Mineralogical evidence of the inevitable losses of tin during ore processing at the Pravourmiysky deposit (Khabarovsk region)

Автор: Chikisheva T.A., Prokopyev S.A., Prokopyev E.S.

Журнал: Вестник геонаук @vestnik-geo

Рубрика: Научные статьи

Статья в выпуске: 6 (306), 2020 года.

Бесплатный доступ

The article presents the results of a comprehensive mineralogical study of the ores of the Pravourmiysky deposit using optical microscopy and X-ray analysis, scanning electron microscopy. Mineralogical studies have identified and explained the causes of possible losses of tin with enrichment tails. Тhe data obtained were used in the development of the ore beneficiation scheme and were included in the technological regulations for the designing of the beneficiation plant.

Multicomponent tin ores, mineralogical and technological assessment of ores, difficult ores

Короткий адрес: https://sciup.org/149129431

IDR: 149129431 | УДК: 553.45 | DOI: 10.19110/geov.2020.6.3

Текст научной статьи Mineralogical evidence of the inevitable losses of tin during ore processing at the Pravourmiysky deposit (Khabarovsk region)

According to Antaike, a leading Chinese research organization in the field of non-ferrous metallurgy, global demand for tin will exceed supply in the coming years, and the growth rate of its use will amount to more than 10 % per year. However, the lack of tin resources will limit the growth of its production. Worldwide, shipments are declining as a result of declining tin production in Indonesia, which is the world's leading tin exporter. Thus, investments in the discovery of new tin deposits and the development of its production have a good prospect [1].

The main reserves of tin in Russia are concentrated in the east of the country. Three primary tin ore deposits were developing in Russia in 2018: two in the Khabarovsk Region and one in Primorsky Region. Ore processing with the extraction of tin into commercial concentrates is carried out only at the facilities of the Khabarovsk Region [6,7].

From the economic point of view, the main tin ore object is the Pravourmiysky rich ore deposit (1.16% Sn). We can say that the Pravourmiysky deposit is today the only source of tin raw materials in Russia [6,7]. The field is located on the territory Russian Far East (the Verkhnebureinsky district of the Khabarovsk Region. Fig.1).

Evaluation of typomorphic features and properties of minerals that determine the mineralogical and technological types and varieties of ores in terms of cost-effectiveness of their processing is very important in organizing an ore preparation system and choosing the most effective methods for mineral separation [2, 10, 11].

Ores of the Pravourmiysky deposit are complex. Together with tin, tungsten and copper are mined from the ore of the deposit. The purpose of this work is to identify the mineralogical features of the ore that affect its ore dressability and to identify the causes of tin losses with tailings.

Research methods

Mineralogical study of ore was carried out in accordance with the methodological recommendations of the scientific council on the methods of mineralogical research [8, 9].

A complex of ore research has been completed, including:

Fig. 1. Location of the Pravourmiysky deposit

Рис. 1. Местоположение Правоурмийского месторождения

ore with the study of mineral intergrowths (stereoscopic microscope Micromed — MC-2-ZOOM and polarizing microscope Micromed POLAR 3), LLC PC Spirit;

Texture and structural features of ore

The enclosing rocks are represented to varying degrees by greisenized acidic volcanics. The color of the rocks is from light gray to dark gray. The studied rocks are characterized by an inhomogeneous spotty, streaky, breccia-shaped, schistled texture and a different-grain, from fine to mediumgrained, sometimes porphyry structure. Ore mineralization is represented by arsenic minerals (arsenopyrite, lollingite) and copper sulfides (chalcopyrite, bornite, chalcocite, covellite). Ore minerals form veins, inclusions and clusters. Chalcopyrite and bornite prevail among copper minerals.

