Laser processing of titanium alloys to increase the strength of adhesive joint with cfrp

Автор: Rudenko M.S., Girn A.V., Mikheev A.E., Taigin V.B.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.24, 2023 года.

Бесплатный доступ

Titanium alloys are hard-to-bond materials due to the fact that a thin oxide film is always present on their surface, which prevents the formation of interatomic and intermolecular bonds between the adhesive and the substrate. In the load-bearing structures of spacecraft (SC), an adhesive bond between a titanium alloy and a composite material is often used. But the strength of such knots is relatively small compared to the mechanical connection. The purpose of this work is to increase the strength of the adhesive joint, due to laser processing of the working surface of the titanium alloy for gluing. Texturing of the surface of the tita-nium alloy OT-4 was carried out on an ytterbium pulsed fiber laser in 4 processing modes. The treated sur-face was glued with KMU-4 carbon fiber over an area of 300 mm2 using a VK-9 three-component adhesive. The adhesive strength test was carried out on a Eurotest T-50 tensile tester. The test showed that the strength of the laser-treated samples increased by more than 80% relative to the average value of mechan-ical grinding. The highest value of shear strength was shown by samples with laser processing No. 1 and No. 3. This is due to the greatest increase in the area of bonding of the surface, as well as the mechanical locking of the adhesive in the microrelief of the structure. The increase in shear strength caused by laser surface treatment is a mixed effect of increasing surface area, mechanically locking the adhesive, and changing the surface chemistry. The chemical composition of the surface structure under the influence of laser scanning is gradually transformed from Ti and Ti2O3 to crystalline TiO2. The nature of the destruc-tion of the adhesive joint in the samples with laser processing is predominantly cohesive, but samples with the destruction of the carbon fiber material were also observed, that is, the shear stress in the composite material exceeded the adhesive strength. The effect of pretreatment of the composite material on the strength of the adhesive joint was not considered in this work.

Laser processing, adhesive strength, titanium alloy, carbon fiber

Короткий адрес: https://sciup.org/148329685

IDR: 148329685 | УДК: 620.1:669.295 | DOI: 10.31772/2712-8970-2023-24-1-188-194

Текст научной статьи Laser processing of titanium alloys to increase the strength of adhesive joint with cfrp

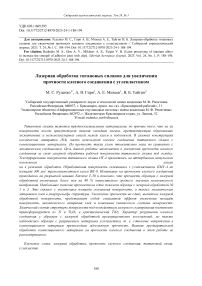

Titanium alloys are widely used as fasteners, hinges, power elements in a spacecraft (SC). In particular, titanium alloys are used to create one-piece adhesive joints of carbon fiber structures. As traditional connection methods (welding, soldering) used for metal parts cannot be used for parts made of composite materials (CM) or complicate the design (threaded, riveted joints, etc.) [1–3], CM is glued to metal elements through which the connection is provided. The fitting of the SC lock, which is an adhesive pair “titanium - carbon fiber” is shown in Fig. 1.

Despite the visible advantages of adhesive bonding, the strength of such knots is rather low. This is due to the fact that titanium alloys are hard-to-glue materials, since there is always a thin oxide film on the alloy surface, which prevents the formation of interatomic and intermolecular bonds between the adhesive and the substrate. The adhesive strength of titanium alloys can be increased by pre-treatment before bonding. Titanium processing methods to increase the adhesive strength during bonding are considered in [4; 5]. Laser processing is a promising method for increasing the adhesive strength of a titanium alloy [6]. This method has high productivity and stability of the properties of the treated surface, and, in contrast to chemical methods of surface treatment, the environmental friendliness of the process. In [7–11], the mechanisms of laser processing on metals (Al, Ti) by lasers of various types are considered.

Рис. 1. Механическое устройство батареи солнечной:

1 – силовой трубчатый элемент (углепластик); 2 – фитинг (титановый сплав)

Fig. 1. Mechanical device of solar battery:

1 – power tubular element (carbon fiber); 2 – fitting (titanium alloy)

Previous studies have been carried out [12; 13], where the influence of the titanium alloy surface treatment method on the strength of the adhesive joint of the titanium-titanium pair was determined. It was found that laser ablation of the surface has a positive effect on the adhesive strength of the titanium alloy surface.

