Логистика в складировании строительных материалов и изделий

Автор: Радченко Артем Эдуардович, Петроченко Марина Вячеславовна

Журнал: Строительство уникальных зданий и сооружений @unistroy

Рубрика: Технология и организация строительства

Статья в выпуске: 1 (28), 2015 года.

Бесплатный доступ

В данной краткой обзорной статье рассматриваются основные вопросы, которые возникают в современных строительных организациях при выполнении процессов хранения и приобретения строительных материалов, конструкций и изделий на строительные площадки, участки и централизованные склады. В статье предлагаются решения и практические рекомендации по предотвращению этих проблем. Реализация предлагаемых мер позволит строительной компании повысить производительность труда и минимизировать убытки при хранении строительных материалов.

Проектирование, логистика, отделы закупок и складирования, система управления складом, строительная площадка, гражданское строительство, управление складским хозяйством

Короткий адрес: https://sciup.org/14322173

IDR: 14322173 | УДК: 624.05

Текст научной статьи Логистика в складировании строительных материалов и изделий

This short review article discusses the main issues that arise in today's construction organizations in carrying out the processes of storage and purchase of building materials, structures and products of building sites, plots and centralized warehouses. It proposes solutions and practical recommendations to prevent these problems. Implementation of the proposed measures would allow the construction company to increase productivity and minimize losses during storage.

Contents

Introduction: role of logistics processes in building organizations33

A brief literature overview33

The features of storage in the system of production construction products34

Problems in the organization of purchase and storage in today's construction organizations34

Possible ways out from the situation35

Summary36

Introduction: role of logistics processes in building organizations

Construction organization presents today not only the system which works directly with the development structures and buildings. The reality is that every construction firm, enterprise, facility has in itself consistence not only construction subdivision, designing subdivision and subdivision of control for quality of building production, but some different services and departments like accounting department, purchasing service, storage service, delivery service and many others. So that every construction organization is the difficult versatile system and the final result of activity of this system is getting profit by sale of ready building products [1, 7].

Purchasing and storage services are integral parts of the organization of building production enterprise today. The work of these departments provides trouble-free delivery on building areas necessary makings, constructions, materials, equipment, and so on, in common, all that is needed for development of buildings and constructions [21]. Oftentimes organization of work in these departments poses not always the optimal and the corresponding requirements of the increasingly growing rate of building production. Untimely arrival on central storages of necessary materials and makings from sources, wrong organization of intra-depot streams, nonoptimized inventory, paper chase, and many other negative factors can lead to delays on the construction site and consequently to dropping of rate of construction and, as a result, to decline in profit due to the shift in timing of facility commissioning. And this situation refers to not only central storages of large building organizations but to on-site storages. Repeated failure of comply with the POC of the organization on-site warehouses, irrational storage of materials, products and structures, the constant need to send small orders may increase the time required to search for products, downtime with any necessary construction processes, loss of productivity of worker and, consequently, of teams and site of works as a whole, and, as a result, again to shift the facility commissioning, increase costs and lower profits.

The manager of purchase department in organization, on-site managers and masters must consider these circumstances and seek for optimizing of material streams both within the centralized warehouses and on-site storage areas.

A brief literature overview

The research of logistics processes has huge attention in economic researches sphere. The development of transport systems, supply systems, logistics chains of supply from manufacturer to consumer meets many difficulties last time. How can manager optimize the process? How can he minimize costs for the organization and functioning of logistics processes? How to extract the maximum profit?

Economical researchers, theoretics of logistics especially Bauersocks D., Kloss D. [8], Hamilton S. [11], Van den Berg J., Zijm W. [13] and etc. laid down the fundamental principles of logistics, organization, processes, distribution, supply and sale of products by their researches for the last two years. These principles can be applied not only economic sphere but in many another sectors: information [19], food industry [6] and etc. The further development of logistic systems, integration of information technologies in it are presented in materials of Choua J.-S., Tseng H.-C. [19], Khan, A., Ehsan, N., Mirza, E., Sarwar, S.Z. [20]. For example, J.-S. Choua gives an example of successful introduction of program product named “CargoBeacon” on a huge warehouse with 2500 m2 square in his article. This program product made it possible to minimize costs of production storage, to rationalize the distribution of goods in warehouse and to increase of labor productivity and then profit of the company. The research works in this field still have not stopped.

The huge massive of work in researches of logistic processes integration in construction management has been made by foreign researchers [14-17, 21, 22]. Shin T.-H., Chin S., Yoon S.-W. and Kwon S.-W. in their work present the implementation in supply system of construction materials, products and components the RFID/WSN technology for optimal and fast tracking of cargo movements and control of the delivery “without losses”. Introduction of such system let the supply-operator to get actual information in real time, to optimize supply routes and organize even supply nets of construction materials for different consumers.

