Mining Waste Management of the Arctic Industrial Enterprises: Environmental Protection and Economics of Production

Автор: Ivanov S.V., Tsukerman V.A.

Журнал: Arctic and North @arctic-and-north

Рубрика: Social and economic development

Статья в выпуске: 55, 2024 года.

Бесплатный доступ

The problems of mining waste management at industrial enterprises and increasing the economy of production are among the most urgent ones, especially for the Arctic ecosystems, characterized by high sensitivity to external factors and the complexity of recovery. The research was conducted on the example of large industrial corporations directly operating in the Arctic, including PJSC PhosAgro, PJSC MMC Norilsk Nickel, Severstal Resource division of PJSC Severstal and PJSC NOVATEK. The key indicators related to waste management for 2018-2022 were analyzed. The trend of increasing volumes of mining waste in the Arctic was revealed, while the level of its utilization remained practically unchanged. It is proposed to intensify scientific research in the field of rational use of mining waste and to develop technologies for their processing, taking into account the impact on the Arctic ecosystems. It is suggested to create research and production centers for each industrial enterprise using the experience of the balanced “triple helix” model. It is recommended to actively participate in the Interdepartmental Scientific Council of the Russian Academy of Sciences on the development of the mineral resource base and its rational use, created in 2023, to develop the scientific foundations for the extraction and processing of minerals and accelerate import substitution.

Industrial enterprises, Arctic, ecological indicators, waste management, innovation technologies, economy

Короткий адрес: https://sciup.org/148329522

IDR: 148329522 | УДК: [622:502](985) | DOI: 10.37482/issn2221-2698.2024.55.40

Текст научной статьи Mining Waste Management of the Arctic Industrial Enterprises: Environmental Protection and Economics of Production

DOI:

The development of mineral resources in the Arctic zone of the Russian Federation (hereinafter referred to as the Arctic) by mining enterprises is accompanied by the formation of waste, which has a negative impact on the natural environment. For the Arctic ecosystems, the problem of waste is particularly important, since the natural environment in this region is extremely sensitive to external influences and is characterized by slow recovery, so the consequences can be irreversible [1, Smirennikova E.V., Ukhanova A.V., Voronina L.V. , p. 73; 2, Tsukerman V.A., Ivanov S.V.]. In this regard, the issues of reducing the formation of mining waste at production enterprises and increasing the efficiency of their use are especially relevant. Mining waste management involves collection, transportation, processing, recycling or disposal.

The main decisions and legal framework of state policy aimed at reducing waste by industrial enterprises are formulated in laws No. 7-FZ “On environmental protection” and No. 89-FZ “On production and consumption waste”, as well as Decrees of the President of the Russian Federation No. 164 “On the fundamentals of the state policy of the Russian Federation in the Arctic for the period until 2035” and No. 204 “On national goals and strategic objectives of the development of the Russian Federation for the period until 2024” and other legislative documents of the Government of the Russian Federation 1, 2, 3, 4. Mining enterprises need to comply with Russian and international legislation related to industrial waste, develop and implement innovative technologies and take the necessary measures to ensure environmental safety.

Wastes are divided into five hazard classes according to the degree of their impact on the environment 5. Mining wastes are assessed as practically non-hazardous (hazard class 5), however, they are a source of permanent and significant pollution of territories, including after the completion of field operation [3, Nevskaya M.A., Seleznev S.G., Masloboev V.A. et al., p. 13]. Already at the early stage of storage of such wastes, deterioration of technological qualities and change of properties of mineral masses in dumps begin due to hypergenesis. These wastes pose a serious threat to the atmosphere, soil and water because of dusting and migration of pollutants, which has become persistent in mining regions [4, Derome J., Lindroos A.J.; 5, Csavina J., Field J., Taylor M.P. et al.; 6, Zhang X., Yang L., Li Y. et al.; 7, Liang J., Feng Ch., Zeng G., et al.; 8, Cheng Z., Jiang J., Fajardo O.A. et al.]. Long-term disposal results in widespread and irreversible contamination of the surrounding areas.

