Modeling of the organic Rankine cycle based on the theory of energy chains

Автор: Kireev N., Kudaschev S., Zhang Q.

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 6 т.10, 2024 года.

Бесплатный доступ

This paper examines an experimental setup of an organic Rankine cycle and proposes a method for describing it using differential equations. The aim of the work is to obtain approximate values of the setup's characteristics before conducting the experiment. The constructive scheme of the experimental device and its operating principle are described in detail. The power circuit of the setup is composed, and complex impedance, frequency function, amplitude-frequency, and phase-frequency characteristics are obtained based on the mathematical transformation of the circuit. The frequency response of the circuit is constructed. As a result of the calculations, the amplitude-frequency and phase-frequency characteristics are obtained, and graphs are plotted based on them. Conclusions are drawn about the dependence of the characteristics on the change in parameters, and the shape of the graphs is explained. The results of the work can be used to predict the behavior of the experimental setup of the organic Rankine cycle and optimize its parameters before conducting physical experiments.

Organic rankine cycle, power circuit, frequency response, amplitude-frequency characteristic, phase-frequency characteristic, modeling

Короткий адрес: https://sciup.org/14130533

IDR: 14130533 | УДК: 621.372.2 | DOI: 10.33619/2414-2948/103/43

Текст научной статьи Modeling of the organic Rankine cycle based on the theory of energy chains

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 621.372.2

The study of hydraulics and heat transfer processes is crucial for understanding and optimizing various engineering systems. Mathematical modeling, particularly using differential equations, has been widely used to address this challenge. However, the complexity of hydraulic and heat transfer systems often requires a systematic approach to model development and analysis.

In recent years, the application of energy circuit theory to describe hydraulic and heat transfer processes has gained attention. Despite the growing interest in these methods, there is still a need for a comprehensive study that combines the energy circuit approach with differential equations and black-box modeling to describe hydraulic and heat transfer processes.

The novelty of this work lies in the integration of energy circuit theory, differential equations, and black-box modeling to create a unified framework for describing hydraulic and heat transfer processes. The proposed methodology involves building an energy circuit, compiling equations, setting input and output through the black box, calculating equations using the black box, writing equations for the image, compiling the complex resistance equation, distinguishing coefficients, writing the frequency function for the energy circuit, and distinguishing the real and imaginary parts of the complex resistance to calculate the amplitude-frequency and phase-frequency characteristics.

Material and methods of research

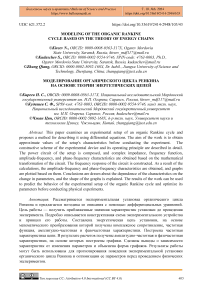

Figure 1. Experimental device for organic Rankine cycle

Table 1

SYMBOLS IN FIGURE 1

|

Position |

Name |

|

1 |

Evaporator |

|

2 |

Superheater |

|

3 |

Turbine |

|

4 |

Generator |

|

5 |

Condencer |

|

6 |

Cooler |

|

7 |

Pump |

The principle of operation of the experimental setup

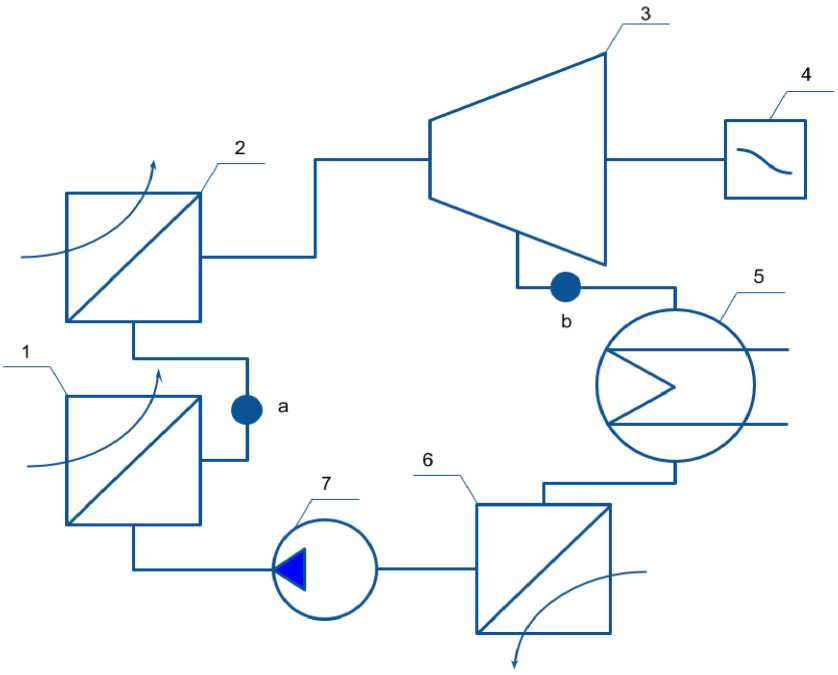

Figure 2 shows an experimental installation of a waste heat exchanger with a phase change.

