Mathematical modeling of the technological process of improving the quality of polymeric products of machine-building purposes

Автор: Larchenko A.G., Filippenko N.G., Livshits A.V.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 1 т.20, 2019 года.

Бесплатный доступ

In this scientific work, a method of controlling high-frequency products from polymeric composite materials is con- sidered. The authors of the work present the rationale for choosing a method of high-frequency diagnostics as the most suitable for non-destructive testing of products from polymeric materials of machine-building and rocket-space pur- poses. In the presented article, the primary task of creating and studying a mathematical model of the effect of high- frequency radiation on a polymer product, including those with a “metallic inclusion” defect, has been stated and solved. In addition, the work presents the calculations of diagnostic parameters using the mathematical model devel- oped during the study. The calculation of the dynamics of heating the product and the temperature distribution during the control process is presented. The results of the calculation of specific power are described, the dependence of the instantaneous power consumption on the warm-up time is found. In the study based on a mathematical model, the Aleo- Diagnost software package was developed and registered, which is directly intended to ensure the functioning of the diagnostic devices and the investigation of the monitoring process. In addition, the developed complex allows solving a number of such practical problems as the calculation of the operating voltage depending on the geometrical parameters of the product and the determination of the value of energy consumed for monitoring the product for a specified period of time. This stage was necessary, as the consumed energy is the main output parameter of the diagnosis. In addition, the value of energy consumed is taken as the basis for the organization of the process of non-destructive testing in the automated mode. The solution of the tasks in this work has significantly reduced the cost of preparation of diagnostic operations, as well as improve the quality of control of products on an industrial scale at the stages of manufacture, operation and during repair work. The article also presents practical results, conclusions.

Control of high frequency currents, device for products diagnosing, polymer products, automated control system, diagnosing products of complex configuration, mathematical model of the diagnostic process, software, non destructive testing

Короткий адрес: https://sciup.org/148321889

IDR: 148321889 | УДК: 620.192 | DOI: 10.31772/2587-6066-2019-20-1-106-111

Текст научной статьи Mathematical modeling of the technological process of improving the quality of polymeric products of machine-building purposes

Introduction. Intensive development of modern science and technology demands the development and use of structural materials with special physic-mechanical characteristics. In this regard polymeric composite materials got great prospects for application in various branches of mechanical engineering and the rocket industry. With the increasing volume of polymeric products and increased performance requirements, the problems of materials quality improvement and reduction of manufacture costs have become relevant [1–6]. The main means in the solution of the problem of manufactured products quality improvement at various stages of life cycle is the use of nondestructive monitoring. One of such ways of monitoring is the high-frequency method (HF) of diagnosing implemented in industrial conditions on the basis of the UZP 2500 device [7–9]. This method is based on local defects identification mainly in products from polymeric, composites by the impact of an external electric field on the studied object, and further amplitude intensity synthesis of the complex of output, operated diagnostics parameters emergence. HF method allows to carry out high precision monitoring without mechanical influence, to define a type of defect, to restore physic-mechanical properties of a product [10].

Main problems. Research tasks statement. It should be noted that in modern production process a wide range of products and details of complex spatial shape applied in mechanical engineering and space industry creates particular difficulties in the course of diagnosing using the high-frequency radiation method. The conducted theoretical and pilot research results presented in works [11–15] confirm that for the process of complex configuration products monitoring it is necessary to select the mode of high-frequency diagnosing each time, to develop rather complex design devices (electrodes) and the equipment. Taking into account the complexity of industrial equipment manufacture, difficulty of equipment setup and also the selection of diagnostics modes for polymer products, it is obvious that the development and practical use of mathematical model operation of monitoring process, and implementation of the software on the basis of the designed model will allow to reduce considerably the cost of preparation for diagnostic operations and also to increase the quality of monitoring of polymeric composites products on an industrial scale. Proceeding from the aforesaid during the research the primary tasks of the development and research of a mathematical model of high-frequency radiation impact on a polymeric product, including with “metallic inclusion” defect type and also the development of the accompanying software for testing, setting and ensuring diagnostic devices operation were set.

