Justification of dual-level opener parameters in digital twin by the discrete element method

Автор: Mudarisov S.G., Farkhutdinov I.M., Bagautdinov R.Yu.

Журнал: Инженерные технологии и системы @vestnik-mrsu

Рубрика: Агроинженерия

Статья в выпуске: 2, 2024 года.

Бесплатный доступ

Introduction. The discrete element method is the most promising method for modeling soil tillage. With the use of DEM modeling it is possible to create a digital twin for technological process of interaction of tools with soil, analyze the operation of tillage and seeding machines having various design and technological parameters, and predict energy and agrotechnical indicators of еtheir work. To improve the prediction accuracy, it is necessary to compare the obtained data with the results of field experiments. Aim of the Study. The study is aimed at developing a digital twin of the tillage bin through using the discrete element method and optimizing the main design and technological parameters of the dual-level opener.

Modeling of technological process, sowing, tillage, coulter, traction resistance, contact model, hertz-mindlin model, jonson-kendall-roberts model, virtual soil bin

Короткий адрес: https://sciup.org/147243816

IDR: 147243816 | УДК: 631.33.024.2 | DOI: 10.15507/2658-4123.034.202402.229-243

Текст научной статьи Justification of dual-level opener parameters in digital twin by the discrete element method

Vol. 34, no. 2. 2024 ENGINEERING TECHNOLOGIES AND SYSTEMS

Introduction. The discrete element method is the most promising method for modeling soil tillage. With the use of DEM modeling it is possible to create a digital twin for technological process of interaction of tools with soil, analyze the operation of tillage and seeding machines having various design and technological parameters, and predict energy and agrotechnical indicators of еtheir work. To improve the prediction accuracy, it is necessary to compare the obtained data with the results of field experiments.

Aim of the Study. The study is aimed at developing a digital twin of the tillage bin through using the discrete element method and optimizing the main design and technological parameters of the dual-level opener.

Materials and Methods. To simulate the process of the soil-opener interaction, there was used the discrete element method; the advanced Hertz ‒ Mindlin model was used as a contact model. For DEM modeling there is created a virtual tillage bin, which is filled with spherical particles of 10 mm diameter with the specified rheological parameters of the selected contact model. The main design factors for carrying out computer experiments in order to optimize them were the opener blade rake angle α and the furrow rake angle β . The opener traction resistance R was chosen as the output optimization parameter.

Results. Implementation of multifactor experiments on the digital twin of the soil bin in the Rocky DEM program allowed to optimize the design and technological parameters of the dual-level opener: bit inclination angle α = 75o, furrow former inclination angle β = 21o, vertical distance between the bit and furrow former Δ a = 11 ‒ 14 mm.

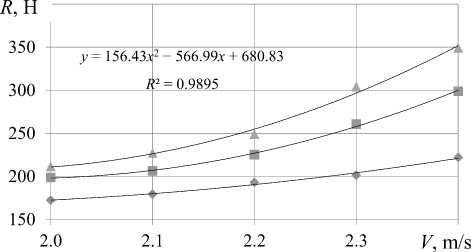

Discussion and Conclusion. As a result of the modeling, it was found that the opener traction resistance increases in quadratic dependence on the opener operating speed and surface energy of the contact model.

Conflict of interest: The authors declare no conflict of interest.

Funding: The research is carried out at the expense of a grant from the Russian Science Foundation No. 23-76-10070.

Контент доступен по лицензии Creative Commons Attribution 4.0 License .

This work is licensed under a Creative Commons Attribution 4.0 License .

Обоснование параметров комбинированного сошника в цифровом двойнике методом дискретных элементов

С. Г. Мударисов , И. М. Фархутдинов, Р. Ю. Багаутдинов Башкирский государственный аграрный университет

( г. Уфа, Российская Федерация )

Введение. Наиболее перспективным для моделирования процессов обработки почвы является метод дискретных элементов. Моделирование методом дискретных элементов позволяет создать цифровой двойник технологического процесса взаимодействия рабочих органов с почвой и провести анализ работы почвообрабатывающих и посевных машин с разными конструктивно-технологическими параметрами, а также спрогнозировать энергетические и агротехнические показатели работы орудий. При этом для увеличения точности прогнозирования результатов, полученных в ходе реализации виртуальной модели, необходимо сопоставлять данные с результатами лабораторных и полевых исследований.

Цель исследования . Разработать цифровой двойник почвенного канала методом дискретных элементов и оптимизировать с помощью него основные конструктивнотехнологические параметры комбинированного сошника.