Figure 2. Experimental device for organic Rankine cycle: 1 – evaporator; 2 – superheater 3 – turbine; 4 – generator; 5 – condencer; 6 – cooler; 7 – pump

The working steam generated in the evaporator 1 reaches the turbine 3 through the superheater 2 for improving energy potential. After producing a work in the generator 4, low-potential gas make a phase change to the fluid in the condencer 5. After decreasing of temperature in the cooler 6, working fluid reaches to the pump 7. The heat transfer principle is shown in Figure 5.

In the course of the study, for a better understanding of the scheme, it was decided to study 2 characteristics of hydraulic and thermal, in order to better understand the nature of the forces arising and to more accurately determine the required parameters on the obtained model.

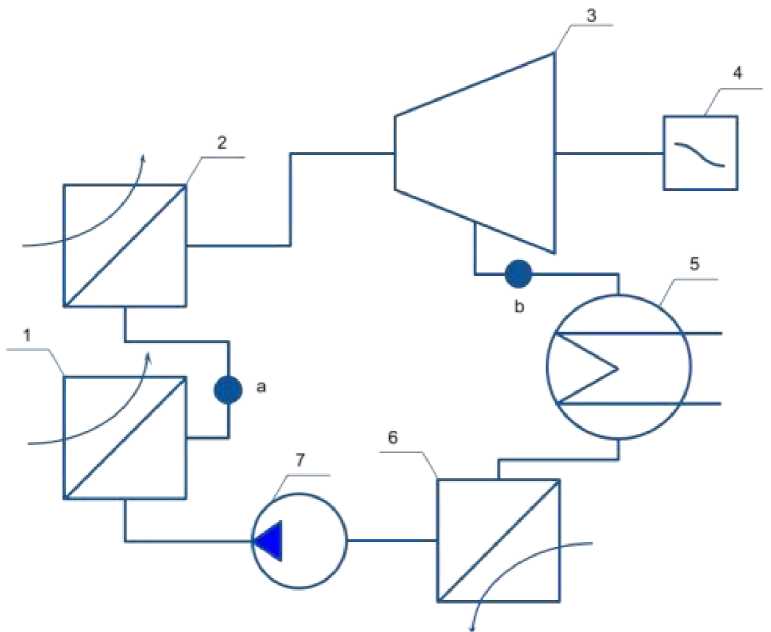

The first is hydraulic, which takes into account elastic properties of a spring with pliability 11 (pliability is the inverse of elasticity), inertial properties of a liquid by mass m1, pressure losses in the pipeline by means of active resistance r1. The third part is the network pump, and elastic properties of the spring with pliability 11 (pliability is the value of the inverse elasticity) cylinder walls by active resistance.

In the first power circuit the hydraulic characteristics at the moment of closing of the shock valve is considered. This circuit contains 2 elements.

Figure 3. Hydraulic circuit

The circuit link equations:

Г p = r1V12 + m 1 V 1 + r2V ? + P3 { V = l i P + I 2 P 2 + V 2

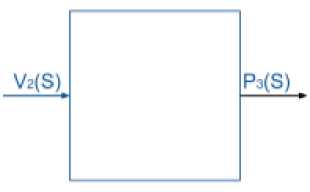

Black box:

Figure 4. Black box for hydraulic energy circuit

Equations for P3,P2,P 1 :

P3 = P30 + P3

P2 = r2V22 + P3

P1 = mV1 + P2

Equations for V2,V 1 :

V2 = V20 + V2

Vi = I2P2 + V20 + V2

Equation for P2:

P2 = r2V22 + P3 = r2V22o + 2^20^2 + P30 + P3

Equation for P2:

P2 = 2^20^2 + P3

Equation for V 1 :

Vi = 2l2r2V2oV2 + I2P3 + V20 + V2

Equation for V 1

5 1 = 2 ^ 2 Г 2 ^ 20 ^ 2 + / 2 P 3 + К 2

Equation for K 2 :

К20 + (^'г^О5 + /2P3 + 52)] ~ 520 + 2^2o(2^2r2^20^2 + /2P3 +^

Equation for K22:

^22 = 520 + 2К2 0Ё2 + 1'2

Equation for P:

P = 71(^220 + 4^ЛГ2!>2 + 2^2 0^2Рз + 2^2 0^) + т^^оК + /2P3 + 5)

+ Z^V 2^ 20 ^ 2 + 5 2 ) + P 30 + Р з

= т^з + 27 1 / 2^3 + P 3 + P 30 + 2™^^ + М^лМ + mJ

+ I^ 2 (4r 2 5 2 0 + 2 ' 1 5 2 0 ) + 2 ' 2 5 2 0 + ' 1 5 220

Equation for images:

(a 1 s2 + a2s + a3)V2(s) = -(b 1 s2 + b2s 1 + b3)P3(s) (14)

Coefficients:

a 1 = m 1 /2 a 2 = 2 ' 1 / 2 5 20 а з = 1 b 1 = Zm^' z^O b 2 = 4/ 2 ' 1 7 2 К22о + m 1 b 3 = 4r 2 5 20 + 2 ' 1 5 20

Complex circuit resistance Z (s):