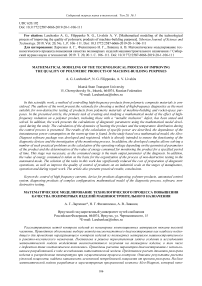

Mathematical model of high-frequency radiation impact on a polymeric product. The mathematical model in the research is necessary for calculation of key parameters of the monitoring process of complex configuration machine-building products both in the manual, and in the automated mode. The calculation was carried out for a sample from 8 mm thickness polyamide-610 material with 30 mm diameter with "metallic inclusion" defect type. The defect of 1 mm thickness, of 4 mm2 is simulated between two polyamide plates of 3 mm and 4 mm thickness. When designing a mathematical model, the studied sample was considered as a set of three areas: the first area – the polyamide without a defect, the second area – the polyamide located over the defect, the third area – the polyamide located under the defect. The scheme for the studied sample is shown in fig. 1.

Fig. 1. Scheme of the simulated sample with a defect type “metallic inclusion”

Рис. 1. Схема смоделированного образца с дефектом типа «металлическое включение»

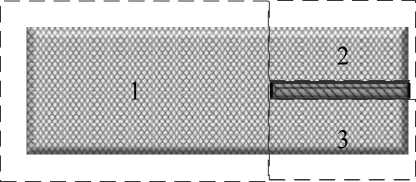

To perform the given tasks there was also a need for the development of high-frequency impact technological scheme shown in fig. 2, which is a set of electrodes, a variable quantity of heat insulators and a product to be heated with the defect.

Taking into account the presented high-frequency impact technological scheme, the calculation of dynamics of warming up in each area and temperature distribution in a multilayered plate are described by a set of equations of transient heat conduction [1; 5]. The area warming up without a metal plate is described by a set of equations (1), and the dynamics of increase in temperature of areas with metal inclusion is characterized by a set of equations (2).

А = X 1 d 2 T ;

дт c p 1 ( Ш d x 2 ;

8 T 2 = X 2 d 2 T 2 ;

д т C p 2 ( T 2 )P 2 d x 2 ’

8 T 3 = X 3 d T 3 + p 3 ( т )

д т C p 3( T 3 )P 3 d x 2 C p 3( T 3 )P 3;

8 T 4 = X 4 d 2 T 4 ;

8 т cp 4 ( T 4 )p 4 d xx ’

8 T5 = X5

_д т C p 5 ( T 5 )P 5 d x 2 ;

'TA X 4

8 т C p4 ( Ш 8 x 2;

SJ^ X2

( 8т Cp2(T2)p 2 dx2 ;

d T 33 = X 3 ,8 X + p , 3 ( т ) ;

8г cpa(M,3)^-3 dx2 cp 3( T,>3’ d T-4 X4 8 2 T-4

,5 т C p , 4( T -4 )P , 4 d x 2;

where for the second area 1 = 12; 2 = 11; 3 = 10; 4 = 9; for the third area 1 = 6; 2 = 7; 3 = 8; 4 = 9; Т j – local temperature of a layer, С°; x – current thickness of a layer, mm; λ j – thermal conductivity, W / (m ∙ K); с рj – specific heat, KJ / (kg ∙ K); ρ j – material density, Pa; p j – specific power of an internal source of heat of W/m3; j – layer number: 1, 5, 6, 12 – electrodes; 2, 4, 7, 11 – insulators; 3, 8, 10 – polymer; 9 – metal inclusion.

х 1

х 2

х 3

х 4

х 5

х 6

х 7

Fig. 2. Technological scheme of high-frequency impact on a product with a defect of the type “metallic inclusion”: 1 , 5 , 6 , 12 – electrodes; 2 , 4 , 7 , 11 – insulators;

3 , 8 , 10 – polymer; 9 – metal inclusion

Рис. 2. Технологическая схема высокочастотного воздействия на изделие с дефектом типа «металлическое включение»:

1 , 5 , 6 , 12 – электроды; 2 , 4 , 7 , 11 – изоляторы; 3 , 8 , 10 – полимер; 9 – металлическое включение

Boundary conditions on external borders of electrodes correspond:

-

- X I T I = x. = a , A T , ;(i = 5, 1, 12, 6), (3)

dx where α – heat exchange coefficient; ΔТ – difference of surface temperatures of a body and surrounding medium.