Материалы и методы . Для моделирования процесса взаимодействия сошника с почвой методом дискретных элементов в качестве образца контакта выбрана усовершенствованная модель Герца ‒ Миндлина. В таком случае создается виртуальный почвенный канал, который заполняется сферическими частицами диаметром 10 мм с заданными реологическими параметрами выбранной модели контакта. Основными конструктивными факторами для проведения компьютерных экспериментов в целях их оптимизации приняты угол наклона долота сошника α и угол наклона бороздообразователя β , в качестве выходного параметра оптимизации – тяговое сопротивление сошника R .

Результаты исследования. Реализация многофакторных экспериментов на цифровом двойнике почвенного канала в программе Rocky DEM позволила оптимизировать конструктивно-технологические параметры комбинированного сошника: угол наклона долота α = 75о, угол наклона бороздообразователя β = 21о, расстояние между долотом и бороздообразователем по вертикали ∆ a = 11–14 мм.

Обсуждение и заключение . В результате моделирования установлено, что тяговое сопротивление сошника растет по квадратичной зависимости от его рабочей скорости. Увеличение поверхностной энергии контактной модели также ведет к росту тягового сопротивления сошника.

Конфликт интересов: авторы заявляют об отсутствии конфликта интересов.

Финансирование: исследование выполнено за счет гранта Российского научного фонда № 23-76-10070.

Introduction. Meeting the needs of modern fast-developing agriculture requires constant improvement in the operational efficiency of agricultural machinery and tools. The methods of theoretical analysis, modeling and experimental research are most often used to develop new and improve existing machines in order to increase their efficiency. In view of the developed numerical methods for implementing various theoretical approaches using applied engineering calculation programs, computer modeling is the most promising tool for designing machines. Computer modeling has a number of advantages such as low cost and lack of reference to seasonality compared to experimental studies.

To model the tillage technological process, various modeling methods based on the numerical implementation of systems of equations for various media dynamics are used, such as computational fluid dynamics (CFD), the smoothed particle hydrodynamics method (SPH), the finite element method (FEM) and the most promising to date the discrete elements method (DEM) [1].

A limiting factor in the effective application of the discrete element method for modeling soil is the important need for computing resources and high requirements for calibrating the parameters of the contact models used, because of the great variability of the physical and mechanical properties of soils and their anisotropy.

Literature Review. At the initial stage, the study of the discrete element method application for solving soil tillage problems was aimed at calibrating the parameters of the contact models used. The parameters of the contact models were calibrated mainly by the angle of repose [2–4]. Despite its simplicity, a comparison of the results by the angle of the pile formed by the soil and discrete particles resting on a horizontal base after pouring out of a cylindrical or cone-shaped funnel made it possible to determine the range of changes in the parameters of contact models [5; 6].

The studies show that the behavior of the modeled soil, obtained by modeling discrete elements, largely depends on the choice of the contact model parameters. At the same time, a large number of studied factors such as the Poissonʼs ratio, static and dynamic friction coefficients, Youngʼs modulus, surface energy, particle diameter, etc must be taken into account as the main parameters of contact models and properties of model particles. The evaluation of the parameters significance was carried out by S. G. Mudarisov [7]. It was found out that the pattern of change in the angle of responce of the soil medium, modeled by the discrete element method, is affected significantly by the surface energy and particle diameter.

Then, the contact models parameters were specified by more complex calibration methods, for example, by the draught resistance of working tools or soil movement (formation of ridges and furrows) based on the results of field tests and modeling.

The research by C. Saunders, M. Ucgul, R. J. Goodwin presents the results of parameters calibration of a soil modeled simulated by the discrete element method using spherical particles of different diameters [8]. A tillage bin model with particles having a radius of 1.5 mm with upper layer of 20 mm thick and a lower layer of particles with a radius of 10 mm showed the most reliable results of simulating draught resistance of a tillage tool.

The input parameters of the DEM were calibrated to model a cohesive soil using a contact model with a hysteresis spring coupled with a linear cohesion model for

^J ИНЖЕНЕРНЫЕ ТЕХНОЛОГИИ И СИСТЕМЫ Том 34, № 2. 2024 spherical particles with a diameter of 10 mm in the angle of natural slope and in the displacement of particles (formation of ridges and furrows) when interacting with an anchor coulter (K. A. Aikins et al.) [9]. According to the research results, the following input parameters of the contact model are recommended for modeling cohesive soils: damping coefficient equal to 0.05, stiffness coefficient equal to 0.95, soil liquid limit equal to 2.8 MPa, particle cohesive energy density equal to 46,400 J/m3, particle cohesive energy density-tool equal to 14,900 J/m3.