Experiment

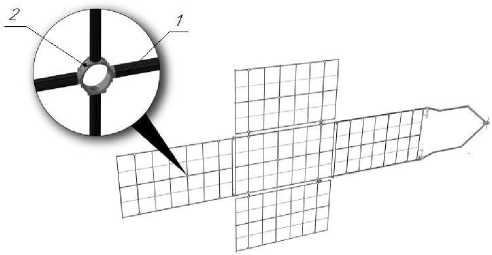

In this study, samples of titanium alloy OT-4 with dimensions of 70×20×2 mm and samples of bidirectional carbon fiber reinforced plastic KMU-4 with dimensions of 70×20×2 mm were used. The samples were glued together with a three-component adhesive VK-9 (OST 1-90281-86) with an overlap. Gluing was carried out according to OST 92-0949-74. Adhesive joint area S=300 mm2. A batch of 5 samples was tested to ensure statistical reliability. The geometric dimensions of the test specimen are shown in Fig. 2.

Рис. 2. Геометрические размеры образца клеевого соединения титана с углепластиком

Fig. 2. Geometrical dimensions of the sample of adhesive joint of titanium with carbon fiber

To determine the strength of the adhesive bond of the pair “titanium - carbon fiber”, shear tests were carried out. Mechanical testing was carried out 24 hours after gluing on a universal tensile testing machine (Eurotest T-50, S.A.E. IBERTEST, Spain) at a speed of 5 mm/min.

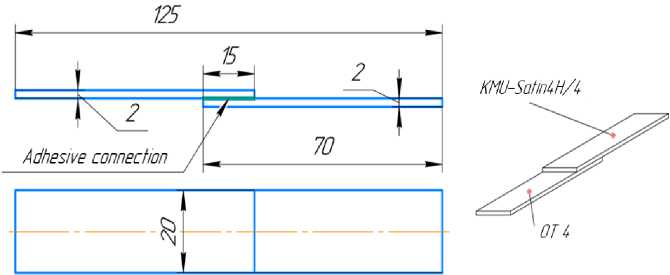

Laser treatment of the surface was carried out on an ytterbium pulsed fiber laser (IPG, YLPM-1 -4×200-20-20). In a previous study [13], characteristic surface textures were identified, which were taken as a basis in this work. Modes of laser processing are presented in Table 1. Laser wavelength is 1.064 µm, pulse repetition rate is 40 kHz, and pulse energy is 0.5 mJ. The laser beam movement pattern is bidirectional shading along one axis. The microstructure of the titanium alloy surface, depending on the processing mode, is shown in Fig. 3.

Titanium Alloy Laser Surface Treatment Parameters

Table 1

|

Mode No. |

1 |

3 |

12 |

13 |

|

Laser power, W |

10 |

20 |

20 |

10 |

|

Processing speed, mm/s |

200 |

200 |

200 |

400 |

|

Number of stripes per 1 mm |

15 |

15 |

25 |

25 |

Рис. 3. Микроструктура поверхности титана при лазерной обработке: a – режим № 1; b – режим № 3; c – режим № 12; d – режим № 13

Fig. 3. The microstructure of the titanium surface during laser processing: a – mode № 1; b – mode № 3; c – mode № 12; d – mode № 13

For comparison, specimens were made and shear tested with mechanical methods of surface treatment of titanium alloy: manual surface grinding in two directions and with sandblasting. The roughness of the treated surface was measured with a profilometer (TR110, TIME Group Inc., China). The results of surface roughness are presented in Table 2. The average value of CFRP roughness is 0.85 µm.

