Mechanical and water absorption performance of sheep wool-reinforced compressed stabilized earth bricks

Автор: Nasrat Nasratullah Abdul Ghafoor, Abu-Mahadi Mohammed Ibrahim, Obeid Mahmoud Abdelsalam Aref

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 5 (119), 2025 года.

Бесплатный доступ

The object of research is the evaluation of the mechanical performance and water absorption characteristics of compressed stabilized earth bricks (CSEBs) in considering varying contents of cement and sheep wool fiber (SWF). The experimental work was conducted on bricks produced using locally sourced raw materials in Kabul, Afghanistan. Method. In this study, the bricks were prepared using 28% clay-silt and 72% machine crushed sand as the primary raw materials. Sheep wool fiber (SWF) was incorporated as a reinforcement at contents of 0%, 0.05%, 0.1%, 0.2%, 0.3%, and 0.4% by weight of the soil mix, while ordinary Portland cement (OPC) was used as a stabilizing agent at dosages of 0%, 5%, and 10%. Mechanical performance was evaluated through tests on dry-state and wet-state compressive strength, as well as flexural tensile strength. Dry-state compressive strength was assessed for all mix designs, including combinations with 0% cement and 0% SWF, as well as varying proportions of cement and SWF, to determine the influence of these additives on structural performance. For the wet-state compressive strength test, a constant cement content of 10% was used with varying SWF contents to evaluate the effect of SWF on the retention of compressive strength under saturated conditions. Flexural tensile strength (or modulus of rupture) was assessed across mixtures with 0% cement and 0% SWF, as well as combinations with varying amounts of cement and SWF, to investigate the influence of these components on flexural resistance. For water absorption behavior, total water absorption and capillary water absorption tests were conducted using a constant cement content of 10% and varying SWF contents, to determine the impact of fiber inclusion on the bricks' water absorption characteristics. Result. The study found that the inclusion of SWF in CSEBs has a negative impact on dry compressive strength, with increasing SWF content leading to a reduction in strength. However, SWF inclusion shows a positive effect in preserving compressive strength under wet conditions and significantly reduces capillary water absorption compared to bricks without SWF. The addition of SWF up to 0.3% improves flexural tensile strength; however, exceeding this dosage leads to a decrease in flexural performance and the development of horizontal cracks in the bricks. Overall, the findings demonstrate that CSEBs incorporating appropriate proportions of cement and SWF show mechanical performance and water absorption characteristics that meet or exceed the requirements of relevant standards. This indicates their capability as sustainable, structurally sound, and load-bearing construction materials suitable for use in a variety of building applications.

CSEBs, Dry compressive strength, Wet compressive strength, Flexural strength, Cement effect, Sheep wool effect, Water absorption

Короткий адрес: https://sciup.org/143185207

IDR: 143185207 | DOI: 10.4123/CUBS.119.1

Текст научной статьи Mechanical and water absorption performance of sheep wool-reinforced compressed stabilized earth bricks

Soil is the most affordable, cheapest and plentiful building material resource. However, the addition of cementitious materials or reinforcing elements can significantly enhance the engineering properties of earthen bricks [1]. Compressed Stabilized Earth Bricks (CSEBs) provide a substantial amount of thermal mass in buildings, making them suitable for passive solar heating strategies. This contributes to improved indoor thermal comfort and reduces the demand for active heating and cooling systems. As the bricks contain a major amount of clay, these bricks will naturally "breathe," managing indoor humidity levels and improving indoor air quality. Additionally, buildings constructed with compressed stabilized earth bricks will have an interior relative humidity that ranges from 40% to 60% [2]. Compressed stabilized earth bricks produced from various local soil types will have distinct physical and thermal properties. By the variations in local soil properties, CSEBs produced from different sources will exhibit differing mechanical characteristics [3], [4]. These bricks are compressed manually or motorized and cured for 28 days to get the desired compressive strength; they offer a sustainable alternative to burnt clay bricks/cement concrete blocks. The energy consumption of one m³ of CSEB is around four times lower than that of one m³ of burned bricks and roughly twice lower than that of the typical brick-making industry due to the little quantity of stabilizer used. Upon application, the blocks can be solid, hollow, round, or customized and can be used for floors, columns, and roof construction, as a load-bearing structure can withstand up to 4 floors without concrete columns [3].