Stored mining wastes are used in a limited volume and placed in dumps and tailing ponds, the maintenance of which requires serious economic costs [9, Suvorova O.V., Manakova N.K., p. 1; 10, Tsukerman V. A., Kozlov A. A.; 11, Maslov A.D., Melnikov N.N., Kalashnik A.I. et al.; 12, Kalash-nik A.I., Gilyarova A.A., Kalashnik N.A. et al.]. It should be especially noted that wastes are not losses and can be effectively used to obtain marketable products that can be widely used in the national economy. Depletion of the raw material base, decrease in the quality of raw materials, involvement in processing of more difficult to enrich ores and lack of efficiency of the existing enrichment technologies increase the interest in the search for unconventional and alternative sources of raw materials, which forces to consider mining wastes as technogenic deposits with great economic potential, especially in the case of extraction of mainly limited mineral components [13, Ivanova V.A., Mitrofanova G.V., p. 135; 14, Goryachev A.A., Makarov D.V., Svetlov A.V., p. 116]. Increasing the rational use of such technogenic deposits by involving them in economic circulation, for example, to obtain building materials, is cost-effective, since mining wastes are located, as a rule, in close proximity to the processing plants of enterprises, and the cost of their processing is low [15, Churkin O.E., Gilyarova A.A. p. 908; 16, Abaka-Wood G.B., Ehrig K., Addai-Mensah J. et al.]. This makes it possible to strengthen the mineral resource base, providing additional sources of mineral raw materials, to increase the efficiency of its exploitation and reduce the resource intensity of products, as well as to reduce the negative impact on the unique Arctic natural environment [17, Gromov E.V., Opalev A.S., Ivanova V. O.A., Khokhulya M.S.; 18, Tsuker-man V.A., Ivanov S.V.]. However, mining enterprises operate over a long period of time, and their high level of energy capacity and resource consumption seriously hinders technical re-equipment and reconstruction [19, Lèbre É., Corder G.D., Golev A.].

Materials and methods

The main objectives of the study include effective management of industrial waste, creation of the necessary conditions and infrastructure for waste processing, increasing the share of waste recycling, creating an environmental regulation system, developing and implementing innovative technologies to protect the environment and improve economic performance.

The purpose of the work is to study the possibility of reducing the environmental impact of Arctic mining enterprises by reducing production waste and their scientifically justified application in order to increase economic performance and stimulate environmentally oriented management of these enterprises.

The study was carried out using the example of large industrial corporations that directly operate in the Arctic and provided data in the public domain, namely: PJSC PhosAgro, PJSC MMC Norilsk Nickel, Severstal Resource division of PJSC Severstal and PJSC NOVATEK.

The methodological basis of the study is the systems approach and the theory of strategic management, which involves research into methods for analyzing various environmental and economic systems and developing strategic directions for their development. The assessment methodology involves consideration of problems of environmental protection and economic development, taking into account international recommendations of the Arctic countries. Various methods of analysis have been used to achieve the set goal, the information basis of which are annual reports of enterprises, annual statistical data of Rosstat, reports of regional divisions of the Minis- try of Natural Resources, relevant legislative requirements and scientific publications. Methods for specific handling of overburden waste and enrichment and their disposal at each of the presented Arctic industrial enterprises were considered. Key waste management indicators were analyzed, including: waste generation, disposal and neutralization, which reflect the future direction of waste use for product manufacture and application for various purposes, including processing, combustion and disposal.

Based on official indicators of the Federal State Statistics Service, a comparison of the Russian Federation and the Arctic in terms of the volume of generation, recycling and neutralization of production and consumption waste for the period 2018–2021 was made (Table 1).

Table 1 Generation, recycling and neutralization of production and consumption waste in the Russian Federation and the Arctic, million tons 6

|

2018 |

2019 |

2020 |

2021 |

|

|

Waste generation in the Russian Federation |

7 226 |

7 751 |

6 956 |

8 449 |

|

Waste generation in the Arctic |

351.6 |

410.4 |

437.3 |

462.1 |

|

Waste management and neutralization in the Russian Federation |

3 818 |

3 882 |

3 429 |

3 937 |

|

Waste management and neutralization in the Arctic |

321.8 |

244.2 |

167.4 |

314.3 |

It can be noted that in the Arctic, as well as in the Russian Federation, there is a certain upward trend in production and consumption waste generation over the period under review. The share of recycled and neutralized waste in the Russian Federation is increasing, and in the Arctic there is also an increase after a reduction in 2020.