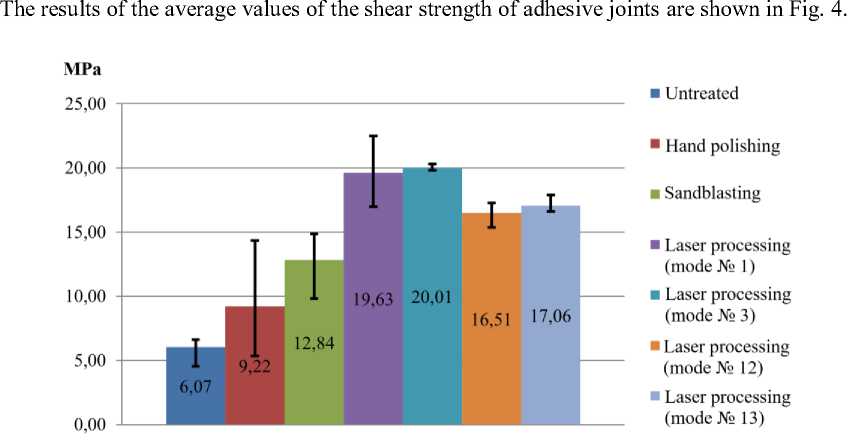

Рис. 4. Результаты испытаний прочности образцов на сдвиг

Fig. 4. Results of testing the strength of specimens for shear

Table 2

Surface Roughness Value of Titanium Alloy with different processing methods before gluing

|

Processing method |

Ti without processing |

Manual grinding |

Sandblasting |

Laser processing mode No. 1 |

Laser processing mode No.3 |

Laser processing mode No.12 |

Laser processing mode No.13 |

|

Ra, мкм |

0.78 |

1.23 |

1.15 |

6.5 |

9.65 |

5.37 |

1.76 |

Results and discussions

In Fig. 2 it can be seen that laser treatment of the titanium alloy surface favorably affects the strength of the adhesive bond of the titanium-carbon fiber pair. Comparing the results, the laser treatment increased the strength by more than 160% compared to the untreated surface. Since the metal is machined in production to increase the bonding area before bonding the metal to the composite, it is more accurate to compare the strength of laser-cut specimens with that of hand-ground specimens. Consequently, the strength of laser-treated samples increased by more than 80% relative to the average value of mechanical grinding

The highest value of shear strength was shown by samples with laser processing No. 1 and 3. This is due to the largest increase in the surface bonding area, as well as mechanical locking of the adhesive in the microrelief of the structure. Mode No. 13, having a slight increase in surface area, as can be seen from the surface roughness, showed a significant increase in the strength of the adhesive joint. This means that the improvement in shear strength caused by laser surface treatment is a mixed effect of increasing surface area, mechanically locking the adhesive, and changing the surface chemistry. The chemical composition of the surface structure under the influence of laser scanning is gradually transformed from Ti and Ti 2 O 3 to crystalline TiO 2 . Laser processing promotes the transformation of metal elements and oxides with low valence into an oxide with high valence [14; 15], which contributes to the adhesive bonding with the surface.

The nature of the destruction of the adhesive bond in the samples with laser processing is predominantly cohesive, but samples with the destruction of the carbon fiber material were also observed, i.e., the shear stresses in the composite material exceeded the adhesive strength. The nature of the destruction of samples without processing, with manual grinding and sandblasting showed adhesive and mixed destruction. It is worth noting that tests of samples with manual grinding showed a large spread of values, which indicates a low reliability of this gluing method.

If the results of the previous study [5] are compared with those presented, a decrease in the strength of the adhesive joint in the same laser processing modes by 25%, which is associated with the influence of the preparation of carbon fiber before gluing, can be observed.

Conclusion

The study showed that laser treatment of the titanium alloy surface before bonding to CFRP increases the adhesive strength by more than 80%, compared with modern bonding technology (machining). The highest strength index was shown by samples with processing modes that provide the largest bonding area (mode No. 1 and 3).

Список литературы Laser processing of titanium alloys to increase the strength of adhesive joint with cfrp

- Yang G., Yang T., Yuan W., Du Y. The influence of surface treatment on the tensile properties of carbon fiber-reinforced epoxy composites-bonded joints. Composites Part B. 2019, Vol. 160, P. 446–456.