Referring to rather low heating temperatures of the studied polymeric products at implementation of diagnosing and high dynamics of a warming up, heat exchange with its surrounding medium when monitoring the first and single products can be considered negligibly small:

-

-X ^T = 0(4)

d x |x = x i

On borders of layers heat fluxes and temperatures are equal:

T,= T-+1; (j• = 1^4; 6^11);(5)

d Td

Xj^T = Xj+1 4j+1; (j = 2^4; 6^11); (6) dxd

The specific power of P l is other than zero only for polymer

Pl * 0; (l = 3, 8, 10);(7)

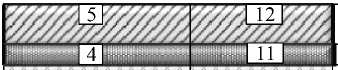

The carried out research calculations with the created mathematical model use showed that the sample is heated non-uniformly, the required temperature on areas with metal inclusion is reached in 25 seconds. The analysis of the received results allows to draw a conclusion on a possibility of mathematical model use for calculation of necessary diagnosing time which excess will lead to the material melting and, therefore, to product rejection. The following necessary research phase was finding of the instantaneous power consumption dependence on the heating time P мпм ( t ) in each area which chart is presented in fig. 3.

The received dependences of specific power on temperature P мпм1 ( t ), P мпм2 ( t ), P мпм3 ( t ) were approximated in the form of a polynomial function and used when determining the energy spent monitoring a sample with the defect type “metallic inclusion”:

Э потреб = J Р мпм ( t ) ■ dt . (8)

Compliance check of the model with actual diagnosing processes showed that when monitoring samples of brand 610 polyamide of 8 mm thickness and with a 15 mm radius, the time is 111 sec., and the heating time of the same sizes sample with the defect type “metallic inclusion” of 4 mm3 in 25 seconds, the deviations on heating time from the pilot research make no more than 2 % that confirms the mathematical model correctness. At the same time the power consumption of a standard sample is 1.3 W ∙ h, and a sample with the defect – 0.35 W ∙ h [1; 9; 12; 13].

On the basis of the given research it is possible to draw a conclusion that the more the amount of metal inclusion in a polymer, the less energy and time is spent on monitoring object heating. The analysis of the results received by means of the created mathematical model allowed to reveal the additional controlled parameter hav- ing informational content – the consumed energy. Besides, the obtained data confirm the pilot studies presented in works [1; 8].

For the use of a high-frequency control method and diagnosing process control it is necessary to provide a fixed level of power impact when monitoring different materials and products of various configuration. The presented mathematical model allows not only to determine the voltage necessary for specific power control preservation but also provides the opportunity for electrothermal equipment input data determination at automated control of high-frequency diagnosing process, differing in the established by mathematical dependence of operating voltage supply on the form and sizes of the controlled product [1; 4].