Previous research has demonstrated that compressed earth bricks offer numerous advantages over conventional fired bricks. In particular, compressed stabilized earth bricks (CSEBs) are more environmentally sustainable, exhibit higher strength and enhanced durability, and possess thermal conductivity similar to that of traditional burnt clay bricks. Moreover, studies have confirmed that their durability is on par with that of conventional fired bricks [5]. CSEBs compared to fired bricks, need less energy, emit 80% less CO 2 into the atmosphere, and the production cost of CSEBs is also less than fired clay bricks [6].

Soils tend to naturally exhibit low tensile and compression strength, absorb more water and are susceptible to scraping and erosion [7]. Stabilization improves the compressive strength, flexural tensile strength, and both physical and chemical properties of the available soil [8]. The addition of appropriate stabilizers can significantly enhance the soil's strength, stability, permeability, and durability by promoting effective compression during molding and good curing [9], [10].

The inclusion of granules or fibers, along with the compaction process, can influence the mechanical and thermal performance due to their physico-mechanical interactions within the soil matrix [11]. Numerous research studies have looked into the potential use of sheep wool in conjunction with various matrices, such as cement mortar or unfired clay adobe, for mechanical and thermal applications [12], [13]. Statuto et al. [14] conducted compression experiments on adobe clay bricks reinforced with sheep wool and wheat straw. They found that the compressive strength of brick reinforced with sheep wool fibers was significantly greater than that of brick reinforced with wheat straw.

In Afghanistan, approximately 95% of buildings are constructed using soil as the primary building material. The most common types of soil-based construction include sun-dried mud bricks (adobe walls) and cob walls. In most regions of the country, the soil contains a significant amount of clay, and sand is readily available, making it well-suited for the production of CSEBs [15].

The use of sheep wool as a natural ingredient in CSEBs to improve their mechanical performance has not been studied in Afghanistan. Since sheep farming is so common in Afghanistan, sheep wool is readily available. It has exceptional tensile strength and may be able to increase the flexural tensile strength of earthen bricks.

This study investigates the mechanical performance, specifically compressive and flexural strength, and water absorption behavior of compressed earth bricks stabilized with varying cement contents and reinforced with varying amounts of sheep wool fiber (SWF). The research aims to evaluate their structural capacity, durability, and viability as a load-bearing construction material. Given the notable absence of prior studies on compressed stabilized earth bricks (CSEBs) in the Afghan context, this work addresses a critical knowledge gap in sustainable building technologies for the region. The findings are intended to inform the development of locally sourced, cost-effective building materials suited for affordable housing solutions in both rural and urban areas of Afghanistan.