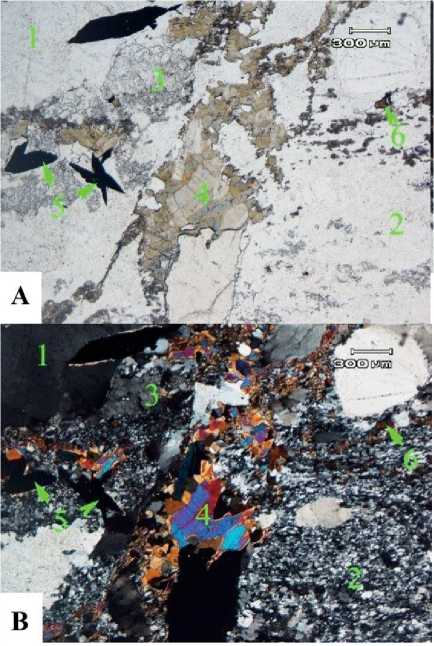

Microscopic examination showed that the studied rock is a closely intergrowth grains of quartz, topaz, tourmaline, feldspars, fluorite, sericite, biotite, cassiterite and ore sulfide minerals (Fig. 2, 3).

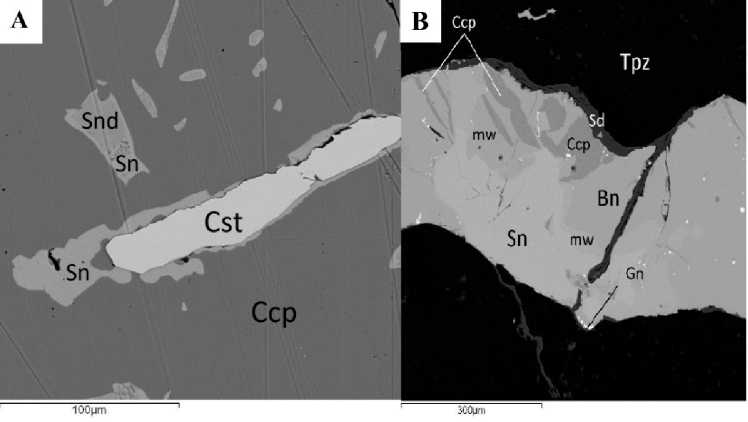

The main tin-containing mineral is cassiterite. In lesser numbers, stannite, stannoidite, and mawsonite are found. Sulfostannates of iron and copper are visualized in the decomposition structures of solid solutions based on chalcopyrite and bornite (Fig. 4). Tin-containing sulfide minerals have no industrial value and are not extracted during ore processing. However, the presence of iron and copper sulfostannates plays a significant role in the process of sulfide flotation, because its affect the quality of the products obtained.

The problem of determining the parameters of tin ore dressing is related to the size of tin minerals in the ore and their fragility. The basic requirement for ore preparation of

Fig. 2. Grains of porphyry quartz (1), fine-grained quartz (2), topaz (3), tourmaline (4) interspersed with ore mineral (5) and cassiterite (6) Micrograph of thin section. A — in plane-polarized light, B — with crossed polars

Рис. 2. Порфировые выделения кварца (1) в неоднородной основной массе тонкозернистого кварца (2), топаза (3), турмалина (4) с вкраплениями рудного минерала (5) и касситерита (6). Микрофотография фрагмента прозрачного шлифа. А - николи ||, B - николи х

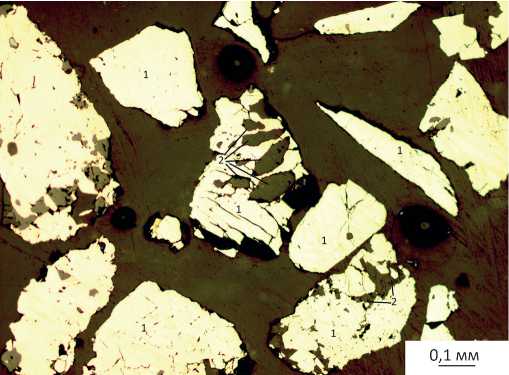

Fig. 3. Micrograph of massive accumulations of ore minerals, in which there is a close intergrowth of cassiterite (1), arsenopyrite (2), lollingite (3), and topaz (4). Polished thin section in plane-polarized light