Kirovsk branch of JSC Apatit

An analysis of waste utilization by the Kirovsk branch of JSC Apatit for the period 2018–

2022 is presented (Table 2)

Table 2

Landfill disposal and waste utilization at the Kirovsk branch of JSC Apatit, million tons

|

2018 |

2019 |

2020 |

2021 |

2022 |

|

|

Disposal of wastes at the landfill, including: |

67.1 |

81.6 |

102.4 |

104 |

85.2 |

|

Overburden rocks |

54.9 |

69.1 |

89.5 |

90.5 |

72.3 |

|

Enrichment wastes |

12.2 |

12.6 |

13 |

13.5 |

12.9 |

|

Utilization of wastes, including: |

21.3 |

19.7 |

18.6 |

15.9 |

24.3 |

|

Overburden rocks |

9 |

7.2 |

6.6 |

3.4 |

11.3 |

|

Enrichment wastes |

12.3 |

12.5 |

12 |

12.5 |

13.1 |

|

Current environmental |

4 587.7 |

4 351.9 |

4 825.3 |

5 510.3 |

6 534.6 |

6 Rosstat. Environmental protection in Russia. 2022: Statistical collection, Moscow 2022, p. 112.

7 Annual reports of PJSC PhosAgro. URL: (accessed 19 June 2023).

|

protection costs, mln rub. |

Rock, overburden rocks and enrichment wastes from the Kirovsk branch of JSC Apatit make up the bulk of the solid waste generated by PhosAgro (about 63%). An increase in the amount of waste recycled and disposed of at the landfill can be noted. However, the share of recycled rock overburden relative to stockpiled rock has decreased. The volume of recycled rocks varied depending on the company’s recycling capabilities. At the same time, the share of recycled enrichment waste remained practically unchanged. These wastes are mainly used to fill mined-out spaces. Depending on the volumes of waste disposal, the volumes of current costs were used, taking into account the change in the cost of activities.

It should be noted that at the Kirovsk branch of JSC Apatit, some waste is recycled and neutralized at special thermal neutralization plants in order to eliminate waste accumulation sites. Dust suppression measures are being implemented at tailing dumps.

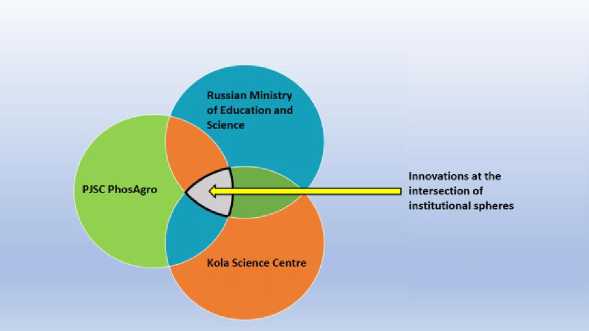

At the St. Petersburg International Economic Forum 2023, a cooperation agreement was signed between the Russian Ministry of Science and Higher Education, the Kola Science Centre of the Russian Academy of Sciences and PJSC PhosAgro. The agreement provides for the creation of a research center for the study of apatite-nepheline ores of promising extraction and the implementation of projects in the field of new production technologies. It is planned to conduct comprehensive research on the development and implementation of innovative technologies for ore preparation and enrichment. It is planned to consider the problem of using mining waste from the Kirovsk branch of JSC Apatit. Essentially, the authors of the article consider it advisable to use a balanced model of the triple helix of interaction, based on the interaction of the state, research organizations or universities and industrial enterprises, presented in Fig. 1. This model is effectively used by foreign countries, especially the Arctic ones, which increases the practical significance of improving the efficiency of mining waste management.

Fig. 1. “Triple helix” interaction [20, Tsukerman V.A., Zharov N.V.].

