Modeling the dynamic loads affecting a bridge crane during start-up

Автор: Antipas I.R.

Журнал: Advanced Engineering Research (Rostov-on-Don) @vestnik-donstu

Рубрика: Машиностроение и машиноведение

Статья в выпуске: 2 т.24, 2024 года.

Бесплатный доступ

Introduction. The dynamic loads during the start-up of a bridge crane can cause excessive stress in the structure and components, leading to potential safety hazards and increased wear and tear. To reduce the influence of the dynamic loads, various strategies can be implemented including optimization of the acceleration and deceleration profiles, using the soft start controls, implementing the vibration damping systems. It is vital to ensure that the proper crane maintenance and inspection protocols are in place. By reducing the impact of dynamic loads during the start-up, the overall performance and longevity of a bridge crane can be improved, ultimately enhancing safety and efficiency of the industrial operations. The present research offers a new approach to improving the efficiency and safety of industrial operations by providing a more precise account of the dynamic loads during the start-up of a bridge crane. The objective of this study is to develop a mathematical model for investigating the mechanical properties of the bridge cranes by analyzing the dynamic loads that occur during lifting operations.Materials and Methods. The development of the mathematical model was based on the kinetic model of the system, which included three connecting blocks and two flexible connections for a more accurate description of the bridge crane structure. Lagrange’s equations incorporating the information about the geometry and structure of a bridge crane were used. They made it possible to describe the motion of a system with the multiple elements and degrees of freedom. Processing and analysis of the results of the mathematical model were carried out in the MATLAB program using the Runge-Kutta method.Results. As a result of the research, a mathematical model was developed to study the dynamic loads affecting a bridge crane during lifting operations. Graphs describing the dependences of speed, acceleration, load, and rope angle over time, and their influence on the crane beam were plotted. The changes in these parameters over time, including their maximum values, were analyzed. The reasons for load changes and factors influencing the extension of lifting machines’ service life as well as reducing metal consumption during production thereof were identified.Discussion and Conclusion. The developed mathematical model and its numerical solution using the specialized software (MATLAB) allow for conducting the dynamic analysis of the bridge crane structures and determining the optimal design solutions. The analysis of the factors influencing the load changes leads to the conclusion that the use of this model can significantly reduce the load magnitudes and metal consumption, as well as increase the service life of lifting machines. The results obtained with the developed mathematical model and its numerical solution are useful for optimizing the crane structures, providing compliance with the operational requirements, and extending the service life of lifting machines.

Bridge crane, dynamic load, kinetic model, load lifting, dynamic analysis

Короткий адрес: https://sciup.org/142241590

IDR: 142241590 | УДК: 531.3 | DOI: 10.23947/2687-1653-2024-24-2-190-197

Текст научной статьи Modeling the dynamic loads affecting a bridge crane during start-up

Original Theoretical Research

Оригинальное теоретическое исследование

Моделирование динамических нагрузок, воздействующих на мостовой кран в момент пуска

И.Р. Антибас

Донской государственный технический университет, г. Ростов-на-Дону, Российская Федерация

Введение . Динамические нагрузки во время запуска мостового крана могут вызывать избыточные напряжения в конструкции, приводя к потенциальным рискам и увеличению износа. Для снижения влияния динамических нагрузок можно применять различные стратегии, включая оптимизацию профилей ускорения и замедления, использование плавного пуска, внедрение систем амортизации. Важно обеспечивать исполнение правильных протоколов обслуживания и инспекции кранов. Путем снижения воздействия динамических нагрузок во время запуска можно улучшить общую производительность и долговечность мостового крана, повысив в конечном итоге безопасность и эффективность промышленных операций. Данное исследование предлагает новый подход к повышению эффективности и безопасности промышленных операций за счет более точного учета динамических нагрузок мостового крана при пуске. Цель работы — разработка математической модели для изучения механических свойств мостовых кранов путем анализа динамических нагрузок, возникающих во время подъемных операций.

Материалы и методы . Разработка математической модели была выполнена на основе кинетической модели системы, включающей три соединительных блока и два гибких соединения для более точного описания конструкции мостового крана. Использованы уравнения Лагранжа, включающие информацию о геометрии и структуре мостового крана. Они позволили описать движение системы с несколькими элементами и несколькими степенями свободы. Обработка и анализ результатов математической модели были произведены в программе MATLAB с применением метода Рунге-Кутты.

Результаты исследования . В результате исследования была разработана математическая модель для изучения динамических нагрузок на мостовой кран во время подъемных операций. Построены графики, описывающие зависимости скорости, ускорения, нагрузки и угла каната относительно времени и их влияние на балку крана. Проанализировано изменение этих параметров во времени, включая их максимальные значения. Определены причины изменений нагрузки и факторы, влияющие на увеличение срока службы и снижение металлоемкости при производстве подъемных машин.