-

2 Materials and Methods

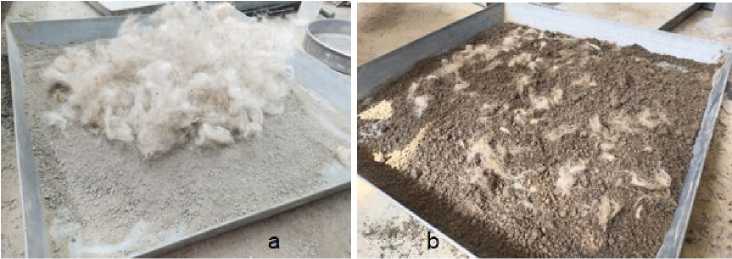

Soil: For this study soil was selected from the Deh-Sabz district that is widely utilized for fired bricks, sun-dried brick production, and other masonry construction activities within Kabul province, Afghanistan. The used soil properties, like pH = 9.5, specific gravity = 3.33, plastic index (PI) = 8.45%, and clay & silt content = 90%, were found before use, which is essential for CSEB production and has an effect on the selection of stabilizer and brick quality. Moreover, the soil intended for the brick mixture was sieved through about a 2.5 mm mesh to remove nodules and other impurities. Based on recommendations from [10], the mixture composition for the study consisted of 28% clay and silt, and 72% sand. These proportions were determined by evaluating the observed shrinkage cracks and the composition of the clay and sand used for CSEB production. To determine the suitability of a given soil for use in CSEBs, certain preliminary tests such as smell test, soil composition analysis, and consistency tests are necessary [16]. Carefully choosing the proper soil, sand, stabilizing agents, and water is essential for producing high-quality earth bricks, while in (Figure 1), the raw materials and mix for CSEBs production are shown for this study. Furthermore, since these elements have a high impact on the bricks' quality and longevity, it is also crucial to make sure the bricks in the mold are properly compacted and that there is enough curing time. The soil used for the produce of compressed stabilized earth bricks shall be of a suitable quality, free of deleterious and organic materials graded in accordance with ISO 14688-1 [17].

Fig. 1—Shows: a) CSEBs' dry state mix raw material, b) mixture for CSEBs

Image by the author of the article

Sand: The used sand was machine-crushed sand sourced from a local crushing plant. The sand’s properties (AASHTO T-84 / ASTM C-128) included a bulk specific gravity (SSD) of 2.69, a specific gravity of 2.9, and 0.6% water absorption, indicating low porosity and suitability for construction use. The sand was sieved with a 4.75 mm sieve and was free from impurities and organic matter and indicated an appropriate grain composition. It is advised to utilize coarse sand for the production since the blocks will be stronger and have a higher density [18]. Despite that, the natural river sand is also accessible in the mentioned area and generally used in certain construction activities, such as mortar preparation and plastering. But its grain size was very fine, and it often contains an obvious amount of organic matter in its composition. Therefore, for the study, selected crushed sand.

Stabilizer: Walker P.J. [6].described that most of the soil types in natural conditions have a shortage of stability, strength and durability. Thus, it is need to recovered the characteristics of the soils by using of mechanical and chemical stabilization in compressed stabilized earth bricks (CSEBs) production. Chemical stabilization involves incorporating cementitious materials such as cement, lime, fly ash, bitumen, or combinations thereof into the soil to chemically react with its components and improve its structural performance [19], [20]; whichever, for compressed stabilized earth block production, the most widely utilized stabilizers are cement and lime [21].

In this study, as a stabilizer agent, ordinary Portland cement (Grade 53) was utilized in amounts of 0%, 5%, and 10% relative to the dry soil weight. Hari, D.S. [16] recommended 5% to 10% of cement, and [22] suggests that more than10% cement is uneconomical for CSEBs production. While [23] reported that bricks with less than 5% of cement are often too friable to handle.

Sheep wool fiber (SWF): Sheep wool is multicellular materials composed of three main structural parts of medulla, cortex, and epidermis, which consist of mixture of soft, intermediate and coarse hair. Because of its physicochemical characteristics, it can be utilized as a reinforcing component in composites materials [24]. Compressed stabilized earth bricks, reinforced with fiber, present better flexural tensile strength, higher compressive strength, and improved cracks and crack diffusion resistance, depending on fiber types and soil [25]. Sheep wool's unique physicochemical properties make it suitable for use in composite materials, which supports bioeconomy and sustainable development efforts. [26]. Aymerich et al. [27] studied earthen specimen’s flexural strength, and they used 2-3% and 2-3 cm lengths of sheep wool fibers. The authors found that the fibers improved the material's residual strength, ductility, and energy absorption following the initial cracking.

The amounts of sheep wool added to the soil mixture in this study were 0%, 0.05%, 0.1%, 0.15%, 0.2%, 0.25%, 0.3%, and 0.4% in relation to the dry weight of the soil (Fig. 1a). The wool fibers utilized, which ranged in length from 2 to 10 cm, were sourced from local markets.

Bricks Preparation : Soil nodules (≥ 5 mm), considering their amounts, influenced brick quality; therefore, the clay soil was sieved prior to mixing through about a 2.5 mm mesh to remove nodules and other impurities.

