Эпоксидные композиты, модифицированные каменноугольной смолой

Автор: Ерофеев В.Т., Богатов А.Д., Кондакова И.Э., Ивлев В.И., Юдин В.А., Афонин В.В.

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Строительное материаловедение

Статья в выпуске: 6 т.16, 2024 года.

Бесплатный доступ

Введение. Показано, что, несмотря на значительный прогресс в создании высококачественных полимерных композитов с уникальным сочетанием ключевых показателей, отдельные вопросы в этой области изучены недостаточно полно. В данной работе приведены результаты исследований структуры материалов на эпоксидно-каменноугольном связующем и анализа физико-механических свойств на уровне микроструктуры, на которые влияют различные факторы: количественное содержание модифицирующих добавок и различных наполнителей, степень дисперсности частиц, их размер и форма. Выявлено, что одним из потенциальных модификаторов микроструктуры композитов являются частицы наноразмерного уровня.

Полимерные композиты, эпоксидная смола, каменноугольная смола, растворители, наполнители, наночастицы, прочность, деформативность, химико-биологическая стойкость, долговечность

Короткий адрес: https://sciup.org/142243713

IDR: 142243713 | УДК: 678.072 | DOI: 10.15828/2075-8545-2024-16-6-533-548

Текст научной статьи Эпоксидные композиты, модифицированные каменноугольной смолой

Ерофеев В.Т., Богатов А.Д., Кондакова И.Э., Ивлев В.И., Юдин В.А., Афонин В.В. Эпоксидные композиты, модифицированные каменноугольной смолой // Нанотехнологии в строительстве. 2024. Т. 16, № 6. С. 533–548. – EDN: PVHJTC.

В строительной отрасли широкое применение находят различные полимерные материалы,

увеличение объемов использования которых достигается за счет синтеза новых и модификации уже освоенных промышленностью крупнотоннажных полимеров [1, 2, 3, 4].

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Теоретическим вопросам создания, оценки свойств и прогнозирования долговечности полимерных материалов посвящено большое количество работ российских и зарубежных авторов [5, 6, 7, 8, 9 и др.]. Так, в работе [5] проанализированы различные структуры, в том числе кластерные, решеточные и каркасные полимерных композитных материалов на основе синергетики – это новая дисциплина, связанная с изучением самоорганизующихся временных и пространственных образований в сложных неупорядоченных системах различной природы и механики композитных материалов. В работе [7] выполнено конечно-элементное моделирование межфазного сцепления компонентов полимербетона. В граничных слоях у полимера формируются иные, чем в объеме, структура и свойства, неоднородные по толщине этих слоев. Это вызывает упрочнение адгезии полимера к поверхности наполнителя [1]. В работе [6] приводятся результаты исследований по изучению сопротивления композитов агрессивным средам и разработки способов его повышения. Получены выражения, позволяющие оценивать сопротивление композитов действию окружающей среды при их изготовлении и эксплуатации в зависимости от времени, размеров изделий, параметров проницаемости и химического взаимодействия. Также разработаны теоретические основы предлагаемых способов защиты композитов от воздействия агрессивных сред. В работе [10] наиболее полно представлены теоретические вопросы, связанные с исследованиями биоповреждений и способов повышения биостойкости материалов, включающие рассмотрение механизмов разрушения, моделирование биодеградации, прогнозирование долговечности материалов.

Как известно, наиболее эффективное применение полимерных строительных материалов достигается в том случае, когда требуется их повышенная химическая стойкость [8, 11, 12].

В зданиях с агрессивными средами наиболее долговечными являются полимербетоны, антикоррозионные защитные покрытия и т. д. [6, 13, 14, 15, 16, 17]. Из широкого класса вяжущих, используемых для изготовления полимербетонов, более всего востребованы эпоксидные смолы [19, 20, 21, 22, 23]. Созданные на их основе полимерные композиты обладают универсальной стойкостью к активному химическому воздействию [24, 25, 26]. Важно отметить, что значимые проблемы в ходе эксплуатации вызывает повышенная хрупкость этих материалов, что связано с образованием густой пространственной сетки при отверждении. Уменьшение плотности поперечных сшивок возможно за счет введения в композит модификаторов, содержащих гибкие длинные цепи [27, 28, 29]. В качестве модификато-

ров при этом используют каучуки, фталаты, битум, каменноугольную смолу и др. [30].

В качестве защитных покрытий на бетонных, железобетонных и металлических поверхностях надежность и довольно высокую эффективность продемонстрировали эпоксидно-каменноугольные композиты. Данная проблема находится в центре внимания исследователей, но вместе с тем структурообразова-ние, оптимизация составов и технология изготовления этих композитов изучены в недостаточной степени. Решение этих проблем позволит расширить практику применения перечисленных материалов. Весьма важным качеством антикоррозионных покрытий является стойкость материалов в химически и биологически агрессивных средах. В нынешней ситуации совершенствование полимерных композиционных материалов связано с исследованием объектов, создаваемых по принципу многокомпонентных структур на различных размерных уровнях [7, 31, 32, 33]. Изучение роли специальных добавок в пластификации эпоксидных композиций в рамках нашего исследования осуществлялось в сочетании с различными наполнителями. Одним из потенциальных модификаторов микроструктуры являются наноразмерные частицы [9, 34, 35].

МАТЕРИАЛЫ И МЕТОДЫ

Связующие, отвердители, модификаторы

Эпоксидная смола марки ЭД-16 (ГОСТ 1058784). В качестве отвердителя эпоксидной смолы использовался полиэтиленполиамин (ПЭПА) (ТУ-6-02-594-85), в качестве модификатора – каменноугольная смола (ГОСТ 4492-65).

Растворители, пластификаторы

Бензин (ГОСТ 2084-77), ацетон (ГОСТ 276884), растворитель 646 (ГОСТ 18188-72), дизельное топливо (ГОСТ 305-82), скипидар (ГОСТ 1571-82), уайт-спирит (ГОСТ 3134-78), дибутилфталат (ГОСТ 8728-66).

Наполнители, которые применялись при проведении экспериментальных исследований, представлены в табл. 1 и 2.

Наполнители наноразмерного уровня: технический углерод (сажа) марки П234 и углеродные нанотрубки «Туанит-М» производства ООО «Нанотехцентр». Структура отвержденных композиций исследовалась методом полуколичественной фурье-ИК-спектроскопии (он дает возможность оценить изменение реакционно-способных групп в структуре полимера по изменению оптической плотности на характерных полосах поглощения связей).

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

ИК-спектры образцов фиксировались на фурье-спектрометре ИнфраЛЮМ ФТ-02. Для механических испытаний образцов была использована универсальная испытательная машина Autograph Shimadzu серии AG-X с записью диаграммы «нагрузка-деформация». Такие параметры, как предел прочности при сжатии, изгибе, модуль упругости определялись по стандартным методикам. Управление процессом испытаний и предварительная обработка полученных данных проводились с применением программного обеспечения TRAPEZIUM X×1. Испытания образцов на грибостойкость и наличие фунгицидных свойств осуществлялись в соответствии с ГОСТ 9049-91. Виды микромицетов, использованные в качестве тест-организмов: Asperqillus oryzae (Ahiburq) Cohn, Asperqillus niqer vqn Tieqhem, Asperqillus terreus Thom, Chaetomium qlobosum Kunze, Paecilomyces varioti Bainier, Penicillium funiculosum Thom, Penicillium chrysoqenum Thom, Penicillium cy-clopium Westlinq, Trichoderma viride Pcis, ex Fr. При проведении испытаний были использованы методы 1 и 3. Ускоренные испытания на биостойкость полимерных композитов осуществлялись в модельной микробиологической среде, включающей водный раствор лимонной кислоты и перекись водорода различных концентраций согласно [10].

