Methods for cleaning mechanical impurities formed in the pipe during the transportation of petroleum products of various compositions

Автор: Asgarova N.A.

Журнал: Мировая наука @science-j

Рубрика: Основной раздел

Статья в выпуске: 5 (98), 2025 года.

Бесплатный доступ

In the article, methods of reducing the formation of the mixture formed during sequential pumping are studied. Therefore, in the article, any of the products, which are sequentially pumped, are transported by gas saturation. In many cases, gas saturation of the product (mixing of gas with the product) leads to the fact that the product acquires viscoelastic properties. In this case, the volume of the mixture will be reduced due to the viscoelastic properties of the gas-saturated product during successive pumping. The article shows the possibility of reducing the volume of the mixture during successive pumping depending on the gas saturation of various products (depending on the gasification of the products before them, how viscous and elastic they are).

Oil product mixture, degree of saturation, separation properties, sequential pumping, separation plugs, mixture formation, viscoelastic properties

Короткий адрес: https://sciup.org/140311522

IDR: 140311522 | УДК: 622.692.4.052.6.532.529.001.5

Текст научной статьи Methods for cleaning mechanical impurities formed in the pipe during the transportation of petroleum products of various compositions

Separating plugs [1,2], which are currently used in the processes of sequential pumping of various products, have not found wide application due to a number of reasons (low efficiency, complexity of operation, lack of possibility of recycling, etc.). Therefore, the possibility of using one of the gas-saturated pumped products as a separator plug is considered below, since the latter in some cases, showing viscoelastic properties, can contribute to reducing the mixture formation.

To determine the separation properties of gas-liquid systems, experiments were conducted on the displacement of one liquid by another (diesel fuel and water) during sequential movement along the pipe and alternating saturation with carbon dioxide. The experiments were carried out on a laboratory hydraulic installation, the main element of which was a pipeline with a length of 6.5 m and a diameter of 16·10-3 m. The pressure at the entrance of the pipeline was maintained constant and equal to 105 Pa with the help of a reducer installed on the container for the pumped liquid. The experiments were conducted in the following sequence [3]. The pipeline model was filled with one liquid and then displaced by another, saturated with gas, and vice versa.

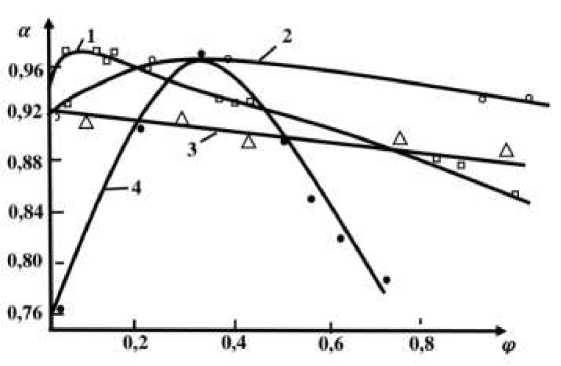

Fig. 1. Dependence of the product mixture volume (α) on the degree of gas saturation (φ)

1-behind the low-viscosity product (water), saturated with gas, in front of the high-viscosity product (ДТ); 2-high-viscosity product (DT) in front, saturated with gas, low-viscosity product (water) behind

After filling the container with the product under study, the latter was saturated with gas for 15-50 seconds, and after it was pushed into the pipeline, it was closed with cut-offs from both sides. The remaining part of the liquid was drained from the container and filled with the second product in the volume of 3 liters. Then, with open cut-offs, liquid transfer was carried out at a pressure of 0.05·105 Pa on the final section of the pipeline [5,7]. The displaced liquid flowed into the separator, where it was separated from the gas. The total volume of the liquid (1.32 l) and the volume of the resulting "wedge" - a mixture of products - were also measured here. The results of the measurements are presented in Fig. 1-3 in the form of curve dependences of displacement coefficients a = Vdc/Vgc on gas content

-

V = Vdc/VSc

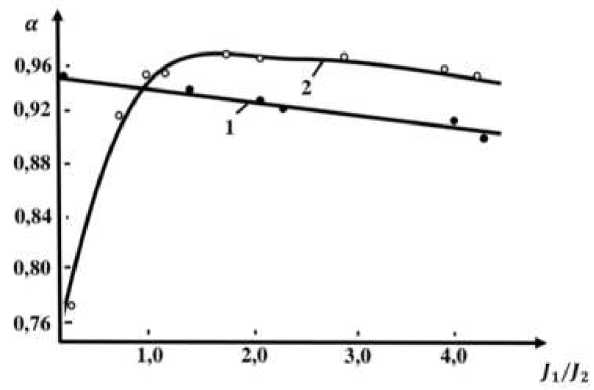

Fig. 2. Dependence of the volume of the mixture (α) on the degree of gas saturation (φ)

1-in front of the low-viscosity product (water), behind the high-viscosity product (ДТ); 2-in front of the low-viscosity product, behind the high-viscosity product, saturated with gas; 3-both products are saturated with gas, the low-viscosity product is ahead; 4- both products are saturated with gas, ahead is a high-viscosity product

It follows from the dependences of the curves presented in Fig. 1-3 that the smallest volume of the mixture is formed when one liquid is successively displaced by another in the case when the gas-saturated product is the displacing low-viscosity product (curve 1 in Fig. 1) [4, 8],. In this case, the volume of the mixture is 15...16% less than with the same sequence of displacement of non-aerated liquids (the abscissa of curves 1 and 2 in Fig. 1 is equal to 0) and 1.5...2% less than in the case when the gas-saturated product is a displaced high-viscosity product (curve 2 in Fig. 1). In the reverse sequence of displacement, when the displacing product is a displaced high-viscosity product, the minimum volume of the mixture in the case of gas saturation of the following product is reached at larger values of the gas factor than in the case of gas saturation of the low-viscosity product in front. However, in both noted cases of sequential displacement, the volume of the resulting mixture is 5..6% less than in experiments on the displacement of non-carbonated products (abscissa of curves 1 and 2 on Fig. 2 is equal to 0).

Fig. 3. Dependence of the volume of the mixture on the relative value of gas saturation

1-both products are saturated with gas, the low-viscosity product is ahead;

-

2- both products are saturated with gas, ahead is a high-viscosity product

Somewhat different results are obtained during gas saturation of the product contact zone, when the displaced liquid is a low-viscosity product [6,7, 8], (curve 3 on Fig. 2, curve 1 on Fig. 3). In this case, the volume of the resulting mixture of products is greater than in experiments with non-aerated liquids. Positive results are obtained only if a highly viscous product moves ahead (curves 4 and 2, respectively, on Fig. 2 and 3).

Thus, the conducted experiments showed the possibility of using gas-saturated systems as a separating plug during sequential pumping of petroleum products, and the greatest effect is achieved when the gas-saturated product is a displacing product.