( , _ P3(s) _ a1s2 + a2s + аз

(s) = y 2 (s) = —b 1 s2 — b 2 s —Ь з

Frequency function of the circuit:

s ^ jQJ2 = -1

Frequency function of the circuit:

—a 1 b 1 fi4 + a1b3fi2 — a1b2jfi3 + a2b1jfi3 — a2b3jfi — a2b2fi2

+a3b1fi2 — a3b3 + a3b2jfi

= (b 1 fi2 — Ьз)2 + b22fi2

Г—a 1 b 1 fi4 + (a2b 1 — a1b2)jfi3 + (a1b3 — a2b2 + a3Ь1)fi2l

= L________________ +(a з b 2 — a 2 b з )jfi — a з Ь з ________________ J

(b 1 fi2 — Ьз)2 + b22fi2

The real part of the frequency function:

—a 1 b 1 fi4 + (a 1 b з — a 2 b 2 + a з Ь 1 ) fi2 — a з Ь з (19)

^e(jfi) =------------------------------5--------------

(b 1 fi2 — Ьз)2 + b22fi2

Imaginary part of the frequency function:

. (а 2 ^ 1 - а 1 ^ 2 )^3 + (а 3 ^ 2 - a 2 ^ 3 )a .

Im(]a) =] (Ь1П2 - ь3)2 + Ь22П2

Amplitude-frequency response (frequency response) of the circuit:

А(]П) = ^Re(jO)2 + Im(jO)2

Phase frequency response (FFC) of the circuit:

Im(jO)

^(ia) = -arctBR^

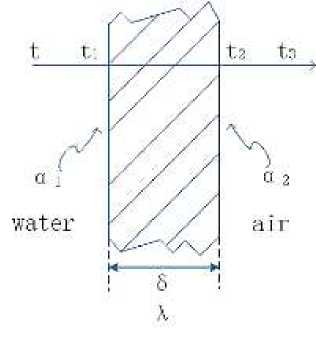

Figure 5 shows the part of the installation where heat transfer takes place.

Figure 5. Part of the heat transfer plant: t - the temperature of hot water; t1 , t2 - wall temperature; t3 -the temperature of the air; α 1 - convective heat transfer coefficient of water and left wall; α 2 - convective heat transfer coefficient of air and right wall; δ - the thickness of the wall surface; λ - Thermal conductivity of the wall

When the hot water flows, the convective heat transfer coefficient between the water and the left wall is h 1 , and the temperature of t is greater than t 1 , so the wall absorbs the heat brough by the hot water, and the wall temperature rises. When the temperature rises to t 1 , the surface temperature of the left wall is stable. The thickness of the wall is λ, and the heat is transmitted from the left wall to the right wall by means of heat conduction. When the temperature rises to t 2 , the surface temperature of the right wall reaches a stable state. The right wall carries out convective heat transfer with the air, and the convective heat transfer coefficient is h 2 . Through convective heat transfer, heat is transferred to the air until the air temperature t 3 reaches a stable state.

Calculate the convective heat transfer thermal resistance r 1 :

r1 = a1F

Calculate the convective heat transfer thermal resistancer2:

r 2

Calculate the convective heat transfer thermal resistance r3:

r 3 =^ ^ 2 ^

Total thermal conductivity k.

1 _ 1 (26)

r 1 +r2 + г3 1 8 1

a 1 F + AF + a2F

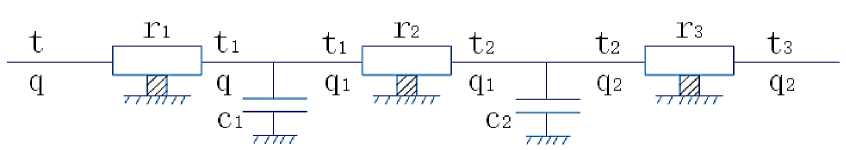

Figure 6. Heat transfer energy circuit

The circuit link equations:

1 1 = ГД + ЪЯ 1 + Г з Ц 2 + 1 з

I q = C i t i + C 2 t 2 + q 2

The input and output of the energy chain for thermal calculation are presented in the form of a “black” box.

Figure 7. Black box for heat transfer

Equations for t3,t2,t2,t 1 ,q2:

^3 = t30 + t3

t2 =r3q2+ t3

t2 = t2 = r3q2 + t3

ti=r2qi + t2

q2 = q20 + q2

Equations on q 1 from the 1st link:

qi = C2t2 +q2 = С2(т3к + £3) + q20 +q2= C2r3q2 + C2t3 + q20 + q2

Equations on t2 from the 1st link:

t2 = r3q2 + £3 = r3q20 + r3q2 + £30 + ^3(34)

The equation on t 1 :

I^i = r2qi + ^2 — r2(c2r3q2 + ^^ + q20 + Я2) + (ГзЯ20 + Г3Я2 + t30 + ^3)

= С2Г2Г3Я2 + £2^3 + Г2Я20 + Г2Я2 + Г3Я20 + ^3^2 + t30

— c 2 r 2 r 3 q 2 + (r 2 + r 3 )q 2 + (r 2 + Г3)я20 + С2Г2 * 3 + ^ 3 + t 30

The equation on ti :

ti — c2r2r3q2 + (r2 + ^2 + c2r2t2 + t3

The equation on я :

