Model of a heat exchanger air heating booster

Автор: Li Jie, Golyanin Anton

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 8 т.8, 2022 года.

Бесплатный доступ

To solve the problem of energy crisis in today’s world, energy conservation is more and more get the attention of people, heat exchanger occupies an important place in the field of energy saving, however, because of the heat exchanger is a traditional energy-intensive heavy industry, one of the most widely used equipment in it as preheating, mainly in the process of waste heat recovery, refrigeration equipment, made outstanding contributions to energy saving. In this paper, spiral plate heat exchanger as the research object, select the established model, through the analysis of the existing heat transfer enhancement theory, combined with the classical optimization algorithm genetic algorithm spiral plate heat exchanger programming optimization, through iterative calculation to get the optimal spiral plate heat exchanger structure parameters. On this basis, based on the theory of dissipative, puts forward a new physical volume of fire, and established a new heat exchanger performance evaluation standard unit total cost model of heat transfer, and the objective function, analyzes the structural parameters in the spiral plate heat exchanger (cold and hot fluid flow, heat exchanger, plate spacing) and their relationship. Because the total cost per unit heat transfer not only considers the thermodynamic performance of the heat exchanger but also the economic feasibility of the heat exchanger. Finally, combined with the simulation calculation of the performance of the heat exchanger before and after optimization structure parameters, further analysis of its internal flow. The research in this paper provides a theoretical basis for the design, structure optimization and performance prediction of spiral plate heat exchanger.

Spiral plate heat exchanger, genetic algorithm, small volume dissipation, performance evaluation, fluent simulation

Короткий адрес: https://sciup.org/14124771

IDR: 14124771 | УДК: 621.311.243 | DOI: 10.33619/2414-2948/81/31

Текст научной статьи Model of a heat exchanger air heating booster

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

UDC 621.311.243

Relevance of the research topic. Russia is a country with a huge, branched heating system. Mechanical engineering today cannot provide a complete set of energy-efficient equipment. But there have been positive developments in this direction. In this regard, plate heat exchange equipment is a modern and reliable device with high performance, optimal price, and compact dimensions. Consequently, the operation of such equipment requires a high technological culture and discipline to ensure the required water regime.

Scientific novelty lies in the study of plate heat exchangers and the selection of their rational parameters. The practical significance of the study lies in the use of this technology in practice in the energy sector in general, as well as in resource-supplying organizations. The dissertation consists of an introduction, three chapters, a conclusion, a list of references, applications.

Material and research methods

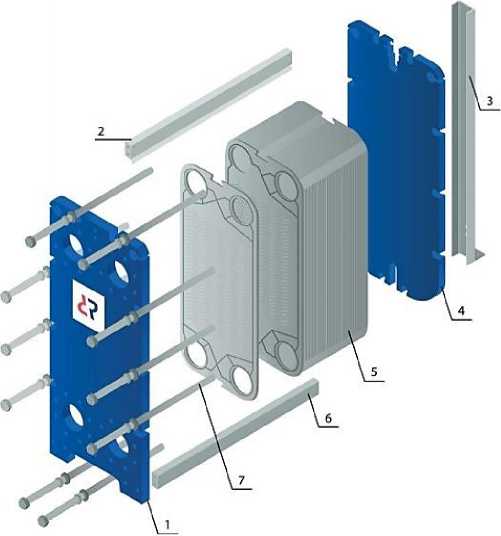

A plate heat exchanger is a device in which the process of transferring heat from one medium to another is carried out - from a hot coolant to a cold (heated) one and vice versa. Accordingly, depending on the purpose, such heat exchangers are used for both heating and cooling. The plate heat exchanger is a frame consisting of a rear fixed panel and a front movable plate, which are pulled together by guides. Stamped plates made of stainless steel are placed between the plates.

The plates are made of stainless steel or corrosion-resistant alloys. Gaskets are distinguished by high endurance and quality; their service life is measured in decades. Figure 1 shows a collapsible plate heat exchanger of the HH type.

Advantages and disadvantages of collapsible units. In boiler houses, thermal power plants, GRESS, nuclear power plants and other heat supply organizations, collapsible heat exchangers are often used. Their main advantage lies in the possibility of mechanical cleaning. Various deposits can form inside the unit, which can significantly impair the operation of the device. Therefore, the possibility of periodic cleaning makes it easy to maintain collapsible devices. The disadvantages of these devices include the complexity of installation and high cost.

