Mathematical modeling of the flat ingot casting process for solving automation problems

Автор: Novikov V.A., Piskazhova T.V., Doncova T.V., Belolipetskii V.M.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.25, 2024 года.

Бесплатный доступ

Aluminum alloys are widely used in the production of aircraft due to their strength, lightness, corrosion resistance, and necessary electrical conductivity. At the same time, aluminum ingots used in further processing of the space industry must be of high quality. Technological problems and defects arise when temperature, speed, and other technological parameters of casting are not observed, or when modes change. At the same time, foundry processes are partially automated; the human factor significantly affects product quality and work safety. Therefore, automation of these complex processes using mathematical models to predict casting parameters is an urgent task. The goal of the work is to create mathematical models available for use in automated process control systems (APCS), as well as for the development of a digital twin. The work presents simplified formulas for modeling the temperature distribution of an aluminum ingot during the casting process, cooling the metal when moving along a metal path, and test calculations of the temperature distribution inside the ingot when the ingot reaches a fixed length. The results of this work can be used to improve the efficiency and accuracy of controlling the process of casting aluminum ingots, to eliminate emergency situations.

Mathematical model, semi-continuous casting of aluminum ingots, digital twin

Короткий адрес: https://sciup.org/148329730

IDR: 148329730 | УДК: 65.011.56 | DOI: 10.31772/2712-8970-2024-25-1-144-156

Текст научной статьи Mathematical modeling of the flat ingot casting process for solving automation problems

Aluminum is one of the lightest metals, therefore it is widely used in the aerospace industry, where minimizing weight is a critical factor for improving efficiency and fuel economy. At the same time, aluminum has high strength, which makes it possible to create lightweight components with sufficient strength to withstand high loads during flight. Aluminum is also highly resistant to corrosion, which is an important quality for materials used in the aerospace industry. The air and space environment can be aggressive, so materials must retain their properties and durability for a long time.

The casting process of aluminum ingots is an important part of industrial production in various industries, and the quality and mechanical properties of the resulting ingots depend on effective control of the casting process and control of temperature distribution during solidification.

However, traditional methods of control and optimization of the casting process based on trial and error can be time-consuming, expensive and limited in accuracy. In this regard, mathematical modeling becomes a powerful tool for optimizing and controlling the casting process of aluminum ingots[1].

The process is characterized by technological problems and defects, such as porosity, cracks, liquation surges, thermal stress and deformations, which negatively affect the quality and reliability of the ingots obtained. Deffects usually occur when casting technology is violated, recipes are not followed, or new casting recipes are tested. A mathematical model that reflects the cooling rate of the metal inside the ingot during casting, allows you to predict and analyze the thermal processes occurring inside the ingot during cooling, and provides information about temperature gradients and heat distribution.

The use of a mathematical model allows for virtual experiments and optimization of process parameters in order to improve the quality of ingots and prevent possible defects [2]. Important parameters that can be optimized using such a model are the temperature of the melt and the environment, as well as external factors such as heat exchange with the crystallizer and the cooling rate.

In addition, from the point of view of safety, it becomes possible to control the thickness of the crystallized layer of the ingot at the outlet of the mold, thereby preventing metal breakthroughs into the caisson.

At the same time, if we consider a mathematical model for use in a digital twin [3] of a casting unit, it should be computationally efficient and capable of producing results in a reasonable time. The model should be flexible and customizable for various types of ingots, alloys and casting processes, as well as validated and verified using experimental data.

Technological process

The technological process of casting aluminum ingots is carried out using the method of semi-continuous casting. The molten raw aluminum is transported in vacuum buckets from the electrolysis production buildings to the foundry and poured into a mixer with a capacity of 40-100 tons. In the mixer, the metal is mixed, settled and reaches the required temperature with the help of heating elements located in the upper part of the mixer.