Polar division and Kola MMC of PJSC MMC Norilsk Nickel

The indicators of the formation and disposal of mining waste at the Polar division and Kola MMC of PJSC MMC Norilsk Nickel for the period 2018–2022 are presented (Table 3)

Table 3

Waste generation and disposal at industrial enterprises of the Polar division and Kola MMC of PJSC MMC

Norilsk Nickel, million tons 8

|

2018 |

2019 |

2020 |

2021 |

2022 |

|

|

Waste generation at the Polar division |

16 |

16 |

15 |

14 |

14 |

|

Waste utilization at the Polar division |

15.8 |

14.3 |

10.6 |

6.1 |

8.1 |

|

Waste generation at the Kola MMC |

8 |

8 |

8 |

8 |

7 |

|

Waste utilization at the Kola MMC |

2.5 |

4.3 |

6.1 |

4 |

4 |

|

Current environmental protection costs of MMC Norilsk Nickel, bln rub |

19.2 |

21.6 |

21.8 |

18.1 |

34.4 |

Almost all wastes generated are overburden and enrichment wastes. The volume of waste generation at the Polar division has a negative trend; the volume of waste disposal is also decreasing. The volume of waste generation at the Kola MMC remains practically unchanged, while the volume of waste disposal has increased, especially in 2020, due to the need to use waste directly by the enterprise: for example, in the preparation of filling mixtures, as flux when melting metal in smelting furnaces, for filling the mined-out spaces, backfilling quarries, roads, leveling sites, embanking railway tracks and strengthening tailings dumps. Most of the generated mining waste is used in own production, the rest is transferred to third-party companies for disposal. Unused waste is disposed of in tailings dumps at the Talnakhskaya concentrating plant, the Nadezhdinskiy metallurgical plant and the concentrating plant in Zapolyarnyy. Environmental protection costs have a positive trend, except for costs in 2021.

Severstal Resources division of PJSC Severstal

Research was conducted on the generation and disposal of waste in the Severstal Resources division of PJSC Severstal for the period 2018–2022. The results are shown in Table 4.

Table 4

Waste generation and utilization in the Severstal Resources division of PJSC Severstal, million tons 9

|

2018 |

2019 |

2020 |

2021 |

2022 |

|

|

Waste generation, including: |

193 |

202.6 |

208.7 |

203.5 |

179 |

|

Overburden rocks |

160.1 |

170.1 |

175.7 |

170.5 |

149 |

|

Enrichment wastes |

31.6 |

31.9 |

32.8 |

32.9 |

30 |

|

Expenditures on environmental protection measures in the sphere of waste management at PJSC Severstal, mln rub. |

634.6 |

683.8 |

476.9 |

740.7 |

663.3 |

Overburden ores and enrichment waste make up the bulk of waste generated by the Severstal Resources division. The company operates two tailings dumps at the enterprises of JSC Olkon and JSC Karelskiy Okatysh. Mining industrial waste is largely used directly by the corporation, primarily for construction, road repair, crushed stone production and dam embankment. The volume of overburden and enrichment wastes generated has increased significantly, except for the 2022 figures, mainly due to the withdrawal of the Vorkutaugol enterprise from the PJSC Severstal Corporation. Utilization indicators for the Severstal Resources division are not presented in the reports for the period under review. Expenditures on environmental protection measures in the field of waste management have a positive trend, except for 2020.

PJSC NOVATEK

Quantitative data on waste generation, utilization and neutralization at PJSC NOVATEK for the period 2018–2021 are presented (Table 5).

