Многофункциональные металлизированные эластичные ткани

Автор: Ф. Ф. Казоков, О. А. Арипова, Н. Н. Саттарова

Журнал: Современные инновации, системы и технологии.

Рубрика: Машиностроение, металлургия и материаловедение

Статья в выпуске: 3 (4), 2023 года.

Бесплатный доступ

В данной статье обоснована металлизация тканей, которая может быть использована для защиты изделий от коррозии, гниения, эрозии, а также использоваться в декоративных и других целях. Исследован процесс металлизации, заключающийся в нанесении на ткань тонких слоев различных металлов: алюминия, хрома, кадмия, олова, цинка, серебра, золота и других металлов, а также некоторых сплавов и неорганических веществ или, вместо них, органических нитей, очень тонко проникающих в ткань. В статье представлены образцы металлизированных тканей, а также тканей с экранирующими свойствами. В результате представлена таблица, характеризующая снижение силы электромагнитного излучения при использовании таких тканей.

Ткань, покрытие, нить, металлоткань, коррозия, эрозия, проволока, фольга, микропроводник, крашение, напыление

Короткий адрес: https://sciup.org/14128899

IDR: 14128899 | УДК: 544.537 | DOI: 10.47813/2782-2818-2023-3-4-0201-0207

Текст статьи Многофункциональные металлизированные эластичные ткани

DOI:

Metallization is the coating of the surface of a product with metal and the physicochemical, mechanical or other properties of the metallized (source) material upon contact [1-3]. Metallization is used to protect products from corrosion, rotting, erosion, and is used for decorative and other purposes. Fabric metallization is the application of thin layers of various metals to the fabric: aluminum, chromium, cadmium, tin, zinc, silver, gold and other metals, some alloys and inorganic substances, or instead of organic threads that penetrate the fabric very thinly. “Thin” metal wire” gives decorative properties to any fabrics, and also makes them heat-resistant, conductors, dielectrics, etc. [4-6]

Metallization methods can be easily classified according to the technological methods for producing coatings, or more precisely, according to the principles underlying these methods.

Mechanical methods of metallization. Metallization using foil thread and wire, where the coating is pre-formed and then attached to the surface to be coated.

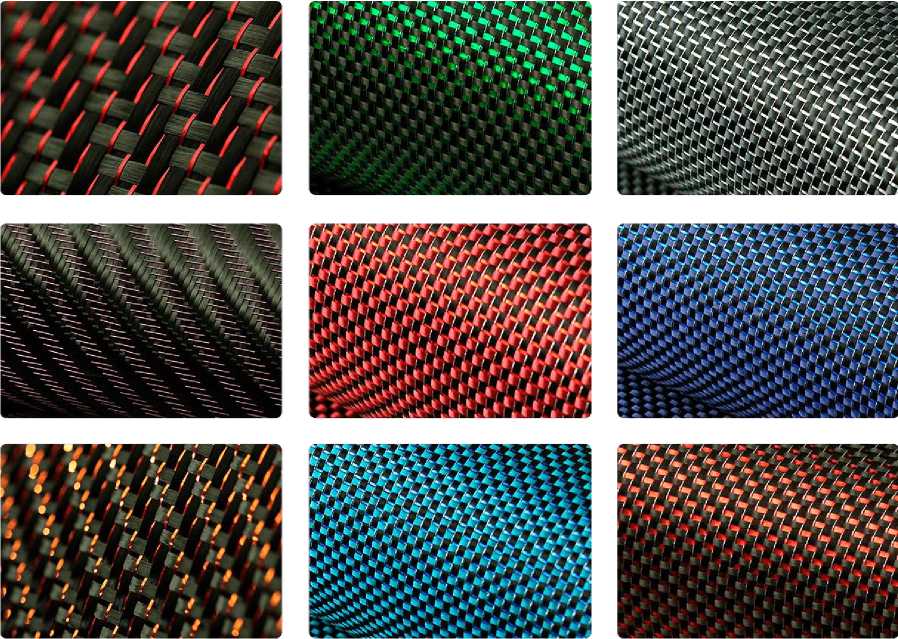

Among the products obtained as a result of mechanical metallization, the most widespread are foil plastics and threads, as well as organic-metal composites or metallized threads. If metal wire or yarn wrapped in metal foil is used as a screening fabric, then the screening properties of such fabric are determined by its specific composition [7]. Figure 1 shows samples of metallized fabric in various colors.