РЕЗУЛЬТАТЫ И ОБСУЖДЕНИЕ

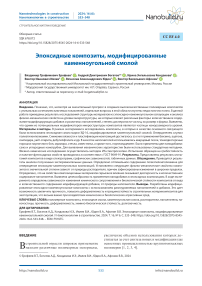

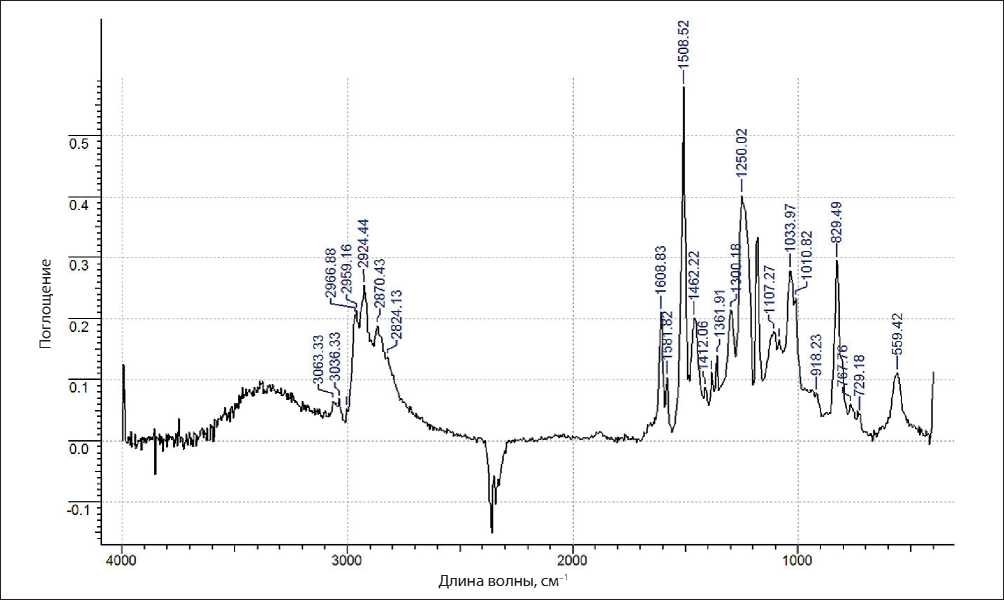

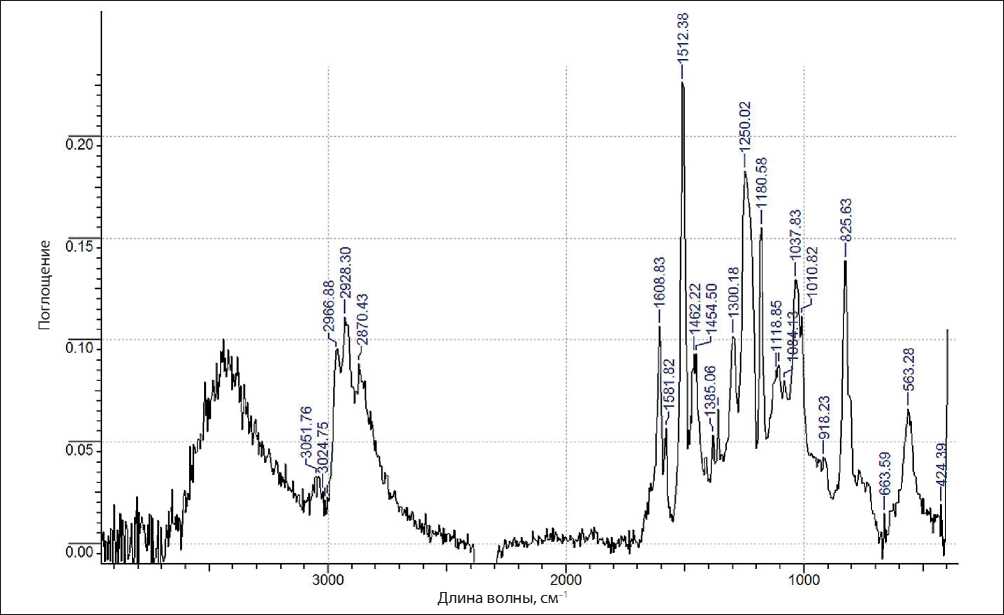

По результатам исследований, проведенных методом ИК-спектроскопии (рис. 1–3), был сделан вывод, что при введении в эпоксидную смолу каменноугольной смолы и битума и отверждении ее полиэтиленполиамином не наблюдается качественных изменений в ИК-спектрах отвержденных образцов. В образцах с дибутилфталатом зафиксировано появление новой полосы поглощения при 1724 см–1, которая характеризует поглощение карбонильной группы в сложноэфирной группе самого дибутилфталата.

С целью количественного сравнения полученных спектров рассчитаны интенсивности наиболее характерной полосы для эпоксидной группы при 3001 см–1 (полосы при 914 и 864 см–1 менее характерны, так как в этих областях может накладываться поглощение скелетных колебаний полимера) с применением поглощения «пульсационных» колебаний ароматического кольца при 1508 см–1 в качестве внутреннего стандарта. Результаты отражены в табл. 3.

Из данных представленной табл. следует, что при использовании дибутилфталата интенсивность полосы поглощения при 3001 см–1, характеризующей содержание в отвержденном композите свободных

Таблица 1

Химический состав наполнителей

|

№ |

Вид наполнителя или заполнителя |

Химический состав |

||||||

|

SiO2 |

Al 2 O 3 |

Fe 2 O 3 |

СaO |

MgO |

SO3 |

другие соединения |

||

|

1 |

Кварцевый песок |

91,93 |

5,36 |

0,56 |

0,04 |

0,9 |

0,2 |

1,01 |

|

2 |

Кирпичный бой |

55–80 |

5–15 |

3–15 |

25 |

3 |

3 |

15 |

|

3 |

Известняковый песок |

3,1–8,2 |

1,9–3,6 |

0,4–3,0 |

49–50 |

0,6–1,3 |

– |

– |

|

4 |

Мраморный порошок |

26 |

– |

0,05–0,8 |

40,6–55,5 |

10 |

0,5 |

32 |

|

5 |

Стеклобой |

68,5–72,9 |

1,0–1,5 |

– |

5,0–6,0 |

3,2–3,7 |

– |

16,8–22,3 |

|

6 |

Портландцемент |

23,08 |

5,45 |

2,99 |

66,91 |

1,42 |

0,15 |

– |

Таблица 2

Значения плотностей наполнителей

|

№ |

Вид наполнителя или заполнителя |

Истинная плотность, г/см3 |

Насыпная плотность, г/см3 |

|

1 |

Кварцевый песок |

2,56 |

1,45 |

|

2 |

Кирпичный бой |

1,6–1,8 |

1,3 |

|

3 |

Известняковый песок |

1,8 |

1,23 |

|

4 |

Мраморный порошок |

2,6 – 2,8 |

1,4–1,55 |

|

5 |

Стеклобой |

2,4–2,6 |

0,82–0,95 |

|

6 |

Портландцемент |

3,1 |

1,1 |

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Рис. 1. ИК-спектр эпоксидной смолы ЭД-16, модифицированной каменноугольной смолой (10 мас.ч.) и отвержденной ПЭПА (10 мас.ч.) (Область 500–4000 см–1)