Я — Citi + c2t2 + Я2(37)

— C i [c2r2r3q2 + (r 2 + Г 3 )Я 2 + C2r2t2 + t3] + С 2 (г 3 Я 2 + £ 3 )

+ ( Я 20 + q 2 )

— с1с2г2г3Я 2 + (c i r 2 + c i r 3 + C 2 r 3 )q 2 + Я 2 + Я 20 + C i C 2 r 2 t 2

+ (C i + C 2 )t3

The equation on t:

1 — Г 1 Я + Г 2 Я 1 + Г 3 Я 2 + t 3 (38)

— r i [c i C 2 r 2 r3q2 + ( C i r 2 + C i r 3 + C 2 r^ 2 + Я 2 + Я 20 + C i C 2 r 2t2

+ (C i + C 2 )t3] + ^2^2 + C 2 t 3 + Я 20 + Я 2 ) + Ъ(Я 20 + Я 2 ) + { 30 + * 3

— [с 1 С 2 Г 1 Г2Г 3^ 2 + ( C i r i r2 + C i^3 + C2r i r3)q 2 + r i q 2 + Т 1 Я 20 + C i C 2 r i r2t2

+ (c i r i + с2Г1)£3^ + (c 2 r 2 r 3 q 2 + С2Г2 * 3 + r 2 q 20 + r 2Cl2 ) + (r 3 q 20 + r 3( 1 2 )

+ t 30 + ^

— С 1 С 2 Г 1 Г 2 Г 3~ Я2 + ( C i r i r 2 + C i r i r 3 + С 2Г1Г3 + С 2 Г 2 Г 3^ Я 2 + (r i + r 2 + ^2

+ (r i + r 2 + ^20 + C i C 2 r i r 2 t 2 + (С^ + С 2 П + C 2 r 2^3 + t 3 + t 30

— biq2 + Ь 2 Я 2 + Ь3Я 2 + Ь4Я 20 + aih + a 2 t3 + chh + a^

Equation for images:

(d i S2 + ( 2 $ + a^T^s) — - ( b i S2 + b 2 S + b3^Q 2 ( s' ) (39)

Coefficients:

d i — C i C 2 r i r 2 (40)

( 2 — C i r i + C 2 r i + C 2 r 2

а 3 — 1

b i — C i C 2 r i r 2 r 3

b 2 — C i r i r 2 + C i r i r 3 + C 2 r i r 3 + C 2 r 2 r 3

b 3 —r i + r 2 + r 3

Complex resistanceZ(s):

, T 3 ( s) -b i S2-b 2 S-b 3 (41)

Z (s) — тт-гт —---?----------- Q 2 (s) ais2 + a2s + a3

Frequency functions of the circuit:

s ^ j^,j2 — -1 (42)

Frequency function of the circuit:

= T3(s) = —bis2 — b2s — b3 = Ь1°2 — Ь2}° — ^3

Q2(s) p1s2 + p2s + а3 —а1О2 + а2]О + а3 (biO2 — Ь2]О — b3)[(—а^О + а3) — а2]О]

[(—а 1 О2 + а3) + а2]О][(—а 1 О2 + а3) — а2Щ]

(

—a1b1O4 + a3b1Q2 — а2b1jO3 + я1Ь2]О3 — +a1b3O2 — a3b3 + a2b3jO

аз^Щ — а 2 Ь 2 ^2^

——а1Ь1^4 + (а1Ь2

(—а 1 О2 + а3)2 + а 2 О2

— a2b1)jQ3 + (u3b 1 — a2b2 + a1b3)O2 +

(P^ —aзb2')}O —aзbз

]

(—а 1 О2 + а3)2 + а^2

We derive the real part of the complex resistance:

„ ( _ а1^1^4 + (р3Ь1 ^^ + а 1 ^ з )^2 Р3Ь3

^1) = (—а 1 О2 + а3)2 + а^О2

We derive the imaginary part of the complex resistance:

, . (а1Ь2

Im(j^) =----

— a 2 b 1 )a3 + (a 2 b з

—

азЬ2№

(—а 1 О2 + а3)2 + а2О2

We obtain the amplitude-frequency function of the energy circuit:

A(jO) = jRe(jn)2 + Im(jn)2

Get the phase-frequency function of the energy circuit:

Im(jU)

rt^-a^RRe^

Construction of frequency characteristics of the circuit when changing at

least

three

parameters. The known conditions: P - pressure, kPa; V - volume flow, l/s [liter per second]; r 1 -active resistance, [ ~~^ ]; m 1 - mass of working fluid, [kg]; 1 1 , l2 - hydraulic compliance, [““^], 1 litre = 10-3metre.

Parameter are calculated or found from the experiment.

Are set by the input power of the circuit, for example n0 = 400 W, as well as the inlet pressure P0 = 100 kPa. Hire the pressure loss on the active resistance is assumed 5 ± 10%.

n0 400

^РТшТ4 l/s

According to equation write the formula for r 1 ,r2:

P ri=-

—

V 2

P 1 _ 0.1 x 100

! = 4 2

P

Г2=~

—

P 2

V ?

