Modernization trends of forestry complex in the region (the Karelia Republic's case)

Автор: Prokopyev Egor Aleksandrovich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Branch-wise and regional economy

Статья в выпуске: 3 (15) т.4, 2011 года.

Бесплатный доступ

The article is devoted to the issue of the traditional branches’ enhancement. Karelia Republic’s forestry complex is considered as the example of the region’s traditional branch. The comparison of Karelia’s wood industry and Finland’s one is represented. The author chooses labor productivity (the factor of the intensive development) as the key parameter of enhancement. The dynamics of the wood complex’s development in Karelia from 1990 till 2009 is considered. The branch enhancement’s directions are offered according to the revealed tendencies.

Modernization, forestry and forest industry, competitiveness, labor productivity

Короткий адрес: https://sciup.org/147223269

IDR: 147223269 | УДК: 332.05

Текст научной статьи Modernization trends of forestry complex in the region (the Karelia Republic's case)

The course to the economy’s enhancement, chosen by the country’s administration, has the overall objective that is to raise the Russian enterprises’ competitiveness. This problem can be especially observed at the enterprises representing traditional branches.

The urgency of the mentioned problem lies in the contemporary economic conditions such branches’ enterprises loose competitive advantages such as cheap raw material, energy carriers, and qualified labor, therefore the enhancement’s realization becomes the necessary requirement for their survival and development.

At the problems’ solution on the enhancement process’ management it is necessary to take into account a lot of factors influencing it. It is important to realize, that the enhancement’s driving forces can be represented by various groups of interests.

Forestry complex is traditional in the Karelia’s economy. About 9.7% of all employed work in the complex’ organizations. Export of the complex’ production prevails in the Republic’s foreign commerce. In 2009 export forestry production made 665 million US dollars (64% of all export deliveries of the Republic). In the commodity export structure of timber and its products the greater share was made by raw wood products. In deliveries newsprint and craft paper prevailed in the cellulose-and-paper production’s export [1].

Forestry complex’ enhancement assumes movement to modern highly effective use of resources, production of qualitative competitive goods of deep processing. The best samples of forestry can be found in such countries, as Canada, the USA, Sweden and Finland. Traditionally the Karelian forestry complex is compared to the Finnish one.

The woods’ structure in Karelia and Finland is practically similar; the wood reserves are also comparable. The Finnish forestry, as well as the Karelian one, is focused on export of the production of deep processing with the high added cost. In the majority of branches from 70 to 90% of production are exported [9].

In 2008 in Finland the cost of the exported forestry products 19.4 times exceeded the similar Karelian parameter ($16.4 billion and $849 million accordingly), in 2009 this ratio made 18.2 times ($12.1 billion and $665 million accordingly) [1, 8].

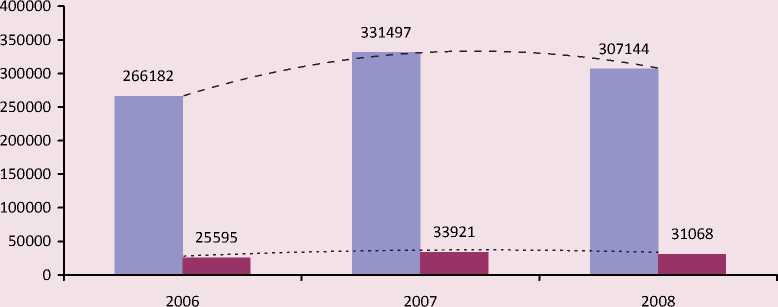

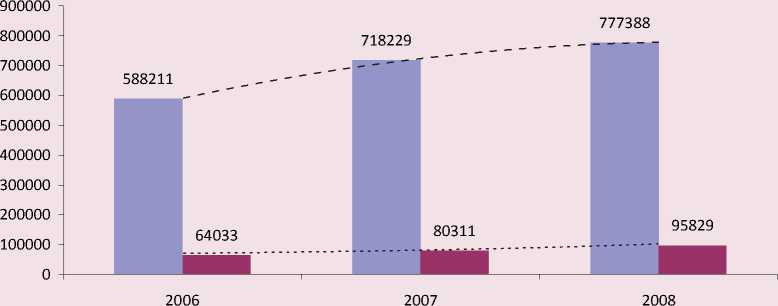

The main objective of the forestry complex’ enhancement is the increase of the complex enterprises’ efficiency and competitiveness. The most simple and informative parameter of an enterprise’s functioning is labor productivity. In labor productivity the Karelian enterprises lag behind the Finnish ones on processing wood products in 9.9 times (fig. 1) , on producing cellulose, wood-pulp, paper, cardboard and products made of them in 8.1 times (fig. 2) .