Another example is work of Scherer R.J., Schapke S.-E. [21]. This article presents a creation and implementation of universal multifunctional model which includes all areas of construction management especially the supply and warehouse module. All of this is integrated in program which allows feeling and seeing the reals processes of interaction of supply system and warehousing with another parts of whole system of construction company work, how it is integrated, how processes of interaction are developed.

Researches of introduction of logistic methods in Russia are only gaining a momentum. Works of Sokolov G. [6], Bolotin S. [9], Dickman L. [10] present bases of functioning of logistic system elements in construction especially system of warehousing and supply. However, today this is not enough. Methods which are contained in works of Antipov D., Gonyakina E., Ptukhina I. [2], Morozova T. [3, 4] disclose and describe the point situation of common and base processes in construction. That is why actuality of recommends design for elements of building sites supply, elaboration and adoption of models of delivery, in general, improvement of logistics in construction enterprises, is hot enough today. This article does not seek to solve these problems. But it will help to further define the vector of the research in this area. Consequently this article allows establishing some bases of economic-logistics methods in system of construction processes.

The features of storage in the system of production construction products

The warehouse department is designed to ensure receipt of materials from the definition of quality and quantity, rational placement and stacking of materials with regard to their physical and chemical properties, mechanization of loading and unloading, improvement of equipment for storage materials, structures and products; organization of withdrawal from stock, accounting wealth [3, 6, 22]. Warehouses are divided into the following types for operational purpose.

Base (central) storages . These warehouses is made in consistence of production and picking bases of managing production and technological completing units, and designed for centralized maintenance of objects which are constructed by building organization. These storages are situated on the territory of largest building site or other than. Materials, makings and constructions are sent subsequently on district and on-site storages and also in facilities for further processing and completing.

On-site storages . These warehouses are situated near for construction objects (working zones). It is open esplanades in most causes which are designed for temporary storage of precast ferro-concrete makings, wall material, and window and door blocks and also for accommodation of trays and containers with a brick and etc. Closed material warehouses, small mobile or collapsible storage containers are made for storage of equipment, overalls, finishing, electrotechnic and other materials. Stands for pre-assembly of building structures usually placed on a platform in the on-site storage area of the erection crane. For temporary storage of materials it is advisable to use permanent buildings [9, 16].

Warehouses of raw materials and finish products of auxiliary enterprises and workshops picking sites . They are situated near the places of placement of plants, workshops or mobile units.

Transshipment warehouses . These places are prepared for temporary storage of materials and makings while overloading them from one vehicle to another. It must be seek for maximum reduction of quantity of overloadings while transportation to reduce costs, organization of a clear system of storage and distribution of building materials [4, 10].

Problems in the organization of purchase and storage in today's construction organizations

As mentioned earlier, the system of supply and, in particular, the storage system as part of a construction company is not perfect. On the modern stage it has difficult in the correct order processing from construction sites as a whole and each of the accountable person (in-site manager) in particular. As a result it is made the formation of large-scale applications is not the supply of a large number of products required for the site, and a large number of small daily papers on materials and products that are needed often minutely, resulting an increasing of flights number of delivery vehicles and increasing quantity of drivers. This situation can bring to enlargement of charges in construction organization and decreasing of profit.

Also it is so important that practically all flow of documents is created in paper. Applications for the supply of products, credit orders in warehouses, registration cards and invoices are made "by hand" and this situation can lead to discrepancies in the verification and delivery of documents. And existence of these verifications is distracting as in-site manager, and supplier from conducting their duties which in turn leads to lower productivity. Paper document flow drop the speed of registration and collection of the order, while also increasing the time of delivery to the site.

The huge problem on building site is irrational and improper storage. In-site managers, masters and gangers often spend more time for searching of necessary equipment, materials and makings that is increasing the time for erection of constructions. And there are existing times when a particular material or making that you want to apply for a scope of work, may be very far away, that can lead to some difficulties in their feed.

Another problem may appear while construction huge objects or complexes. It’s not a secret that in-site managers can “share” storage units with each other as needed. This share is fixed in special journals. But discrepancies may arise while making these writings and it can create chaos in distribution of materials on site and appearing awkward questions from the accounting department.

We can highlight similar problems but in more grand scale while searching central warehousing. Wrong paperwork, non-optimal storage of products and makings on the principle “where free”, lack of reliable information about quantity of stocks, their unoptimized number and more other problems stand quite acute when administered at centralized warehousing storage facilities and distribution.