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

Figure 1. Heat exchanger: 1 - fixed plate, 2 - top guide, 3 - back stand,4 - pressure plate, 5 - package of plates with gaskets,6 - lower guide, 7 - tie rods

In heat supply systems, the transfer of heat to consumers is associated with its multiple transformations in heat exchange equipment. Therefore, the efficiency of systems largely depends on the efficiency of its individual elements, in particular, heat exchange equipment. The most affordable way to improve the efficiency of existing and projected heat exchange equipment is to increase the heat transfer coefficient. Passive methods are based on changing the heat exchange surface, including the installation of additional elements, while increasing the hydraulic resistance of the channels. In active methods, the intensification of heat transfer occurs due to the application of external energy to influence the flow.

The method for calculating plate water heaters can be based on the following initial conditions:

-

- available pressures of heat carriers are known.

-

- the optimum speed of heated water is set.

As a result of using this design of the shock assembly, relatively high reliability and stability of its operation are ensured with high-quality generation of pulses of the momentum of the working medium in a wide range of changes in its parameters, a mechanism for automatically adjusting the alternate opening and closing of the shock valves due to the compliance of the springs is implemented, and friction costs are completely eliminated , as a result, the resource of using the device increases many times.

The analysis of the state of the issue made it possible to determine the scientific problem of the study, which consists in substantiating the device for the purpose of the work is to study the operation of a plate heat exchanger in a pulsating mode.

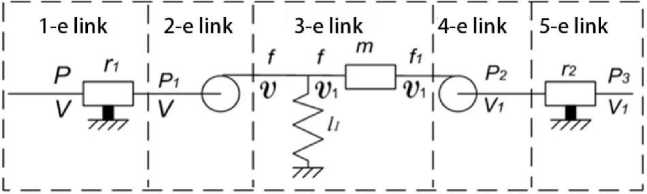

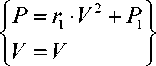

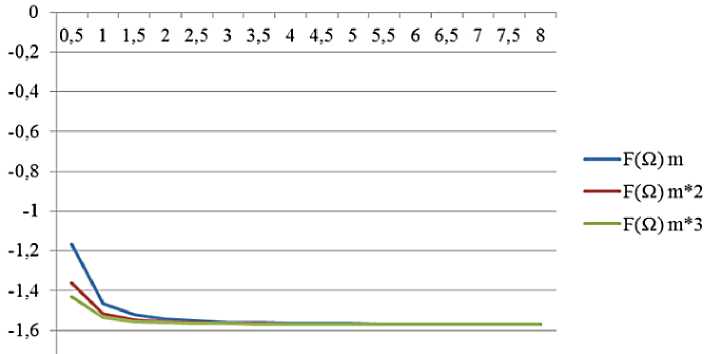

A mathematical model of an installation considering hydraulic processes in a heated (closed) circuit with a pulsating movement of the coolant is proposed, based on the theory of electrical circuits.

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

Figure 2. Energy chain of the installation considering hydraulic processes in a heated (closed) circuit with impulse water heating

' f=P1-Sp'

< V v = —

f = m • v i + f l

5 I

•

. v = l l • f + v l

p = -fl

P2 о

V = Vl • S

Accordingly, the frequency function of the circuit:

. _ - a , •Q 2 + a 2 • j Q + a3 _ (- a vO+ a r T^a M b W

-

- b l • j Q- b 2 - ( b 1 • j Q + Ь 2 ) ’ ( b 1 • J Q- Ь 2 )

- a • b • j . 3 + a • b • . 2 - a • b • . 2 - a • b • j . + a • b • j . - a • b

11 12 21 22 31 32

( b l • J Q ) 2 + b 2

-

a. • b. • j Q 3 + a, • b • Q 2 — a^ • b. • Q 2 — a^ • b • j Q + a, • b. • j Q — a, • b

11 12 21 22 31 32

- b 2Q2 + b 2 2

Real and imaginary parts of the frequency function:

Re( J Q ) =

( a j • b 2 - a2b ) Q 2 - a3b2

- b 2 Q 2+ b 2

a 3 • b 2 - ( a i • b - a 2 ' b ) • Q 2 b 2 Q 2- b 2

Im( J Q ) =

al • b • j Q 3 + ( a 2 • b 2 - a 3 • b ) • j Q

b 2 Q 2 - b ^2

Amplitude-frequency response (AFC):