Table 5

Generation, utilization and neutralization of waste at PJSC NOVATEK, million tons 10

|

2018 |

2019 |

2020 |

2021 |

2022 |

|

|

Generation |

0.071 |

0.08 |

0.047 |

0.054 |

0.091 |

|

Utilization |

0.013 |

0.01 |

0.023 |

0.049 |

0.086 |

|

Neutralization |

0.003 |

0.014 |

0.017 |

0.007 |

0.008 |

|

Expenditures on environmental protection measures for safe waste management, mln rub. |

696 |

394 |

320 |

510 |

871 |

The corporation’s main activities are related to the exploration, production and processing of natural gas and liquid hydrocarbons. In connection with the main activity, drill cuttings account for about 97% of waste generated. The corporation has developed a unique technology for thermal desorption of waste, which, along with physical and mechanical methods, is used for the disposal of drilling cuttings in developed fields, which allows for the reuse of hydrocarbon-based drilling fluid. In addition, the corporation has a system of separate collection, accumulation and disposal of wastes, some of which are transferred to third-party companies. This makes it possible to get a significant environmental and economic effect. According to the data obtained, the volume of generated, disposed and neutralized waste has increased, with the exception of 2020 and 2021. In order to implement the developed technologies, the corporation increased the volume of expenditure in 2018, 2021 and 2022 after the pandemic.

Results and discussions

The research results allow us to consider the possibilities of increasing the efficiency of mining waste management by large Arctic resource corporations in order to improve the environmental regulation system and increase the efficiency of the production economy. Over the

-

10 Reports of PJSC NOVATEK in the field of sustainable development. URL: http://www.novatek.ru/ru/development/ (accessed 19 June 2023).

specified period, the considered Arctic corporations did not demonstrate a significant increase in the efficiency of environmental protection measures in the field of waste management, which is a consequence of insufficient development and implementation of innovative environmental protection technologies. It should be noted that natural and economic conditions make it necessary to identify and overcome institutional barriers to the strategic management of mining enterprises and, in particular, the use of waste. In this regard, Arctic corporations, together with scientific organizations, need to create their own modern base for the innovative development of enterprises, taking into account waste management.

Of particular importance is the stimulation of innovative waste management processes, the formation of environmental laws and the use of natural resources, aimed at maximizing the preservation of environmental balance. This allows us to recommend the development of a strategy for state regulation of waste management of Arctic mining enterprises, taking into account scientific, technological, environmental, socio-economic, and other territorial features. One of the most important goals of the strategy is the creation of an innovative economy in the Arctic territories and the transition from the extensive use of non-renewable natural resources to rational management.

The waste management system of Arctic mining corporations is characterized by low market motivation and the absence of strategic government policy in the sphere of mineral raw materials use. It is more profitable for industrial enterprises to pay for non-compliance with environmental protection requirements than to develop and implement innovative waste processing technologies. Waste management is in fact reduced to compliance with the technological regulations of mineral extraction projects on fulfilment of the main production processes of resource enterprises.

The decline in the quality of the mineral resource base with the continuing trend towards extensive use of subsoil resources allows us to conclude that the mass of waste from enterprises will increase in subsequent years. Wastes with valuable consumer properties and useful minerals contained in them that are not extracted during ore enrichment should be effectively used in economic turnover. In this regard, it should be noted that the organization of waste transfer for the production of valuable products is insufficiently effective. In order to increase the degree of utilization of mineral waste, special projects need to be developed and implemented, which requires the fundamental interest of companies.

Further research should be focused on improving the state environmental policy in the Arctic in the field of waste management and increasing the availability of investments, subsidies or other financial incentives to implement the developed environmental innovations aimed at protecting the environment and increasing the socio-economic development of regions that exploit and process mineral resources.

Conclusion

-

1. The volumes of mining waste from Arctic enterprises had increased over the period under review, while their disposal had essentially remained at the same level, including the use for the corporations’ own purposes.

-

2. The corporations reviewed do not demonstrate a real increase in waste utilization relative to its generation, except for the Kola MMC of PJSC MMC Norilsk Nickel, which shows positive dynamics.

-

3. The research has shown that corporations do not sufficiently provide for financial investments in environmental protection: expenditures on the creation of innovative waste management technologies have not practically increased. The developed technology of waste thermodesorption of PJSC NOVATEK can be noted, which made it possible to increase the recycling and neutralization of waste and, accordingly, to increase efficiency, which allowed to obtain a significant environmental and economic effect due to the increase in the cost of measures. As part of improving the environmental and economic condition of mining enterprises, it is proposed to use scientifically justified amounts of financial resources and make appropriate management decisions.