When the required characteristics of the metal are achieved, the casting process begins. Aluminum is supplied through a metallotract to a casting machine designed for fixing casting equipment, forming ingots of the required cross-section (crystallizers) and length. For casting technical aluminum (AlSi7MgSr, AlSi3, AlSi3Sr), crystallizers with a size of 700×400 mm are usually used. Aluminum enters the water-cooled mold through an adjustable valve and begins to crystallize from the walls of the mold to the center. At the same time, the pallet, located at the start in the lower part of the mold, begins to move vertically downwards and moves until the ingot reaches the required length [4]. This technology for modern casting cascades has the ability to regulate the amount of incoming cooling water to the mold, the speed of lowering the pallet, the volume of metal coming from the mixer into the mold and its temperature in the mixer.

Mathematical modeling to control the casting process

In accordance with the process discussed above, in order to develop a complete digital model of the operation of the devices and their interaction, it is necessary to consider heating the metal in the mixer, releasing the metal from the mixer, metal flowing through the metallotract, pouring metal into the compartments of the casting machine and, in fact, the process of casting ingots itself. Previously, we considered the technology of feeding metal from a mixer into a metal tract for a rotary and stationary mixer and developed control algorithms based on mathematical models [5]. Let's focus on the last points in this article.

A model of metal cooling during passage through a metallotract

The first unit of the construction is a mixer for the preparation of the melt. The temperature of the metal at the outlet of the furnace entering the tray ( T 0) is known.

At a steady casting speed U L and the size of one mold S kr = 700×400 mm, the metal consumption on the casting table of 4 molds will be equal to

Q M = 4 ⋅ S кр ⋅ U Л .

Provided that the level in the tray is maintained at the same point, the metal consumption in the tray can be considered equal to the consumption on the casting table. Knowing the dimensions of the tray, we calculate the area of its cross-section S L.

Then the speed of movement of the metal in the tray when it is filled by 80 % will be determined as follows:

U M =

Q M

S Л ⋅ 0,8.

To calculate the temperature of the metal in the tray T m, we use the thermal conductivity equation for a moving medium. In the stationary case, neglecting thermal conductivity in comparison with advective transfer, similar to the work [6], we use the equation

ρ⋅ с ⋅ U M ⋅∂ T М ∂ x

- K M - E( T М - T E) - K M - ДН( T М - T ДН) - K M - СТ( T М - T СТ),

where K i–j are the heat transfer coefficients; c is the specific heat capacity; p is the density of the metal; T E is the ambient temperature; T DN is the temperature of the bottom of the tray; T CT is the temperature of the walls of the tray; x is the axis directed along the tray.

His analytical solution, taking into account T 0 , will be

( T 0 ⋅ k 0 - а ) ⋅ e + a

TМ (х) = k0

where k 0 = K M - В + K M - ДН + K M - СТ; а = K M - В ⋅ T В + K M - ДН ⋅ T ДН + K M - СТ ⋅ T СТ; b =

ρ⋅ с ⋅ U M

.

Table 1 presents the initial data for calculating the cooling of the metal as it moves along the metallotract.

Table 1

Initial data for calculating the temperature of the metal in the metallotract

|

Parameter |

Meaning |

Dimension |

|

Density of the liquid phase of aluminum ( p ) |

2450 |

kg/m3 |

|

Heat capacity of the liquid phase of aluminum ( c ) |

1100 |

J/(kg·K) |

|

Casting Speed ( U L) |

75 |

mm/min |

|

Crystallizer area ( S KP ) |

0.28 |

2 m |

|

Tray cross-sectional area ( S L ) |

0.0279 |

2 m |

|

Metal–wall heat transfer coefficient ( K M–CT ) |

400 |

W/m2·K |

|

Metal–bottom heat transfer coefficient ( K M–BOTTOM ) |

400 |

W/m2·K |

|

Metal–air heat transfer coefficient ( K M–V) |

50 |

W/m2·K |

|

Wall temperature (TST) |

80 |

°C |

|

Bottom Temperature ( T DAY) |

90 |

°C |

|

Air temperature ( T V ) |

20 |

°C |

|

The initial temperature of the metal ( T 0 ) |

705 |

°C |

|

Length of the metallotract |

2.5 |

м |

Table 2 shows the calculated values of the metal temperature at several points of the path. With the initial data of Table 1, the cooling of the metal from the die to the entrance into the casting machine was 10 ° C.