A ( j Q) = ^( Re ( j Q)2 + Im ( j Q)2)

Phase-frequency characteristic of the circuit (PFC):

/ \ Im ( j Q )

^ ( Q ) = - arctg

( ) S Re (jQ)

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

Table 1

OBTAINED DATA

|

Q |

a 1 |

a 2 |

a 3 |

a 4 |

b 1 |

b 2 |

Re( j Q ) |

Im( j Q ) |

A ( j Q ) |

F ( Q ) |

|

0.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0021 |

187.393 |

203.7557 |

-1.1673 |

|

1 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0084 |

749.585 |

753.8431 |

-1.46446 |

|

1.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0188 |

1686.66 |

1688.558 |

-1.52339 |

|

2 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0335 |

2998.79 |

2999.857 |

-1.54411 |

|

2.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0523 |

4686.22 |

4686.904 |

-1.55372 |

|

3 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.0753 |

6749.29 |

6749.766 |

-1.55893 |

|

3.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.1025 |

9188.42 |

9188.773 |

-1.56208 |

|

4 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.1339 |

12004.1 |

12004.39 |

-1.56412 |

|

4.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.1696 |

15197 |

15197.19 |

-1.56552 |

|

5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.2094 |

18767.7 |

18767.84 |

-1.56652 |

|

5.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.2535 |

22717 |

22717.1 |

-1.56726 |

|

6 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.3018 |

27045.7 |

27045.81 |

-1.56783 |

|

6.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.3544 |

31754.8 |

31754.91 |

-1.56827 |

|

7 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.4112 |

36845.3 |

36845.41 |

-1.56861 |

|

7.5 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.4723 |

42318.3 |

42318.42 |

-1.56889 |

|

8 |

6,48 |

750.2765 |

80 |

0.64 |

0.00864 |

1 |

-80.5377 |

48175.1 |

48175.16 |

-1.56912 |

Table 2

OBTAINED DATA

|

Q |

a 1 |

a 2 |

a 3 |

a 4 |

b 1 |

b 2 |

Re ( j Q ) |

Im ( j Q ) |

A ( j Q ) |

F (Q) |

|

0.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0021 |

-374.889 |

383.3306 |

-1.36055 |

|

1 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0084 |

-1499.59 |

1501.718 |

-1.51749 |

|

1.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0188 |

-3374.26 |

3375.204 |

-1.54709 |

|

2 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0335 |

-5999.24 |

5999.771 |

-1.55746 |

|

2.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0523 |

-9375.03 |

9375.375 |

-1.56226 |

|

3 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0753 |

-13502.3 |

13502.56 |

-1.56487 |

|

3.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1025 |

-18381.9 |

18382.11 |

-1.56644 |

|

4 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1339 |

-24014.9 |

24015.02 |

-1.56746 |

|

4.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1696 |

-30402.4 |

30402.48 |

-1.56816 |

|

5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.2094 |

-37545.7 |

37545.82 |

-1.56866 |

|

5.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.2535 |

-45446.5 |

45446.56 |

-1.56903 |

|

6 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.3018 |

-54106.4 |

54106.41 |

-1.56931 |

|

6.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.3544 |

-63527.2 |

63527.24 |

-1.56953 |

|

7 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.4112 |