Рис. 2. ИК-спектр эпоксидной смолы ЭД-16, модифицированной битумом (10 мас.ч.) и отвержденной ПЭПА (10 мас.ч.) (Область 500–4000 см–1)

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Рис. 3. ИК спектр эпоксидной смолы ЭД-16, модифицированной дибутилфталатом (10 мас.ч.) и отвержденной ПЭПА (10 мас.ч.) (Область 500–4000 см–1)

эпоксидных групп, повышается по сравнению с композитом без добавок (0,050 и 0,046 соответственно), что является свидетельством уменьшения пространственных сшивок в присутствии дибутилфталата. Дополнительно за счет введения в состав композита каменноугольной смолы и битума снижается плотность пространственных сшивок.

Из данных этой табл. следует, что в присутствии дибутилфталата интенсивность полосы поглощения при 3001 см–1, характеризующей содержание в отвержденном композите свободных эпоксидных групп, увеличивается по сравнению с композитом без добавок (0,050 и 0,046, соответственно). Это свидетельствует об уменьшении пространственных сшивок в присутствии дибутилфталата. Введение в состав композита каменноугольной смолы и битума дополнительно уменьшает плотность пространственных сшивок.

Данные факты свидетельствуют о том, что используемые добавки в эпоксидных композициях при низкотемпературном аминном отверждении выполняют роль пластификаторов, распределяясь между элементами структуры эпоксидной композиции и тем самым облегчая взаимные перемещения агрегатов макромолекул. Пластифицирующая способность увеличивается в следующем ряду: дибутилфталат < каменноугольная смола < битум. Результаты механических испытаний образцов показывают, что изученные добавки повышают эластичность, но снижают прочность эпоксидных композитов в вышеприведенном ряду. Это в полной мере подтверждает полученные в настоящем исследовании выводы.

С целью установления оптимального содержания отвердителя в эпоксидно-каменноугольных композитах были проведены исследования с применением метода математического планирования

Таблица 3

Интенсивность полос поглощения при 3001 см–1 (Оптическая плотность А)

|

Добавки (масс. ч.) |

||||

|

Отсутствуют |

Дибутилфталат (10) |

Каменноугольная смола (10) |

Битум (10) |

|

|

ЭД-16 |

0,087 |

– |

– |

– |

|

ЭД-16 + ПЭПА (10 мас. ч.) |

0,046 |

0,050 |

0,053 |

0,059 |

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ эксперимента. В качестве матрицы планирования был использован план Коно, включающий 9 опытов, который представляет собой полный факторный эксперимент 32. В качестве варьируемых факторов выбраны следующие: количественное содержание каменноугольной смолы и полиэтиленполиамина.

В рамках экспериментального исследования рассматривались композиты, где в качестве основного связующего использовалась модифицированная каменноугольной смолой эпоксидная смола марки ЭД-16 – в количестве от 5 до 15%. Наполнителем являлся кварцевый песок объемом 300 мас.ч. на 100 мас.ч. эпоксидной смолы. Отвердитель – полиэтиленполиамин – вводили в композицию в количествах 7,5; 10; 12,5 мас.ч. на 100 мас.ч. эпоксидной смолы.

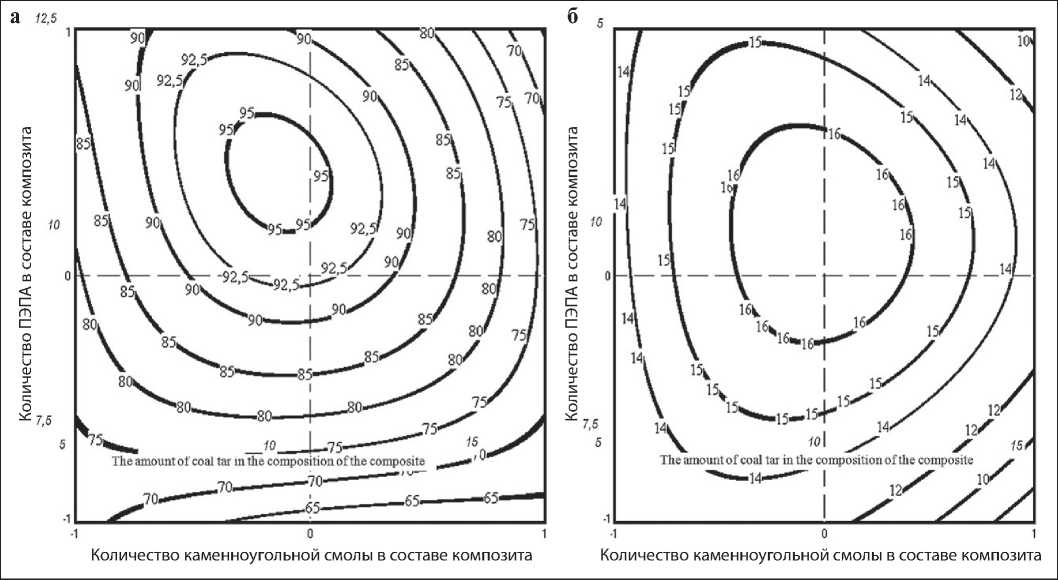

На основе анализа результатов исследований прочностных свойств эпоксидно-каменноугольных композитов определено оптимальное содержание ПЭПА для отверждения эпоксидно-каменноугольной композиции: 10–11 мас.ч. (рис. 4).

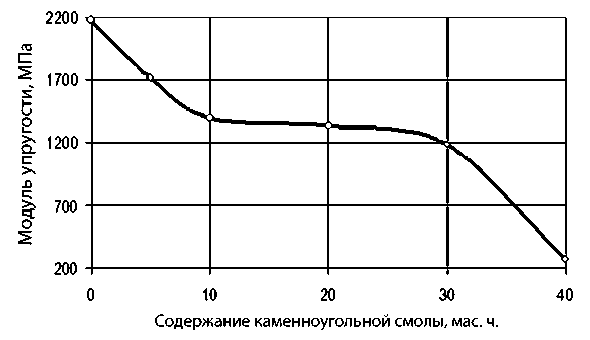

Для определения изменения модуля упругости эпоксидно-каменноугольных композитов использовались образцы с содержанием каменноугольной смолы от 0 до 40 мас.ч. на 100 мас.ч. эпоксидной смолы. В качестве наполнителя был использован кварцевый песок крупностью 0,315–0,63 мм, количественное содержание которого было принято равным 300 мас.ч. По итогам эксперимента был сделан вывод о снижении модуля упругости с увеличением содержания модификатора от 0 до 40% в 8 раз (рис. 5).