Summarizing all the above, we can conclude that the purchasing system should be optimized to reduce working capital costs, improve productivity and increase profit of the organization.

Possible ways out from the situation

After analyzing all mentioned above it can be propose the following measures to help improve the storage and purchasing, thereby increasing the performance of the construction company.

-

1. Applying of modern program complexes in organization of delivering building materials, constructions and makings from central storage to construction site. So that electronic network is prepared between warehouse and building site. This network will provide to organize fast creating applications from in-site manager for specialist-supplier, automate it, thereby allowing more quickly process to order, form the consignment and deliver it to the site, reduce paperwork, discrepancies and errors. Foregoing improvements will make to reach a situation where in-site manager or master will not be necessary to generate orders for delivery of products and control the amount of stock of certain elements at the site, and these functions will be transferred entirely on the shoulders of a specialist department of purchasing. Program complexes are made which can provide these functions [5]. Good example is DefSmeta.

-

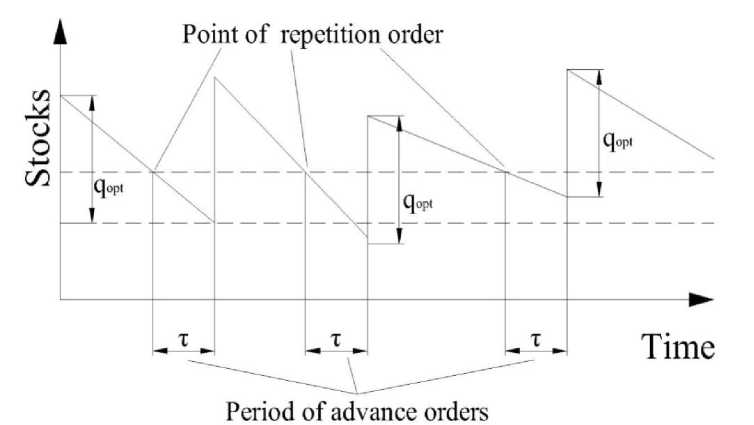

2. Application of orders for delivery of products to the construction site on the basis of a fixed size of the order that provides for the entry of equal pre-determined optimum parties (q opt ) across varying time intervals. The purchase order is given another party with a decrease in the size of the stock on the on-site warehouse to set a critical level – the "point of repetition order" [13, 15]. The system is shown on (Fig. 1).

Also it should be assumed that these processes can be fixed by not only in the system “in-site manager – supply department”, but related with accounting department of company and documentation department. Then necessity of permanent reconciliation of accounting department data and data of in-site manager disappears because all data will document and save in advance. This situation will provide to decreasing mistakes and deviations and, as a result, again for increasing productivity within the enterprise as well as on the construction site. In-site manager will spend more time on proper management of the construction of the building, rather than economic issues. And productivity will grow in head office by automatization of process of delivering documents. Thus, it will be the introduction of so-called modules of ERP-system [2, 18]. This system is oriented on the on continuous balancing and optimization of enterprise resources through specialized integrated suite of software applications, providing a common data model and process for all areas of the organization [11].

Figure 1. System with fixed size of the order

Intervals between purchases of the next party at the warehouse depend on the intensity of consumption of material resources.

The dignity of system with fixed size of the order is delivering of material by the same parties which provides to reduce the cost of delivery and maintenance of a stock.

-

1. Formation of larger orders for the purchasing of necessary goods, i.e. in-site manager or master generates a serious list of required makings, materials, equipment, etc. and provides a comprehensive application [8]. Thus, transport costs of a construction company will reduce as a whole (FLM), the number of vehicles needed in the park will be more optimal, and hence, the number pickers, stevedores, mechanics and other service personnel will be the best. This will reduce the overall expense of the number of flights between the individual sections and the warehouse [20].

-

2. Organization of rational storage and distribution of loads both at the central warehouse of a construction company and the on-site warehouses each site working practices [12, 14]. This improvement implies that, for example, it is necessary to generate an automated warehouse management system on the central warehouse, which allows accurately determine where exactly is the name of the required load. It can be realized by introduction of program complex Radio Beacon WMS which is designed to manage a warehouse complex distribution operations and it is a key part of a complex integrated solution that provides the connection parts such as wireless radios, corporate financial system and automatic storage equipment. In limits of project there should be set points of radio wireless LAN access Symbol Spectrum 24, put the wireless radios Symbol PDT 6848, to perform the marking should be set label printers Zebra 105SL and Z6M [17, 19]. It is necessary to carefully analyze systematized nomenclature of the warehouse center for solving these problems. It is needed to consider optimal zones and places for accommodation on the territory and racks, allocate special zones of storage and processing for flammable, heavy, bulky items on pallets. System provides allocation of these loading units of general storage load-flow and referrals to specialized areas of storage and processing. So that we get the opportunity of operating control for the arrival and unloading of construction products, reducing order processing time and thus increasing productivity.