-73711 |

73711.08 |

-1.56971 |

|

7.5 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.4723 |

-84660.1 |

84660.16 |

-1.56985 |

|

8 |

12.96 |

1500.276 |

80 |

0.64 |

0.00864 |

1 |

-80.5377 |

-96376.8 |

96376.88 |

-1.56996 |

Table 3

OBTAINED DATA

|

Q |

a 1 |

a 2 |

a 3 |

a 4 |

b 1 |

b 2 |

Re W |

Im ( j Q ) |

A Q |

F (Q) |

|

0.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0021 |

-562.386 |

568.0477 |

-1.42949 |

|

1 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0084 |

-2249.59 |

2251.008 |

-1.53525 |

|

1.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0188 |

-5061.85 |

5062.483 |

-1.55499 |

|

2 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0335 |

-8999.69 |

9000.041 |

-1.5619 |

|

2.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0523 |

-14063.8 |

14064.07 |

-1.5651 |

|

3 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.0753 |

-20255.3 |

20255.5 |

-1.56684 |

|

3.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1025 |

-27575.4 |

27575.56 |

-1.56789 |

|

4 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1339 |

-36025.7 |

36025.75 |

-1.56857 |

|

4.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.1696 |

-45607.8 |

45607.83 |

-1.56904 |

|

5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.2094 |

-56323.8 |

56323.85 |

-1.56937 |

|

5.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.2535 |

-68176 |

68176.07 |

-1.56962 |

|

6 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.3018 |

-81167 |

81167.05 |

-1.56981 |

|

6.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.3544 |

-95299.6 |

95299.6 |

-1.56995 |

|

7 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.4112 |

-110577 |

110576.8 |

-1.57007 |

|

7.5 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.4723 |

-127002 |

127001.9 |

-1.57016 |

|

8 |

19.44 |

2250.276 |

80 |

0.64 |

0.00864 |

1 |

-80.5377 |

-144579 |

144578.6 |

-1.57024 |

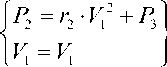

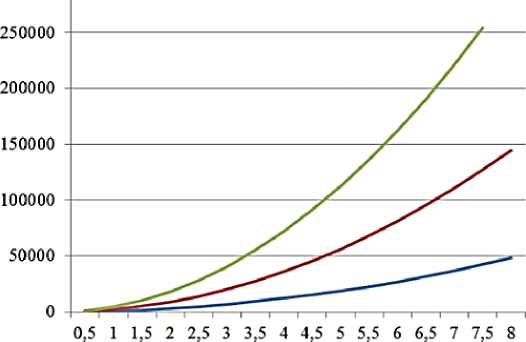

Based on the results of the calculation, graphs of the frequency response and phase response of the chain were plotted for 3 mass values: 2.7; 5.4; 8.1 kg; (Figure 3, 4).

---A(jQ) m*3 ---A(jQ) m*2

---A(jQ) m

Figure 3. Amplitude-frequency characteristics

Figure 4. Phase-frequency characteristics

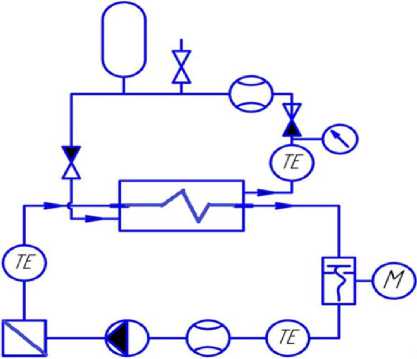

The experimental setup includes: three temperature sensors, a hydraulic accumulator, an impact unit (flow converter), a mechanical gearbox, two counters on different circuits, two check valves, two pressure gauges. A diagram of the cooling circuit with a heat exchanger-supercharger is shown in Figure 5.

Figure 5. Scheme of the cooling circuit with a heat exchanger-supercharger

Sensor for measuring the temperature of the heat carrier in the heating or hot water preparation pipeline. The working element of the sensor is made of a tube made of copper or stainless steel. For hot water systems, it is recommended to install the sensor without a protective sleeve. This contributes to a faster process of responding to changes in the temperature of the coolant.

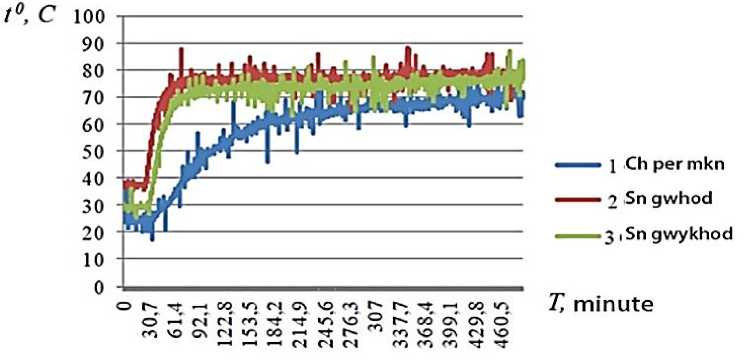

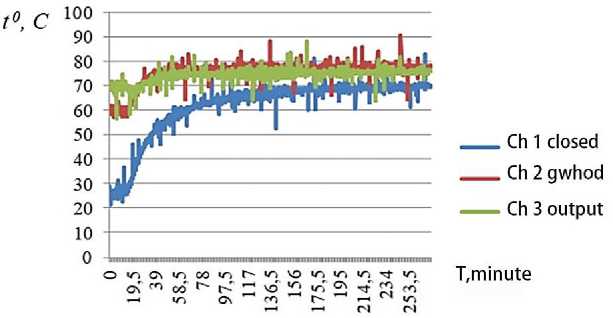

On Figure 6. shows a graph of temperature change over time in a heating and closed circuit at a flow interruption frequency of 0.5 Hz (this corresponds to a supply voltage frequency of 10 Hz).

