Methodology to optimize the anode performance

Автор: Meier Markus W., Perruchoud Raymond C.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 3 т.6, 2013 года.

Бесплатный доступ

An aluminium smelter operating its pots with Soederberg technology has experienced a period with a very high number of anode problems, mainly occurring as spikes, hanging anode ends, leak in stud holes, vertical cracks and dusting. The anode problems hindered a planned amperage increase. This paper describes the methodology that was applied to identify the root causes of the problems and to solve them systematically. This methodology includes the following main steps: Initial plant audit; Revamping of equipment causing bottlenecks; Plant capability test; Dynamic process optimization DPO; Validation of improved anode quality and pot performance. By applying this methodology, the anode problems of the smelter could virtually be eliminated. As a consequence the key plant performance figures (current efficiency, carbon consumption, energy consumption and bubble noise) could be improved substantially. This allowed to increase the line current by 7 %.

Söderberg paste, plant audit, process optimization, anode quality, anode problems, pot performance

Короткий адрес: https://sciup.org/146114739

IDR: 146114739 | УДК: 544.6.076.324.2

Текст научной статьи Methodology to optimize the anode performance

The smelter started up its production in 1971 with VS Söderberg pot technology. In recent years all cells have been upgraded with a closed point feeding system, which has increased the capacity and reduced greenhouse gas emissions. Today the smelter has a nominal capacity of 96’000 tpa.

In 2008 the smelter started to experience a severe crisis with an excessive occurrence of anode problems that peaked in 2009. The main problems were:

– Spikes

– Hanging anode end

– Leak in stud holes

– Vertical cracks

– Dusting.

The audit revealed that the anode quality and pot conditions were interrelated with each other with severe vicious circles, as experienced elsewhere [1]. The presence of carbon dust increased the bath

temperature and increased bath temperature promoted dusting. Indeed, a very large bath temperature variation from 940 to 1’025 °C could be observed.

The following performance figures defined the status quo in 2009, when the problems were peaking:

|

– Line current: |

113 kA |

|

– Current efficiency: |

87,5 % |

|

– Carbon consumption: |

540 kgC/tAl |

|

– Anode problems: |

0,050/potday 100/week |

|

– Energy consumption: |

18,0 kWh/kg. |

The methodology of identifying the root causes of the problems and the systematic steps of solving them are described in this document. The subsequent improvement of the anode quality and the influence on the anode performance are also discussed.

Initial Plant Audit

The key findings drawn from the audit are discussed hereafter.

Anode Raw Materials

The smelter alternately uses two types of calcined petroleum coke that exhibit different key characteristics. Coke A is a rather coarse and dense material, while coke B exhibits just opposite characteristics. In spite of this, both coke types are principally suitable to produce a high quality anode paste.

The two pitch types being used are compatible with each other and also allow producing a high quality anode paste.

Hence in contrast to other experience [2] the direct influence of the raw material quality as a root cause of the anode problems of the smelter can be excluded.

Anode Paste Production

Three areas with a need for improvement could be identified:

Mixing Energy : A low net mixing energy of 0,6 kWh/t (vs. typically 3 kWh/t) was identified, which has a deleterious effect on the resulting paste quality and anode performance in the pots.

The condition of the continuous BUSS kneader was considered as the main bottleneck in the entire anode production. It was decided to refurbish the kneader with top priority to improve the anode quality.

Dry Aggregate Preparation and Recipe Formulation: The three fractions (coarse 10 – 3,15 mm, intermediate 3,15 – 0,35 mm, fines 2’600 Blaine) were not balanced. The maximum grain size of the – 269 –

Table I. Anode quality of the smelter in 2008 and worldwide typical Söderberg range

Fines Circuit: The fines circuit consists of a horizontal overflow ball mill and a dynamic classifier. The rotor speed of the classifier is kept constant and not used to vary the product fineness.

It was concluded that the fines circuit needed to be addressed specifically prior to a process optimization.

Anode Quality

The following selected key properties were measured on the anode paste and the pilot electrode after baking at 1 000 °C for 5 hours, as shown in Table 1.