Table 2

The results of modeling the temperature of the metal in the path

|

Distance from the flight deck, m |

Tм(x), ºС |

Distance from the flight deck, m |

Tм(x), ºС |

Distance from the flight deck, m |

Tм(x), ºС |

|

0 |

705 |

1 |

701.27 |

2 |

697.58 |

|

0.2 |

704.25 |

1.2 |

700.53 |

2.2 |

696.84 |

|

0.4 |

703.50 |

1.4 |

699.79 |

2.3 |

696.47 |

|

0.6 |

702.76 |

1.6 |

699.05 |

2.4 |

696.10 |

|

0.8 |

702.02 |

1.8 |

698.31 |

2.5 |

695.74 |

The model takes into account a number of factors such as the initial temperature of the metal, geometric parameters, thermal conductivity of materials, flow rate and temperature of the cooling medium.

The results obtained using the metal cooling model during passage through the metallotract were compared with real experimental measurements. The comparison showed a good agreement between the model and the measurements, which confirms the adequacy of the model.

A set of models for calculating continuous casting of an ingot

Of course, continuous casting of ingots is a complex thermophysical process and, from the point of view of classical modeling, it is necessary to carry out two- and three-dimensional calculations, as the authors of the articles [7-10] do. But our task is to make simplified models and schemes for fast calculations in the automated control system. At the same time, we try to decompose the problem of the three-dimensional process in two dimensions: in height and width of the ingot.

The processes also need to be divided into casting stages: the initial stage is the filling of molds; the acceleration stage is a gradual increase in casting speed and water consumption; the steady–state mode is the movement of the platform at a constant speed.

The models described below are suitable for all stages, but we will perform calculations for a steady state with a constant lowering speed of the casting platform.

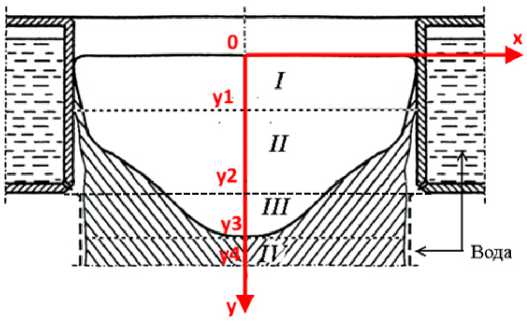

Figure 1 identifies four regions for modeling the temperature distribution in the ingot section:

I – cooling of the metal in interaction with the crystallizer;

-

II – the formation of an air gap between the ingot and the crystallizer, water does not enter this region;

-

III – the beginning of the water supply to the walls of the ingot, there is a hole;

IV– all surfaces are in the water, there is no hole.

The depth of the hole in flat ingots can be expressed by the equality of [11; 12]:

h Л -

[ q + 2 c v T P - T H )] -v л b 2 X- T P - T h )

where c is the heat capacity of the solid phase; γ is the density of the solid phase; b is half the thickness of the ingot; q is the specific heat of crystallization; T KR is the crystallization temperature; v Л - casting speed; X - thermal conductivity of the alloy; T H is the temperature of the outer surface.

Introduction of the coordinate system. The origin of coordinates is located on the surface of the liquid metal in the middle of the long side, the y axis is directed downward in the direction of movement of the table, the x axis is in the middle of the longitudinal side.