The brick constituents were first blended in a dry state, after which water was gradually added until the optimum moisture content (OMC) was achieved. For determining the optimum moisture content (OMC) for the mix, three samples were prepared using 10%, 12%, and 14% water content (by weight of dry soil) with 10% cement stabilization. The prepared samples, by using a manually operated CINVA Ram press (QRTDW / Qaderdan Rural Technology and Development Workshop, Kabul, Afghanistan), machine, were weighed in a wet state and then placed in an autoclave for 24 hours at 105°C to achieve complete drying and determine the dry bulk density. In the dried state, the sample prepared with 12% water content exhibited the highest dry bulk density compared to the other two samples. This indicates that 12% represents the OMC for the given cement content (10%).

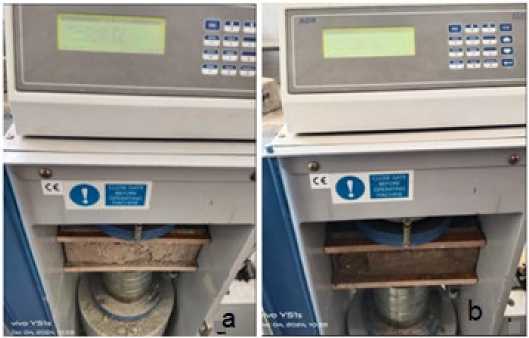

It is important to note that both cement content and the natural moisture of the soil influence the OMC. Therefore, during sample preparation, the optimum moisture content (OMC) of the mix was determined using the drop test method, following the NZS 4298 (1998 [28] standard. Groundwater was used for both mixing and curing for bricks. The bricks were compacted in mold using a manually operated CINVA-Ram press, a machine commonly used for compressed earth brick production (Fig. 2). The bricks were produced in 302 × 152 × 102 mm dimensions. After molding, the bricks were maintained in a moist state for up to 7 days. In accordance with [28], all tests on the bricks were conducted after a 28-day curing period.

Fig. 2- Shows: a) CINVA-Ram machine, b) produced CSEBs Image by the author of the article

-

2.1 Methodology for Mechanical Performance

Compressive strength. Compressive strength is the most widely accepted measure for evaluating brick quality. However, factors such as the type and amount of stabilizer, soil composition, and compaction rate in the mold have a considerable impact on the bricks properties. For this test, used digital compressive machine (ELE/international- ADR Touch SOLO 1500 Compression Machine with Digital Readout, Milton Keynes, UK). The compressive strength test was conducted on sheep wool reinforced compressed stabilized earth bricks (CSEBs), unreinforced compressed stabilized earth bricks and non-stabilized compressed earth bricks (CEBs) in dry conditions (Table 1), (Fig.3a) to compare the stabilizer and SWF effect. However, only dry state compressive strength does not fully depute real-world fulfilment. In the regions with seasonal flooding, high rainfall, or humidity, CSEBs are consequently subjected to moisture, which can decrease the soil matrix, disintegrate binders, and produce cracking or disintegration. Therefore, to determine the effect of water absorption on CSEBs compressive strength and compare their strength with the dry state. Also, CSEBs were tested in wet conditions (Fig. 3b). For wet state experiment, we examined 4 types of specimens considering SWF and cement contents (Table

-

2) . According to [28], the specimens were fully immersed in water for 24 hours before testing. The compressive strength was calculated by using "Equation (1)".

F F , ,

P = —, p = — = N / mm2 d , w

Where:

P d - Dry compressive strength (N/mm2);

P w - Wet compressive strength (N/mm2);

F - Total applied load (N);

A - Bed area of the brick (mm2).