Revamping of Equipment Causing Bottlenecks

The refurbishment of the kneader (BUSS K500KE-7D) required the complete replacement and modernization of the main shaft with improved geometry and design (see Fig. 1). Additionally an automated flap gate was installed. With the modernized kneader the paste plant was ready for the stepwise optimization of all relevant processing parameters.

Plant Capability Test

In a first plant capability test, the main goal was to see the influence of parameters such as recipe formulation, dry aggregate temperature, throughput and flap gate position on the specific mixing – 270 –

Fig. 1. Refurbished BUSS kneader with reduced shearing gap for Söderberg application and automated flap gate energy. As a consequence of these trials the specific net mixing energy could be increased from 1.8 up to 3,4 kWh/t, which had a positive effect on the resulting paste quality.

In a second plant capability test, the limitations of the ball mill were quantified. In particular the influence of the classifier speed and the secondary air on the fines fineness was checked. With the purpose to produce a paste with a high binding force of the binder matrix, the fines fineness was increased up to 4’000 Blaine. As the kneader is designed for a considerably higher throughput than the actual throughput of 13,0 t/h, the ball mill turned out to be a bottleneck for the planned process optimization.

Dynamic Process Optimization

On behalf of the third plant test the actual dynamic process optimization (DPO) was conducted in October 2010 according to the methodology described in [3]. Three optimization targets were investigated during the trials:

– Variation of the fines content with standard fines (3 400 Blaine);

– Variation of fines content with finer fines (4 100 Blaine);

– Fine tuning of thermal conditions.

During these trials the specific net mixing energy could be increased from 2,0 to 3,1 kWh/t. As already expected during the plant capability test, the DPO trials were largely limited by the production capacity of the ball mill. Nevertheless, compared to the starting point in 2008 a massive improvement of the paste quality could be obtained with 3’400 Blaine, as shown in Table 2.

Based on the sound test results it was safe to implement the findings of the DPO trials into the routine production which allowed to validate the improved paste quality on full scale in the reduction pots.

Table 2. Improvement of anode quality from 2008 to 2010 (DPO)

|

Property Unit |

2008 |

DPO in 2010 |

|

App. density baked kg/dm3 |

1,41 |

1,519 |

|

Spec. electr. resistance mWm |

79 |

63 |

|

Flexural strength MPa |

7,5 |

11,1 |

|

Thermal conductivity W/mK |

2,4 |

3,6 |

|

Air permeability nPm |

30 |

12,5 |

|

CO 2 reactivity residue % |

82,6 |

82,2 |

|

Air reactivity residue % |

56,8 |

68,4 |

Validation of Improved Anode Quality and Evolution of Performance in Pots

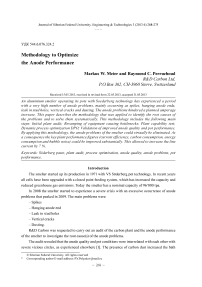

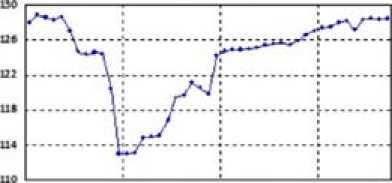

In the first half of 2008 the pot rooms of the smelter were operated at a record high line load of 128.5 kA (average for both lines), after years of increasing in small steps. The number of anode problems had slowly increased, but from May 2008 the problems jumped to a higher level. To counteract, the line load was reduced to 125 kA, while the number of anode problems stabilized at 60 per week. Even lowering the line load to 113 kA (due to the worldwide financial crisis) did not help to reduce the number of anode problems. In fact, the frequency continued to increase to a record high of 100 anode problems per week during several months in 2009. When the markets were improving, the line load was again stepwise increased, but was hindered to increase above 120 kA due to the severe anode situation.

After the improvements had been implemented in the paste plant, the anode performance gradually improved to a very good condition which is sustained even at a level close to record high line load.