Figure 6. Graph of temperature change over time in the heating and closed loop at a flow interruption frequency of 0.5 Hz

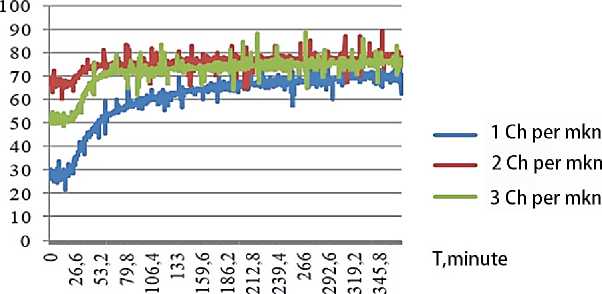

On Figure 7. According to the results of the second experiment, a graph of temperature changes over time in the heating and closed circuits is shown at a flow interruption frequency of 0.6 Hz (this corresponds to a supply voltage frequency of 12 Hz).

Figure 7. Graph of temperature change over time in the heating and closed loop at a flow interruption frequency of 0.6 Hz

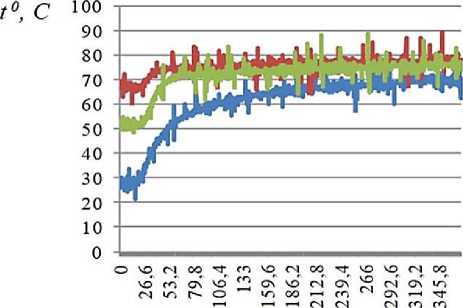

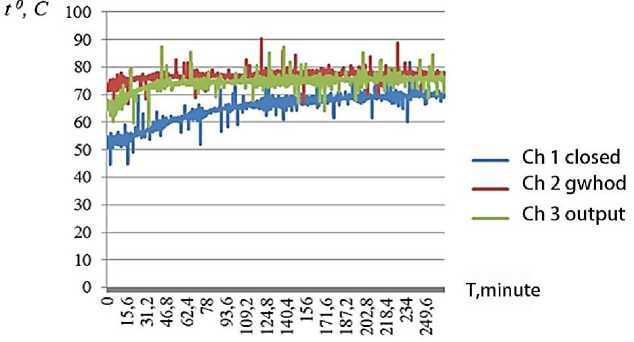

O n Figure 8. a graph of the temperature change over time in the heating and closed circuit is shown at a flow interruption frequency of 0.7 Hz (this corresponds to a supply voltage frequency of 14 Hz).

_ Ch 1 permk _ Ch 2 gwhod _____Ch 3 output

Figure 8. Graph of temperature change over time in the heating and closed circuit at a flow interruption frequency of 0.7 Hz

T,minute

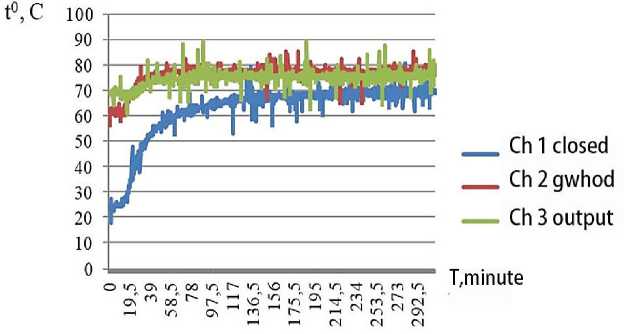

On Figure 9. a graph of the temperature change over time in the heating and closed circuit is shown at a flow interruption frequency of 0.8 Hz (this corresponds to a supply voltage frequency of 16 Hz).

Figure 9. Graph of temperature change over time in the heating and closed loop at a flow interruption frequency of 0.8 Hz

On Figure 10. shows a graph of temperature change over time in the heating and closed circuit at a flow interruption frequency of 0.9 Hz (this corresponds to a supply voltage frequency of 18 Hz).

Figure 10. Graph of temperature change over time in the heating and closed loop at a flow interruption frequency of 0.9 Hz

On Figure 11. shows a graph of temperature change over time in a heating (closed) circuit at a flow interruption frequency of 1 Hz (this corresponds to a supply voltage frequency of 20 Hz).