Рис. 3. Микрофотография массивных скоплений рудных минералов, в которых отмечается тесное срастание касситерита (1) с арсенопиритом (2), лёллингитом (3), топазом (4). Полированный шлиф. Николи || tin-containing ores is a maximum disclosure of a valuable mineral and a minimum grinding of ore. The texture and structural features of the ore are difficult. The following main types of inclusions of ore minerals are observed [3]:

-

1. Ore and non-metallic minerals do not form inclusions in each other;

-

2. Ore minerals form inclusions inside the grains of rock-forming minerals;

-

3. Ore minerals form in other ore minerals;

-

4. There are inclusions of rock-forming minerals in grains of ore minerals.

All of the types of inclusions are established in the ore.

The first and second types are predominant, and the third and fourth types are also found. In the presence of inclusions of the first type, ore destruction occurs along intergranular boundaries, which have the least strength. This allow to disclose valuable minerals without the formation of a large number of their intergrowths with other minerals. Other types of impregnation are more complex — inclusions of cassiterite in topaz with high hardness and strength are often observed in ore, inclusions of other minerals are also present in cassiterite grains. The crushing of such ore leads to the formation of a large number of intergrowths, including a closed type, with further grinding of which brittle cassiterite becomes sludge. Optical methods have shown that large cassiterite clusters in ore samples consist of separate, smaller (from 0.1 to 2 mm) cassiterite grains. Almost all cassiterite grains catalyzed, broken by systems of numerous cracks, due to which grains and clusters of cassiterite have a block structure. Such clusters of cassiterite already at the first stages of ore grinding can go into fineness less than 0.1-0.3 mm.

Mineral composition of ore

The mineral composition of the ore, crushed to a particle size less than 2 mm (table 1) was obtained using a set of methods (optical microscopy, x-ray diffraction analysis, scanning electron microscopy).

According to table 1, cassiterite in the ore accounts for 1.37 %. Sulfostannates of iron and copper (stannite, mawsonite, stannoidite) are noted in single grains.

When grinding ore, many intergrowths of cassiterite with other minerals are formed. The distribution of cassiterite in enrichment products depends on the types of its intergrowths with other ore minerals. The extraction of cassiterite intergrowths into the products of gravitational enrichment also depends on the density of the mineral with which it grows together. For example, cassiterite inclusions in quartz are extracted into tails, and arsenopyrite inclusions are extracted into concentrate. In addition, the density of intergrowths can vary depending on the volume of the ore phase in it. The predominant rock-forming minerals are quartz and topaz. They have different densities (quartz 2.5– 2.8 g/cm3, topaz 3.4–3.57 g/cm3), which determines the density of their intergrowths with cassiterite (table 2).

Fig. 4. BSE images of sulfostannates of iron and copper. A — the decomposition of the solid solution of stannite and stannoidite in the chalcopyrite matrix, B — the intergrowth of mawsonite, stannite, bornite and chalcopyrite with galena inclusions.

Cst — cassiterite, Sn — stannite, Snd — stannoidite, Ccp — chalcopyrite, Bn — bornite, mw — mawsonite, Gn — galena, Sd — siderite, Tpz — topaz

Рис. 4. Сульфостаннаты железа и меди. А — распад твёрдого раствора станнина и станноидита в матрице халькопирита, B — срастание моусонита, станнина, борнита и халькопирита c включениями галенита. Прожилок в топазе. Изображения в обратнорассеянных электронах

Table 1. The mineral composition of the ore Таблица 1. Минеральный состав руды

|

Mineral / Минерал |

Content, % wt. Содержание, % мас. |

Mineral / Минерал |

Content, % wt. Содержание, % мас. |

|

Cassiterite / Касситерит |

1,37 |

Topaz / Топаз |

14,92 |

|

Stannite, stannoidite and mawsonite Станнин, моусонит, станноидит |

Single grains Единичные зёрна |

Tourmaline / Турмалин |

3,74 |

|

Wolframite / Вольфрамит |

0,04 |

Fluorite / Флюорит |

0,98 |

|

Native bismuth, wittichenite / Самородный висмут, виттихенит |

Single grains / единичные зёрна |

Pyroxene / Пироксен |

0,04 |

|

Arsenopyrite / Арсенопирит |

2,61 |

Zirkon / Циркон |

Single grains Единичные зерна |

|

Lollingite / Лёллингит |

2,30 |

Titanite / Титанит |

Single grains Единичные зерна |

|

Copper sulphides (chalcopyrite, bornite, сhalcocite, сovellite) Сульфиды меди (халькопирит, борнит, халькозин) |

