispensing and dying systems, and ThreadSol software with artificial intelligence to enhance their business operations. Automation and cutting-edge technologies show the Bangladeshi garment industry's ingenuity and competitiveness. Automatic knitting machines, robotic systems, AI-powered software, and digital printers are examples. The industry's investment in automation shows its dedication to technological innovation and a sustainable future.

Figure 1. Smart Textiles.

Рисунок 1. Умный текстиль.

REVIEW OF LITERATURE

A literature review is a crucial step in the research process since without a thorough exposure to the pertinent literature; one would remain ignorant of the fundamentals of the field. It is nearly always necessary to research the pertinent literature in order to properly synthesize the body of information already known in the field, identify knowledge gaps, and ultimately characterize the challenges [10, 11]. As novice researchers, we have endeavored to examine pertinent books, journals, and essay research reports in order to carry out the investigation; nevertheless, several investigations have already been carried out in the area by various magazines and newspapers [12]. Some inevitable constraints, such as those related to cost and energy prevented us from gathering all the study papers [13, 14]. Director of the Arunima Group Nabil bin Faruq discusses the effects of automation on man-based labor in Bangladesh's apparel industry. Bangladesh's clothing sector is one of the main drivers of the country's employment and economic growth [15]. Therefore, it is crucial to think about how automation can affect the sector. In 2021, Hoque et al. performed research which found that automation in the garment sector had resulted in increased production and efficiency [16]. According to the survey, automation has helped firms lower labor expenses, boost production quality and speed, and minimize production costs [17-19]. Although the research indicates that automation has yielded favorable results for the sector, it also highlights several obstacles that require attention, including the requirement for a greater number of trained laborers and the development of improved machinery and systems to facilitate automation [20]. The survey also found that the labor market has changed as a result of automation, with more occupations now needing greater levels of ability and competence [21]. Overall, the study indicates that automation has the potential to significantly impact Bangladesh's garment industry's growth, but it is crucial to make sure that the right steps are done to guarantee automation's effective implementation [2224]. Automation seems to be a factor that Bangladeshi garment manufacturers will probably have to deal with soon. Customers may benefit from more effective, personalized, and affordable final goods and services as a result [25]. To guarantee the safe and ethical manufacture of clothing, automation should only be used when absolutely necessary [26, 27]. Additionally, all processes should be routinely checked, assessed, and optimized. Ultimately, even if automation has the potential to increase Bangladesh's apparel output, human labor must continue to play a crucial role in the manufacturing process to guarantee the ethical and safe creation of clothing [28].

METHODOLOGY

Fabrication methods

A hybrid approach is a technique that combines textile and commercial functionalities to create smart textiles. This approach involves using conductive textile threads, which can be added to smart textiles later through techniques like knitting, weaving, embroidery, laminating, and sewing. The direction of the conductive threads plays a significant role in the application of smart textiles. Lower conductivity yarns are ideal for situations requiring heating, while strong conductivity is required for lightning-smart textile scenarios.