N. R. Makange et al. have compared the DEM of the soil-tillage interaction modeling with a mouldboard plow was compared with the results of field experiments on the horizontal and vertical draft forces and bulk density of the soil [10]. In their study, the model of a hysteresis spring and a linear cohesive contact (HS/LC model) was used as a contact model. According to the experimental results, the accuracy of the prediction of the vertical force turned out to be higher than the accuracy of the horizontal force.

S.G. Mudarisov et al. calibrated the parameters of the contact model for the improved Hertz‒Mindlin JKR model by comparing the horizontal, vertical and lateral components of plow body resistance according to the results of laboratory and field studies and also modelling of a similar body geometrically using the discrete element method [11]. It was found that the most similar results with an relative error of 4.6–7.6% are observed at the surface energy of discrete particles equal to 270–400 J/m2.

After obtaining comparable results of modeling by the discrete element method and of soil behavior, the researchers evaluated the energy and agro-technical indicators of soil tillage and justify the structural and technological parameters of the tillage machine tools.

In the work by S. Xuefeng et al. the use of the discrete element method made it possible to justify the rake angle of the hiller used in ridge-furrow technique for grain farming at lower draught resistance [12].

The design and technological parameters of a deep-filler in a virtual bin filled with discrete spherical particles having a diameter of 6 mm was substantiated by S.H. Hosei-nian et al. [13]. The parameters of the Hertz‒Mindlin contact model with parallel connections were calibrated by the natural angle of repose and by the draft force in a soil bin in a sandy loam.

L. Liu et al. has been developed a model to analyze the soil covered with straw and the T-shaped furrow-opener interaction by discrete element method [14]. The accuracy of the model was confirmed by comparing the draught force, down force, displacement of soil forward and sideways, as well as displacement of straw forward through physical and simulation experiments. The modeling helped to justify the shape of the opener side blades and the range of operating speeds for effective performance.

K. Liu et al. used a discrete soil simulation to evaluate the impact of structural and technological parameters of a subsioler on draught resistance [15]. The modeling made it possible to justify the rake angle of the ripper paw with a lower draught resistance. At the same time, as in the previous case, the simulation results were compared with the results of field studies on the tillage bin.

The analysis of works shows that discrete element modeling allows analyzing the interaction of soil with tillage and seeding tools having different design and technological parameters. It is also possible to predict energy and agro technological operating results

Vol. 34, no. 2. 2024 ENGINEERING TECHNOLOGIES AND SYSTEMS ^?j of the tools. At the same time to increase the accuracy of predicting the results obtained during virtual model implementation of soil-tillage tool interaction, it is necessary to compare the data received with the laboratory and field study results.

The aim of the study is to develop a digital twin of a tillage bin by using the discrete elements method and optimize the basic design and technological parameters of the dual-level opener.

Materials and Methods. To develop a model of soil and dual-level opener interaction process there was used the discrete element method. The improved Hertz‒Mindlin JKR (Johnson Kendall Roberts) model was selected as a contact model based on previous studies [7; 11] to take into account the adhesive and cohesive properties of the soil. For this model, the Young«s modulus E , MPa, Poissonʼs ratio ν , coefficient of static friction fst , dynamic friction coefficient fd , surface energy Js , J/m2 and etc. are established as rheological parameters included in the contact model. For conducting experiments, according to the data of previously conducted [11] experiments, the following values of these parameters were taken (Table 1).

The parameters of the Hertz‒Mindlin JKR model were calibrated by comparing the components of the draught resistance of the plow body at different humidity levels according to the results of laboratory studies on the tillage bin and modelling by the discrete elements method in an early study [11].

T a b l e 1

Contact Model Parameters

|

№ |

Parameters |

Value |

|

1 |

Young’s modulus of soil particles Е, MPa |

1х108 |

|

2 |

Young’s modulus of steel (dual-level opener) Еst, MPa |

1х1010 |

|

3 |

Poisson’s ratio ν |

0.3 |

|

4 |

Soil-on-soil static friction coefficient fst |

0.7 |

|

5 |

Soil-on-soil dynamic friction coefficient fd |

0.6 |

|

6 |

Surface energy Gs , J/m2 |

300–340 |

|

7 |

Recovery coefficient |

0.3 |

|

8 |

Coefficient of static friction fst.k |

0.3 |

|

9 |

Coefficient of dynamic friction fd.k |

0.15 |

Source: Hereinafter in this article all tables were drawn up by the authors.