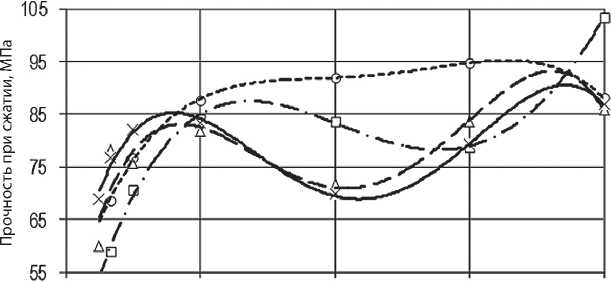

Рис. 4. Зависимость предела прочности при сжатии (а) и предела прочности на растяжение при изгибе (б) композитов от количественного содержания каменноугольной смолы и отвердителя

Рис. 5. Зависимость модуля упругости эпоксидно-каменноугольных композитов от содержания каменноугольной смолы

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Проведены экспериментальные исследования механических свойств эпоксидно-каменноугольных композитов с использованием в качестве наполнителей кварцевого песка и тонкоизмельченного мрамора. В качестве варьируемых факторов рассматривались: количественное содержание отвердителя (полиэтиленполиамина), содержание каменноугольной смолы, крупность наполнителя, степень наполнения и фактор, учитывающий степень взаимодействия (вид и соотношение) наполнителей. Перечисленные факторы и уровни их варьирования приведены

в табл. 4, матрица планирования и результаты эксперимента – в табл. 5.

С целью уточнения максимальных и минимальных механических свойств исследуемого композита была создана модельная матрица планирования с учетом первых четырех факторов, а также их возможных взаимодействий. При этом была применена программа для ЭВМ [36], с помощью которой определены коэффициенты уравнения регрессии с учетом взаимодействия факторов. Условные обозначения факторов и их взаимодействия выглядят следующим образом:

Таблица 4

Факторы и уровни их варьирования

|

№ |

Факторы |

Обозначения |

Уровни факторов |

|

|

+1 |

–1 |

|||

|

1 |

Содержание отвердителя, (мас.ч.) |

Х 1 |

10 |

5 |

|

2 |

Содержание каменноугольной смолы, (мас.ч.) |

Х 2 |

20 |

0 |

|

3 |

Крупность наполнителя |

Х 3 |

0,315–0,63 |

0,14–0,315 |

|

4 |

Степень наполнения связующего |

Х 4 |

1:3 |

1:1 |

|

5 |

Фактор, учитывающий степень взаимодействия, (вид и соотношение) наполнителя |

Х 5 |

А: кварцевый песок 100% В: песок на основе мрамора 100%, С: А-75%, В-25%, Д: А-50%, В-50%. |

|

Таблица 5

Матрица планирования и результаты эксперимента

|

№ п/п |

Матрица планирования |

Физико-технические свойства в МПа |

||||||

|

Х 1 |

Х 2 |

Х 3 |

Х 4 |

Х 5 |

R сж, |

R изг, |

упр , |

|

|

1 |

+1 |

+1 |

+1 |

+1 |

А |

49,7 |

14,9 |

50,6 |

|

2 |

–1 |

+1 |

+1 |

+1 |

С |

57,6 |

15,0 |

173,8 |

|

3 |

+1 |

–1 |

+1 |

+1 |

В |

35,2 |

8,5 |

118,4 |

|

4 |

–1 |

–1 |

+1 |

+1 |

Д |

52,7 |

8,2 |

42,63 |

|

5 |

+1 |

+1 |

–1 |

+1 |

В |

39,2 |

11,7 |

51,2 |

|

6 |

–1 |

+1 |

–1 |

+1 |

Д |

54,9 |

11,7 |

145,3 |

|

7 |

+1 |

–1 |

–1 |

+1 |

С |

29,6 |

8,0 |

55,0 |

|

8 |

–1 |

–1 |

–1 |

+1 |

А |

30,6 |

6,1 |

69,3 |

|

9 |

+1 |

+1 |

+1 |

–1 |

С |

57,9 |

13,5 |

126,9 |

|

10 |

–1 |

+1 |

+1 |

–1 |

А |

41,9 |

11,2 |

157,8 |

|

11 |

+1 |

–1 |

+1 |

–1 |

Д |

35,3 |

5,6 |

159,5 |

|

12 |

–1 |

–1 |

+1 |

–1 |

В |

44,8 |

7,4 |

117,4 |

|

13 |

+1 |

+1 |

–1 |

–1 |

Д |

54,6 |

14,9 |

177,1 |

|

14 |

–1 |

+1 |

–1 |

–1 |

В |

27,6 |

6,9 |

95,7 |

|

15 |

+1 |

–1 |

–1 |

–1 |

А |

20,5 |

2,9 |

61,4 |

|

16 |

–1 |

–1 |

–1 |

–1 |

С |

27,8 |

4,8 |

54,5 |

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Х0, Х1, Х2, Х3, Х4, (Х1•Х2), (Х1•Х3), (Х1•Х4), (Х2•Х3), (Х2•Х4), (Х3•Х4), (Х1•Х2•Х3), (Х1•Х2•Х4), (Х1•Х3•Х4), (Х2•Х3•Х4), (Х1•Х3•Х4), (Х2•Х3•Х4), (Х1•Х2•Х3•Х4), где Х0 тождественно равно единице.

После вывода уравнений регрессии для Rсж, Rизг., Еупр. с помощью [36] производилась кубическая интерполяция (метод Makima) уравнений регрессии. Это дало возможность определить более точные максимальные значения пределов прочности на сжатие (Rсж), на изгиб (Rизг.) и модуля упругости (Еупр.). Результаты расчетов представлены в табл. 6.

По итогам ранжирования средних значений всех рассматриваемых показателей был сделан вывод о том, что эффект фактора X4 незначим для всех показателей, фактор X1 незначим для прочности на сжатие, на растяжение при изгибе, Х3 – незначим для модуля упругости. Эффекты остальных факторов для всех показателей значимы.

Использование в качестве наполнителя кварцевого песка в сочетании с мраморным порошком в соотношении 50% на 50% вызывает улучшение контактного взаимодействия эпоксидного связующего, модифицированного каменноугольной смолой, при содержании каменноугольной смолы 20%. Введение каменноугольной смолы повышает деформативность, модуль упругости при этом снижается на 13,5%. Модифицированные полимербетоны обладают достаточно высокими прочностными показателями. В частности, прочность при сжатии равна 54,6 МПа, а прочность на растяжение при изгибе – 14,9 МПа.

Помимо этого, нами проведены исследования влияния количественного содержания модификатора – каменноугольной смолы на механические свойства эпоксидных полимербетонов, а также воздействия на них растворителей и наполнителей.

