Метод воздушного посева семян пустынных растений и использование моторных дельтапланов для посева

Автор: К. Д. Астанакулов, С. М. Ураков

Журнал: Современные инновации, системы и технологии.

Рубрика: Инженерные агропромышленные науки и лесное хозяйство

Статья в выпуске: 5 (1), 2025 года.

Бесплатный доступ

В статье анализируются площади пустынь в мире и Узбекистане, их состояние и деградация, методы посева семян пустынных растений и технические средства для их реализации. Согласно данным, текущая площадь пустынь в мире составляет 21,0 млн квадратных километров, а в Узбекистане — 32,0 млн гектаров, при этом около 40% пустынь испытывают различные степени деградации. Одним из способов улучшения растительного покрова пустынь для предотвращения их расширения и повышения питательной ценности пастбищ является дополнительный посев семян пустынных растений. На основе анализа состояния и особенностей пустынь сделан вывод о том, что воздушный посев семян пустынных растений является наиболее эффективным методом для холмистых и неровных территорий пустынь. Для реализации этого метода с минимальными затратами предлагается использовать моторные дельтапланы. В связи с этим разработан метод посева семян пустынных растений с использованием дельтапланов, оснащенных устройствами для посева семян. Применение данного метода и технических средств обеспечивает выполнение технологического процесса в соответствии с установленными стандартами при высокой эффективности работы и снижении затрат.

Пустыня, деградация, посев семян пустынных растений, воздушный посев, моторный дельтаплан, устройство для посева

Короткий адрес: https://sciup.org/14133017

IDR: 14133017 | УДК: 631.559:631.67:504.4 | DOI: 10.47813/2782-2818-2025-5-1-4001-4006

Текст статьи Метод воздушного посева семян пустынных растений и использование моторных дельтапланов для посева

DOI:

As of today, еhe desert is part of the ecosystem and the total area of deserts worldwide is 21.0 million square kilometers, accounting for 14% of the Earth's land surface [1, 2]. Nowadays, the drought is currently observed in more than 100 countries, covering 30% of the planet’s surface and affecting regions inhabited by nearly 2 billion people. Due to climate change, drought is becoming more severe globally, leading to a decline in vegetation cover and accelerating desertification [3, 4].

In Uzbekistan, the total area of desert and semidesert lands is 32 million hectares, of which 16.6 million hectares are used as pastures. This constitutes 79% of the country's total rangelands [5]. However, currently, 40% of desert pastures have undergone various degrees of degradation, and their average productivity has decreased by 20-30%. The degraded pastures that require urgent restoration in the country cover approximately 8.0 million hectares [5, 6].

Desertification is also increasing in Uzbekistan. As a result of the Aral Sea disaster alone, more than 5.5 million hectares of land have turned into the Aralkum Desert. Currently, due to dust storms and strong winds, sand drift is spreading, leading to an expansion of desert and semi-desert areas in the country [4 - 6].

Geobotanical research conducted on pastures indicates that approximately 13% of pastures have experienced degradation, while the vegetation cover has significantly declined in 32% of them. As a result, the productivity of desert pastures is currently 1.5-2.0 centners per hectare, which is two times lower compared to neighboring countries such as Kazakhstan and Kyrgyzstan [6].

It is well known that preventing pasture degradation is crucial, but equally important is increasing their productivity by enhancing vegetation cover. Natural vegetation in pastures helps prevent sand drifts, dust storms, and strong winds while also improving the feed base for livestock. This, in turn, enhances the efficiency of land use, promotes the development of sheep and goat farming, cattle breeding, camel breeding, and horse breeding, increases household incomes, and boosts livestock production. Therefore, increasing vegetation cover in deserts plays a key role in addressing various urgent environmental, social, and economic challenges.

However, to prevent pasture degradation, maintain stable vegetation cover, and, if possible, increase it, desert plant seeds must be sown in these areas [7-9].

Analyses show that the most effective method for sowing plant seeds in deserts is aerial seeding, using motorized hang gliders as the primary sowing tool. This method enables cost-effective seeding operations even in hilly and sandy areas where ground vehicles cannot reach or operate efficiently.

MATERIALS AND METHODS

The condition of desert pastures worldwide and in Uzbekistan was studied based on internet data, scientific articles, manuals, monographs, and dissertations by researchers in this field. In this process, heavily degraded desert pastures within the country's regions were identified, and their total area and the proportion of degraded land in each region were determined.

Methods for sowing plant seeds in desert pastures, as well as the structures, technological processes, and technical means used for their implementation, were examined based on information from literature sources, electronic resources, and articles published in journals and collections.

The advantages and disadvantages of equipment design and technological processes were analyzed using morphological analysis, synthesis, and the ARIZ (Algorithm for Inventive Problem Solving) methods. The development of the structural scheme for the desert pasture seed-sowing device was carried out using CAD/CAM/CAE methods.

RESULTS AND DISCUSSION

The “AGRO-PARVOZ” multi-sector aviation production enterprise (“AGRO-PARVOZ” MAPE) has been utilizing motorized hang gliders for sowing desert plant seeds. The advantage of using motorized hang gliders for this purpose lies in their ability to perform agrotechnical operations with higher efficiency compared to machine-tractor aggregates, especially in conditions where ground vehicles cannot operate. Additionally, they offer significantly lower costs compared to airplanes.