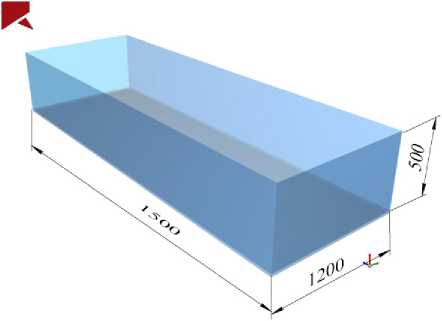

For discrete element modeling a virtual tillage bin is created. Its dimensions are determined on the zone of soil deformation by working tools. According to the technique described in our previous study [7], in order to avoid exposure of tillage bin walls on soil mass, which is formed during soil-opener interaction, the tillage bin dimensions are taken as follows: width is 1,200 mm, height is 500 mm, length is 1,500 mm (Fig. 1а). 3D model of a tillage bin with specified dimensions is created in COMPASS 3D program, which is then imported to RockyDEM program.

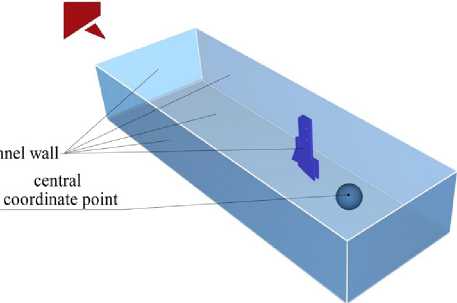

The tillage bin is filled with particles at one cycle by creating layers of particles around a specified central starting point of coordinates (Fig. 1b). These layers continue to be created, increasing a number of particles of a specified size and shape until one of Agricultural engineering 233

the two things happens: either they reach a specified mass value or they reach specified limits of the tillage bin walls (Fig. 1b). Based on the previously justified data [16], for this series of experiments there were adopted the particle parameters presented in Table 2.

T a b l e 2

Parameters of Discrete Particles for Filling the Bin

№ Parameter Value

-

1 Diameter of particles, mm10

-

2 Shape of particles sphere

-

3 Apparent density of particles, kg/m31,400

-

4 Density of particles, kg/m32,333

-

5 Number of particles in a bin 716,198

а)

b)

F i g. 1. Virtual soil bin: а) bin size dimension; b) the process of filling the bin with particles Source: Hereinafter in this article all figures were drawn up by the authors.

716,198 particles are required for filling the tillage bins with given geometric dimension.

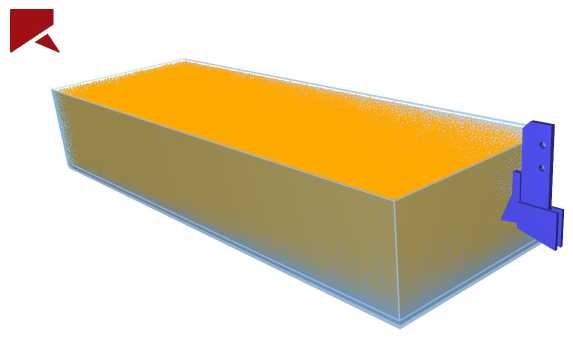

At the top of the tillage bin a 3D model of opener is installed at a specified seeding depth. It is designed in COMPASS 3D program for the design and technological parameters specified according to matrix of conducting experiments (Fig. 2). For modeling the soil-opener interaction process, the opener must move along the channel at a speed corresponding to its operating speed.

Fig. 2. Tillage bin, filled with discrete particles

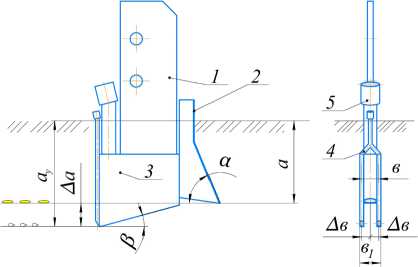

F i g. 3. Dual-level opener for variable depth application of fertilizers and seeds: 1 – tine; 2 – share; 3 –furrower; 4 – a tube for applying liquid complex fertilizer; 5 – grain tube

To implement the proposed scheme of separate sowing and fertilization, we introduce a dual-level opener (Fig. 3). The technological process of multi-depth application of liquid fertilizers and seed sowing is carried out by installing two furrowers 3 on the sides of the share 2 . The tubes for applying liquid complex fertilizers 4 are installed behind them at a certain distance from the seeds.

The share 2 of the dual-level opener forms a seedbed in the furrow, where seeds enter through seed ducts 5 , and furrowers 3 form two grooves in the soil, where liquid fertilizers enter through tubes 4 . After the dual-level opener has passed, the formed furrows are closed with crumbled soil and pressed with a roller [16].

The main design and technological parameters of the dual-level opener are the depth of sowing а , the depth of applying fertilizers ау , the working speed V and the width of the share в . The best-investigated design and technological parameters are working speed, stroke depth of the working body, and the width of the dual-level opener. The influence and dependencies of these parameters on the energy indicators are well known. The optimal position of fertilizers to seeds in our case determined by the vertical and horizontal distances of the soil between the dual-level opener and the furrowers is justified by C. J. Baker [17].