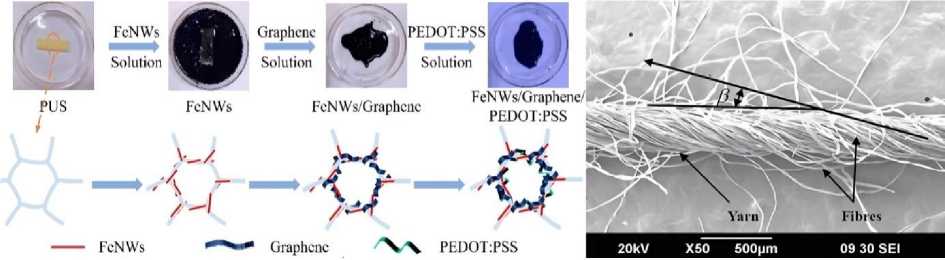

The process ability of textiles is another important factor in the use of conductive yarns. Low-resistance wires can break and tangle easily, and fabrics containing conductive metal wires cannot be cut using the same technique due to their high thermal conductivity. In the Figure 2, Yarn and Conductor management creating intricate conductive yarns with an insulating layer can enhance their strangeness and wash ability in various settings. The second technique involves producing large-area textile surfaces through knitting and weaving [29, 6, 7]. This involves intertwining two perpendicular sets of strands, known as warp and weft, to create a two-dimensional cloth. Other 3D constructions are built on fibers or threads that are entangled, interlaced, or intermeshed longitudinally, crosswise, and vertically. Despite the incorporation of an inflexible chemical that enhances stiffness, the fabrics maintain their comfort factor and visual appeal due to their three-dimensional shapes.

Figure 2. Yarn and Conductor management.

Рисунок 2. Управление пряжей и проводником.

The third approach involves adding the final touches to smart textiles, which are textiles that have a particular capacity built into them after they are fabricated. The employment of electrical devices to link lines inside textiles is one example of this technique [30, 31]. Making electrical connections between the gadgets and the fabric framework is the primary concern. Figure 3 a– c shows three examples.

Figure 3. Fabric-printed PEDOT lines with conductive adhesive micro-contact and LEDs make up the strain sensor.

Рисунок 3. Напечатанные на ткани линии PEDOT с проводящим клеевым микроконтактом и светодиодами составляют датчик деформации.

THE VARIATION OF SMART TEXTILES

Smart textiles can be categorized into three types: passive, active, and intelligent. Passive textiles sense only their surroundings, while active textiles can perceive and respond to environmental stimuli. Intelligent textiles can change their behavior based on the situation, making them more versatile and efficient.

Smart color-changing fabric textiles

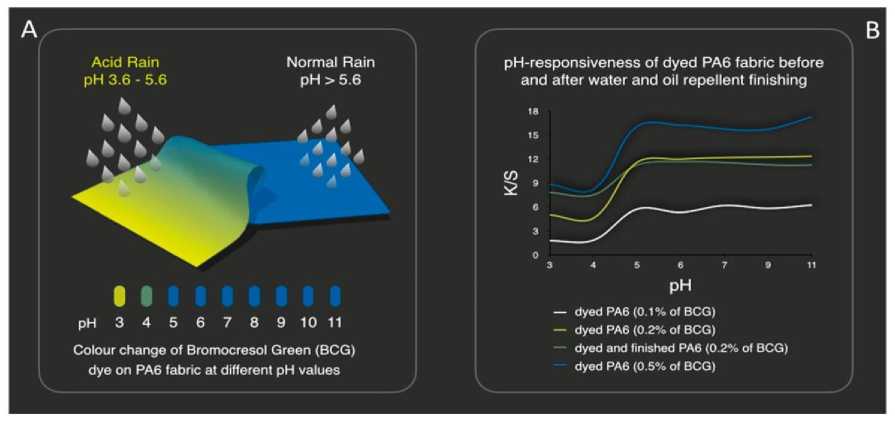

Smart textiles that change color actively respond to environmental stimuli, unlike passive smart textiles that only sense external conditions. The color change mechanism involves a material's electron density or molecular structure changing in response to an external stimulus, resulting in a color shift. Factors such as photochromic, thermochromic, electro chromic, solvent chromic, halo chromic, tribochromic, and mechanochromic factors contribute to color shift [32, 33]. With a high potential for global adoption, color-changing textiles in fashion and decoration will increase in the future. Color-changing smart textiles can be used for applications such as firefighter suits and aesthetics. Thermo chromic dyes have an additional thermoregulation impact, causing fibers to shorten at high temperatures and reducing body warmth. Thermo chromic dyestuff also retains body warmth at low temperatures by closing pores and extending fibers. A pH-change-based color-changing mechanism was investigated, with proteins separated from silk ink and suspended in water. Lactate oxidase and pH-sensitive indicators were added to determine wearer's weariness, showed in Figure 4. A pH-responsive textile used as an acid rain sensor showed an instant color shift when exposed to acidifying air pollutants.