Before the market transformations in 1990s only 10 % of the round timber were delivered for export, the rest amount of it was processed

Figure 1. Annual labor productivity of a woodworker, in dollars

■ Finland ■ Karelia Republic

Figure 2. Annual labor productivity of a woodworker producing cellulose, woodpulp, paper, cardboard and products made of them, in dollars

■ Finland ■ Karelia Republic

at the woodworking and the pulp-and-paper mills in the Republic and the country.

At the end 1990s almost 70% of the provided wood in the Republic began to be delivered for export as raw material, from its general volume (97%) to Finland, that resulted in dissociation of the complex – the “raw” enterprises were reoriented to export, and the processing ones – to cheaper raw material from the neighbor regions. As a result the dynamics of the branches’ development of the Karelian forestry complex essentially differed.

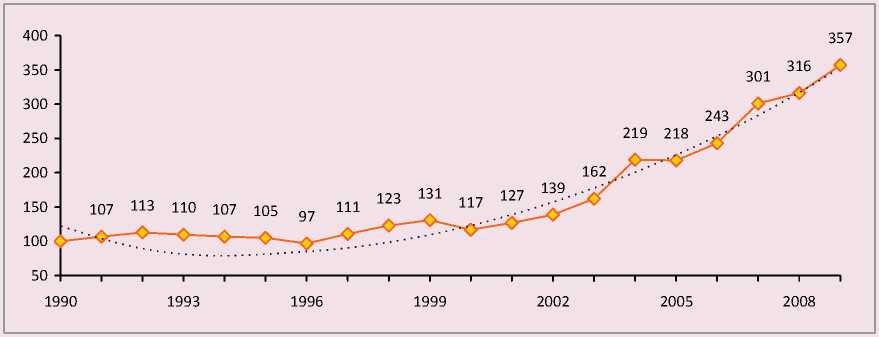

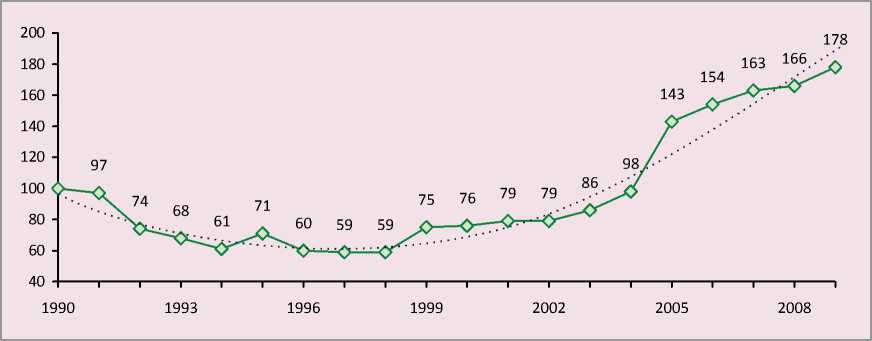

The requirements to the quality of the wood, provided by the Republic, from the part of the Finnish enterprises, high speed of the capital turnover in logging have resulted in its enhancement, the transition to the sorting technology of wood production which means lumbering complex’ use (harvester and forwarder as one). One lumbering complex is capable to operate instead of some brigades of woodcutters with a skidder. Nowadays in Karelia, by experts’ estimations, to 90% of wood are provided according to sorting technologies. As a result of transition to the sorting wood providing the labor productivity at logging in Karelia did not reduce in 1990s and has abruptly increased in 2000s, by 2009 it increased more than in 3 times in comparison with 1990s (fig. 3) .