In this regard, the main factors for conducting computer experiments with the purpose of optimizing them, there are taken the following design and technological parameters of the dual-level opener (Fig. 3):

-

1. X1 is the rake angle the coulter share α , degrees;

-

2. X2 is the rake angle of the furrower β , degrees.

The draught resistance of the coulter R is accepted as the output parameter of the optimization of the experiment.

Three measurements are taken for each of the factors: the lower, zero and upper levels. Table 3 shows the values of the experimental factors at these levels and the conditions for conducting a full-factor experiment (FFE). The experiments were carried out according to the plan 32 = 9 for encoded and decoded values of factors. Factor X1 varied between 70о and 90о with a zero level of 80о, factor X2 varied between 15о and 35о with a zero level of 25о.

T a b l e 3

FFE conditions – values of experimental factors

|

Plan characteristics |

Х1 = α, degrees (dual-level opener rake angle) |

Х2 = β , degrees. (furrower rake angle) |

|

Lower level |

70 |

15 |

|

Zero level |

80 |

25 |

|

Upper level |

90 |

35 |

|

Variation interval |

10 |

10 |

The laboratory experiments were carried out on a tillage bin filled with chernozem soil of loamy sand mechanical composition at a humidity level of 17.9–19.5%.

For the experiments, there were manufactured removable furrowing devices with different angles β . In addition, the design of the experimental dual-level opener made it possible to change the distance ∆ a between the share and the furrower vertically (Fig. 3) that was an additional factor in the experiments. Thus, the furrower rake angle β and the distance ∆ a between them were chosen as factors of laboratory experiments, and the draft resistance of the opener R was chosen as the output parameter.

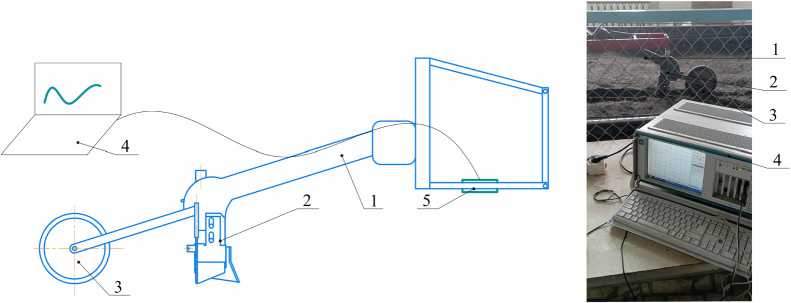

The experimental segment with a dual-level opener (Fig. 4b) trough a parallelogram mechanism was fixed to a three-point suspension device of a tillage bin drive trolley (Fig. 4a). Strain gauges are installed in the hitch draft arm allowing the load to be recorded up to 3 tons (Fig. 4b).

Measuring complex MIC-400D was used for recordings the readings of strain meters during the experiments (Fig. 4). The calibration of the measuring sensors of the Strain gauge was carried out using a calibrator – a hydraulic breaking machine GRM-20.

а) b)

F i g. 4. Experimental section with dual-level opener on a tillage bin:

а) dual-level opener; b) general view of the device. The photo by S. G. Mudarisov, 2023

The software package for statistical analysis STATISTICA was used to process the experimental results obtained during the implementation of a multifactorial experiment.

The obtained results were processed by methods of mathematical statistics, the adequacy of the model was evaluated according to the Fisher criterion.

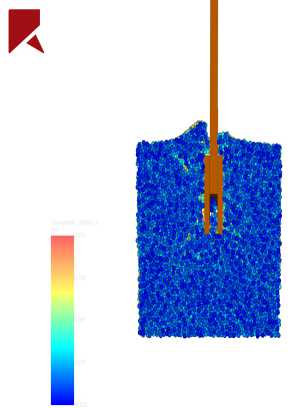

Results. The implementation of the developed digital twin of the tillage bin by the discrete element method allows visualizing the soil and dual-level opener interaction. Figure 5 shows a fragment of the soil deformation process by dual-level opener during operating in the longitudinal plane. Figure 6 shows the process of furrow and seedbed formation after share applying and compacted furrow after furrow opener applying. The colour palette on figures shows the vertical motion of particles.