Normal Rain pH > 5.6

Colour change of Bromocresol Green (BCG) dye on PA6 fabric at different pH values pH-responsiveness of dyed PA6 fabric before and after water and oil repellent finishing

— dyed PA6 (0.1% of BCG)

— dyed PA6 (0.2% of BCG)

— dyed and finished PA6 (0.2% of BCG)

dyed PA6 (0.5% of BCG)

Acid Rain pH 3.6 - 5.6

pH 3 4 5 6

8 9 10 11

Figure 4. Color changing schematic for varied pHs.

Рисунок 4. Схема изменения цвета при различных значениях pH.

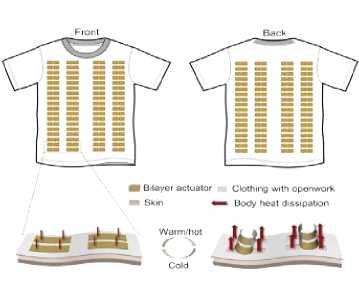

Temperature-controlling fabric textiles

High-tech textiles with temperature control are designed to maintain comfortable temperatures in various conditions. NASA developed materials with phase transitions from solid to liquid in the 1980s, which can absorb and release energy. Some technologies include temperature-sensitive pores that open or close based on body temperature, increasing the textile's waterproof and breathable properties [34]. Highly aligned boron nitride (BN)/poly (vinyl alcohol) (PVA) fabric, or a-BN/PVA fabric, can enhance thermal transport characteristics for personal cooling, in figure 5 (The images are used under permission from). This technology is demonstrated in Figure 5, showing a colored cloth used for personal cooling.

Figure 5. Temperature-controlling fabric textiles.

Рисунок 5. Терморегулирующие ткани.

Shape memory fabric textiles

Shape memory fabrics have various applications including finishing, breathability, damping, skincare, wound-dressing, deodorant, and intelligent energy storage. These fabrics can recall and recover significant programmed deformation in response to various external stimuli, such as chemical, mechanical, magnetic, and electrical ones. The activation effect of these compounds is activated at temperatures almost equal to body temperature. Shape memory alloys consist of two or more elements combined with different elasticity and hardness values at different temperatures [35]. When applied to fabrics, these alloys can result in flat looks, crease retention, and bagging recovery. A t-shirt without needing ironing was created by Corpo Nove, an Italian company. Shape memory polymers are sandwiched between two layers of fabric to achieve molecular mobility and conformational states at high temperatures. These polymers offer the best comfort in every setting and can withstand high temperatures. Shapememory alloys like nickel and titanium are used for withstanding high temperatures, medical surgical threads for endoscopic procedures, tiny implants for incision surgeries, and ornamental and artistic uses.