Fig. 3- Shows: the compression tests on CSEBs, a) dry state, b) wet state

Image by the author of the article

Table 1. Bricks specimens, for dry state compressive strength

|

Specimen |

SWF content, % |

Cement content, % |

|

BK1 |

0.3 |

10 |

|

BK2 |

0.25 |

10 |

|

BK3 |

0.2 |

10 |

|

BK4 |

0.15 |

10 |

|

BK5 |

0.1 |

10 |

|

BK6 |

0.05 |

10 |

|

BK7 |

- |

10 |

|

BK8 |

- |

5 |

|

BK9 |

0.1 |

5 |

|

BK10 |

0.1 |

- |

|

BK11 |

- |

- |

Table 2. Bricks specimens, for wet state compressive strength

|

Specimen |

SWF content, % |

Cement content, % |

|

BK1 |

0.2 |

10 |

|

BK2 |

0.1 |

10 |

|

BK3 |

0.05 |

10 |

|

BK4 |

- |

10 |

Flexural tensile strength (Modulus of rupture) . Flexural tensile strength, often referred to as modulus of rupture, is a certain mechanical property that specified a material’s capability to resist cracking and fracture under bending stresses, induced by wind load, thermal moment, differential settlement and seismic activity, which mostly occurred in load bearing and non-load bearing walls.

This strength of the bricks was determined using the three-point bending method, as specified by ASTM C67/C67M-19 and [28], [17], employing a manually operated hydraulic testing machine (ELE/international- Hand operated flexural machines, Milton Keynes, UK). The bricks were positioned in the testing apparatus in a manner simulating their orientation in a wall (Fig. 4). In this experiment, we examined 11 types of specimens considering SWF and cement contents (Table 3). In test conducting, Nasrat, N.A.G.; Abu Mahadi, M.I.; Obeid, M.A.A.

Mechanical and water absorption performance of sheep wool-reinforced compressed stabilized earth bricks;

load was gradually applied at the midpoint of the brick specimen until failure occurred. The flexural tensile strength ( f ₜ ) was calculated using Equation (2).

3 X F X L

2 x b x d2

= N / mm 2

Where:

f t - Flexural tensile strength (N/mm2);

F - Applied failure load (N);

-

L - Effective span of the brick (mm);

-

b - Width of the brick (mm);

-

d - Thickness of the brick (mm).

-

2.2 Water Absorption Experiments

Fig. 4- Shows the flexural tensile testing apparatus Image by the author of the article

Table 3. Bricks specimens, for flexural strength

|

Specimen |

SWF content, % |

Cement content, % |

|

BK1 |

0.4 |

10 |

|

BK2 |

0.3 |

10 |

|

BK3 |

0.25 |

10 |

|

BK4 |

0.2 |

10 |

|

BK5 |

0.15 |

10 |

|

BK6 |

0.1 |

10 |

|

BK7 |

0.05 |

10 |

|

BK8 |

- |

10 |

|

BK9 |

0.1 |

5 |

|

BK10 |

0.1 |

- |

|

BK11 |

- |

- |

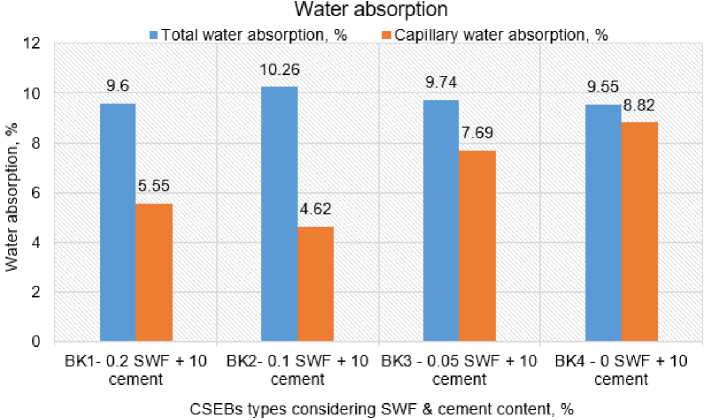

Water absorption is a critical durability property for CSEBs, as it directly effects their resistance to frost weathering, damage, erosion, and long-term structural integrity. In regions having high humidity or heavy rainfall, severe water absorption can result in strength loss, swelling, cracking, and a decreased service life. It is important to measure the water absorption rate in compressed stabilized earth bricks whichever by causing of clay and cement content. Thus, assessing both capillary and total water absorption offers critical information on how well stabilization works and whether CSEBs are appropriate for use in a variety of climatic conditions. Turco C. et al. [29] studied and observed that the texture of aggregates affects water absorption. Bricks containing finer-textured aggregates exhibit higher water absorption rates compared to those with coarser-textured aggregates, both in the short and long term. Beckett C.T.S. et al. [30] suggest that total immersion and accelerated erosion tests are categorized as short-term assessments of stabilizer effectiveness and, more likely, extreme events. However, the capillary absorption test is a long-term durability test that can be used to evaluate durability in nonextreme situations rather than being able to forecast the rate of erosion. Panagiotou R. et al. [31] reported that it is possible to avoid making imprecise or inaccurate assessments regarding the blocks’ durability to weathering by testing multiple disintegration mechanisms.