F i g. 5. Soil deformation process by dual-level opener

F i g. 6. Furrow formation process for seeds and fertilizers

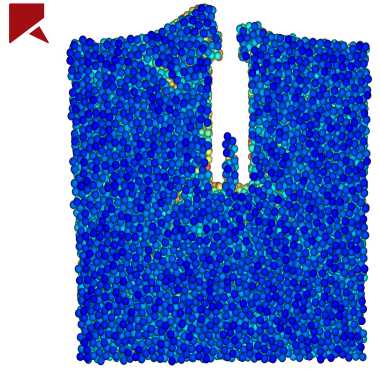

As a result of the implementation of the FFE, a regression equation was obtained in decoded form:

R = 124.50 + 1.29α + 13.25αβ2– 11.40α2β, which allows us to assess the influence of factors – the rake angle of the coulter share α and the furrower β of the coulter on its draught resistance R.

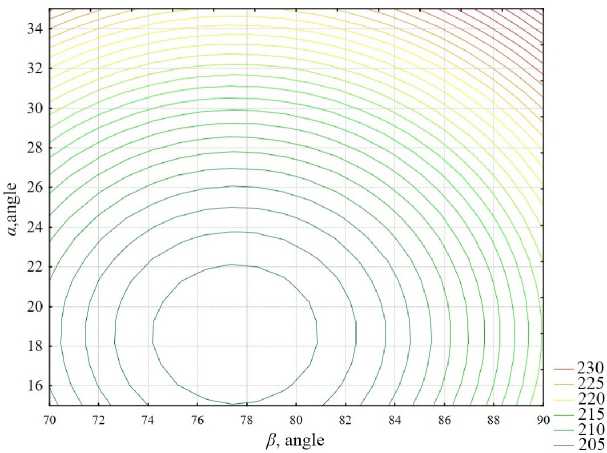

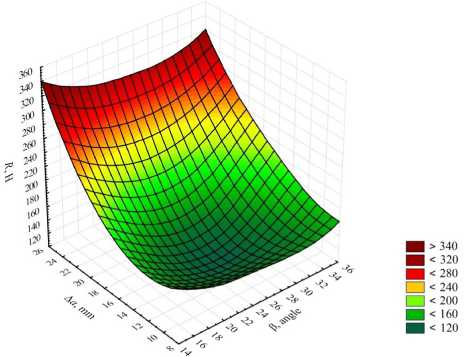

Figure 7 shows 3D surface dependency graph of draught resistance R of dual-level opener and rake angles of share α and furrower β . Figure 8 shows counter plot graph (two-dimensional sections) of this dependency.

From the presented dependencies (Fig. 7, 8) it can be seen that the draught resistance of the coulter has its minimum values at the angles of furrower to the bottom of the furrow equal to β = 15–22о and share installation at α = 74–81о.

In the course of computer model experiments to clarify calibrated parameters the influence of surface energy JS and operating coulter speed V on its draught resistance R was evaluated.

F i g. 7. Three-dimensional surface dependency graph of draught resistance R on share rake angles α and furrower β of dual-level opener

F i g. 8. Counter plot dependency graph of draught resistance R on share rake angles α and furrow opener β of dual-level opener

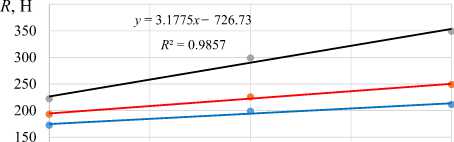

Figure 9 shows the graphical interpretation for the dependencies of the opener draught resistance R on its working speed V at different values of surface energy JS of the discrete elements contact model.

300 310 320 330 Js, J/m 2

F i g. 9. Dependence of dual level opener draught resistance R on velocity V at the change of contact model JS surface energy: 1 – JS = 300 J/m2; 2 – JS = 320 J/m2; JS – 340 J/m2

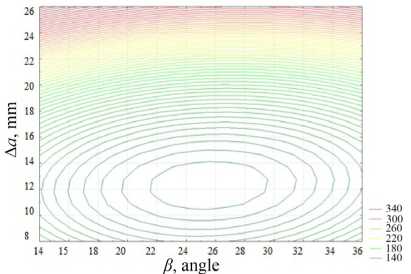

Figure 10 shows three-dimensional surface graph of dependency of draught resistance R on the angle of furrow opener installation β and the distance between share and furrower ∆ а . Figure 11 shows two-dimensional section of this dependency at the share width b = 15 mm according to the results of laboratory experiments on tillage bin.

F i g. 10. Three-dimensional surface graph of dependency of draught resistance R on the angle of furrower installation and the distance between share and furrower а

F i g. 11. Counterplot graph of dependency of draught resistance R on the angle of furrower installation and the distance between share and furrower а

From the obtained dependencies (Fig. 10, 11) it can be seen that coulter draught resistance R is minimal if used with furrower having rake angle β = 21–29о and the vertical distance between share and furrower ∆ a = 11–14 mm.

Discussion and Conclusion. From the obtained dependencies (Fig. 8) it can be seen that the coulter draught resistance R increases according to quadratic dependence which does not contradict the laws of classical agricultural mechanics.