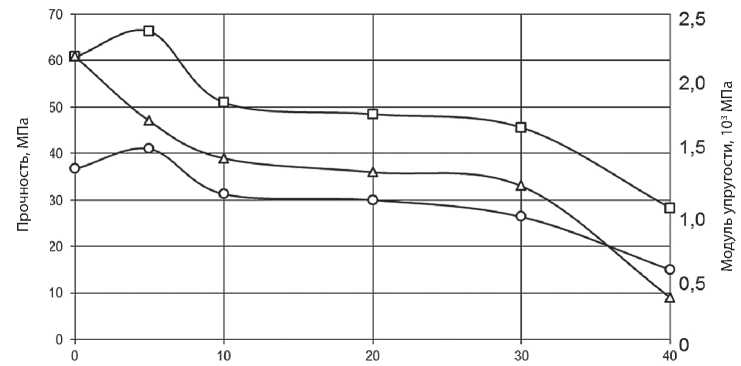

Предметом исследования были эпоксидно-каменноугольные композиты с содержанием каменноугольной смолы в связующем от 5 до 40 мас.ч. на 100 мас.ч. эпоксидной смолы. В качестве наполнителя был выбран кварцевый песок крупностью 0,315–0,63 мм. Содержание отвердителя – поли-

этиленполиамина – принималось из расчета 10% от массы эпоксидной смолы. Влияние содержания каменноугольной смолы на свойства эпоксидных композитов анализировалось путем испытания призм размером 1×1×3. Результаты испытаний отражены на графиках (рис. 6).

На основании анализа полученных зависимостей можно сделать вывод, что введение каменноугольной смолы в количестве до 5% вызывает повышение прочности при сжатии и на растяжение при изгибе. При увеличении объема содержания прочность уменьшается. Добавка приводит к снижению модуля упругости эпоксидно-каменноугольных композитов. С увеличением содержания каменноугольной смолы до 40% коэффициент водостойкости возрастает в 1,28 раза по сравнению с контрольным составом. Это происходит, по всей вероятности, благодаря процессам взаимодействия эпоксидной и каменноугольной смол, способствующим повышению гидролитической устойчивости.

В рамках исследования проанализировано, как природа растворителя влияет на свойства эпоксиднокаменноугольного связующего. Растворители: ацетон, бензин, дизельное топливо, скипидар, растворитель 646, уайт-спирит. Контрольными по отношению к составам, состоящим из эпоксидно-каменноугольного связующего с включением растворителя, стали составы на эпоксидной смоле без модифицирующей добавки и на эпоксидно-каменноугольном вяжущем при отсутствии растворителя (табл. 7).

По итогам испытания можно сделать вывод об изменении в широких пределах физико-механических свойств композитов – в зависимости от природы растворителя. Причем лучшие показатели прочности при сжатии демонстрируют составы с использованием растворителя 646, скипидара и бензина, а прочность на растяжение при изгибе – ацетона, растворителя 646, скипидара. Применение растворителей оправдано в том числе с технологических позиций – оно дает возможность исключить предварительное разогревание компонентов из процесса приготовления эпоксидно-каменноугольных композитов.

Таблица 6

Результаты определения максимумов физико-технических свойств композита

|

Максимумы физико-технических свойств |

Значения максимумов для матрицы планирования с учетом эффектов взаимодействия, МПа |

Кодированные значения факторов матрицы планирования с учетом эффектов взаимодействия |

|

Максимум R сж |

58,4827 |

1 1 1 1 –1 1 1 –1 1 –1 –1 1 –1 –1 –1 –1 |

|

Максимум R изг. |

15,6863 |

1 –1 1 1 1 –1 –1 –1 1 1 1 –1 –1 –1 1 –1 |

|

Максимум Е упр. |

177,2901 |

1 1 1 –1 –1 1 –1 –1 –1 –1 1 –1 –1 1 1 1 |

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Содержание каменноугольной смолы, мас. ч.

– ○ – Предел прочности на растяжение при изгибе – ■ – Предел прочности при сжатии – ▲ – Модуль упругости

б

Содержание каменноугольной смолы, мас. ч.

____ Коэффициент водостойкости – .. – Водопоглощение, %

Рис. 6. Зависимость предела прочности на сжатие, на растяжение при изгибе и модуля упругости (а) и коэффициента стойкости, водопоглощения (б) от количественного содержания каменноугольной смолы в эпоксидном связующем

Таблица 7

Прочность эпоксидно-каменноугольных композитов

|

№ состава |

Вид растворителя в модифицированных составах |

Предел прочности при сжатии, МПа |

Предел прочности на растяжение при изгибе, МПа |

|

1 |

Без модификатора |

104,7 |

78,5 |

|

2 |

Ацетон |

77,5 |

72,4 |

|

3 |

Бензин |

89,2 |

52,3 |

|

4 |

Ацетон + бензин (1 : 1) |

85,0 |

57,4 |

|

5 |

Дизельное топливо |

87,0 |

51,8 |

|

6 |

Растворитель 646 |

96,4 |

68,6 |

|

7 |

Скипидар |

90,7 |

65,0 |

|

8 |

Уайт-спирит |

84,4 |

56,9 |

|

9 |

Без растворителя |

96,7 |

63,5 |

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ

Ключевую роль в создании композиционных материалов играет природа наполнителя. Наибольшие значения прочности и стойкости у композитов, получаемых сочетанием определенных пар «вяжущее – наполнитель». Чтобы определить влияние природы минеральных наполнителей на свойства наполненной эпоксидно-каменноугольной композиций, были проведены сравнительные исследования. Применялись следующие наполнители: кварцевый песок

и измельченные порошки известняка, боя стекла, мрамора и керамического кирпича. Крупность наполнителя была принята равной 0,315–0,63 мм. Количество вводимого наполнителя обеспечивало соотношение вяжущее/наполнитель – 1/1. Информация о прочностных свойствах композитов представлена в табл. 8.

В ходе исследования определено, что среди рассмотренных эпоксидно-каменноугольных наполнен-

Таблица 8

Прочность эпоксидно-каменноугольных композитов на различных наполнителях

|

№ п/п |

Вид наполнителя |

Предел прочности, МПа |

|

|

при сжатии |

на растяжение при изгибе |

||

|

1 |

Без наполнителя |

68,7 |

9,2 |

|

2 |

Кварцевый песок |

83,2 |

20,9 |

|

3 |

Известняк |

140,8 |

22,7 |

|

4 |

Мрамор |

133,9 |

17,0 |

|

5 |

Кирпичный бой |

117,3 |

21,4 |

|

6 |

Стеклобой |

111,1 |

20,9 |

0 12 3 4

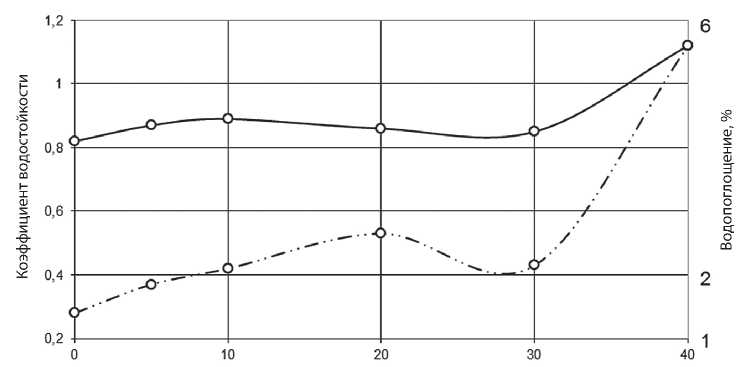

---- Фракция < 0,071 мм – . – Фракция 0,071–0,14 мм – – – Фракция 0,14–0,315 мм ___ Фракция 0,315–0,63 мм