Обсуждение и заключение . Разработанная математическая модель и ее численное решение с использованием специализированного программного обеспечения (программа MATLAB) позволяют проводить динамический анализ конструкций мостового крана и определять оптимальные конструктивные решения. Анализ факторов, влияющих на изменение нагрузки, позволяет сделать вывод, что при использовании данной модели можно значительно снизить величину нагрузок и металлоемкость, а также увеличить срок службы подъемных машин. Результаты, полученные при помощи разработанной математической модели, и ее численное решение полезны при оптимизации конструкции кранов, обеспечении соответствия операционных требований и продлении срока службы подъемных машин.

Машиностроение и машиноведение

Introduction. The analysis of dynamic processes in the mechanical part plays an important role in the development of new overhead cranes and modernization of existing ones in order to reduce loads on control devices and extend their service life [1] .

The bridge crane is subjected to dynamic loads during non-static operations, such as acceleration and braking. Analysis of these processes allows identifying hidden impacts on the dynamic behavior of the bridge crane. Therefore, it is paramount for the researcher to make an optimal design choice to reduce these loads, ensuring that the crane can meet the required operating conditions [2] .

In [3] , a dynamic model of a crane lifting system was developed, using which an accurate direct numerical integration method was proposed for calculating the dynamic loads of the system.

Papers [4, 5] studied dynamic loads in a metal structure, taking into account fatigue of the metal material. However, the researcher neglected the impact of forces from the drive of the lifting mechanism operating with artificial parameters.

In [6] , dynamic loads in a bridge crane were determined during the operation of a lifting mechanism when hoisting a load suspended on a rope. The most important case studied was the effect of dynamic loads on the crane when removing a load from a solid foundation, at the moment of lifting-off.

Steel structures of bridge cranes experience non-stationary loads with different stress amplitudes and asymmetry of the working cycle [7] . To study the real load of bridge cranes under typical operating conditions, constant recording of their stress state is required, which is labor-intensive [8] . Therefore, statistical processing of the obtained results is used to assess the loading elements of metal structures of bridge cranes [9] . This involves changing individual components of the total load of metal elements, such as the gravity of the load being lifted, the angle of rotation of the load, and weather loads, and then summing them according to the laws of probability theory [9 ,10] . This approach is less labor-intensive than a comprehensive study of loading under typical operating conditions. However, determining the probabilistic characteristics of individual random loads also takes time, so the method for calculating load combinations is widely used in crane construction [11] .

In [12] , it was found that during the stage of selecting the rope slack, the value of the stator current of the electric motor of the lifting mechanism did not depend on the mass of the suspended load. However, as the load increased, the time of its rise also increased, and at the stage of separating the load from the surface, the amplitude values of the current increased. Furthermore, a noticeable difference appeared after five periods of mains voltage from the beginning of the stage. However, the researcher neglected the significant influence of forces arising from the drive of the lifting mechanism working with artificial elements.

By using the developed mathematical model, the research aims at optimizing the design of bridge cranes through studying the dynamic loads that occur during lifting operations, ensuring that the crane has the ability to meet the required operating conditions.

Materials and Methods

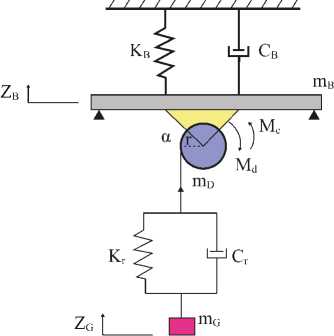

Kinetic Model of the System under Study. When developing a kinetic model of the system under study, it can be represented that the construction of a bridge crane for a given motion form consists of three connecting blocks and two flexible joints, and has the form shown in Figure 1:

Fig. 1. Bridge crane kinetic model

m B — mass of the main bridge, moving along the X -axis; m D — mass of the lifting mechanism, moving along the Y -axis; m G — payload; K B and C B — elasticity modulus and damping coefficient of the main bridge; K R and C R — elasticity modulus and damping coefficient of the ropes; α — swing angle of lifting mechanism winding.

Derivation of Kinetic Equations Reflecting the Motion of the Dynamic Model

Mathematical equations representing the motion of the dynamic model are derived from the partial differential Lagrange equation, which is considered to be one of the best methods used specifically in cases where the system consists of more than one element and when it has several degrees of freedom.

dL д q i

I д 1 1

д L д D = Qi , д q i д q i

L = T - U , (2)

д I д д U ^ д T д U

= Q i ,

^ I I — ++ дt ^ дi[i дq ) дqi дqi where T — kinetic energy; U — potential energy; D — damping energy; Q — external forces affecting the whole system; qi — common system of coordinates; i — degrees of freedom of the model under study.