1,26 |

Monazite / Монацит |

Single grains Единичные зёрна |

|

Quartz / Кварц |

23,69 |

Iron hydroxides Гидроксиды железа |

0,65 |

|

Feldspars / Полевые шпаты |

0,73 |

Scorodite / Скородит |

Single grains Единичные зёрна |

|

Mica / Слюды |

2,49 |

Mineral aggregates Обломки пород |

45,17 |

|

Total / Итого: |

99,99 |

||

According to table 2, we can conclude that, quartz with cassiterite-poor intergrowth and its inclusion of cassiterite in quartz during the process of gravitational enrichment will be extracted in tails. However, cassiterite intergrowths of the same quality with topaz will be concentrated in the intermediate products along with other intergrowths. Cassiterite containing in intergrowths will be extracted after the grinding of the material of intermediate products. Thus, it can be concluded that in the process of ore grinding, cassiterite grains are sludged and a large number of cassiterite intergrowths are formed with other minerals of the ore. Loss of cassiterite during gravitational ore dressing may be associated with sludge. Cassiterite -containing intergrowths can be extracted into the intermediate product and cassiterite can be extracted from them after the grinding processes.

Tin losses analysis

The studied ore is enriched according to the gravityflotation scheme. As part of the enrichment study, mineralogical studies of enrichment products were carried out to determine the losses of tin with gravity enrichment tailings and sulphide flotation tailings. Optical-mineralogical analysis revealed that 96.1% of cassiterite in the sample of gravitational tails is in size less than 40 microns in the form of free grains. Losses of cassiterite in the size range of -2 + 0.5 mm are mainly associated with cassiterite-poor intergrowths and cassiterite inclusions in quartz. Such intergrowths, due to their low density (table 2), are distributed in the tail part and are inevitable losses of tin during gravitational enrichment. When analyzing briquette thin sections made from the classified material of flotation sulfide tails, it was found that the tin losses in them are associated with intergrowths of cassiterite with arsenopyrite of predominantly closed type (Fig. 5) and with tin sulfide mineral — stannite 18

(Fig.6). Phase chemical analysis revealed that 98-99 % of the tin in the sample of sulphide flotation tailings is contained in the sulphide form — stannite, mawsonite, stannoidite. Tin associated with cassiterite is present in subordinate quantities.

In the sulfide flotation product, 89.7 % of cassiterite is distributed in fineness of less than 40 microns. In the particle size classes —2 + 1 mm, -0.5 + 0.25 mm and in the particle size range —0.125 + 0.040 mm no cassiterite grains were noted. Cassiterite in the size class —1 + 0.5 mm accounts for 7.7%, it is located in intergrowths with rockforming minerals. In the size class —0.25 + 0.125 mm, 2.6% of cassiterite is in the form of free grains.

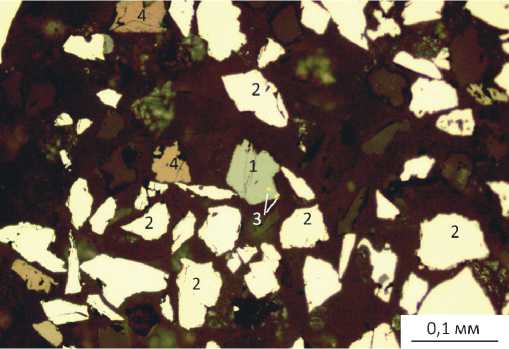

Fig. 5. Microphotograph of cassiterite intergrowths (2) with arsenopyrite (1) in a sulfide flotation product. Briquette section