Рис. 1. Разделение слитка на области в процессе литья. Введение системы координат

Fig. 1. Dividing the ingot into regions during the casting process. Introduction of the coordinate system

The temperature distribution over the height of the ingot, taking into account the speed of its movement, is considered similarly to the model of temperature distribution and crystallization of a moving metal in a casting wheel [13]. We consider the movement along the y axis and , accordingly , the temperature only along this axis Т ˆ ( t , y ) . Moreover, we will make assumptions that all dynamic changes along the y axis consist in a change in the casting speed, in our terminology, the speed of metal movement.

The complete equation of heat distribution in moving media is given, for example, in [14]. In our assumptions, the following equation is the starting one:

dT_ ,S2T pCU -X—— + Q, ду dx 2

where T is the temperature of the moving medium; ρ is the density; C is the specific heat capacity; λ is the coefficient of thermal conductivity; Q – internal heat sources; x , y are coordinates; U is the speed of movement of the platform (casting).

Introduction of the average temperature values for the thickness of the layer (in x coordinate):

л

Т=

Х /2

δ

∫ Tdx .

- Х /2

Here δ is the thickness of the ingot (on the long side); δ = X is the longitudinal size of the ingot.

Integration of the equation (6) according to the thickness of the ingot:

л

ρ CUdT = λ∂ T dу δ ∂ х

- Х

λ ∂T

-

δ ∂х

+ Q .

Х х =

We use boundary conditions:

∂T λ

∂ х

Х

х =-

∂T =λ

∂ х

Х х =

л

=α i ( Т M - Т i ),

where Т i is the outer temperature at the current calculation stage ( i = 1, 2, 3, 4 – crystallizer, gap, water, water) and α i is the corresponding heat transfer coefficient.

Then we get the following equation:

ˆ

ρ CU dТ =- 2 α i ( Т ˆ - Т i ) + Q . dу δ

To proceed to a numerical solution, we present the ratio (10) as a difference scheme:

ˆˆ

Т ˆ n = Т ˆ n - 1

+ ∆у ⋅

α i ( Т n - 1 δ

- Т i n ) + Q

ρ CU

The initial condition for equation (10) is the temperature of the metal at the outlet of the metallotract, calculated by the formula (4). Q sources are present in regions I, II, and III due to the release of heat during metal crystallization.

Thus, according to the formula (11) with the set casting parameters, we obtain the average temperature value for the thickness of the ingot, Тˆ(у), which we will coordinate as the initial condition for calculating the temperature change in the thickness of the ingot.

We formulate boundary problems for the heat transfer process in the selected regions.

X

The region I is characterized by coordinates 0 ≤ y ≤ y1; 0 ≤ x ≤ 2 (Fig. 1), a one-dimensional equation of thermal conductivity is used:

∂ T ∂ 2 T

c ρ 1 =λ 1. 1 1 ∂ t 1 ∂ x 2

Boundary conditions:

T 1

0 = Т ( y 1/2) = Т I , 0

λ 1 ∂ T 1 ∂ x

Х x =

= -α 1 ( Т 1 - Т KР ),

where ТKР is the temperature of the crystallizer. The initial condition: Т 1 ( х ,0) = ТI .

Region II - y < y < y 2 ; 0 < x < — :

Boundary conditions:

T 2

dT2 _. d2 T2

Cl Р2 — ^2 0 ‘

22 d t 2 dx2

. — T ( У 1 + ' ) — Т II.

x — 0 2

„ 5 T _ „

X 2 Т“ — -a 2 (T 2 - T ВОЗД )'

d x x — X

The initial condition: Т 2 ( х , 0) — T II .

Region III - y 2 < y < y 3 ; 0 < x < — .

In this region, the coordinate is y 3 linked to the depth of the hole (5) and can change.

d T T

C3 Рз —3 — X —r3 dt 3 dx2

Boundary conditions:

T 3

„ — T( y 2 + y 3^2 ) — Tш . x — 0 2

x, 'T dx

.

X x—

a 3( T 3 T ВОДЫ)-

_ Л

The initial condition: T 3 ( х , 0) — T I .