Analogy of this system can be organized in on-site storage, central storage of huge object or complex of objects.

Список литературы Логистика в складировании строительных материалов и изделий

- Bolotin, S., Dadar, A., Ptuhina, I. (2014). Construction work tasks duration: pessimistic scenarios based on PERT method. Advanced Materials Research.2014. No. 945-949. pp. 3026-3031.

- Antipov, D., Gonyakina, E., Ptukhina, I. (2014). Application of ERP-systems in Russian construction sites Applied Mechanics and Materials.2014. No. 635-637. pp. 1921-1925.

- Морозова Т.Ф., Лаптева Н. Оценка присков при реализации инвестиционно-строительного проекта Инженерно-строительный журнал//2011. № 2(20). С. 48-51.

- Морозова Т.Ф., Петрова Е.М. Сокращение площади строительной площадки за счет оптимизации графиков движения рабочих//Инженерно-строительный журнал. 2011. № 7(25). С. 76-81.

- Kovács, A. Optimizing the storage assignment in a warehouse served by Milkrun logistics. (2011). International Journal of Production Economics.2011. No. 133(1). pp. 312-318.

- Соколов Г. Технология и организация строительства. Седьмое издание М., «Академия» 2008. 528 с.

- Стерлигова Ю. Управление запасами в цепях поставок М., Инфра-М, 2008. 430 с. (rus)

- Bauersocks, D., Closs, D. Logistical Management: The Integrated Supply Chain Process. Moscow: Olimp-business, 2008. 640 p.

- Болотин С. Организация строительного производства: третье издание М.: «Академия» 2009. 208 с.

- Dickman, L. Organization of construction production: Third Edition. ABH, 2006. 608 p.

- Hamilton, S. Maximizing your ERP system: a practical guide for managers. McGraw-Hill, 2003. 392 p.

- Rouwenhorsta, B., Reuterb, B., Stockrahmb, V., Van Houtumc, G., Mantela, R., Zijmc, W. (2000). Warehouse design and control: Framework and literature review.2000. European Journal of Operational Research. No. 122(3). pp. 515-533.

- Van den Berg, J., Zijm, W. (1999). Models for warehouse management: Classification and examples.1999. International Journal of Production Economics No. 59 (1-3). pp 519-528.

- Wang, Y. (2013). Research on Risk Control of Logistics Park Construction Project Based on Reliability Theory.2013. Procedia -Social and Behavioral Sciences. Volume 96. pp. 2194-2200.

- Shin, T.-H., Chin, S., Yoon, S.-W., Kwon, S.-W. (2011). A service-oriented integrated information framework for RFID/WSN-based intelligent construction supply chain management. Automation in Construction.2011. Volume 20. Issue 6. pp. 706-715.

- Nunes, K.R.A., Mahler, C.F., Valle, R.A. (2011) Reverse logistics in the Brazilian construction industry.2011. Journal of Environmental Management. Volume 90, Issue 12. pp. 3717-3720.

- Park, T., Kim, H. (2013). A data warehouse-based decision support system for sewer infrastructure management. Automation in Construction.2013. Volume 30. pp. 37-49.

- Shiaua, J.-Y., Lee, M.-Ch. (2010). A warehouse management system with sequential picking for multi-container deliveries. Computers & Industrial Engineering.2010. Volume 58. Issue 3. pp. 382-392.

- Choua, J.-S., Tseng H.-C. (2011). Establishing expert system for prediction based on the project-oriented data warehouse. Expert Systems with Applications.2011. Volume 38. Issue 1. pp. 640-651.

- Khan, A., Ehsan, N., Mirza, E., Sarwar, S.Z. (2012). Integration between Customer Relationship Management (CRM) and Data Warehousing. Procedia Technology.2012. Volume 1. pp. 239-249.

- Scherer, R.J., Schapke, S.-E. (2011). A distributed multi-model-based Management Information System for simulation and decision-making on construction projects. Advanced Engineering Informatics.2011. Volume 25. Issue 4. pp. 582-599.

- Shabtai, I., Bockb, T., Stoliar, Y. (2014). A New Approach to Building Design Modularization. Procedia Engineering.2014. Volume 85. pp. 274-282.