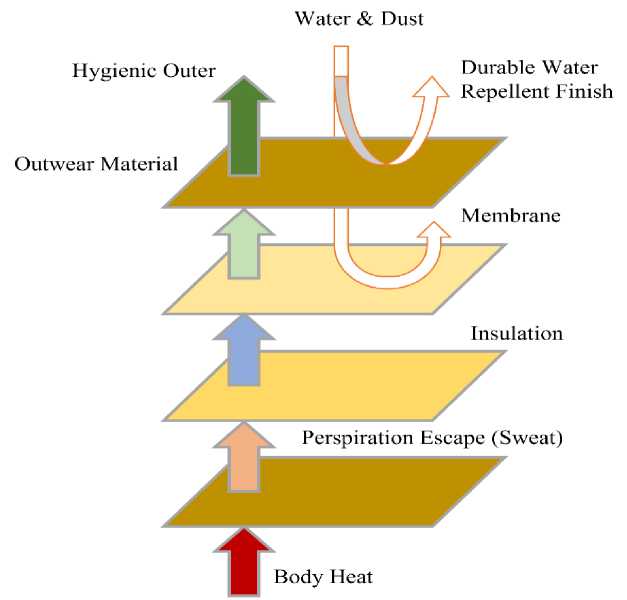

The human body releases heat through perspiration and heat waves, making fabric essential for protection from environmental elements like heat, wind, and water. Fabric must be breathable to allow water vapor dispersion and waterproof to prevent water seepage. Breathability affects the design of specialized goods, as materials used in textiles are typically smaller than liquid water, blocking water flow but larger than water molecules, allowing water vapor to pass [36]. The speed at which moisture vapor is transmitted is also crucial. In high-perspiration environments like firefighting or racing suits, fabric must maintain optimal moisture vapor data transfer or energy transfer by light with the transfer rates while shielding itself from external heat and pressure [15].

Figure 6. Examples of waterproof and breathable fabric textiles.

Рисунок 6. Примеры водонепроницаемых и дышащих текстильных изделий.

The waterproofing and breathability concepts for smart fabric textiles are illustrated in Figure 6. The best possible control over moisture and heat are among the desired qualities of waterproof breathable fabric.

-

• Recuperation of excess heat.

-

• Resistance to water.

-

• Good permeability to water vapor and air.

-

• Quick drying to avoid becoming cold, long-lasting, and machine-washable.

-

• Stability in terms of dimensions even in the presence of water.

-

• Soft, pleasant to the touch, and lightweight.

Phase-changing textiles

Phase change materials are textile substrates that regulate temperature, resulting in altered heat absorption/dissipation properties when a material reaches its melting point at a predetermined temperature. The temperature range for phase change can be modified if two or more phase-changing materials are used concurrently [37-38]. Fabrics need to be sensitive to their surroundings, having a thermoregulation effect that varies depending on the material and its thermal capacity. The temperature at which the material will be used most must also be the temperature at which it changes phases to maximize efficiency. Microencapsulated phasechanging materials can be coated on textile surfaces, inserted into nonwoven structures, or integrated into textile structures during fiber drawing. The design of the product is crucial, as improper design may cause heat dissipation rather than maintaining constant temperature. Commercially, phase-changing materials are used in hospital beds, pillows, sportswear, shoes, and undergarments, providing patient comfort and aiding in healing.

Application of smart textiles

The military, marines, and other industries are constantly seeking innovations in technical and comfortable materials due to extreme weather conditions, rapid body motions, and chemical protection. The Medical Smart Textile Market is expected to grow at a compound annual growth rate (CAGR) of 7.51% by the end of 2027, reaching USD 2.10 billion. The creation of novel textile-based implantable products is closely linked to delivering better healthcare services and the rise in life expectancy. The market for various textiles, such as knitted, woven, and non-woven textiles, is expected to increase rapidly between 2017 and 2028 due to their hygiene importance. The COVID-19 pandemic has led to large-scale investments in personal protective equipment and home production, with biodegradable and non-biodegradable polymers being developed for items like maternity pads, face masks, and shoe coverings. The apparel market for nanotechnology is expected to expand globally at a CAGR of 24.6%, from $4.61 billion in 2021 to $5.75 billion in 2022. Nanoparticles are combined with textiles to improve surface properties, including microbicidal, waterproof, antistatic, UV-protective, color-durable, dirt-resistant, odor-resistant, stain-resistant, wrinkle-resistant, and thermal performance. These nanotechnologies have applications in geotextiles, home and household, sports and leisure, healthcare, packaging, and military [39]. To stay competitive, major companies in the nanotechnology clothing industry are introducing new wearable technology clothes. This research covers countries like Australia, Brazil, China, France, Germany, India, Indonesia, Japan, South Korea, Russia, UK, and USA, as well as the nanotechnology clothing market. Shah et al. provide an overview of various approaches to functionalize nanomaterial and incorporate them into textiles while considering affordability and environmental sustainability.