-

4. To improve the efficiency of waste management, it is advisable to create research and production centers based on the use of a balanced “triple helix” model on the example of a tripartite agreement between the state, research organizations (universities) and industrial enterprises based on the experience of the Arctic countries. Similar agreements between PJSC PhosAgro, the Kola Science Center of the Russian Academy of Sciences and the Ministry of Science and Higher Education of Russia, concluded in 2023, should be supported.

-

5. Special attention should be paid to the development of innovative technologies and the rational use of mining waste to improve the quality of the Arctic environment and the economics of production.

-

6. It is recommended to use the capabilities of the Interdepartmental Scientific Council of the Russian Academy of Sciences, created in 2023, for the development of the mineral resource base and its rational use to assist in the development of the scientific foundations for the extraction and processing of minerals and accelerating import substitution.

Список литературы Mining Waste Management of the Arctic Industrial Enterprises: Environmental Protection and Economics of Production

- Smirennikova E.V., Ukhanova A.V., Voronina L.V. Estimation of the Environment State and Ensuring Environmental Security in the Russian Arctic. Administrative Consulting, 2018, no. 9 (117), pp. 59–78. DOI: https://doi.org/10.22394/1726-1139-2018-9-59-78

- Tsukerman V.A., Ivanov S.V. Waste Management of Mining Enterprises of the Arctic Zone of the Russian Federation, Case Study for Murmansk Region. IOP Conference Series: Earth and Environ-mental Science, 2021, vol. 666, art. 022083. DOI: https://doi.org/10.1088/1755-1315/666/2/022083

- Nevskaya M.A., Seleznev S.G., Masloboev V.A., Klyuchnikova E.M., Konina O.T., Svetlov A.V., Makarov D.V. Geoecological and Business Problems of Mining and Mineral Processing Waste in the Russian Federation. Herald of the Kola Science Centre of RAS, 2020, vol. 12, no. 1, pp. 11–25. DOI: https://doi.org/10.37614/2307-5228.2020.12.1.002

- Derome J., Lindroos A.J. Effects of Heavy Metal Contamination on Macronutrient Availability and Acidification Parameters in Forest Soil in the Vicinity of the Harjavalta Cu-Ni Smelter, SW Finland. Environmental Pollution, 1998, vol. 99, iss. 2, pp. 225–232. DOI: https://doi.org/10.1016/s0269-7491(97)00185-1

- Csavina J., Field J., Taylor M.P., Gao S., Landazuri A., Betterton E.A., Saez A.E. A Review on the Im-portance of Metals and Metalloids in Atmospheric Dust and Aerosol from Mining Operations. Sci-ence of the Total Environment, 2012, vol. 433, pp. 58–73. DOI: https://doi.org/10.1016/j.scitotenv.2012.06.013

- Zhang X., Yang L., Li Y., Li H., Wang W., Ye B. Impacts of Lead/Zinc Mining and Smelting on the Envi-ronment and Human Health in China. Environmental Monitoring & Assessment, 2012, vol. 184, pp. 2261–2273. DOI: https://doi.org/10.1007/s10661-011-2115-6

- Liang J., Feng Ch., Zeng G., Gao X., Zhong M., Li X., Li X., He X., Fang Y. Spatial Distribution and Source Identification of Heavy Metals in Surface Soils in a Typical Coal Mine City, Lianyuan, China. Environmental Pollution, 2017, vol. 225, pp. 681–690. DOI: https://doi.org/10.1016/j.envpol.2017.03.057

- Cheng Z., Jiang J., Fajardo O.A., Wang Sh., Hao J. Characteristics and Health Impacts of Particulate Matter Pollution in China (2001–2011). Atmospheric Environment, 2013, vol. 65, pp. 186–194. DOI: https://doi.org/10.1016/j.atmosenv.2012.10.022

- Suvorova O.V., Manakova N.K. Recovery of Waste and Side Products of Apatite-Nepheline and Eudi-alyte Ores Processing in Manufacture of Heat-Insulating Foam Glassy-Crystalline Materials. Vestnik of MSTU. Scientific Journal of Murmansk State Technical University, 2017, vol. 20, no. 1–2, pp. 189–196. DOI: https://doi.org/10.21443/1560-9278-2017-20-1/2-189-196