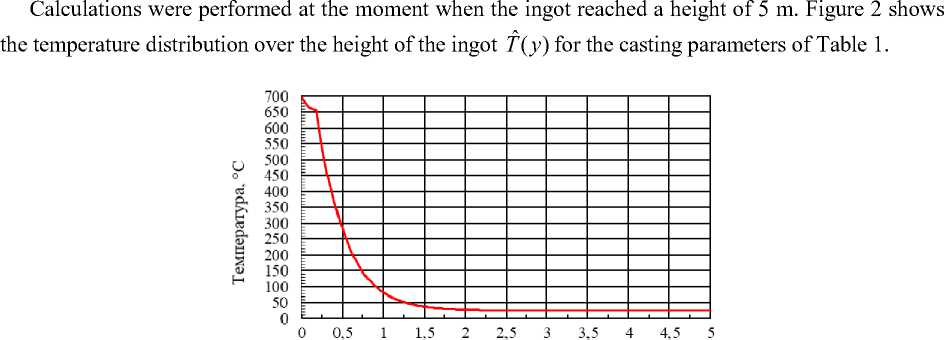

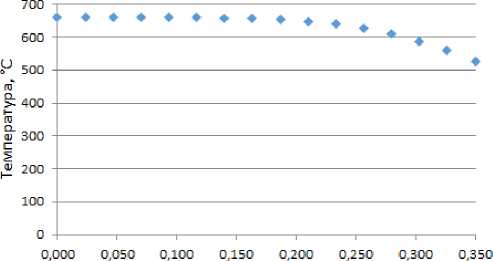

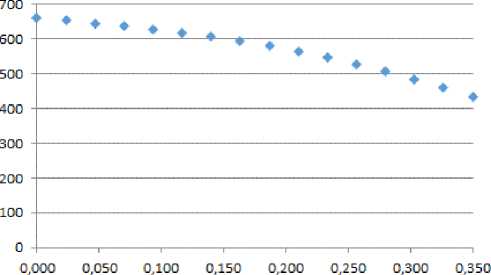

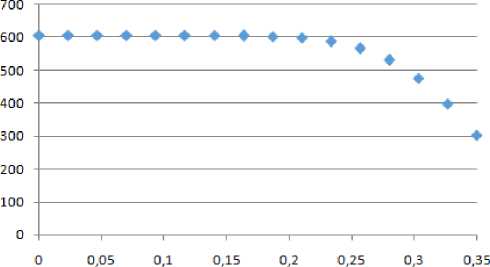

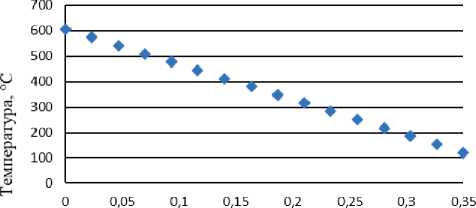

Region IV -y3 < y < y4; 0 d T4 _. d2T4 c4Р4 Л. — X4 2 • dt dx Boundary conditions: T4 = T(y3 + ) — TIV, x—0 2 у n- X4 5x X x—— — a4(T4 Tводы). The initial condition: T4( х ,0) — TIV. The numerical solution of the boundary value problem is found according to an explicit scheme. A uniform coordinate difference grid is introduced. Ax — xi+1- xi, x1 — 0, xi — X /2, 1 < i< ii. Grid equations for internal points, where Δ t is the time step (index n), are written T n=Tn-1 + ———(Tn-1 i iT. 2 (i+1 Ax2c-p _ 2Tn-1+ T--1). For the boundary points, xii — X /2 relations are obtained for calculating the temperature on the ingot wall: rpn_[a- Ax rp . nn Ta— I X THc +Ti-1 where ТНСis the temperature of the external environment; α is the coefficient of heat exchange with the external environment; λ is the thermal conductivity of the metal in this region of the ingot. The calculation procedure based on the simulation model of the casting machine will be as follows: 1. Calculation of the temperature change of the metal as it moves along the metallotract according to the formula (4). The temperature value at the end of the path is considered the initial condition for the next step. 2. Calculation of the depth of the hole at the specified casting parameters according to (5). 3. Numerically solving equation (10), we obtain the temperature distribution over the height of the ingot. 4. We find the temperature distribution over the thickness of the ingot in the middle of region I, the temperature of the ingot walls, numerically solving tasks (12) and (13). 5. We find the temperature distribution over the thickness of the ingot in the middle of region I, the temperature of the ingot walls, numerically solving tasks (12) and (13). 6. We find the temperature of the ingot walls in the upper part of area III, since it is here that an accident may occur due to water entering an insufficiently crystallized surface. 7. We find the temperature distribution over the thickness of the ingot in the middle of area I, the temperature of the ingot walls, numerically solving tasks (12) and (13). 8. We find the temperature distribution over the thickness of the ingot in the middle of region I, the temperature of the ingot walls, numerically solving tasks (12) and (13). 9. We change the height of the ingot, go back to calculating the depth of the hole (step 2). The numerical solution of problems (12)–(19) is carried out according to the difference schemes (20) and (21). Calculations of ingot temperatures during the casting process Test calculations of the temperature distribution in the ingot were performed based on the formulas obtained and the calculation procedure presented. The initial data for the calculation are given in Table 3. Table 3 Initial data for calculating ingot temperatures Parameter Meaning Dimension Density of the liquid phase of aluminum (p) 2450 kg/m3 Heat capacity of the liquid phase of aluminum (c) 1100 J/(kg·K) Casting Speed (U L) 0.00108 m/sec Length step (∆y) 0.01 м Coefficient α (metal – metal) 1000 