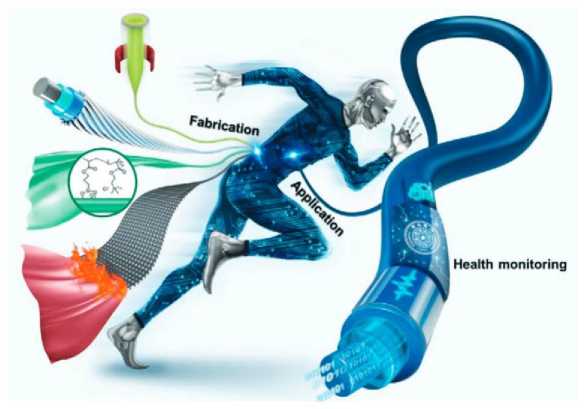

Wearable electronics smart textile

Wearable electronics are devices that generate, store, and consume energy, with fabric-inherent components that are resistant to external influences. These devices automatically recognize user activity and behavioral status, allowing them to sense their environment and modify system functionality. Smart fabrics are used in wearable electronics, ensuring physical flexibility and standard size. In the Figure 7, wearable electronic smart textiles as various wearable electronics products have been developed, including respiration and ECG garments for biological monitoring, biomedical garments for medical condition monitoring, sensing patches for bodily fluid sensing, contactless sensors for ECG and EMG monitoring, and vital parameter sensing products. These devices must not impede physical flexibility or be visible in the finished product.

Figure 7. Some examples of wearable electronic smart textiles.

Рисунок 7. Некоторые примеры носимого электронного интеллектуального текстиля.

The University of California, San Diego has demonstrated a method for screen-printing biological sensors into garments using elastic bands of men's underwear. The sensors detect hydrogen peroxide and NADH enzymes linked to various biological activities. The sensors can withstand mechanical strain from wearer activities without affecting data. The Smart Bra, an Australian invention, uses conductive polymer coated materials to adjust its characteristics in response to breast movement [40]. The bra can limit breast mobility, prevent soreness, and reduce sagging. The Smart Bra's straps can be tightened or loosened, and its cups can be relaxed when it senses excessive movement. Virginia Polytechnic Institute and State University in Blacksburg have developed smart trousers that recognize wearer's movement, speed, rotation, and position using a wireless signal. The trousers are powered by a loom that stitches the cloth and wires together. Aero gel, a low-density, lightweight, and transparent material, is ideal for smart clothing due to its adaptability and thermal insulation properties. ITV Denkendorf's interdisciplinary research team is developing a sensory infant vest with sensors that monitor body temperature, skin, heart rate, and lungs, enabling early diagnosis and tracking of heart and circulation illnesses. The vest aims to protect newborns from potentially fatal conditions like cot death, and the sensors are designed to remain silent during sleep.

Intelligent garment for fire fighters

VIKING, a Danish company, has developed a new line of firefighter jackets that control temperature around and inside the coat. The jackets use thermal sensors integrated with the coat's external and internal layers, with two LED screens on the back and sleeve. The batteries are detachable and reusable, and the microelectronic chips can be washed.

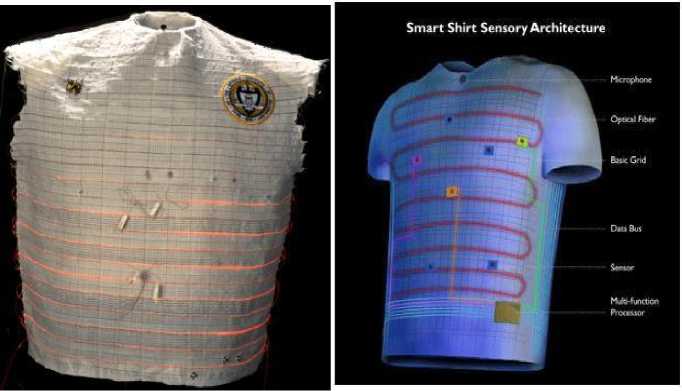

Figure 8. Left: The GTMW of the Georgia Tech, Right: The Smart Shirt by Sensatex.