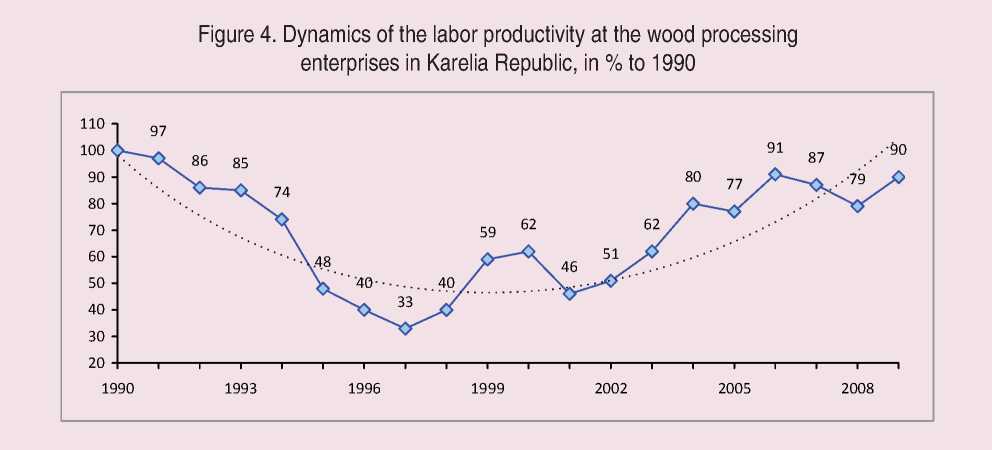

At the period from 1990 till 1998 the Republic’s wood processing enterprises experienced the significant recession caused by a number of reasons. At the majority of enterprises the out-of-date equipment did not allow to release qualitative production required by the market as it resulted in the over-expenditure of raw material which cost considerably increased in Karelia. In the result the local enterprises faced the wood shortage as they could not pay for wood raw material as much as the Finnish ones did. The efficiency of investments into wood processing in comparison with raw materials’ export was much lower.

The period of reforms revealed a low management level at the Karelian enterprises, inability to operate in the changing conditions which were used by unconscientious partners. In 1992, for instance, Ilyinsky timber enterprise lost its production for the sum of 600 000 dollars because of the frauds of the foreign partner from France. At the same time, a number of enterprises becoming public corporations were redeemed from the workers by speculators, specially bankrupted and resold. The decline of the work productivity during this period of time was also caused by the fact that the enterprises did not reduce their staffs, hoping to return to the former political system.

Figure 3. Dynamics of the labor productivity at Karelia Republic’s loggings, in % to 1990

By virtue of these and other reasons the Karelian enterprises could not find means for enhancement, and by 1997 the labor productivity had fallen in 3 times (fig. 4) .

It is revealed, that the increase in the production volumes from 1998 till 2000 is connected to the ruble devaluation which made Karelia Republic’s woodworking profitable for some time, and from rather expensive Karelian raw material due to the modern technologies it became possible to produce competitive production. It is also revealed, that the dynamics of the labor productivity was influenced by several factors. First, the increase in the labor productivity basically took place due to loading unused capacities. Second, the growth of the labor productivity was connected to the new equipment’s and technologies’ occurrence: highly-efficient lines on manufacturing straughan-molded products; less powerintensive drying chambers; the processing centers on manufacturing windows and other equipment (at the enterprises in Petrozavodsk and Segezha); and the technologies on manufacturing laminated panels. Thirdly, the role of the factor constraining the growth of the labor productivity is played by the artificial restriction of competition, as from 1998 to 2002 the republican authority did not let outside investors into the wood branch. By the year of 2001 the effect of devaluation had been settled.

Since 2003 in Karelia in the sphere of forestry complex the role of competition in development is growing. New wood processing enterprises are created, that in the certain degree caused the enhancement of the old ones. Due to the financial stability (2003 – 2006) the enterprises used credits and leasing circuits, the branch became more attractive for investments.

Till 2006 in Karelia a big Russian investor, holding “InvestLesProm” appeared. The frontier position also assisted to the occurrence of enterprises with foreign participation “SvedWood-Karelia”, “SetLes”) with the high work efficiency. At the same period in the Republic a new direction of activity – bioenergetics – appeared. Public Corporation “Karelia Profile” (Petrozavodsk) and Closed Joint-Stock Company “North Inter House” (Lahdenpohya municipal area) set the equipment for manufacturing fuel granules (pellets) from waste products of lumbering and fuel chips accordingly. Public Corporation “BioGran” bought a pellet factory in Finland and transferred it to Petrozavodsk. Despite of the new enterprises’ occurrence and the enhancement of the old ones the labor productivity in 2006 couldn’t even reach the level of 1990.