0.2 x 100

кРа ■ s2l

= 0-625 hH

Г кРа ■ s2l

■=1-25hH

The mass of working fluid depends on the volume of pipelines.

rn 1 = 10 kg

The compliance is found for equation:

l 1

V- V 1

■ p

0.1 x 4

0.5 x 100

0.008

г lit • s' [ kPa

l 1 = l 2

0.008

г lit • s' [ kPa

Algorithm for plotting graphs.

The values of the coefficients are calculated:

a 1 = m 1 l2 = 10 x 0.008 = 0.08 (53)

a2 = 2r 1 l2V20 = 2 x 0.625 x 0.008 x 4 = 0.04П

a3 = 1

b 1 = 2m 1 l2r2V20 = 2 x 10 x 0.0 08 x 1.25 x 4 = 0.8

b2 = 4l2r 1 r2V220 + m 1 = 4 x 0.008 x 0.625 x 1.25 x 16 = 0.4

b3 = 4r2V20 + 2r 1 V20=4x 1.25 x 4 + 2 x 0.62 5 x 4 = 25

The limit of change Q is accept, Q = 1... 10 rad/s. Calculation of the real and imaginary part of the frequency function: Q = 1 rad/s

-a1b1^4 + (a 1 b3 — a2b2 + a 3 b-J.fi2 — a3b3

(b 1 fi2 -b3)2 + b22fi2

Г —0.08 x 0.8 x 1 4 + ( 0 . 08 x 25 - 004 x 0 . 4 + ) x 1 2

1 x 0.8

= L__________________ -1 x 25 __________________

(0.8 x 12 - 25)2 + 0.42 x 12

= -0.038033

( a 2 b 1 - a 1 b 2 )^3 + ( a 3 b 2 - a 2 b 3 )^ .

' m(1)-- (M^-bF+b2^---7

r(0.04x 0.8-0.08 x 0.4)xl3 + (-010xx0-425

_ L______________________ x 1 _____________________

(0.8 x 12 - 25)2 + 0.42 x 12

= -0.001024

Л(1) = V^e(1)2 +/m(1)2 = 7(-0.038033)2 + (-0.001024)2 = 0.038047

lm(1) -0.001024

^(1) = -arcta-—— = -arctg—- пппппо = -0.026923 ^e(1) -0.038033

According to equation write the formula for

Table 2

CIRCUIT PARAMETERS

|

m 1 ,kg |

kPa ■ s 2] |

fisiii |

!5-S| |

P 30 , kPa |

V 30 ,lit/s |

|

r 1 ,[ lit ] |

4 Pa J |

l 2 ,1 Pa J |

|||

|

10 |

0.625 |

0.008 |

0.008 |

100 |

4 |

|

10 |

0.625 |

0.008 |

0.016 |

100 |

4 |

|

10 |

0.625 |

0.008 |

0.024 |

100 |

4 |

Dependency graphs are plotted based on the input values. For the best perception of graphs values are taken only those that affect the dependence. The values obtained for the first stage of the energy circuit are shown in Table 2.