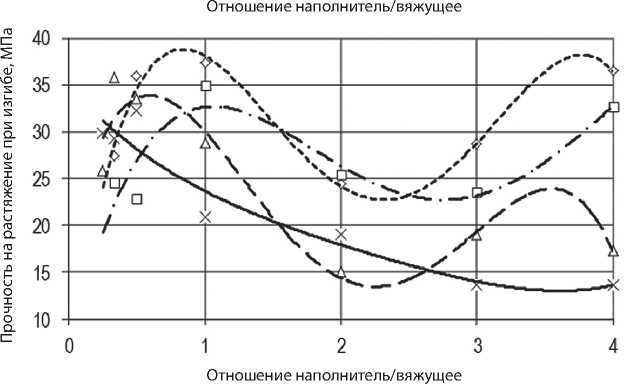

Рис. 7. Зависимость прочности при сжатии и растяжении при изгибе эпоксидно-каменноугольных композитов от содержания и дисперсности наполнителя

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ ных композитов наибольшая прочность при сжатии и на растяжение при изгибе свойственна композитам, наполненным известняком. Следует отметить, что значительное влияние на свойства композиционных материалов оказывает дисперсность и количественное содержание наполнителя (рис. 7).

Наибольшая прочность присуща композитам, наполненным порошками высокой дисперсности (фракция < 0,071 мм). Заметные эффекты получены при использовании в качестве наполнителей нанодобавок: печной сажи и углеродных нанотрубок «Туанит-М» [37]. Причем добавки вводились как по отдельности, так и совместно. В некоторых слу-

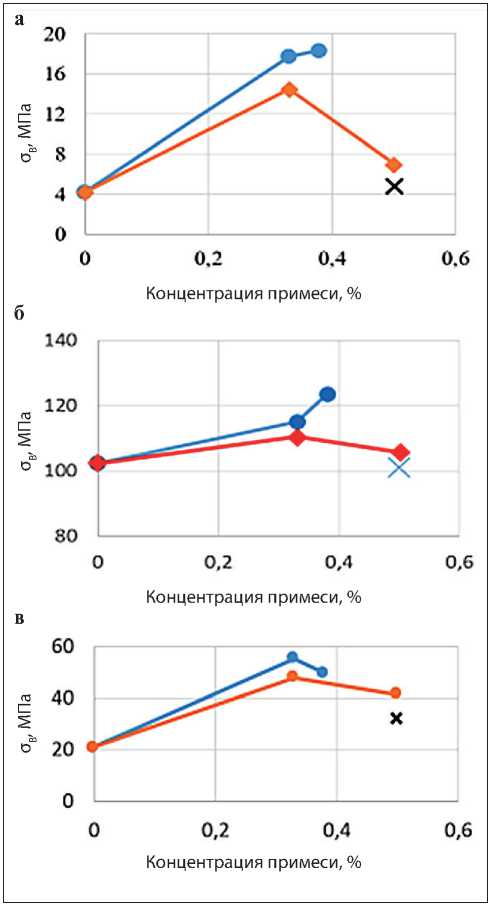

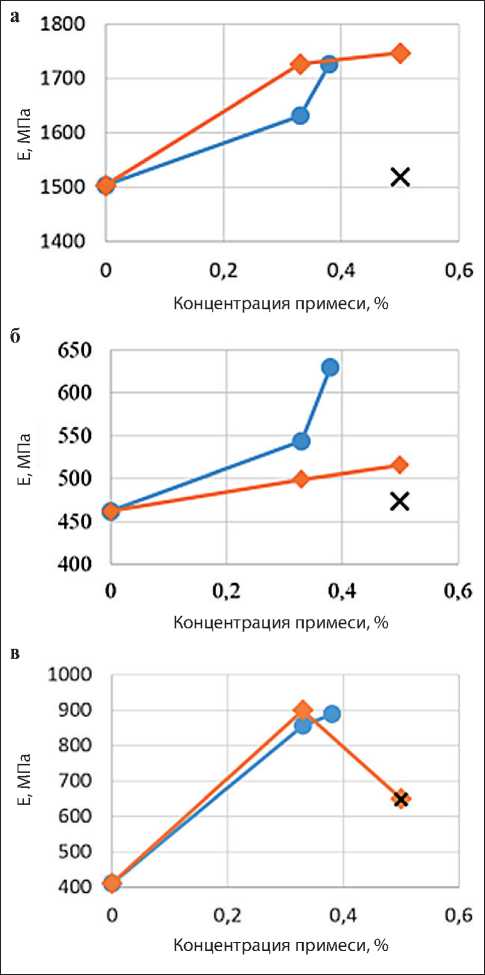

чаях совместное влияние нескольких нанодобавок вызвало улучшение свойств полимерных композитов [35, 38] (рис. 8–10).

На представленных графиках видно значительное влияние нанодобавок на механические свойства отвержденной смолы. Так, предел прочности при растяжении вырос почти в 5 раз, при изгибе – в 3 раза. При этом эффект от введения нанотрубок в большинстве случаев оказался несколько меньшим, чем при использовании сажи.

Рис. 8. Зависимость изменения прочности на растяжение (а), сжатие (б) и изгиб (в) от вида и содержания нанодобавок:

• – сажа, ♦ – УНТ, × – сажа + УНТ

Рис. 9. Зависимость изменения эффективного модуля при испытании на растяжение (а), сжатие (б) и изгиб (в) от вида и содержания нанодобавок:

• – сажа, ♦ – УНТ,×–сажа + УНТ

Таблица 9

Составы, примененные для испытаний на химическое сопротивление

|

Компоненты |

Содержание массовых частей в составах |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Эпоксидная смола марки ЭД-16 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Полиэтиленполиамин |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Каменноугольная смола |

— |

5 |

10 |

20 |

30 |

40 |

20 |

20 |

20 |

20 |

|

Кварцевый песок |

300 |

300 |

300 |

300 |

300 |

300 |

||||

|

Портландцемент |

300 |

|||||||||

|

Известняк |

300 |

|||||||||

|

Стеклобой |

300 |

|||||||||

Таблица 10

Составы, примененные для испытаний на биологическое сопротивление

|

Компоненты |

Содержание массовых частей в составах |

||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

Эпоксидная смола марки ЭД-16 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Полиэтиленполиамин |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Каменноугольная смола |

– |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

Кварцевый песок |

100 |

100 |

50 |

||||||

|

Стеклобой |

100 |

||||||||

|

Известняк |

100 |

||||||||

|

Мрамор |

50 |

100 |

|||||||

|

Кирпичный бой |

100 |

||||||||

|

Портландцемент |

100 |

||||||||

СТРОИТЕЛЬНОЕ МАТЕРИАЛОВЕДЕНИЕ кислоты (0,1–10%) и перекиси водорода (0,03–3%) в водном растворе (продукты метаболизма микроорганизмов). Составы агрессивных сред и их концентрации определены с учетом условий применения полимербетонов в промышленном и сельскохозяйственном строительстве (табл. 10 и 11).

Табл. 11 содержит физико-технические показатели эпоксидно-каменноугольных композитов после испытания в биологически агрессивных средах: наиболее агрессивной является среда № 1 (содержание лимонной кислоты 1%, перекиси водорода 0,3%) и № 8 (содержание лимонной кислоты 0,1%, перекиси водорода 0,3%).