To date, two types of such protective fabric have been developed in our country: with open and hidden metallization. The first type of fabric is made from cotton threads wrapped in metal foil.

Fabric woven from such threads has a metallic sheen. The second type of protective fabric has hidden metallization. In this case, a thin, durable microconductor is woven into cotton threads and welded [8].

MATERIALS AND METHODS

Fabrics made from such threads do not have the disadvantages inherent in open metallized fabrics, and their appearance does not differ from the usual one.

Until recently, B-1 fabrics were widely used (article 7289; STU-'Zb-12-199-63). Length 10 cm, contains 320 threads. Of these, every 2 out of 3 cores have a microconductor inside. It consists of 210 threads 10 cm long, each of which has a microconductor inside. Basically, this fabric reduces 23.5 dB (225 times) on the weft weave and 23.93 dB (241 times) on the warp weave. In this case, the attenuation in the radiation frequency range of 0.6-10 GHz is 20-30 dB.

The results of measuring the reduction coefficients for these tissues are presented in the table. At high radiation frequencies, the level of protection decreases, so the upper limit for the use of personal protective equipment (PPE) made from such material is up to tens of gigahertz, and the low limit is 0.3-0.6 gigahertz [9]. These limitations in the gigahertz range are due to the occurrence of resonant changes in the magnitude of the decrease in the correspondence of the radiation wavelength to the size of clothing in fabric conductors, and in the MHz range there is not enough communication between them.

Elastic screens made of metallized fabrics, curtains, drapes, curtains, covers, special clothing - overalls, robes, hoods can be designed to protect the energy of workers from electromagnetic radiation. The material for elastic screens is a special fabric in which thin metal threads form a mesh with a cell size of 0.5x0.5 mm. Figure 2 shows samples of fabrics with shielding properties.

RESULTS AND DISCUSSION

A thin metal wire is wrapped with cotton threads, which protect against external influences and serve as electrical insulation. Cotton threads fill the spaces between the metal threads and give these fabrics density and elasticity. Fabric “Cotton fabric for microwave oven, art. 7289". It has a name and technical characteristics - STU-136-12-199-63. The reduction in the strength of EMR electromagnetic radiation when using such fabric is presented in Table 1.

Современные инновации, системы и технологии // (сс) ® 2023; 3(4) Modern Innovations, Systems and Technologies

Table 1. Protective properties of microconductor cotton fabric (article 7289 STU-36-12-199

Wavelength, sm 0.8 3.1 10 25 50 400

Attenuation (attenuation), 20 28 40 43 46 54

dB

The protective properties of the fabric are maintained at ambient temperatures of -40°C - +100°C and relative humidity up to 98%. The fabric can be washed, ironed, dyed and sewn on traditional sewing machines. Information about the attenuation of the strength of tissuegenerated EMN is sufficient for most practical situations. These fabrics act as radio-absorbing shields. These shielding agents are most effective in the microwave range, where their use at low frequencies is limited by diffraction. Metallization by dyeing or dyeing fabric. One of the simplest methods of physical plating is plating by immersion or spreading with liquid metal or amalgam. All that is required is good adhesion to the metal surface. Dyeing fabrics with metallic dyes by spraying with a special sprayer; technologically the most important are simple methods of metallization. To apply a metal layer to fabric, both manual methods and automatic devices can be used, allowing for continuous metallization of fabric in rolls with fairly high productivity.

To control the melting and surfacing of metal, as well as the air flow, special devices of various designs are used. The operating principle of most devices is to melt a metal wire through a strong current from the wire and spray droplets of molten metal onto the surface of the fabric. Metal particles falling on the surface of the fabric form a film coating.

Relatively low-melting metals can be used for metallization of fabrics, since at a high temperature of the metal particles, the fibers overheat, as a result of which they collapse and even burn. The fabric is usually coated with tin, lead, zinc, aluminum and alloys of these metals. After particles of such metals fall on the surface and form a coating element, they are very quickly cooled by a stream of compressed air, which actively washes away the attached coating particles. Particle size is of great importance in the metallization process. When metallizing fabrics in continuous layers, fine-grained spraying is an advantage, since small particles cool faster and have less effect on the properties of the fabric.

CONCLUSION

Among the products obtained as a result of mechanical metallization, the most widespread are foil plastics and threads, as well as organic-metal composites or metallized threads. If metal wire or yarn wrapped in metal foil is used as a screening fabric, then the screening properties of such fabric are determined by its specific composition.