W/m2·K Ingot thickness (δ) 0.7 м Crystallizer temperature (Tkr) 200 °C Water temperature 25 °C Metal temperature (T 0) 695 °C Heat of crystallization 390000 J/kg Coefficient α (metal – metal) 700 W/m2·K Coefficient α (metal – metal) 3000 W/m2·K Air Gap Temperature (air) 300 °C Liquidus temperature 622 °C Solidus temperature 570 °C Density of the liquid phase of aluminum (p) 2710 kg/m3 Hole height (H L) 0.43 м Heat capacity of the liquid phase of aluminum (c) 1027 J/(kg·K) Thermal conductivity of aluminum (λ) 203.5 W/m·K Высота слитка, м Рис. 2. График расчета температуры слитка по высоте Fig. 2. Graph for calculating the temperature of the ingot by height Presentation of the graphs of calculations of the horizontal temperature distribution for region II (y from 0.15 to 0.2 m). Figures 3 and 4 show the calculation at different points in time from the beginning of the calculation (from the beginning of the receipt of new metal in this region). Расстояние от центра слитка до боковой грани, м Рис. 3. График распределения температуры слитка по горизонтали, область II в момент времени t = 60 с Fig. 3. Graph of the horizontal temperature distribution of the ingot in region II at time t = 60 s It can be seen that the temperature distribution becomes almost linear 5 minutes after the start of the calculation (Fig. 4). At the same time, the minimum temperature reached by the end of the ingot in this region during prolonged cooling is 350 ° C. For the analysis of region III, we will consider not the middle, but the beginning of this region, since this place is of the greatest interest. It is here that, with an insufficiently crystallized outer crust, metal spills are possible. This place corresponds to the height of the ingot y = 0.2 m. Fig. 5 shows that with the specified casting parameters, the solidus point is located at the moment the ingot leaves the mold (30 seconds after the start of the calculation) under a stream of water at a distance of 10 cm from the ingot surface, i.e. there is 10 cm of solidified metal. 3-5 seconds after the start of the calculation, the solidus point is located at a distance of 4-5 cm from the end of the ingot. It should be noted that the models presented above are not complete for determining such an important point as the thickness of the solidified metal at the end of the ingot when going under water cooling. As an initial condition for region III, it is necessary to take not the average temperature of the layer, but the temperature distribution along the x coordinate at a certain design moment when calculating layer II. This can be applied to all regions except I, but for this it is necessary to correctly correlate the casting speed, i.e. the movement of the ingot, with the calculation speed. In the future, this will be done, but for now, the estimates of the temperature distribution can be considered maximum and quite suitable for determining the temperature stabilization time in the ingot. Расстояние от центра слитка до боковой грани, м Рис. 4. График распределения температуры слитка по горизонтали, область III в момент времени t = 300 с Fig. 4. Graph of the horizontal temperature distribution of the ingot, region III, at time t = 300 s Расстояние от центра