Currently, “AGRO-PARVOZ” MAPE primarily uses Poisk-06 SX motorized hang gliders, which have been specially equipped for carrying out agrotechnical operations in desert plant seed sowing (Figure 1).

Figure 1. Poisk-06 SX motorized hang glider equipped with a desert plant seed sowing device.

The Poisk-06 SX motorized hang glider consists of a frame, engine power unit, pilot seat, propeller, wings, landing gear, fuel tank, and control panel. For sowing desert plant seeds, it is equipped with a specially designed seed-sowing device (Figure 2).

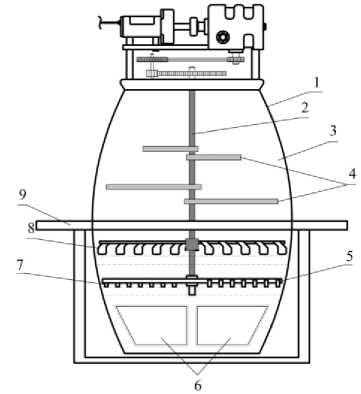

The device consists of a seed hopper (1) and a main working shaft (2). The hopper is divided into two sections: the seed storage section (3) and the seed metering section (5). In the seed storage section (3), dusting elements (4) are attached to the main shaft (2), while in the seed metering section (5), a propeller (7) is installed for seed discharge, along with a distributor (8) for transferring seeds to the sowing chamber.

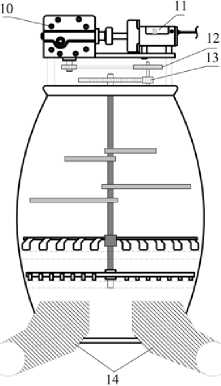

At the bottom of the sowing chamber, there are air intake vents (6), while at the rear, seed-air mixture outlets (13) are installed. The main shaft of the device is driven by a worm gearbox (10) mounted at the top of the hopper (1), which reduces speed and transmits motion via an electric motor (11) through a belt-gear drive assembly (12).

The hopper (1), along with all its working and auxiliary components, is mounted on a frame (9), which is also used to attach the device to the motorized hang glider.

-

a) Front view

b) Rear view

Figure 2. Schematic diagram of the seed-sowing device for motorized hang gliders.

The technological operation of the device is carried out as follows: Seeds intended for sowing are loaded into the upper section (3) of the hopper (1). Once the motorized hang glider takes off and heads toward the designated sowing area, the seed-sowing process begins. Upon reaching the sowing location, the electric motor (11) is activated, which, through the worm gearbox (10), reduces the rotational speed and drives the main working shaft (2). The dusting elements (4) attached to the main shaft (2) continuously mix the seeds, preventing them from clumping inside the hopper and directing them through the slot to the distributor (8). The distributor

-

(8) further evenly distributes the seeds and delivers them through the slot to the propeller (7). The propeller (7) pushes the seeds forward, releasing them into the dispersion chamber through the main opening. As the motorized hang glider moves through the air, a continuous airflow enters through the intake vents (6) and exits through the seed-air mixture outlets (13). This creates a constant airflow inside the dispersion chamber, which carries the released seeds, dispersing them over a wide area in the air before they fall onto the ground. Currently, this device is widely used for sowing desert plant seeds (Figure 3).

Figure 3. Motorized hang glider equipped with a sowing device in operation.

The developed device is fundamentally different from other sowing devices, and its innovative design has been granted an invention patents No. IAP 06868 by the Intellectual Property Agency of the Republic of Uzbekistan [10]. The sowing rate can be adjusted by changing the rotation speed of the main distribution shaft and the flight speed of the motorized hang glider, while the sowing width can be modified by adjusting the position of the distribution outlets.

When using the aero-sowing device installed on the "Poisk-06 SX" motorized hang glider for sowing saxaul and other desert plant seeds in arid regions [11], the operational efficiency reached an average of 100-400 ha/h, with a fuel consumption of 0.25 kg/ha. The uniformity of seed distribution along the flight path of the aero-sowing device was 97.2%, while the coverage uniformity across the sowing width was 91.7%. This device not only ensures uniform seed distribution in desert areas when used with motorized hang gliders but also reduces operational costs for sowing by 149,588.3 UZS per hectare.

CONCLUSION

To prevent desertification, mitigate vegetation degradation, and increase plant cover in desert areas, additional seed sowing operations must be carried out. Utilizing motorized hang gliders equipped with a completely new type of sowing device enables efficient sowing and afforestation efforts in areas where ground-based machinery is either ineffective, difficult to access, or entirely inaccessible, while also minimizing financial costs. When using the aerosowing device installed on a motorized hang glider for sowing saxaul and other desert plant seeds, the operational efficiency ranges between 100-400 ha/h, with a fuel consumption of 0.25 kg/ha. The uniformity of seed distribution along the flight path of the aero-sowing device is 97.2%, while the coverage uniformity across the sowing width is 91.7%.