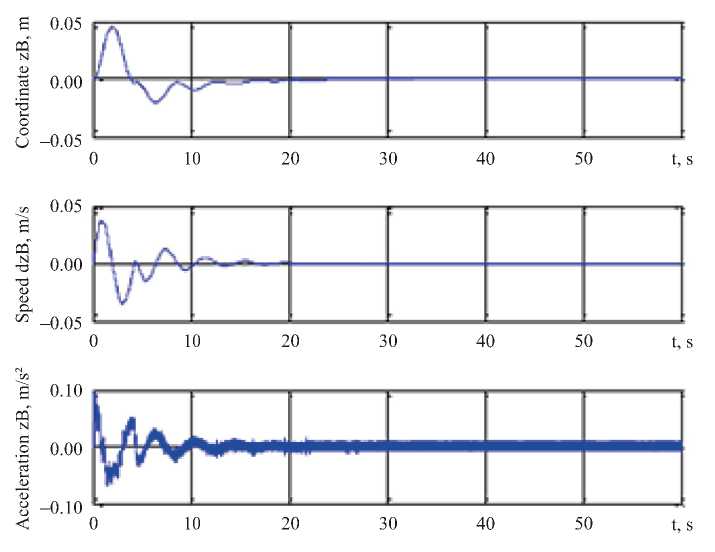

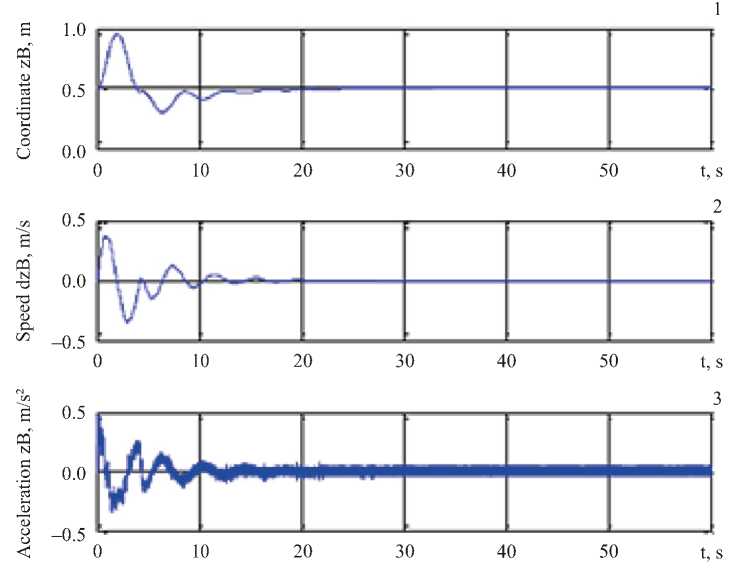

Kinetic energy equation:

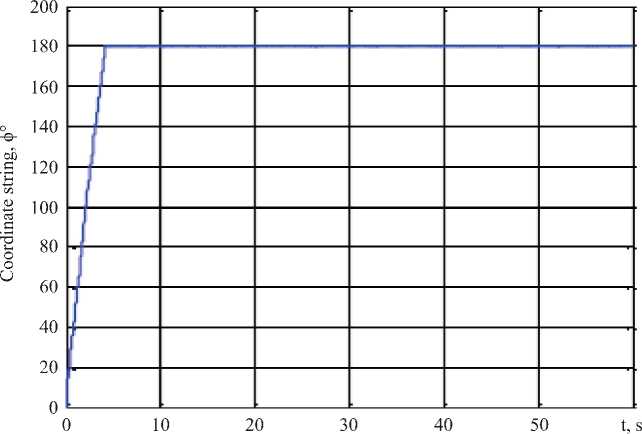

T = 0. 5 mBzB + 0. 5 mDzB + 0. 5 mGzG + 0. 5 J- Potential energy equation: U = 0.5KBzB + 0.5Kr (zG - ra + zB )2. Damping equation: D = 0. 5 CBzB + 0. 5Cr (zG - ra + zB) . System equations: (mB + mD ) Zb + KbZb + Kr (Zb - ra + Zg ) + CbZb + Cr (Zb - rit- + Zg ) = 0, *mGZg + Kr- (Zg - ra + Zb ) + Cr ZG - ra + zB ^ = 0, *J -a + Krr (a- Zg - Zb ) + Cr ■ r (a- Zg - Z в ) = Md - Mc, where Md, Mc — resistance momentum and lifting mechanism momentum; J — inertia of rotating mass of the lifting mechanism. Numerical Solution of a Mathematical Model Using the Fourth-Degree Equation of Runge-Kutta The numerical solution of equations (7–9) was obtained using the Runge-Kutta method in the MATLAB program. The dynamic equations were derived within the program, incorporating the input data and a set of commands to process these equations. The resulting graphs illustrate the interconnections between the various blocks and components of the crane structure under consideration. The Conditioning of the Input Values Required to Solve the Model The study was conducted on an ACE type bridge crane consisting of three parts (Fig. 2): - lifting trolley; - main bridge, which supports the lifting mechanism; - end trucks, which support the main bridge. Fig. 2. Main parts of a bridge crane ACE To align the operation of the bridge crane with a standard set of coordinate axes, the following assumption was made: - the lifting trolley functions as a unit responsible for raising a load along the Z-axis and allows for horizontal motion along the Y-axis relative to the main bridge, which is the axis along which the crane moves. A study was conducted on a prototype bridge crane with a lifting capacity of 10 tons and a width of 21.5 meters. The following characteristics were considered: - payload: mG = 10,000 kg; - mass of the two main bridges: mB = 8,100 kg; - mass of the lifting mechanism with the trolley: mD = 700 kg. When determining the input values, all the laws of designing the structures of lifting devices were followed, and the connections of all components were taken into account. The main factors considered were: - power of the drive of the lifting mechanism along the Z-axis; - stiffness coefficient of the steel structure (KB); - stiffness coefficient of the rope (Kr); - damping coefficient of the metal frame (CB); - damping coefficient of the ropes (Cr). Машиностроение и машиноведение Table 1 Element name Value Unit of measurement Notation Load 10 Ton mG Crane mass 8,100 Kg mB Trolley mass 700 Kg mD Crane length 21.5 m L Height of lift 5 m H Beam device degree 2 — A Gear box ratio 4.5 – im Coil radius 0.25 m R Rope diameter 16.5 mm dk Engine power 30 kW Nn Speed of the engine rotor core 905 r.p.m nn Rope stiffness coefficient 11 169.8 N/mm KB Rope damping coefficient 23 934.4 N/mm Kr Rope damping coefficient 83.37 N.sec/m Cr Metal frame damping coefficient 30.29 N.sec/m CB Research Results Shows the elements of the design structure of the bridge crane that was studied. Study of the Model Operation Using a Computer Structural Behavior of a Metal Bridge Crane under Momenta Loads The structural behavior of a metal bridge crane during the process of lifting a load is depicted by three curves (Fig. 3). Fig. 3. Coordinates of vertical motion, speed and acceleration of the COG of the bridge cranes versus time curves In Figure 3, the first curve shows the coordinates of the bridge crane along the ordinate axis as a function of time. During lifting, some vibration of the crane's metal structure is observed for 5–10 seconds, which then stabilizes and does not affect its rigidity. The second curve in this figure depicts the change in the speed of the center of gravity of the bridge crane over time. During lifting the load, the speed initially increases and then gradually decreases until stabilization. This indicates that the center of gravity of the bridge crane assumes a stable position within the specified time period, during which the vibration stabilizes. The third curve reflects the change in the center of gravity of the bridge crane over time. It is noteworthy that the acceleration value at the moment of lifting the load is 0.07 m/s², with the dynamic load reaching its maximum.° Load Curves Figure 4 shows three curves that reflect motion of the load during the crane operation at the time of lifting. Fig. 4. Coordinates of the speed and acceleration of the load lifting versus time curves In Figure 4, the first curve reflects the change in the position of the center of gravity of the load over time during its lifting to a certain height, calculated by the program, by rotating the drum by 180 degrees and then stopping. The height of the load suspension indicated on the graph is 0.78 m. The second curve on this graph shows the change in the lifting speed of the load over time. When the drum rotates, the lifting speed of the load initially increases, then gradually decreases until it stabilizes. The third curve represents the change in the acceleration of the load lifting over time. At the moment of lifting the load, the acceleration reaches a maximum value of 0.26 m/s² in 0.8 seconds, and then stabilizes. From the analysis of these three curves, it can be noticed that the stabilization time of the crane operation is almost constant. Coil Angle Curve Figure 5 shows the dependence of the winding rotation on time in degrees. Fig. 5. Coil Angle Curve Машиностроение и машиноведение Figure 5 shows the change in the angle of rotation of the drum over time. The rotation angle stabilizes when reaching a value of 180 degrees, after which it remains stable, meaning it repeats. Discussion and Conclusion. Analysis of the above graphs leads to the following conclusions. The mathematical model and algorithms allow for a detailed study of the motion of a bridge crane at all stages. Adjusting the winch operation and improving the metal structure of the crane have many positive aspects, including reducing dynamic displacements in the metal frame of the crane and transmission elements (such as clutch, gearbox, motor, and pulleys), as well as in the hoisting ropes. This reduction in dynamic loads leads to a decrease in rapid wear of these elements. Additionally, cost savings on maintenance and the development of an optimal metal structure design are achieved, as well as an increase in the crane's service life. This is evident from changes in the center of gravity of the load, speed, and acceleration during its lifting over time. It has been established that the height of the load during lifting, which is directly related to the length of the hoisting ropes, as well as the mass of the lifted load and the design of the main bridge, including its shape and dimensions, significantly influence the dynamic loads experienced by the structure. The mathematical model offers a new approach to improving the efficiency and safety of industrial operations by providing a more precise understanding and accounting for dynamic loads during the start-up of a bridge crane.