Рисунок 8. Слева: GTMW Технологического института Джорджии, справа: «Умная» рубашка от Sensatex.

The display flashes at 250ºC, 79ºC, 350ºC, and 50ºC. In the Figure 8, Georgia Tech developed the first SFIT system, a "Wearable Motherboard" (GTWM) for combat situations.

The garment uses specific sensors that interface with optical fibers to identify bullet wounds. The computerized shirt functions as a flexible motherboard for medical sensing devices, allowing for quick identification of injuries or physical issues. The smart shirt can be customized to suit the wearer's needs, such as tracking chemical or oxygen concentrations, body temperature, and respiration rate. Sensatex Company is now producing the smart shirt for commercial purposes, including medical, illness, newborn, sports, and military use.

Smart way of fashion

Smart textile technology has been used in various products and prototypes, including the ICD+ jacket, which features an MP3 player and remote-controlled cell phone, and electrically heated wool socks designed for hiking and walking. These devices are ideal for those with poor circulation or working in cold environments. In 2006, G-Tech introduced a wireless keyboard using Eleksen's touch-sensitive fabric, while in 2007, Levi's RedWire DLX jeans introduced the iPod control system [41]. Burton Snowboards integrated Fibretronic's push-to-talk (PTT) technology into their Audex line of jackets and packs. These advancements demonstrate the potential of smart textile clothing in various applications, such as music players, emotion conveying, and enhancing user experience.

Power generation and management

Distributed electronics are driving the development of over 26 billion Internet of Things (IoT) devices, requiring energy solutions and sustainability research. The IoT era allows for faster and more efficient material development for various purposes, including large-scale fabrication, 3D printing, self-healing, and more. However, there are challenges in the textile production process, such as creating passive textiles with active warming and cooling systems. These systems modify the human body's structures in response to external conditions, regulating the body's microclimate. These systems offer a novel, adaptable, and sustainable approach to energy-saving architecture. However, the commercialization of these textiles is challenging due to their unique methodologies. More sophisticated textiles can perform tasks such as self-powering, thermal comfort, sensing, computing, and electrical control. The Australian workforce bears an annual burden of $6.2 billion due to temperature fluctuations, and self-regulating textiles are essential for maintaining stability.

ANALYSIS AND RESULTS

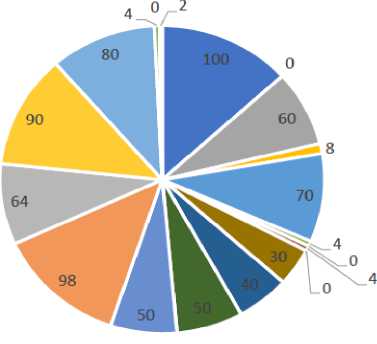

An RMG plant with minimal automation has a Man to Machine Ratio (MMR) greater than 1:2.2, indicating that 2.2 men are employed for every machine. Automation and digitalization can result in an MMR of as little as 1:1.4. Production costs increase with the number of workers used, and the RMG industry uses direct laborers like ironmen, operators, and assistants to increase production. Better MMR is achieved with more machines and fewer support staff. Clothing brands need to push end-to-end digitization, collaborate across functional and corporate boundaries, and dive deeper into sourcing materials. The current addition below demonstrates the use of technology in the Smart Textiles edition, in Table 1.

Table 1: Usage of technology in Smart textiles edition.