- Tsukerman V.A., Kozlov A.A. Innovative Development Management of Mining Industrial Companies in the Russian Arctic Zone. IOP Conference Series: Materials Science and Engineering: International Science and Technology Conference "Fareastсon-2019", 2019, vol. 753, art. 062020. DOI: https://doi.org/10.1088/1757-899X/753/6/062020

- Maslov A.D., Melnikov N.N., Kalashnik A.I., Selin A.A., Lebedev A.V., Sukhoruchenkov A.I. The Ways of Stabilization and Development of Mining and Industrial Complex of Murmansk Region. Mining Journal, 1998, no. 4, pp. 6–10.

- Kalashnik A.I., Gilyarova A.A., Kalashnik N.A., Smirnova O.V. Study of Mining-Concentrating Enter-prises' Tailings in the Kola Region: Analysis of Cost Structure. The North and the Market: Forming the Economic Order, 2015, no. 2 (45), pp. 31–39. EDN: VHOPWP

- Mitrofanova G.V., Chernousenko E.V., Artemiev A.V., Veselova E.G. Specialities of Mineral Composi-tion of Stockpiled Apatite Ore Processing Waste. Trudy Fersmanovskoy nauchnoy sessii GI KNTs RAN [Proceedings of the Fersman Scientific Session of GI KSC RAS], 2021, no. 18, pp. 296–300. DOI: https://doi.org/10.31241/FNS.2021.18.055

- Goryachev A.A., Makarov D.V., Svetlov A.V. Sulfuric Acid Granulation of Copper-Nickel Concentra-tion Tailings in the Climatic Conditions of the Murmansk Region. Mineralogy of Technogenesis, 2021, no. 22, pp. 116–125. EDN: CJIIWM

- Churkin O.E., Gilyarova A.A. Mining Wastes Management as an Investment Direction for the Devel-opment of the Kola Peninsula Mining Industry. Journal of Economics, Entrepreneurship and Law, 2020, vol. 10, no. 3. C. 905–916. DOI: https://doi.org/10.18334/epp.10.3.100742

- Abaka-Wood G.B., Ehrig K., Addai-Mensah J., Skinner W. Recovery of Rare Earth Elements Minerals from Iron-Oxide-Silicate-Rich Tailings: Research Review. Eng, 2022, vol. 3, iss. 2, pp. 259–275. DOI: https://doi.org/10.3390/eng3020020

- Gromov E.V., Opalev A.S., Ivanova V.A., Khokhulya M.S. Efficiency Evaluation of Technogenic Raw Materials Processing of the Kola Mining Complex Ore Deposits. The North and the Market: Forming the Economic Order, 2018, no. 3 (59), pp. 77–90. DOI: https://doi.org/10.25702/KSC.2220-802X.3.2018.59.77-90

- Tsukerman V.A., Ivanov S.V. Environmental Policy of Resource Corporations in Commercial Mineral Production in the Arctic Zone of Russia. Mining Informational and Analytical Bulletin, 2020, no. 10, pp. 56–66. DOI: https://doi.org/10.25018/0236-1493-2020-10-0-56-66

- Lèbre É., Corder G.D., Golev A. Sustainable Practices in the Management of Mining Waste: A Focus on the Mineral Resource. Minerals Engineering, 2017, vol. 107, pp. 34–42. DOI: https://doi.org/10.1016/j.mineng.2016.12.004

- Tsukerman V.A., Zharov N.V. Institutsional'nye aspekty stimulirovaniya innovatsionnykh protsessov evropeyskikh priarkticheskikh stran [Institutional Aspects of Stimulating Innovation Processes in Eu-ropean Arctic Countries]. In: Sever i Arktika v novoy paradigme mirovogo razvitiya. Luzinskie cht-eniya — 2022: Materialy XI Mezhdunarodnoy nauchno-prakticheskoy konferentsii [The North and the Arctic in the New Paradigm of World Development. Luzinskie Readings — 2022: Proc. 11th In-tern. Sci. and Pract. Conf.], 2022, pp. 75–76.