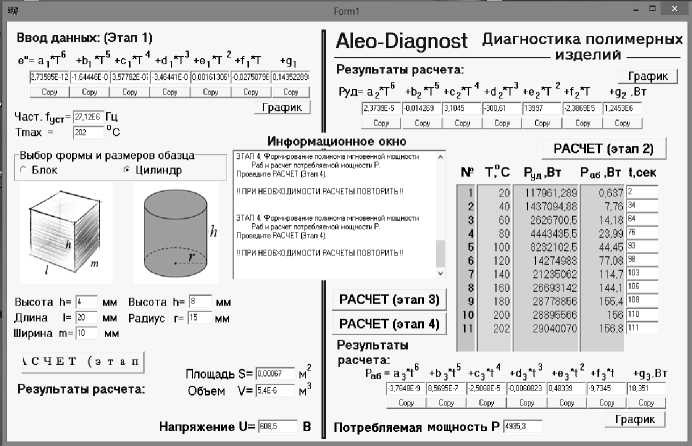

The Aleo-Diagnost software package. Calculations of productive parameters diagnosing were carried out for the particular sample of a specific form and size. The instantaneous power consumption directly depends on two components – the volume of a monitoring object and specific power. For implementation of the developed mathematical model of various forms and sizes products monitoring it is necessary to keep a condition of the dependence of the instantaneous power consumption invariance on time. For adaptation of calculations of diagnosing process necessary parameters with the high-frequency radiation method, the Aleo-Diagnost software was developed and registered [1]. The package interface implemented in the programming language С++ is shown in fig. 4.

Fig. 3. The dependence of the instantaneous power consumption in the areas of polyamide 610 from the heating time

Рис. 3. Зависимость мгновенной потребляемой мощности на участках полиамида 610 от времени разогрева

Fig. 4. Interface of the Aleo-Diagnost software package

Рис. 4. Интерфейс программного комплекса Aleo-Diagnost

The executable file contains the main libraries, forms of input and output. Calculation is conducted in 4 stages. The process of calculations with recommendations and explanations on the corresponding stages is displayed in “Information window”.

When calculating the heating time the Aleo-HFH software package version 2.0 [5; 15] is used. After completion of calculations of products from polyamide materials heating time the software package displays key parameters of calculation for descriptive reasons in the form of tables with the intermediate values of specific and instantaneous power consumption depending on temperature and the time of heating at high-frequency radiation impact. The software package has an opportunity to send calculation results to the text file for their convenient transfer in the approximation module. For reduction of the obtained tabular data to a polynomial form a convenient to use program-approximator is installed in the package allowing to obtain coefficients of polynomical function of the instantaneous power consumption dependence on time for carrying out further research and calculations. There is a module of the consumed energy calculation on a heating sample which results are displayed in the bottom right corner of the program window in the program. Besides, the Aleo-Diagnost allows to solve a number of such practical problems as calculation of operating voltage depending on geometrical parameters of a product for process realization and also the calculation of the energy consumed on diagnostics of a product for the given time period. The solution of these problems was a necessary stage as the consumed energy is the key output parameter of diagnosing. This parameter is assumed as the basis at non-destructive monitoring process organization in the automated mode.

Conclusion. In conclusion, it should be noted once again that the created mathematical model of high-frequency radiation impact on a polymeric product and the software on the basis of the designed model practical use significantly reduces the cost not only of diagnosing operations preparation, but also of the monitoring process. The results of the presented research allow to reduce the time and improve the quality of products non-destructive monitoring in the conditions of production, operation and repair work. Besides, during the research the sensitivity of diagnosing was defined. The developed method allows to reveal the “metallic inclusion” defects type of total volume 0.0017 % that allows to use this method commercially in machine-building and rocket-space industries. At the moment the software package on the basis of the created mathematical model is used in the scientific, educational and production purposes.

Список литературы Mathematical modeling of the technological process of improving the quality of polymeric products of machine-building purposes

- Ларченко А. Г. Система автоматизированного управления высокочастотным диагностированием при производстве и эксплуатации изделий из полимерных материалов: дис. … канд. техн. наук. Иркутск, 2014. 164 с.

- Ла Мантиа Ф. Вторичная переработка пластмасс / пер. с анг. Г. Е. Заикова. СПб.: Профессия, 2006. 400 с.

- Рабек Я. Экспериментальные методы в химии полимеров / пер. с англ. В. В. Коршака. М.: Мир, 1983. 480 с.

- Филиппенко Н. Г. Автоматизация управления процессом высокочастотной обработки полимерных материалов: дис. … канд. техн. наук. Иркутск, 2012. 160 с.

- Попов С. И. Автоматизация управления технологическими процессами восстановления эксплуатационных свойств полимеров: дис. … канд. техн. наук. Иркутск, 2013. 120 с.