- Molitor T. Young. Investigations into the use of excimer laser irradiation as a titanium alloy sur-face treatment in a metal to composite adhesive bond. International Journal of Adhesion & Adhesives. 2004, Vol. 24, P. 127–134.

- Anufrienko V. E., Volkov M. V., Nadein I. O., Filipov A. A. [A method of preparing the surface of metal fittings for gluing with pipes made of composite materials]. Reshetnevskie chteniya: materi-aly XXVI Mezhdunar. nauch.-prakt. konf. [Reshetnev readings: materials of the XXVI Intern. scien-tific-practical. conf.]. Krasnoyarsk, 2022, No. 1, P. 6–8 (In Russ.).

- Sibileva S. V., Karimova S. A. [Surface treatment of titanium alloys to ensure adhesion proper-ties (review)]. Aviatsionnye materialy i tekhnologii. 2013, No. S2, P. 25–35 (In Russ.).

- Frank L. Palmieri, Marcus A. Belcher, Christopher J. et al. Laser ablation surface preparation for adhesive bonding of carbon fiber reinforced epoxy composites. International Journal of Adhesion & Adhesives. 2016, Vol. 68, P. 95–101.

- Baburaj E. G., Starikov D., Evans J., Shafeev G. A., Bensaoula A. Enhancement of adhesive joint strength by laser surface modification. Int. J. Adhes. Adhes. 2007, Vol. 27, P. 268–276.

- Junying Mina, Hailang Wana, Blair E. Carlsonb et al. Application of laser ablation in adhesive bonding of metallic materials: A review. Optics and Laser Technology. 2020, Vol. 128, P. 106188.

- Ziwei Feng, Hongyun Zhao, Caiwang Tan et al. Nanosecond laser ablation for improving the strength of CFRTP and aluminum alloy adhesively bonded joints. Composite Structures. 2021, Vol. 274, P. 114369.

- Moroni F., Musiari F., Favi C. Influence of the laser ablation surface pre-treatment over the age-ingresistance of metallic adhesively bonded joints. International Journal of Adhesion & Adhesives. 2021, Vol. 105, P. 102764.

- Hailang Wan, Junying Min, Jianping Lin et al. Effect of laser spot overlap ratio on surface characteristics and adhesive bonding strength of an Al alloy processed by nanosecond pulsed laser. Journal of Manufacturing Processes. 2021, Vol. 62, P. 555–565.

- Wanying He, Peng Yao, Dongkai Chu et al. Controllable hydrophilic titanium surface with mi-cro-protrusion or micro-groove processed by femtosecond laser direct writing. Optics and Laser Tech-nology. 2022, Vol. 152, P. 108282.

- Rudenko M. S., Marchenko S. V., Ravodina D. V., Girn A. V., Mikheev A. E. [Methods for in-creasing the adhesion of a titanium alloy adhesive joint]. Reshetnevskie chteniya: materialy XXV Mezhdunar. nauch.-prakt. konf. [Reshetnev Readings: Materials of the XXV Intern. scientific-practical. conf.]. Krasnoyarsk, 2021, No. 1, P. 52–54 (In Russ.).

- Girn A. V., Rudenko M. S., Taygin V. B., Mikheev A. E., Ravodina D. V. [Effect of laser sur-face treatment of titanium samples on the adhesive strength of adhesive joints]. Kosmicheskie apparaty i tekhnologii. 2022, Vol. 6, No. 2, P. 90-99. Doi: 10.26732/j.st.2022.2.03 (In Russ.).

- Yifei Wang, Meiju Zhang, Kangmei Li et al. Study on the surface properties and biocompatibil-ity of nanosecond laser patterned titanium alloy. Optics and Laser Technology. 2021, Vol. 139, P. 106987.

- Yifei Wang, Jing Zhang, Kangmei Li, Jun Hu. Surface characterization and biocompatibility of isotropic microstructure prepared by UV laser. Journal of Materials Science & Technology. 2021, Vol. 94, P. 136–146.