Таблица 1: Использование технологий в издании Smart textiles.

|

Serial |

Factor/Digitization |

Percentage |

Weightage |

|

1 |

Use of an automatic machine |

100 |

|

|

2 |

AR |

0 |

5 |

|

3 |

Use of Radio Frequency Identification |

0 |

5 |

|

4 |

Use of Devices and Applications |

60 |

|

|

5 |

Al Cloud Computing Big Data |

8 |

5 |

|

6 |

M2M Communication VR Automation, modeling, |

70 |

|

|

and simulation |

|||

|

7 |

Automated enabled textiles, woven, and knitted |

4 |

|

|

fabric manufacturing. |

|||

|

8 |

Automating in Garment Checking |

0 |

5 |

|

9 10 |

Automating in disseminating and Breaking Computer-aided design - garment design and |

4 30 |

5 |

|

patternmaking |

|||

|

11 |

Automating quality monitoring of textiles and |

40 |

|

|

garment seams |

|||

|

12 |

Industrial engineering utilizes modern tools and |

50 |

|

|

equipment |

|||

|

13 |

Developments in production planning and control |

50 |

|

|

14 |

Mobile Technologies |

98 |

|

|

15 |

3D Printers |

64 |

|

|

16 |

CRM & Product Traceability |

90 |

|

|

17 |

Use of an automatic machine |

80 |

|

|

18 |

AR |

4 |

|

|

19 |

Use of Radio Frequency Identification |

4 |

|

|

20 |

Use of Devices and Applications |

0 |

CHANGE ORIENTED: in New Textile Innovations: Efficiency, Productivity, Cost, Deadline, Goals, Own Training, Coaching, Efficiency, Motivation, EI, Empathy, Supportive, SI, Differentiation, Tech Innovation, Adaptability, Org Environment, Serving, Exit plan, Al.

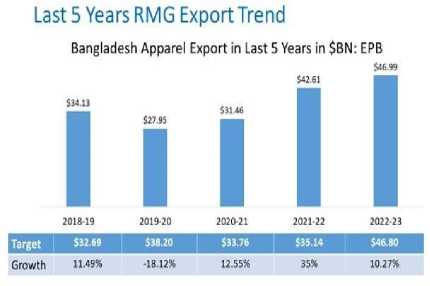

Digitization can have a positive impact on transparency and sustainability, and can support increased traceability, regulatory challenges, manufacturing plant security, and worker payment through mobile banking services. As the garment industry becomes more competitive and costs are cut through more effective manufacturing methods, automation is unavoidable. The emerging nation from an LDC in 2026 poses a threat to the loss of GSP facilities by 2029. Fast fashion's influence in Europe and the USA has also sparked the growth of a new, technologically advanced, lead-time-advantageous garment sector in nearby countries like Turkey and Mexico. After five years of rising electronic textile exports, Bangladesh became the world's second-largest garment producer in 2022 with $57.7 billion in sales. Electronics in clothing have grown 5% annually since 1990. Bangladesh exported 84.7% ready-made clothes in 2023. Increasing demand for smart textiles in healthcare, sports, and fashion allows for development despite technology integration and worldwide competition. Electronic textiles should expand as Bangladesh invests in innovation and technology to enhance textile exports. Despite making up a smaller share of Bangladesh's textile exports, the industry will gain from technical advances and foreign interest. Export share analysis shown in Figure 9 and 10. Despite the challenges of implementing modern machinery, employees who confronted automation reported that it enhanced their productivity rather than causing disruptions, according to an MFO poll [6, 7, 42].

Figure 9. Export Share analysis.

Рисунок 9. Анализ доли экспорта.

Figure 10. RMG Export share analysis.

Рисунок 10. Анализ доли экспорта RMG.

The Bangladeshi garment industry is facing challenges due to outdated machinery and a lack of technological advancements. Employers are hiring graduates from industry-focused educational institutes like BUET, BUTEX and BUFT, reducing reliance on foreign workers for managerial positions. The government has launched the Skills for Employment Investment Program (SEIP) to improve training facilities at Technical Training Centers and Technical and Vocational Education Training (TVET) centers. The industry has a large number of small factories that specialize in specific stages of production, but adoption of automation is slow [41, 42]. As an employee's age reduces, they move to smaller factories, affecting both highly paid and low-paid jobs, as well as skilled and unskilled individuals. Automation-driven growth in the garment industry will boost economic growth and generate new jobs in other high-value industries. However, automation and skilled labor are necessary for the industry's survival, and a comprehensive strategy is needed to support both.