RECEIVED INFORMATION FOR HYDRAULIC

Table 3

|

Ω |

AjQ1 |

(pjH1 |

AjH2 |

(pjH2 |

AjH3 |

(pjH3 |

|

1 |

0,038047 |

0,026923 |

0,036039 |

0,060777 |

0,033997 |

0,103554 |

|

2 |

0,031387 |

0,080428 |

0,021102 |

0,332414 |

0,015611 |

1,251047 |

|

3 |

0,017075 |

0,337578 |

0,046116 |

-0,722008 |

0,245282 |

-1,114882 |

|

4 |

0,026209 |

-0,649549 |

0,489127 |

1,183127 |

0,202355 |

0,176537 |

|

5 |

0,189373 |

-0,577902 |

0,194957 |

0,128051 |

0,141813 |

0,050349 |

|

6 |

0,421689 |

0,436343 |

0,145187 |

0,045688 |

0,124131 |

0,022767 |

|

7 |

0,202674 |

0,099087 |

0,127818 |

0,022798 |

0,116076 |

0,012556 |

|

8 |

0,156562 |

0,044021 |

0,119259 |

0,013346 |

0,111603 |

0,007759 |

|

9 |

0,137424 |

0,024608 |

0,114277 |

0,008597 |

0,108820 |

0,005167 |

|

10 |

0,127145 |

0,015519 |

0,111074 |

0,005907 |

0,106956 |

0,003629 |

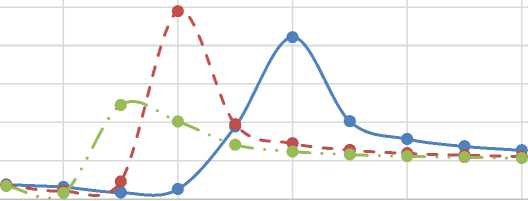

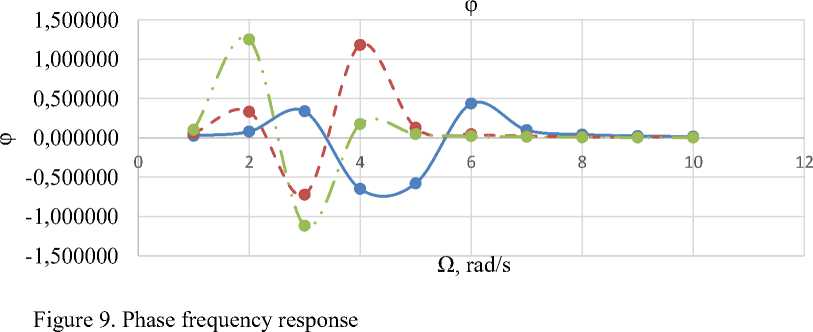

Based on the results of the calculation, the graphs of the amplitude frequency response and phase-frequency response and frequency response of the circuit are constructed. Further in these graphs are under construction:

0,600000

0,500000

0,400000

0,300000

0,200000

0,100000

0,000000

A

AjΩ1

AjΩ2

AjΩ3

2 4 6 8 10

Ω, rad/s

Figure 8. Amplitude frequency response

φjΩ1 φjΩ2

φjΩ3

The graphs show a rapid increase in the amplitude A and phase-frequency characteristics φ of the circuit with increasing сyclic frequency Ω from 1 to 6, after which their smooth decay occurs.

For power circuits of the heat transfer calculations are conducted similarly and are written in table 3. A graphical view is presented in graphs 6-7.

The known conditions:

n0 = 400^

Г1=1ГЁ

(X 1 F

80 x 2

Г kPa • s2l = 625 x 10 -3 HH

^ 2

0.002

350 x 2

kPa • s2l = 2.86X10 | lit |

Г 3

0 2 F

’ 120 x 2

n0 Q o = — = t o

kPa • s2l

=4-17 x 10-3 [—I

400 W

' 100 = 4Й

_ Aq

С 1 = t

Q - t

a 0.1 x 4 l

- = 057100 = °' 008 Ы

C 2 =e 1 = °.°°^[ 7^ ]

Algorithm for plotting graphs.

The values of the coefficients are calculated:

a 1 = С 1 С 2 Г 1 Г 2 = 0.008 x 0.008 x 6.25 x 10-3 x 2.86 x 10-6 = 1.145 x 10-12 (64)

a 2 = С 1 Г 1 + С 2 Г 1 + С 2 Г 2

= 0.008 x 6.25 x 10-3 + 0.008 x 6.25 x 10-3 + 0.008 x 2.86

x 10-6 = 1 x 10-4

a3 = 1

b 1 = С 1 С 2 Г 1 Г 2 Г З = 0.008 x 0.008 x 6.25 x 10-3 x 2.86 x 10-6 x 4.17 x 10-3 = 4,774 x 10-15

Ь 2 = С 1 Г 1 Г 2 + С 1 Г 1 Г 3 + С 2 Г 1 Г 3 + С 2 Г 2 Г 3 = 0.008 x 6.25 x 10-3 x 2.86 x 10-6 + 0.008 x 6.25 x 10-3 x 4.17 x 10-3 + 0.008 x 6.25 x 10-3 x 4.17 x 10-3 + 0.008 x 2.86 x 10-6 x 4.17 x 10-3 = 4.174 x 10-7

b3 = r 1 + r2 + r3 = 6.25 x 10-3 + 2.86 x 10-6 + 4.17 x 10-3 = 1 x 10-2

The limit of change П is accept, П = 1™10 rad/s. Calculation of the real and imaginary part of the frequency function: П = 1 rad/s

Яе(1) =

-a1b1^4 + (a3b 1 — a2b2 + a1b3)^2 — a3b3 (— a 1 Q2 + a 3 )2 + a 2 Q2

— 1.145 x 10-12 x 4.774 x 10-15 x 14 + 1 x 4.774 x 10-15 — 1 x 10-4 x 4.174 x 10-7 ( +1.145 x 10-12 x 1 x 10-2

— 1 x 1 x 10-2

)x12

[(—1.145 x 10-12 x 1 2 + 1) 2 + (1 x 10-4)2 x 1 2 ]

= —0.010425

|

, (a^ - a 2 bi)Q 3 + ^b ^ - a^Q, Im(1) =1 (-a1Q2 + a3)2 + a ^ Q2 -(1.145 X 10-12 X 4.174 X 10-7\ 13‘ V -1 X 10-4 X 4.774 X 10-15 ' + (1 X 10 -4 X 1 X 10"2 ) V -1 X 4.174 X 10-7 / |

66) |

= _L__________ X 1 __________ J

[(-1.145 X 10-12 X 1 2 + 1) 2 + (1 X 10-4)2 X 1 2 ]

= 6.255 X 10-7

4(1) = V^(1)2 + /m(1)2 = ^(-0.010425) 2 + (6.256 x 10-7)2 = 0.010425 67)