It takes the paste 13 to 15 weeks to reach from the anode top the bottom operating surface. However, it took about one year of pot operation with improved paste quality (ca 4 baking cycles) to reach stable pot performance with a low frequency of 20 anode problems per week (eg 0.01 anode problems per potday).

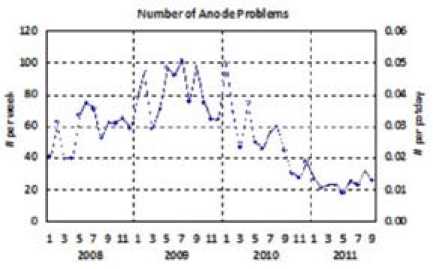

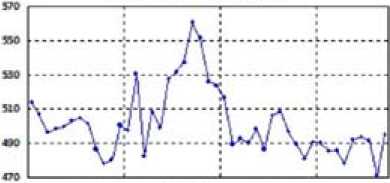

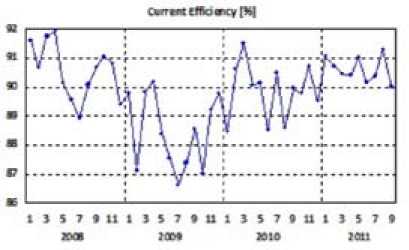

The Fig. 2 to 6 show how the anode paste quality influenced the number of anode problems, paste consumption, current efficiency, specific energy consumption, and line load.

Fig. 2. Anode problems per week and potday monthly data 2008–2011

-anole * ale cewumpoo* [tf/un]

1557» 11 1557» 11 1557» 11 1557»

2001 2001 Ю» ЮЦ

Fig. 3. Anode paste consumption monthly data 2008–2011

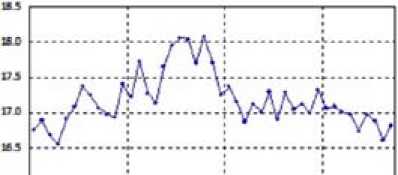

Fig. 4. Current efficiency monthly data 2008 – 2011

spec*. tne'Cv coniem^Pon *M>/M

1 M 7 I U 1 ) 1 M 111 ) I 7 • U 1 1 > 7 f 200» «l* »Ю 2d1 .

Fig. 5. Energy consumption DC in pot rooms monthly data 2008–2011

им loel I*~1F ef ВИН urn) [lu|

lSS7SUlS57BlllSS7BU1517e

200» М» BM 7011

In addition to all improvements of the anode paste, the operation of resetting the anode stubs in the pots was improved in 2010. This also had a positive influence on the overall anode performance.

The accumulated changes made to the anode paste resulted in a different visual appearance of the anode top. A paste produced to a given viscosity target appears visually drier on the anode top today than the same viscosity did before. A new challenge is therefore to adjust the rules and targets for anode top control in such a way that the right viscosity is produced to give optimal results for the baked anodes.

Conclusions

A methodology has been described in this document to systematically optimize the anode performance. The methodology comprises five steps: (1.) initial plant audit, (2.) revamping of equipment causing bottlenecks, (3.) plant capability test, (4.) dynamic process optimization DPO and (5.) validation of improved anode quality and pot performance. The application of the described methodology was illustrated on an actual case of a Söderberg plant [6], but the same methodology can of course also be applied on plants using prebaked anode technology [3, 7].

The described methodology has turned out to be very efficient.

The anode quality and performance in the pots could be improved dramatically:

– Anode problems: from 0.05 to 0.01 per potday (average of all pots) and to 0.00125 per potday in potroom 3;

– Anode paste consumption: from 540 to 485 kgC/tAl;

– Current efficiency: from 87,5 to 90,5 %;

– Energy consumption: from 18,0 to 16,8 kWh/t;

– Bubble noise: doubled.

The massive improvement of these performance figures allowed to increase the line load from 120 to 128,5 kA. The aluminium production cost could be decreased significantly, which has led to a very attractive payback time of the entire project. The combined boost of the line load and current efficiency increase the metal production by 10 %, which corresponds to 9 000 tpa.