В составах эпоксидно-каменноугольных композитов в качестве фунгицидных добавок использовались растворы нитрофунгина и «Тефлекса». Исследования показали, что введение 2% нитрофунгина не оказывает влияния на повышение грибостойко-сти. Повышение содержания нитрофунгина до 5% повышает грибостойкость для состава, наполненного кирпичным боем и ненаполненных составов, дальнейшее повышение содержания нитрофунгина

приводит к снижению его фунгицидного действия. Применение «Тефлекса» более эффективно: его добавление в количестве 2% положительно влияет на грибостойкие свойства, 10% и более – фунгицидные. Использование фунгицидных составов позволяет предотвратить заселение строительных конструкций микроорганизмами и способствует улучшению экологической ситуации в зданиях и сооружениях.

ВЫВОДЫ

Таким образом, на основе результатов, выполненных авторами экспериментальных исследований методами математического планирования, измерения механических свойств, ИК-спектроскопии разработаны модифицированные эпоксидно-каменноугольные композиты с повышенными механическими свойствами, химической и биологической стойкостью, позволяющие использовать изделия из них для эксплуатации в условиях воздействия воды, водных растворов кислот, щелочей, солей, минеральных удобрений и микроскопических организмов.

Таблица 11

Физико-технические показатели эпоксидно-каменноугольных композитов в биологически агрессивных средах

|

Номер состава |

Максимальное значение |

Минимальное значение |

||||

|

Номер среды |

Прочность при сжатии, МПа |

Прочность при растяжении при изгибе, МПа |

Номер среды |

Прочность при сжатии, МПа |

Прочность при растяжении при изгибе, МПа |

|

|

1 |

3 |

70,8 |

24,2 |

1 |

45,63 |

15 |

|

2 |

2 |

70,2 |

19,3 |

5 |

55,87 |

19,2 |

|

3 |

7 |

65,1 |

24,4 |

1 |

47,76 |

11,8 |

|

4 |

7 |

45,7 |

13,6 |

3 |

35,3 |

13,3 |

|

5 |

7 |

73,5 |

15,9 |

9 |

62,9 |

23,3 |

|

6 |

2 |

67,1 |

18,9 |

1 |

43,5 |

17,6 |

|

7 |

1 |

67,6 |

20,3 |

2 |

57,7 |

20,8 |

|

8 |

7 |

75,7 |

26,5 |

5 |

62,4 |

30,4 |

|

9 |

7 |

56,4 |

9,86 |

8 |

28,8 |

13,8 |

Список литературы Эпоксидные композиты, модифицированные каменноугольной смолой

- Хозин В.Г. Усиление эпоксидных полимеров. Казань: Дом печати, 2004. 446 с.

- R. Bedi, R. Chandra, S.P. Singh. Reviewing some properties of polymer concrete. Indian Concr. J. 2014; 88: 47-68.

- S. Daghash, R. Tarefder, M. Reda Taha, A New Class of Polymer Concrete with Improved Fatigue Strength Using Carbon Nanotubes, 2015. https://doi.org/10.1007/978-3-319-17088-6_37

- Y. Feng, Y. Su, N. Lu, S. Shah. Meta concrete: exploring novel functionality of concrete using nanotechnology. Eng. Sci. 2020. https://doi.org/10.30919/es8d816

- Бобрышев А.Н. Физика и синергетика дисперсно-неупорядоченных конденсированных композитных систем: монография / А.Н. Бобрышев, В.Т. Ерофеев, В.Н. Козомазов. СПб.: Наука, 2012. 473 с.

- Федорцов А.П. Физико-химическое сопротивление строительных композитов и способы его повышения. Саранск: Изд-во Мордовского ун-та, 2015. 462 с.

- J. Wang, Y. Fan, C. Zhu, S. Lu, J. Liu. Mesoscopic finite element simulation on the interfacial bonding performance of functionally gradient concrete. ES Mater. Manuf. 2020. https://doi.org/10.30919/esmm5f810

- J.P. Gorninski, C.de S. Kazmierczak. Evaluation of the chemical strength of polymeric concretes in aggressive environments. Ambiente Construído. 2008; 8:105-113.

- B. Fiedler, F.H. Gojny, M.H.G. Wichmann, M.C.M. Nolte, K. Schulte. Fundamental aspects of nano-reinforced composites. Compos. Sci. Technol. 2006; 6: 3115-3125. https://doi.org/10.1016/j.compscitech.2005.01.014

- Соломатов В.И. Биологическое сопротивление материалов: монография / В.И. Соломатов, В.Т. Ерофеев, В.Ф. Смирнов и др. Саранск: Изд-во Мордов. ун-та, 2001. 193 с.

- Erofeev, V., Gubanov, D., Bogatov, A., Bulgakov, A. Frame polymerbetons based on fillers of different nature. Materials Science Forum, 2020;1011: 164–170. https://doi.org/10.4028/www.scientific.net/MSF.1011.164

- Thomas, C., Lombillo, I., Polanco, J.A. Polymeric and cementitious mortars for the reconstruction of natural stone structures exposed to marine environments. Composites Part B: Engineering. 2010; 41(8): 663-672. https://doi.org/10.1016/j.compositesb.2010.08.007

- Berndt, M.L. Evaluation of coatings, mortars and mix design for protection of concrete against sulphur oxidizing bacteria. Construction and Building Materials. 2011; 25(10):3893-3902. https://doi.org/10.1016/j.conbuildmat.2011.04.014

- Valix, M., Zamri, D., Mineyama, H. Microbiologically induced corrosion of concrete and protective coatings in gravity sewers. Chinese Journal of Chemical Engineering. 2012; 20 (3):433-438. https://doi.org/10.1016/S1004-9541(11)60150-X

- Vipulanandan, C., Parihar, A., Issac, M. Testing and Modeling Composite Coatings with Silanes for Protecting Reinforced Concrete in Saltwater Environment. Journal of Materials in Civil Engineering. 2011; 23(12): 1602-1608. https://doi.org/10.1061/ (ASCE)MT.1943-5533.0000330

- Hua, W., Jiang, H., Zhou, Z. Resistance to nitric acid corrosion of latex modified sulphoaluminate cement mortar. Advanced Materials Research, 2012; 382: 404-407. https://doi.org/10.4028/www.scientific.net/AMR.382.404

- Bertron, A., Duchesne, J. Attack of cementitious materials by organic acids in agricultural and agrofood effluents. RILEM State-of-theArt Reports. 2013; 10: 131-173. https://doi.org/10.1007/978-94-007-5413-3_6

- Vipulanandan, C, Liu, J. Polymer Coatings for Concrete Surfaces: Testing and Modeling. Handbook of Environmental Degradation of Materials: Second Edition. September 24. 2012; 12: 621-653. https://doi.org/10.1016/B978-1-4377-3455-3.00021-3

- Nazemi, M.K., Valix, M. Evaluation of acid diffusion behaviour of amine-cured epoxy coatings by accelerated permeation testing method and prediction of their service life. Progress in Organic Coatings. 2016; 97: 307-312. https://doi.org/10.1016/j.porgcoat.2016.04.025