In this study, CSEB specimens (Table 4), containing a constant cement content of 10% and varying percentages of SWF, were tested for both total water absorption and capillary water absorption (Fig. 5) to evaluate the effect of SWF on water absorption behavior. For test conducting the bricks were dried in an oven at 105°C for 24 hours and then weighed for both experiments. According to [28], for the capillary action test, the bricks were immersed to a depth of approximately 1 cm for 24 hours and then weighed. For total water absorption, the bricks were fully immersed in water for 24 hours and then also tacked their weights. In this section, the experiment conducted considered cement content and SWF content to evaluate the effect of SWF content on water absorption.

The capillary action and total water absorption values, expressed as percentages, were calculated using Equation (3).

w —wr, W = ww__wd-

X 100

wd

Where:

W - Absorbed water (%);

W d - Dry weight of the brick (Kg);

W w - Wet weight of the brick (Kg).

Fig. 5- Show: a) CSEBs for capillary absorption, and b) CSEBs for total water absorption Image by the author of the article

Table 4. Bricks specimens, for capillary and total water absorption

|

Specimen |

SWF content, % |

Cement content, % |

|

BK1 |

0.2 |

10 |

|

BK2 |

0.1 |

10 |

|

BK3 |

0.05 |

10 |

|

BK4 |

- |

10 |

3 Results and Discussion

Compressive strength . Compressive strength is a fundamental mechanical property used to evaluate the structural suitability and durability of building materials. The compressive strength results for compressed stabilized earth bricks (CSEBs) in both dry and wet states, considering their sheep wool fiber (SWF) and stabilizer content (%), are presented in (Table 1 and Table 2). Both dry and wet compressive strength are critical indicators of performance under different environmental conditions to identify the decrease in strength of bricks under wet conditions, to assess their minimum performance capabilities under the worst conditions.

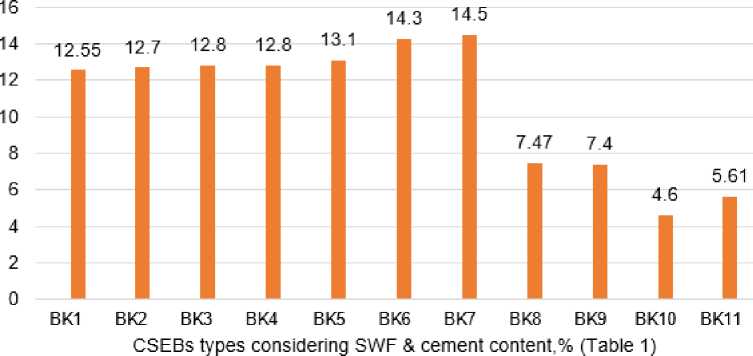

The results for the dry state (Fig. 6) show that the inclusion of SWF generally reduces compressive strength. For instance: Specimens BK11 (5.61 MPa) and BK10 (4.60 MPa) exhibit a 22% decrease in strength with adding of 0.1% SWF. Specimens BK8 (7.47 MPa) and BK9 (7.40 MPa) show only a 0.95% Nasrat, N.A.G.; Abu Mahadi, M.I.; Obeid, M.A.A.

Mechanical and water absorption performance of sheep wool-reinforced compressed stabilized earth bricks;

reduction, indicating minimal effect due to the present of cement content. The difference in compressive strength between sample BK7 (0% SWF) and sample BK1 (0.3% SWF), both with a constant 10% cement content, corresponds to a 15.54% decrease in compressive strength, indicating a notable reduction with maximum SWF inclusion.