Список литературы Modeling the dynamic loads affecting a bridge crane during start-up

- Fedjaeva GA, Kochevinov DV, Lozbinev VP, Lozbinev FYu. Dynamics Simulation of Bridge Crane Electromechanical System. Bryansk State University Herald. 2014;41(1):63-67.

- Mirsad Colic, Nedim Pervan, Muamer Delic, Adis J Muminovic, Senad Odzak. Mathematical Modelling of Bridge Crane Dynamics for the Time of Non-Stationary Regimes of Working Hoist Mechanism. Archive of Mechnical Engineering. 2022;69(2):189-202. http://doi.org/10.24425/ame.2022.140415

- Hanjun Pu, Xiaopeng Xie, Guangchi Liang, Xiangyong Yun, Haining Pan. Analysis for Dynamic Characteristics in Load-Lifting System of the Crane. Procedia Engineering. 2011;16:586-593. https://doi.org/10.1016/ j.proeng.2011.08.1128

- Goncharov KA, Denisov IA. Maintenance of Working Capacity of Movement Mechanism of Load Trolley with Linear Traction Electric Drive of Bridge Type Crane. IOP Conference Series: Earth and Environmental Science. 2017;87(6):062004. https://doi.org/10.1088/1755-1315/87/6/062004

- Jaafar HI, Mohamed Z, Shamsudin MA, Mohd Subha NA, Liyana Ramli, Abdullahi AM. Model Reference Command Shaping for Vibration Control of Multimode Flexible Systems with Application to a Double-Pendulum Overhead Crane. Mechanical Systems and Signal Processing. 2019;115:677-695. https://doi.org/10.1016/ j.ymssp.2018.06.005

- Dooroo Kim, William Singhose. Reduction of Double Pendulum Bridge Crane Oscillations. In: Proc. 8th International Conference on Motion and Vibration Control. Daejeon: Genicom Co., Ltd.; 2006. Р. 300-305.

- Akhtulov AL, Kirasirov OM, Kirasirov MO. Features of Calculation of Steel Structures of Bridge Cranes at Variable Loads. MATEC Web of Conferences. 2019;298:00032. https://doi.org/10.1051/matecconf/201929800032

- Antulov AL. Algorithm of Numerical Calculation of Reactions of Constraints in a Dynamic System of Transport Machine. Journal of Physics: Conference Series. 2018;944:012002. https://doi.org/10.1088/1742-6596/944/1/012002

- Akhtulov AL Kirasirov MO, Kirasirov OM, Mashonsky VA. Building the Automation System for Designing Load-Lifting Cranes of Bridge Type. In: Proc. XVII International Research and Practice Conference "European Science and Technology". Munich: Vela Verlag Waldkraiburg; 2017. Р. 29-35. URL: https://portal.kuzstu.ru/file/view/68427 (accessed: 08.12.2023).

- Spitsyna DN, Polikarpov KV. Dynamics of Cranes with Rigid Load Suspension. Moscow: Bauman Moscow State Technical University; 2009. Р. 160. (In Russ.).

- Yihai Fang, Yong K Cho, Jingdao Chen. Framework for Real-Time Proactive Safety Assistance for Mobile Crane Lifting Operations. Automation in Construction. 2016;72:367-379. https://doi.org/10.1016/j.autcon.2016.08.025

- Semykina IYu, Kipervasser MV, Gerasimuk AV. Study of Drive Currents for Lifting Bridge cranes of metallurgical enterprises for early diagnosis of load excess weight. Journal of Mining Institute. 2021;247:122-131.