Im(1) 6.256 X 10-7

„(1) = -arctg ^ = -arctg -0.010425 = 5.99995 X 10"

According to equation write the formula for

RECEIVED INFORMATION FOR HEAT TRANSFER

Table 4

|

kPa •s 2 |

kPa • s2] |

kPa • s2] |

<4-1 |

|

|

r 1 , [ lit J |

r 2 ,[ lit J |

r 3 , [ lit J |

C 1 , Is • o |

c 2 , Is • О |

|

0.006251 |

2.86×10-6 |

4.17×10-3 |

0.008 |

0.008 |

|

0.06251 |

2.86×10-6 |

4.17×10-3 |

0.008 |

0.008 |

|

0.006251 |

2.86×10-6 |

4.17×10-3 |

0.08 |

0.08 |

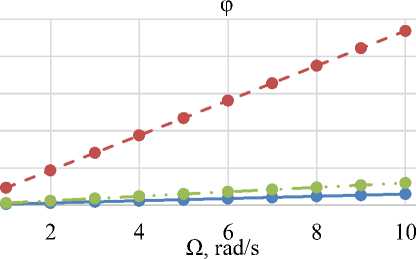

The dependency graph is drawn based on input values. For optimal graph perception, take only those values that affect dependencies. The obtained values for the first stage of heat transfer are shown in Table 4.

VALUE AMPLITUDE FREQUENCY RESPONSE FOR ENERGY CIRCUIT

Table 5

|

Ω |

4/121 |

„j/21 |

4j/22 |

„7122 |

47123 |

„7'123 |

|

1 |

0,010425 |

5,99995E-05 |

0,066684 |

9,37601E-04 |

0,010425 |

1,19999E-04 |

|

2 |

0,010425 |

1,19999E-04 |

0,066684 |

1,87520E-03 |

0,010425 |

2,39998E-04 |

|

3 |

0,010425 |

1,79998E-04 |

0,066684 |

2,81279E-03 |

0,010425 |

3,59997E-04 |

|

4 |

0,010425 |

2,39998E-04 |

0,066683 |

3,75038E-03 |

0,010425 |

4,79996E-04 |

|

5 |

0,010425 |

2,99997E-04 |

0,066683 |

4,68796E-03 |

0,010425 |

5,99994E-04 |

|

6 |

0,010425 |

3,59997E-04 |

0,066683 |

5,62553E-03 |

0,010425 |

7,19993E-04 |

|

7 |

0,010425 |

4,19996E-04 |

0,066682 |

6,56309E-03 |

0,010425 |

8,39992E-04 |

|

8 |

0,010425 |

4,79996E-04 |

0,066682 |

7,50064E-03 |

0,010425 |

9,59990E-04 |

|

9 |

0,010425 |

5,39995E-04 |

0,066681 |

8,43817E-03 |

0,010425 |

1,07999E-03 |

|

10 |

0,010425 |

5,99994E-04 |

0,066681 |

9,37568E-03 |

0,010425 |

1,19999E-03 |

From the power loop heat transfer simulation plots, it can be observed that the amplitudefrequency response of the hydraulic loop A does not change with increasing сyclic frequency Ω, while the phase-frequency response φ increases in direct proportion to its increase.

A

0,08

0,06

<0,04

0,02 — . - --•——•—•—•—•--■•

0,00

0 2 4 6 810

AjΩ1

- • - AjΩ2

—•■ • AjΩ3

Ω, rad/s

Figure 10. Amplitude frequency response

0,010000

0,008000

0,006000

э- 0,004000

0,002000

0,000000

φjΩ1

- • - φjΩ2

—•■ ■ φjΩ3

Figure 11. Phase frequency response

Results and Discussion

The main results obtained from this work are as follows:

A constructive scheme of the experimental setup for the organic Rankine cycle is proposed, and its operating principle is described in detail. The energy circuit of the setup is composed.

Complex impedance, frequency function, amplitude-frequency, and phase-frequency characteristics are obtained through mathematical transformation of the energy circuit. The frequency response of the circuit is constructed.

Modeling of the hydraulic and thermal circuits of the experimental setup is carried out based on the theory of energy circuits.

In the process of modeling the hydraulic energy circuit, it is found that there is a rapid increase in the amplitude-frequency and phase-frequency characteristics of the circuit with increasing cyclic frequency Ω, followed by a smooth decay.

When modeling the heat transfer energy circuit, it is established that the amplitude-frequency response of the hydraulic circuit does not change with increasing cyclic frequency Ω, while the phase-frequency response increases in direct proportion to its increase.

Based on the calculations performed, it is concluded that for the considered scheme of the organic Rankine cycle, the best variant of circuit parameters will be the one in which the hydraulic compliance l2 is twice higher than the initial l1, the cyclic frequency Ω is equal to 4 rad/s, and the active resistance r1 is the largest compared to other calculation variants of r1.

The obtained results are important for predicting the behavior of the experimental setup of the organic Rankine cycle and optimizing its parameters before conducting physical experiments. The proposed approach and modeling methodology have practical value for the analysis and design of similar energy systems.