Рис. 5. Микрофотография срастаний касситерита (2) с арсенопиритом (1) закрытого типа в сульфидном продукте флотации. Брикетный шлиф, отражённый свет

Fig. 6. Micrograph of fragments of arsenopyrite (2) and copper sulfides: chalcopyrite (3) and bornite (4). Stannin grains (1) in intergrowth with chalcopyrite (3). Briquette section

Fig. 6. Микрофотография фрагментов арсенопирита (2) и суёь-ôèäîâ ìåäè: õàëüêîïèðèòà (3) è áîðíèòà (4). Çåðíà îëîâà (1) â ñðàñòàíèè ñ õàëüêîïèðèòîì (3). Áðèêåòíûé øëèô

Table 2. The density of intergrowths of cassiterite with rock-forming minerals

Таблица 2. Плотность сростков касситерита с породообразующими минералами

|

¹ |

Density of intergrowth, g/cm3 Ïëîòíîñòü áåäíûõ ñðîñòêîâ è âêëþ÷åíèé êàññèòåðèòà, ã/ñì3 |

|

|

Quartz + cassiterite Êâàðö+êàññèòåðèò |

Topaz + cassiterite Òîïàç+êàññèòåðèò |

|

|

1 2 3 4 5 6 7 8 9 10 Mean Ñðåäíåå |

2,91 3,11 2,98 3,00 2,90 2,95 2,98 2,91 2,92 2,91 2,96 |

3,73 3,80 3,65 3,91 3,67 3,80 4,00 3,95 3,92 3,88 3,83 |

Conclusions

Mineralogical studies have proved that the ore of the Pravourmiysky deposit is difficult for enrichment according to the following criteria: polymineral variable composition, the joint presence of several forms of tin (cassiterite and sulfostannates of iron and copper), complex structural and textural features of the ore (joint presence of cassiterite, sulfides and rock-forming minerals different shapes and sizes in close association with each other).

As a result of a mineralogical study of the ore enrichment products of the Pravourmiysky deposit, it was found that tin losses in the tails of gravity enrichment are associated with cassiterite grains with a particle size of less than 0.04 mm.

As cassiterite is a brittle mineral, sludging occurs at each stage of crushing and grinding. The degree of sludge increases significantly with regrinding, and grinding of finely disseminated ores also gives a much greater sludge [5].

During the flotation process, tin is lost in the form of sulfostannates of iron and copper, less often in the form of intergrowths of cassiterite with arsenopyrite. It is possible to extract cassiterite from these products after the operation of fine grinding if it is economically feasible. The recovery of iron and copper sulfostannates will also require the operation of regrinding and subsequent selective flotation of sulfides. Moreover, due to the uneven dissemination of minerals, it is recommended to use multi-stage grinding and flotation schemes [4].

Список литературы Mineralogical evidence of the inevitable losses of tin during ore processing at the Pravourmiysky deposit (Khabarovsk region)

- Danilov U. G.& Grigoryev V. P. Problemy i perspektivy razvitiya olovyannoj promyshlennosti Rossii(Problems and perspectives of tin industry in Russia). Gornaya promyshlennost, V. 5 (135), 2017, pp. 83-87

- Pirogov B. I. Evolyuciya tekhnologicheskih svojstv mineralov (Evolution of technological properties of minerals). Geologomineralogicheskij vestnik, V.1 (19), 2008, pp. 5-17

- Smol'yakov A. R.Raskrytie mineralov pri izmelchenii rudy(Opening of minerals at crushing). Gornyj informacionnoanaliticheskij byulleten, V 8, 2007, pp. 224-234.

- Bocharov V. A., Ignatkina V. A. & Yushina T. I. Flotacionnoe obogashchenie poleznyh iskopaemyh: uchebnik (Flotation dressing of mineral resources: textbook). Moscow: Gornaya kniga, 2017.

- Matveev A. I., Eremeeva N. G. Tekhnologicheskaya ocenka mestorozhdenij olova Yakutii (Technological evaluation of tin deposits of Yakutia). Novosibirsk: Geo, 2011.