An increase in surface energy also leads to an increase in draught resistance. With an increase in surface energy from 300 to 340 J/m2, the draught resistance at a speed of 2 m/s increases by 22.6%, and at a speed of 2.3 m/s by 57.1% (Fig. 12). Such an increase of draught resistance coincides with correlation dependencies obtained by S. G. Mudarisov [16] on the values of surface energy modeled by the discrete elements method of the soil environment to the humidity of real soil [11] according to which the increase in surface energy allows us to simulate the type and humidity of the soil. According to [11], the values of the surface energy JS = 320–340 J/m2 correspond to the soil of a heavy loamy mechanical composition, and JS = 300 J/m2 corresponds to a loamy soil mechanical composition.

F i g. 12. Dependence of dual-level opener draught resistance R n surface energy of simulated soil J : 1 – V = 2.0 m/s; 2 – V = 2.2 m/s; 3 – V = 2,4 m/s S

Ultimately, a computer model of the coulter-soil environment interaction process in the soil bin, implemented by the discrete elements method is a digital twin of the developed dual-level opener. The implementation of multifactorial experiments on a digital twin made it possible to visualize the process of coulter-soil interaction and optimize its design and technological parameters:

– the rake angle of the coulter share to the bottom of the furrow α = 74 – 81о;

– the rake angle of the coulter furrower to the bottom of the furrow β = 15 – 22о.

Laboratory experiments with an experimental opener on a tillage bin made it possible to clarify the installation angle of the furrower β = 21 – 29о, at which the traction resistance is minimal. Thus, in the course of modeling and field laboratory experiments, there were obtained results close to optimal values of the angle of inclination of the furrower β = 15 – 22о and β = 21 – 29о, respectively that indicates the right choice of parameters of the contact model when modeling the soil using the discrete element method.

The variation in draught resistance between the results of laboratory and model experiments is 2.9 – 5.8% at the distance between the coulter share and the furrower Δ а = 0 – 15 mm and 1.5 – 4.2% at the distance Δ а = 16 – 35 mm, which shows good convergence of the results when predicting the draught resistance of the coulter based on the results of modelling by the method of discrete elements.

When comparing the results of modelling and field experiments for practical use, the following design and technological parameters of the dual-level opener can be recommended: the rake angle of the share α = 75о, the rake angle of the furrower β = 21о, the distance between the share and the furrower vertically ∆ a =11 – 14 mm.

Discussion and Conclusion. A developed digital twin of the dual-level opener is a computer model of the soil environment-dual-level opener interaction process in the bin by the discrete element method. The improved Hertz - Mindlin JKR model has been adopted as a contact model for taking into account the adhesive and cohesive properties of the soil.

A virtual tillage bin with dimensions filled with 716,198 spherical particles with a diameter of 10 mm was created for discrete element method modelling.

The implementation of multifactorial experiments on a digital twin made it possible to optimize the design and technological parameters of the combined coulter:

– the rake angle of the share coulter to the bottom of the furrow α = 72 – 83о;

– the rake angle of coulter furrower to the bottom of the furrow β = 15 – 25о.

The draught resistance of the coulter increases according to quadratic dependency on its operating speed. An increase in the surface energy of the contact model also leads to an increase in the draught resistance of the coulter. With an increase in surface energy from 300 to 340 J/m2, the draught resistance increases by 22.6% at a speed of 2 m/s and by 57.1% at a speed of 2.3 m/s.

In the course of laboratory studies with an experimental coulter on a tillage bin, the minimum draught resistance of the coulter was obtained at the installation angle of the furrower β = 21 – 29о.

For practical use, the following design and technological parameters of the dual-level opener are recommended: the rake angle of the share α = 75о, the rake angle of the furrower β = 21о, the distance between the share and the furrower vertically ∆ a = 11 – 14 mm.

The digital twin of the soil bin, simulated by discrete element method, allows us to substantiate and optimize the parameters of the of tillage and seeding machines working bodies by numerically modelling their operation, taking into account various options for structural and technological parameters and soil properties. By justifying the parameters of the coulter in a digital twin using DEM, you can get valuable information about the operation of the coulter and make informed decisions on improving its design and characteristics.