- Roghanian, N., Banthia, N. Development of a sustainable coating and repair material to prevent bio-corrosion in concrete sewer and waste-water pipes. Cement and Concrete Composites. 2019; 100: 99-107. https://doi.org/10.1016/j.cemconcomp.2019.03.026

- Herisson, J., Guéguen-Minerbe, M., van Hullebusch, E.D. Influence of the binder on the behaviour of mortars exposed to H2S in sewer networks: a long-term durability study. Materials and Structures/Materiaux et Constructions. 2017; 50(1): 8. https://doi.org/10.1617/s11527-016-0919-0

- Vipulanandan, C., Liu, J. Polymer Coatings for Concrete Surfaces: Testing and Modeling. Handbook of Environmental Degradation of Materials: Second Edition. 2012: 621-653. https://doi.org/10.1016/B978-1-4377-3455-3.00021-3

- Nazemi, M.K.,Valix, M. Evaluation of acid diffusion behavior of amine-cured epoxy coatings by accelerated permeation testing method and prediction of their service life. Progress in Organic Coatings. 1 August 2016; (97): 307-312. https://doi.org/10.1016/j.porgcoat.2016.04.025

- Benosman, A.S., Mouli, M., Taibi, H. Resistance of polymer (PET)-mortar composites to aggressive solutions. International Journal of Engineering Research in Africa. 2011; 5: 1-15. https://doi.org/10.4028/www.scientific.net/JERA.5.1

- Valix, M., Mineyama, H., Chen, C. Effect of film thickness and filler properties on sulphuric acid permeation in various commercially available epoxy mortar coatings. Water Science and Technology. 2011; 64 (9): 1864-1869. https://doi.org/10.2166/wst.2011.743

- Gutarowska, B., Kotynia, R., Bieliński, D. New sulfur organic polymer-concrete composites containing waste materials: Mechanical characteristics and resistance to biocorrosion. Materials, 2019; 12 (16): 2602. https://doi.org/10.3390/ma12162602

- Pereyra, A.M., Gonzalez, M.R., Rodrigues,T.A. Enhancement of biocorrosion resistance of epoxy coating by addition of Ag/Zn exchanged a zeolite. Surface and Coatings Technology. 270, 25 May 2015; 284-289. https://doi.org/10.1016/j.surfcoat.2015.02.044

- Amin, M., Bassuoni, M.T. Response of concrete with blended binders and nanoparticles to sulfuric acid attack. Magazine of Concrete Research. 2018; 70(12): 617-632. https://doi.org/10.1680/jmacr.17.0008

- Achchige, R.S., Vitanage, D., Bustamante, H. The effect of moisture on bonding behaviour of epoxy on concrete. Proceedings of the 4th Asia-Pacific Conference on FRP in Structures, APFIS; 2013.

- Sokolova Yu.A. Modified epoxy adhesives and coatings in construction / Yu.A. Sokolova, E.M. Gottlieb. M.: Stroyizdat; 1990.

- D. Dutta, S. Ghosh. Comparative study on the performance of blended and nonblended fly ash geopolymer composites as durable construction materials. Adv. Civ. Eng. 2018; 1-12. https://doi.org/10.1155/2018/2940169

- M. Muthukumar, D. Mohan/ Studies on polymer concretes based on optimized aggregate mix proportion. Eur. Polym. J. 2004; 40: 2167-2177. https://doi.org/10.1016/j.eurpolymj.2004.05.004

- H. Xie, B. Liu, Q. Sun, Z. Yuan, J. Shen, R. Cheng. Cure kinetic study of carbon nanofibers/epoxy composites by isothermal DSC. J. Appl. Polym. Sci. 2005; 96 (2): 329-335.

- M.R. Taha, U.F. Kandil, E. Soliman, Generation of polymer concretes incorporating carbon nanotubes. US8426501B1, 2011. https://patentimages.storage.googleapis.com/1f/fa/46/d81db94052624e/US8426501.pdf (accessed August 30, 2021).

- X.-L. Xie, Y.-W. Mai, X.-P. Zhou. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng.: R: Rep. 2005; 49: 89-112. https://doi.org/10.1016/j.mser.2005.04.002

- Ерофеев В.Т., Афонин В.В., Ерофеева И.В., Максимова И.Н., Аль Дулайми Салман Давуд Салман, Аль Кадхими Зинах Али Хассун AnyRegression. Заявка № 2021614937 от 09.04.2021. Свидетельство о государственной регистрации программы для ЭВМ № 2021615823. Дата публикации и номер бюллетеня: 13.04.2021 Бюл. № 4.

- Erofeev V.T., Ivlev V.I., Sigachyov A.F., Fomin N.E., Yudin V.A., Blohin A.N., Yel’chishcheva T.F., Suhorukov A.K., Tkachev A.G. Mechanical properties of epoxy resin with additives soot and nanotubes. Materials Physics and Mechanics. 2021; 47(1): 20-30.

- Q. Wang, J. Zhang, Z. Zhang, Y. Hao, K. Bi. Enhanced dielectric properties and energy storage density of PVDF nanocomposites by co-loading of BaTiO3 and CoFe2O4 nanoparticles. Adv. Compos. Hybrid Mater. 2020; 3 (1): 58-65. https://doi.org/10.1007/s42114-020-00138-4

- Kong L., Fang J., Zhou X. Assessment of coatings for protection of cement paste against microbial induced deterioration through image analysis. Construction and Building Materials, 2018; 91: 342-353. https://doi.org/10.1016/j.conbuildmat.2018.10.04

- Berndt M.L. Evaluation of coatings, mortars and mix designfor protection of concrete against sulphur oxidising bacteria. Construction and Buijding Materials. October. 2011; 25(10): 3893-3902. https://doi.org/10.1016/j.conbuildmat.2011.04.014

- Valix M., Zamri D., Mineyama H., Cheung W.H., Shi J., Bustamante H. Microbiologically induced corrosion of concrete and protective coatings in gravity sewers. Chinese Journal of Chemical Engineering. June. 2012; 20 (3): 433-438. https://doi.org/10.1016/S1004-9541(11)60150-X

- Pereyra A.M., Gonzalez M.R., Rodrigues T.A. Enhancement of biocorrosion resistance of epoxy coating by addition of Ag/Zn exchanged a zeolite. Surface and Coatings Technology. May. 2015; 270 (25):284-289. https://doi.org/10.1016/j.surfcoat.2015.02.044

- Ribeiro C.C., Da Silva Pinto J.D., Godoy G.C. Microstructural and topographic characterization of concrete protected by acrylic paint. Materials Research, 2013; 16(4): 817-823. https://doi.org/10.1590/S1516-14392013005000042

- Tokach Y.E., Rubanov Y.K., Vasilenko M.I. Design of new approaches and technological solutions of obtaining biocidal compositions to protect industrial and civil buildings and constructions against biodeterioration. Research Journal of Applied Sciences, 2014; 9(11): 774-778. https://doi.org/10.3923/rjasci.2014.774.778

- Pazoki M., Abdoli M.A., Ghasemzade R. Comparative evaluation of poly urethane and poly vinyl chloride in lining concrete sewer pipes for preventing biological corrosion. International Journal of Environmental Research, 2016; 10( 2): 305-312.