Conclusion

In summary, this work presents a novel and comprehensive approach to modeling and analyzing hydraulic and heat transfer processes using energy circuit theory, differential equations, and black-box modeling. The proposed methodology integrates these techniques into a unified framework, providing a systematic approach to model development and analysis.

The results obtained from the modeling of the hydraulic and heat transfer energy circuits provide valuable insights into the behavior of the experimental setup of the organic Rankine cycle. The conclusions drawn from the calculations can be used to optimize the circuit parameters and predict the system's performance before conducting physical experiments.

The practical significance of this work lies in its potential to enhance the design and optimization of energy systems involving hydraulic and heat transfer processes. The proposed approach and methodology can be applied to similar systems, facilitating their analysis and improvement.

Further research could focus on validating the model through experimental studies and extending the methodology to other types of energy systems. Additionally, the integration of advanced optimization techniques with the proposed framework could lead to more efficient design and operation of hydraulic and heat transfer systems.

Acknowledgements: Kudaschev Sergei Fedorovich, Zhang Qiang and Levtsev Alexey Pavlovich for for assistance in conducting the research and organizing the article.

Список литературы Modeling of the organic Rankine cycle based on the theory of energy chains

- Gogate, P. R., & Pandit, A. B. (2005). A review and assessment of hydrodynamic cavitation as a technology for the future. Ultrasonics sonochemistry, 12(1-2), 21-27. https://doi.org/10.1016/j.ultsonch.2004.03.007

- Hammitt, F. G. (1980). Cavitation and multiphase flow phenomena.

- Sivakumar, M., & Pandit, A. B. (2002). Wastewater treatment: a novel energy efficient hydrodynamic cavitational technique. Ultrasonics sonochemistry, 9(3), 123-131. https://doi.org/10.1016/S1350-4177(01)00122-5

- Jeong, J. H., & Kwon, Y. C. (2006). Effects of ultrasonic vibration on subcooled pool boiling critical heat flux. Heat and mass transfer, 42, 1155-1161. https://doi.org/10.1007/s00231-005-0079-1

- Wang, G., Senocak, I., Shyy, W., Ikohagi, T., & Cao, S. (2001). Dynamics of attached turbulent cavitating flows. Progress in Aerospace sciences, 37(6), 551-581. https://doi.org/10.1016/S0376-0421(01)00014-8

- Barber, B. P., & Putterman, S. J. (1991). Observation of synchronous picosecond sonoluminescence. Nature, 352(6333), 318-320. https://doi.org/10.1038/352318a0

- Mason, T. J. (1988). Theory. Applications and uses of ultrasound in chemistry. Sonochemistry.

- Suslick, K. S. (1991). The sonochemical hot spot. The Journal of the Acoustical Society of America, 89(4B_Supplement), 1885-1886. https://doi.org/10.1121/1.2029381

- Misik, V., & Riesz, P. (1994). Free radical formation by ultrasound in organic liquids: a spin trapping and EPR study. The Journal of Physical Chemistry, 98(6), 1634-1640. https://doi.org/10.1021/j100057a016

- Kumar, P. S., & Pandit, A. B. (1999). Modeling hydrodynamic cavitation. Chemical engineering & technology: industrial chemistry‐plant equipment‐process engineering-biotechnology, 22(12), 1017-1027. https://doi.org/10.1002/(SICI)1521-4125(199912)22:12<1017::AID-CEAT1017-3.0.CO;2-L

- Chzhan, Yui, Li, Yumin & Tszi, Tszyan'bin (2011). Chislennoe modelirovanie gidravlicheskogo kavitatsionnogo ustroistva s diafragmoi, 27(3), 219-223. (in Chinese)

- Badve, M. P., Alpar, T., Pandit, A. B., Gogate, P. R., & Csoka, L. (2015). Modeling the shear rate and pressure drop in a hydrodynamic cavitation reactor with experimental validation based on KI decomposition studies. Ultrasonics sonochemistry, 22, 272-277. https://doi.org/10.1016/j.ultsonch.2014.05.017

- Makeev, A. N. Impul'snaya sistema teplosnabzheniya obshchestvennogo zdaniya: avtoref. dis. ... kand.tekhn. nauk. Penza, 2010. 19 s. (in Russian)

- Levtsev, A. P., Kudashev, S. F., Makeev, A. N., & Lysyakov, A. I. (2014). Vliyanie impul'snogo rezhima techeniya teplonositelya na koeffitsient teploperedachi v plastinchatom teploobmennike sistemy goryachego vodosnabzheniya. Sovremennye problemy nauki I obrazovaniya, (2), 89-89. (in Russian)

- Levtsev, A. P., Makeev, A. N., Makeev, N. F., Narvatov, Ya. A., & Golyanin, A. A. (2015). Obzor i analiz osnovnykh konstruktsii udarnykh klapanov dlya sozdaniya gidravlicheskogo udara. Sovremennye problemy nauki i obrazovaniya, (2-2), 188-188. (in Russian)

- Aleksandrov, A. A., & Grigor'ev, B. A. (1999). Tablitsy teplofizicheskikh svoistv vody I vodyanogo para. Moscow. (in Russian)