слитка до боковой грани, м Рис. 5. График распределения температуры слитка по горизонтали, область III в момент времени t = 30 с Fig. 5. Graph of the horizontal temperature distribution of the ingot in region III at time t = 30 s Расстояние от центра слитка до боковой грани Рис. 6. График распределения температуры слитка по горизонтали, область III в момент времени t = 1200 с Fig. 6. Graph of the horizontal temperature distribution of the ingot in region III at time t = 1200 s Thus, Figure 6 shows the steady-state temperature distribution in the ingot in region III 20 minutes after the start of the calculation. Of course, this area has already gone lower over time, a new metal has entered the region and the calculation is rather a test value for checking the model. The calculation results for regions I and IV are shown in Table. 4 and 5. Table 4 Calculation results for region I Time, sec Distance from the center of the ingot to the outer boundary, m 0 0.46 0.93 0.14 0.21 0.26 0.3 0.35 0 675.0 675.0 675.0 675, 675.0 675.0 675.0 604.6 120 675.0 672.3 667.5 658.0 628.3 594, 547.1 488.6 1200 675.0 644.6 614.1 583.5 537.5 506.7 475.9 444.9 Table 5 Steady-state temperature distribution for region 4 (y = 1 m) Time, sec Distance from the center of the ingot to the outer boundary, m 0 0.46 0.93 0.14 0.21 0.26 0.3 0.35 1200 82.2 75.9 69.6 63.2 53.6 47.2 40.8 34.7 To verify the adequacy of the model, it is necessary to compare it with experimental data. But in the described technological process, it is possible to measure the temperatures of only the metal in the metallotract. All other surfaces of the ingot and tooling are closed or in water. We measured the surfaces of the finished ingot just extracted from the casting machine and performed calculations using ProCAST software [15]. We can talk about the qualitative compliance of the above calculations with possible measurements and calculations in the ProCAST software. For more accurate identification of models in the future, it is necessary to carry out calculations with a change in the height of the ingot, comparing the casting speed and calculation time for the width of the ingot, adjusting the initial conditions in some regions. Conclusion The article presents simplified formulas for modeling the temperature distribution of an aluminum ingot during the casting process. The main intention was to create formulas available for use in automated process control systems in order to develop a digital twin. These formulas are based on key parameters such as the initial temperature of the molten aluminum, the ambient temperature, the casting speed and the thermophysical coefficients of the ingot material. They represent a compromise between accuracy and computational complexity, which makes them possible for use in automated control systems. The implemented algorithm for calculating the temperature of the ingot based on the proposed formulas will allow operators and engineers to quickly obtain information about the temperature regime of the ingot in real time. Further research and experience can help to improve and expand the presented formulas and algorithms, introducing innovations in the field of control of the casting process of aluminum ingots.