The results indicate that when SWF is added and increased while keeping cement content (10%) constant, the dry compressive strength decreases slightly from 14.5 MPa to 12.55 MPa, with a standard deviation (SD) of 0.80 MPa and a coefficient of variation (COV) of 6.07%, indicating consistent but marginally reduced performance. In contrast, increasing the cement content significantly enhances compressive strength. For example, strength rises from 7.47 MPa (BK8, 5% cement) to 14.5 MPa (BK7, 10% cement), representing a 94.1% increase. This comparison clearly demonstrates that cement content has a significant positive effect and inclusion of SWF have negative effect on the compressive strength of CSEBs.

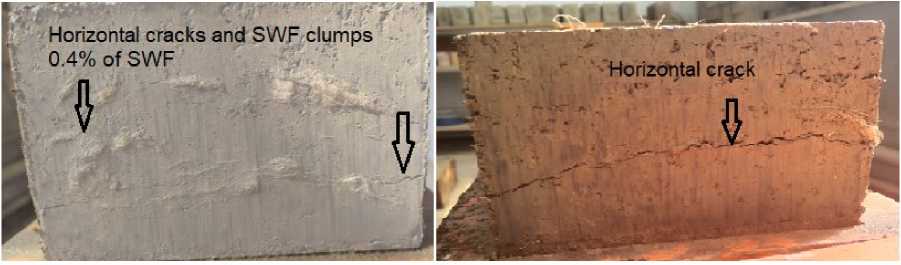

It is noteworthy that when 0.4% SWF was used, horizontal cracks began to appear in the bricks just a few hours after molding (Fig. 7). This phenomenon was attributed to the separation of soil particles within the bricks, likely caused by the clumping or agglomeration of the SWF. Furthermore, the results show that incorporating 0.4% SWF led to a decrease in compressive strength.

Therefore, it can be concluded that the addition of more than 0.3% SWF leads to horizontal cracking and compromises the physical integrity of the bricks.

The specimens (CSEBs) were tested for 56 days; their compressive strength was increased 30– 33% considering their first 28 days’ compressive strength.

Drey compressive strength

Fig. 6- Show dry compressive strength of CSEBs Image by the author of the article

Fig. 7- Show Horizontal cracks in CSEBs due to more (0.4%) SWF inclusion and SWF clumps Image by the author of the article

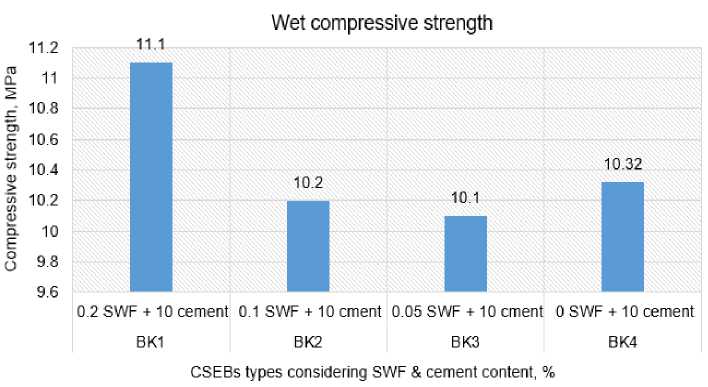

The obtained result (Fig. 8) shows that the compressive strength of the bricks reduced by approximately 15.31% (BK1), 28.43% (BK2), 41.58% (BK3), and 40.78% (BK4) in the wet state compared to their dry state (Fig. 6), with a standard deviation (SD) of 0.46 MPa and a coefficient of variation (COV) of 4.37%. These findings indicate that the inclusion of SWF positively affects the preservation of compressive strength in the wet state, particularly as the SWF content increases. This observed reduction in strength demonstrates the impact of moisture on the structural integrity of the bricks. Overall, the wet compressive strength results of the tested CSEBs are in the range and more than that specified by the [16], [17], [28] standards for class A CSEBs in a dry state.