Список литературы Justification of dual-level opener parameters in digital twin by the discrete element method

- Cundall P.A, Strack O.D.L. A Discrete Numerical Model for Granular Assemblies. Geotechnique. 1979;29(1):47-65. https://doi.org/10.1680/geot.1979.29.L47

- Ucgul M., Fielke J., Saunders C. Three-Dimensional Discrete Element Modelling of Tillage: Determination of a Suitable Contact Model and Parameters for a Cohesionless Soil. Biosystem Engineering. 2014;121(2):105-117. https://doi.org/10.1016/j.biosystemseng.2014.02.005

- Roessler T., Katterfeld A. DEM Parameter Calibration of Cohesive Bulk Materials Using a Simple Angle of Repose Test. Particuology. 2019;45:105-115. https://doi.org/10.1016/j.partic.2018.08.005

- Barr J.B., Ucgul M., Desbiolles J.M., Fielke J.M. Simulating the Effect of Rake Angle on Narrow Opener Performance with the Discrete Element Method. BiosystemsEngineering. 2018;171:1-15. https:// doi .org/10.1016/j.biosystemseng .2018.04.013

- Wang X., Zhang Q., Huang Y., Ji J. An Efficient Method for Determining Dem Parameters of a Loose Cohesive Soil Modelled Using Hysteretic Spring and Linear Cohesion Contact Models. Biosystems Engineering. 2022;215:283-294. https://doi.org/10.1016/j.biosystemseng.2022.01.015

- Qi L., Chen Y., Sadek M. Simulations of Soil Flow Properties Using the Discrete Element Method (DEM). Computers and Electronics in Agriculture. 2019;157:254-260. https://doi.org/10.1016/jxom-pag.2018.12.052

- Mudarisov S., Farkhutdinov I., Khamaletdinov R., Khasanov E., Mukhametdinov A. Evaluation of the Significance of the Contact Model Particle Parameters in the Modelling of Wet Soils by the Discrete Element Method. Soil and Tillage Research. 2022;215:105228. https://doi.org/10.10167j.still.2021.105228

- Saunders C., Ucgul M., Godwin R.J. Discrete Element Method (DEM) Simulation to Improve Performance of a Mouldboard Skimmer. Soil and Tillage Research. 2021;205:104764. https://doi. org/10.1016/j. still.2020.104764

- Aikins K.A., Ucgul M., Barr J.B., Jensen T.A., Antille D.L., Jack M.A. Determination of Discrete Element Model Parameters for a Cohesive Soil and Validation Through Narrow Point Opener Performance Analysis. Soil and Tillage Research. 2021;213:105123. https://doi.org/10.1016Zj.still.2021.105123

- Makange N.R., Ji C., Torotwa I. Prediction of Cutting Forces and Soil Behavior with Discrete Element Simulation. Computers and Electronics in Agriculture. 2020;179:105848. https://doi.org/10.1016/j. compag.2020.105848

- Mudarisov S., Lobachevsky Y., Farkhutdinov I., Khasanov E., Rakhimov I. Justification of the Soil Dem-Model Parameters for Predicting the Plow Body Resistance Forces During Plowing. Journal of Terramechanics. 2023;109:37-44. https://doi.org/10.1016/j.jterra.2023.06.001

- Song X., Dai F., Zhang X., Chen H., Zhang F., Zhao W. Numerical Analyses Ridge-Forming for Whole Film-Mulching and Double Ridge-Furrow, a Discrete Element Method. Computers and Electronics in Agriculture. 2023;215:108364. https://doi.org/10.1016/jxompag.2023.108364

- Hoseinian S.H., Hemmat A., Esehaghbeygi A., Shahgoli G., Baghbanan A. Development of a Dual Sideway-Share Subsurface Tillage Implement: Part 2. Effect of Tool Ggeometry on Tillage Forces and Soil Disturbance Characteristics. Soil and Tillage Research. 2022;215:105200. https://doi.org/10.1016/j. still.2021.105200

- Liu L., Wang X., Zhang X., Cheng X, Wei Z., Zhou H., et al. The Impact of 'T'-Shaped Furrow Opener of No-Tillage Seeder on Straw and Soil Based on Discrete Element Method. Computers and Electronics in Agriculture. 2023;213:108278. https://doi.org/10.1016/jxompag.2023.108278

- Liu K., Sozzi M., Gasparini F., Marinello F., Sartori L. Combining Simulations and Field Experiments: Effects of Subsoiling Angle and Tillage Depth on Soil Structure and Energy Requirements. Computers and Electronics in Agriculture. 2023;214:108323. https://doi.org/10.1016/jxompag.2023.108323

- Godzhaev Z., Mudarisov S., Farkhutdinov I. Evaluation of the Influence of the Discrete Elements' Shape on the Results of Soil Modelling. Springer International Publishing. 2022;602-611.

- Mudarisov S.G., Farkhutdinov I.M., Yamaletdinov M.M., Bagautdinov R.Yu., Kinzyabulato-va E.R. [Dual-Level Anchor Coulter]. Patent 207,073 Russian Federation. 2021 March 22. 4 p. (In Russ.)