Список литературы Mathematical modeling of the flat ingot casting process for solving automation problems

- Shterenzon V. A. Modelirovanie tekhnologicheskikh protsessov [Modeling of technological processes]. Ekaterinburg, Izd-vo Ros. gos. prof.-ped. un-ta Publ., 2010, 66 p.

- Bezrukikh A. I., Baranov V. N., Konstantinov I. L. Modeling of casting technology of largesized ingots from deformable aluminum alloys. The International Journal of Advanced Manufacturing Technology. 2022. Doi: 10.1007/s00170-022-08817-w.

- GOST R 57700.37–2021. Komp'yuternye modeli i modelirovanie. Tsifrovye dvoyniki izdeliy. Obshchie polozheniya [State Standard R 57700.37–2021. Computer models and simulation. Digital twins of products. General provisions]. Moscow, Standartinform Publ., 2022.

- Napalkov V. I., Cherepok G. V., Mahov S. V., Chernovol Ju. M. M. Nepreryvnoe lit'e alyuminievykh splavov [Continuous casting of aluminum alloys]. Moscow, Intermet Inzhiniring Publ., 2005. 512 p.

- Novikov V. A., Piskazhova T. V., Doncova T. V. [Solving some problems of automation in control of a casting machine]. Tehnologiya metallov. 2023, No. 9, P. 38–48 (In Russ.).

- Piskazhova T. V., Sidel'nikov S. B., Belolipeckij V. M. et al. [Virtual CC&RP – a mathematical model for the control of the unit CC&RP and its visualization with the help of software products WINCC 7.0 and STEP 7]. Vestnik SibGAU. 2015, No. 2(54), P. 140–144 (In Russ.).

- Minakov A. V., Pervuhin M. V., Platonov D. V., Hacajuk M. Ju. [Mathematical model and numerical simulation of aluminum casting and solidification in magnetic fields with allowance for free surface dynamics]. Zhurnal vychislitel'noj matematiki i matematicheskoj fiziki. 2015, Vol. 55, No. 12, P. 2094 (In Russ.). Doi: 10.7868/S0044466915120091.

- Budilov I. N., Lukashhuk Ju. V., Lukashhuk S. Ju. [Modeling of formation of aluminum ingot in process of half a continue cast]. Vestnik Ufimskogo gos. aviac. tehnich. un-ta. 2011, Vol. 15, No. 1(41), P. 87–94 (In Russ.).

- Fomina E. E., Zhiganov N. K. [Computer modeling and visualization of discrete-continuous casting of nonferrous metal and alloys]. Komp'yuternye issledovaniya i modelirovanie. 2009, Vol. 1, No. 1, P. 67–75 (In Russ.).

- Bezrukih A. I., Konstantinov I. L., Grishko G. S. et al. [Simulation of the process of aluminum alloy ingots chrystallization in semi-continuous casting]. Metallurg. 2023, No. 11, P. 159–164 (In Russ.). Doi: 10.52351/00260827_2023_11_159.

- Napalkov V. I., Frolov V. F., Baranov V. N. et al. Plavlenie i lit'e alyuminievykh splavov: monografiya [Melting and casting of aluminum alloys] Krasnoyarsk, Sib. feder. un-t Publ., 2020, 716 p.

- Hnykin A. V. [Study of the dependence of the hole shape of an aluminum ingot on the type of crystallizer]. Fiziko-himicheskiy analiz svojstv mnogokomponentnyh sistem. 2006, No. 4, P. 6 (In Russ.).

- Jakiv'juk P. N., Piskazhova T. V., Belolipeckij V. M. [Mathematical model to control rotary crystallizer cooling]. Vestnik Irkutskogo gosudarstvennogo tehnicheskogo universiteta. 2017, Vol. 21, No. 9(128), P. 104–113 (In Russ.). Doi: 10.21285/1814-3520-2017-9-104-113.

- Landau L. D., Livshic E. M. Teoreticheskaja fizika. T. VI. Gidrodinamika. [Theoretical physics. Vol. VI. Hydrodynamics]. Moscow, Nauka Publ., 1986, 736 p.

- ProCAST Casting Simulation Software. Available at: https://www.esi-group.com/products/ procast (accessed: 05.01.2024).