Functions of smart textiles

An intelligent suit consists of five functions: sensors, data processing, actuators, storage, and communication. These functions are essential for clothing to function as comfortable, long-lasting, and resistant to textile care procedures. Sensors convert signals into electrical ones, which are then used in practical equipment. The body is mostly covered in textile materials, making them useful measurement instruments. Bio-signals such as temperature, bio potentials, acoustic, ultrasound, motion, humidity, and pressure are discussed in literature. Finding the ideal parameters for monitoring bodily systems and creating suitable algorithms for data interpretation are challenging tasks. Existing suits monitor temperature, mobility, humidity, heart rate, and respiration rate using traditional sensors embedded in fabric. Real-world textile sensors for mobility, heart rate, and respiration rate have been demonstrated with positive outcomes [35].

Data processing

Data processing is a crucial element in smart textiles, but interpretation is the primary barrier. Textile sensors can provide numerous data points, but their interpretation is complex due to large differences in signals across patients, time-dependent and stationary signals, and lack of objective standard values. Electronic components are needed for data processing, which can be found in flexible and miniature forms. However, their longevity is limited. Before computer fibers are available, practical issues like connectivity, deformation, and washing speed must be resolved. Smart suits require energy storage for sensing, data processing, actuation, and communication. Efficient energy management requires a suitable mix of energy supply and storage capacity. Energy sources include body heat, mechanical motion, and solar energy. Communication can take various forms, including transmitting information from the wearer to the suit, the suit to the wearer or surroundings, or even within a single part of the suit. Actuators, such as shape memory materials, are ideal for use in smart textile applications due to their ability to respond to temperature changes. However, there are few documented uses of shape memory alloys in textiles.

FiberTronics

Smart textiles, also known as electronic textiles, are created by integrating digital and computational elements into textiles. The primary goal is to integrate electrical components, using conducting and semi-conducting materials like conductive textiles. Commercial fibers like metallic fibers are used to create conducting fibers, but metals and traditional semiconductors are not suitable due to their stiffness. E-textiles must be washable and have electrical components that act as an insulator. Organic electronics materials, which can function as inks and polymers and be conducting or semiconducting, are better suited for e-textiles.

cc) @

DISCUSSION AND FUTURE CHALLENGE

Recent advantages and challenges

Smart textiles are revolutionizing the global textile industry, with the potential to revolutionize personal healthcare, sportswear, and other end-use industries. The global market for smart textiles, which began in the late 1980s, has expanded to include temperatureregulating suits, shape-memory and environment-responsive fabrics, and self-cleaning carpets. These textiles are used in sports, protective gear, casual wear, geotextiles, biomedical textiles, and apparel, particularly for winter wear. The Gore Company created Gore-Tex in 1978, the first intelligent fabric, which is windproof, waterproof, and breathable. The market is projected to grow at a 25% CAGR between 2021 and 2031, reaching a valuation of US$23.82 by the end of that year. Recent advancements in smart textile performance include space transportation systems, sportswear, ultrasonic assembly, and space travel fabric. The application field is broad, including automotive, medical, and healthcare sectors. The growth rate is driven by the pursuit of lightweight and comfortable materials for sports and fitness applications. However, compatibility issues between fabrics and electronic systems limit the use of certain smart textiles. The market is expected to exhibit profitable development prospects and applications across various end-use industries.

CONCLUSION

The most innovative development in textile engineering is smart textiles. Some stories about the creation of smart fabrics may seem like science fiction, yet it goes well beyond imagination. The effect and economic potential of smart textiles are enormous. The conventional textile industry may now reach a high-technological level thanks to the development of smart textiles. Furthermore, it seems that this can only be accomplished by close collaboration between experts in several fields, including computer science, material science, and biotechnology, microelectronics, and polymer science. Further study is necessary to improve its practicality in our daily lives.