Figure 11. Graph of temperature change over time in the heating and closed loop at a flow interruption frequency of 1 Hz

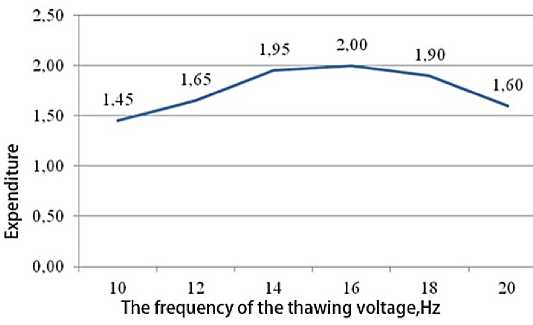

On Figure 12. a graph of change in the flow rate of the coolant from the frequency of the supply voltage in a closed circuit is shown.

Figure 12. Graph of the dependence of the coolant flow rate on the frequency of the supply voltage in the heated (closed) circuit

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

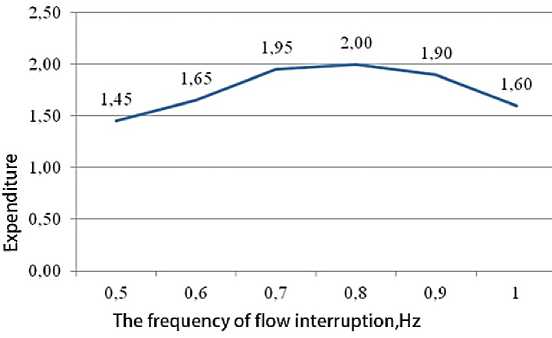

On Figure 13. a graph of the change in the flow rate of the coolant from the frequency of flow interruption in a heated (closed) circuit is shown.

Figure 13. Graph of the dependence of the coolant flow rate on the frequency of flow interruption in a heated (closed) circuit

The thermodynamic analysis of the heat exchanger before and after optimization is done, that is, the related parameters such as entropy production and exergy are calculated for the heat exchanger before and after optimization. The analysis results of the entrance and the thermal resistance of the heat exchanger also show that the thermodynamic performance of the heat exchanger after optimization is better than that before optimization.

Список литературы Model of a heat exchanger air heating booster

- Kaladgi A. R., Vishwanath K. C., Madhu P., Chandrashekar A., Chaluvaraju B. V. Effect of copper oxide nano fluids as coolant on thermal performance of spiral heat exchanger // IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2021. V. 1189. №1. P. 012037.

- Mazaheri N., Bahiraei M. Energy, exergy, and hydrodynamic performance of a spiral heat exchanger: Process intensification by a nanofluid containing different particle shapes // Chemical Engineering and Processing-Process Intensification. 2021. V. 166. P. 108481.

- Tamborrino A., Veneziani G., Romaniello R., Perone C., Urbani S., Leone A., Servili M. Development of an innovative rotating spiral heat exchanger with integrated microwave module for the olive oil industry // LWT. 2021. V. 147. P. 111622.

- Sultan K. F., Jabal M. H., Jaddoa A. A. Energetic and Exergetic Assessment of Spiral Heat Exchanger Using Mineral and Oxide Mineral Oil Nanofluid // Journal homepage: http://iieta. org/journals/ijht. 2021. V. 39. №2. P. 531-540.

- Davoudi A., Daneshmand S., Monfared V., Mohammadzadeh K. Numerical simulation on heat transfer of nanofluid in conical spiral heat exchanger // Progress in Computational Fluid Dynamics, an International Journal. 2021. V. 21. №1. P. 52-63.

- Bahiraei M., Mazaheri N. A comprehensive analysis for second law attributes of spiral heat exchanger operating with nanofluid using two-phase mixture model: Exergy destruction minimization attitude // Advanced Powder Technology. 2021. V. 32. №1. P. 211-224.

- Fei Z., Yanxia L., Zhongliang L., Yongzhi T. Flow and heat transfer characteristics of oil-based drilling cuttings in a screw-driving spiral heat exchanger // Applied Thermal Engineering. 2020. V. 181. P. 115881.

- Hong Y., Reimers J. L. Spiral heat exchanger as preheater in polymer devolatilization processes: пат. 10718571 США. 2020.