Fig. 8- Show wet compressive strength of CSEBs Image by the author of the article

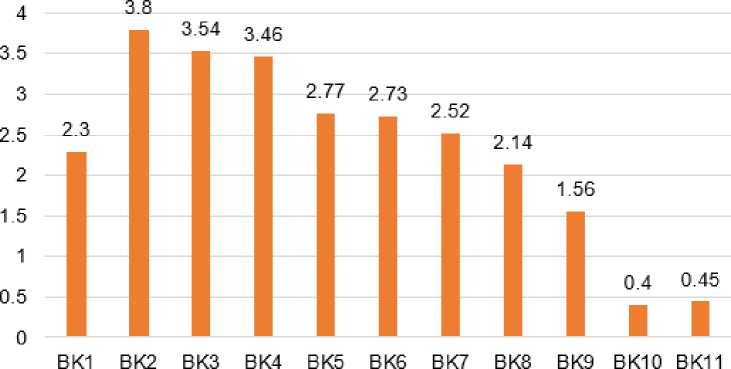

Flexural tensile strength (Modulus of rupture). The results (Fig. 9) indicate that with a constant cement content of 10%, incorporating and increasing the SWF content from 0.05% (BK7) to 0.3% (BK2) enhances the flexural tensile strength of the bricks, with a standard deviation of 0.53 MPa and a coefficient of variation (COV) of 16.88%. However, further increasing the SWF content to 0.4% (sample BK1) results in a reduction in flexural tensile strength.

It is worth noting that cement content plays a significant role in improving flexural tensile strength. For instance, samples BK10 (0.1% SWF + 0% cement), BK11 (0% SWF + 0% cement), and BK9 (0.1% SWF + 5% cement) illustrate this trend. Notably, the strength difference between BK9 and BK8 (0% SWF + 10% cement) highlights that flexural tensile strength increases with higher cement content. The results indicate that the use of SWF in the absence of cement has a negligible effect on flexural tensile strength. However, when compared to the reference sample BK8 (0% SWF) with constant cement content, the inclusion of 0.05% and 0.1% SWF in samples BK6 and BK7 leads to improvements in flexural tensile strength by 17.76% and 27.57%, respectively.

The specimens (CSEBs) were tested for 56 days; their flexural strength was increased 10 - 12% considering their first 28 days’ flexural strength.

For comparison, specimens BK10 and BK11 (with 0% cement content) meet the minimum flexural strength equivalent to the flexural tensile strength specified for class B bricks in standards [16], [17] and [28] standard, while all other specimens exceed the strength requirement for Class A bricks.

Flexural strength

Fig. 9- Show Flexural strength of CSEBs

Image by the author of the article

Water absorption . The results (Fig. 10) show that the addition of SWF has a considerable effect on total water absorption. As SWF content increases, water absorption also increases. However, it should be noted that bulk density also influences water absorption: bricks with higher dry bulk density exhibit lower water absorption due to fewer voids in the matrix. Specimen BK1 has more SWF content and a higher dry bulk density (2106 kg/m³) than that of the other BK2 = BK3 = 2074 kg/m³ samples but has lower water absorption. Despite this, when comparing specimens BK2, BK3, and BK4 (2049 kg/m³), where BK4 has 0% SWF and lower dry bulk densities than the others, water absorption increases with the adding and increasing of SWF content. This indicates that, independent of minor variations in density, the total water absorption capacity of the bricks increases with the addition and increase of SWF caused voids due to inclusion of SWF. The average total water absorption (9.79%), with a standard deviation (SD) of 0.33% and a coefficient of variation (COV) of 3.37%, indicates good consistency and low variability in the material performance.

Unlike the total water absorption, the capillary values decrease with the addition and increase of SWF, and the maximum amount is in the sample without SWF (BK4), despite the fact that the cement content is constant (10%) in all samples. This phenomenon may be attributed to the hydrophobic nature of SWF, their pore-blocking effect, and the modification of pore structure within the matrix.

Overall, the results demonstrate that the water absorption rates of the prepared CSEBs specimens are significantly lower than the maximum allowable limits specified in [16], 20%, and [17], [32] [33], which mentioned 15%, established standards.

Fig. 10- Show Total water absorption and capillary water absorption of CSEBs Image by the author of the article