In 2007 in the USA the hypothec crisis began which developed into the global financial crisis in 2008. As a result of the reduction of individual housing construction in the USA manufacturers of the saw-timbers from Canada, working basically for the USA market, started to deliver their products to Europe. The increase in the offer of saw-timbers in the European market resulted in abrupt falling of the prices, that negatively affected local manufacturers, as the cost price of the wood raw material in Europe is traditionally higher than in Canada. As a result of the toughening competitive struggle the Karelian woodworkers who were basically focused on the European market of saw-timbers, were compelled to sell their products almost 40% cheaper and their losses made hundreds million rubles. As the consequence, the majority of the branch’s enterprises had to work in one change; some enterprises stopped their activity (Kemsky, Shalsky and Ilyinsky timber, Kondopozhsky wood-export plant, Public Corporation “Belomorskaya wood processing company”).

The only wood processing enterprise of the Republic which in 2009 not only kept but also increased the volumes of production was Solomensky timber plant. This enterprise is one of the advanced in the Republic and is focused on the Japanese market which is very demanding to the quality of the delivered production.

Pulp-and-paper production in the Republic by the beginning of the market transformations was submitted by five enterprises in Kondopoga, Segezha, Pitkyaranta, Suoyarvi and Lyaskelya. The consequences of transition to the market economy resulted in the significant decrease of the industrial parameters at the period from 1990 till 1998. The reasons of decrease were the same, as at the wood processing enterprises. One more specific reason affecting the delay of the branch’s development is revealed: the necessity to coordinate the enterprise’s development with the requirements of a city (an area) where it settles.

Kondopozhsky pulp-and-paper plant after privatization became the property of the labor collective under the administration of the initiative director V. Federmessera who could adapt for the new conditions quickly. In the result since 1994 the enterprise has increased the output which significant part goes for export, and new projects are realized.

At the Segezh pulp-and-paper plant such team of managers led by V. Preminin appeared only in 1998 then the growth of production and the enterprise’s enhancement began. The previous proprietor of this plant, the Swedish firm “Assidomen” could not do business in the Russian conditions and find the way out for the enterprise from the crisis. In the result paper bags’ production reduced almost in 11 times, commodity markets were lost.

The increase in volumes of production in 1999 occured due to the ruble’s devaluation and restoration of manufacture in Segezha. A relatively slow growth of the parameters of the years 2000 – 2003 was connected with the fact that except for two successful enterprises some enterprises got into the hardest financial position, such as public corporation “North-Ladoga paper-producing plant “Lyaskelya”” and public corporation “Suoyarvi”. In August, 2003 public corporation “Kondopoga” launched the high-speed paper-producing machine №10 due to which by 2004 the release of newsprint increased for 20.8%. In the result in 2004 the labor productivity at the enterprises of the pulp-and-paper industry left at the level of the year of 1990. Pulp-and-paper plants in Kondopoga and Segezha began to compete successfully to the foreign enterprises in the world market. For the economy of Karelia Republic this branch has strategic value.

In 2004 the stage of the scale enhancement at Segezha pulp-and-paper plant (modernization of paper-producing machines №10, stream of continuous boiling, sorting and cellulose washing) was completed. At the public corporation “Suoyarvi cardboard containers”

Figure 5. Dynamics of the labor productivity at the enterprises of cellulose production, pulp and paper, cardboard and products made of them in Karelia Republic, in % to 1990

the new proprietors restored the paperproducing machine, and the volumes of manufacture began to increase, that in 2005 resulted to the considerable step of the labor productivity in the branch. From 2006 to 2009 the branch’s enterprises continued the enhancement of manufacture that was reflected in the growth of the labor productivity (fig. 5) .

Despite of the crisis, the pulp-and-paper enterprises of the Republic continue the enhancement of manufacture. At the public corporations “Cellulose factory “Pitkyaranta” and “Kondopoga” the plans on enhancement are designed till 2015. The primary goals in these plans are submitted as follows: the electric power economy, reduction of the harmful substances’ dump, the improvement of cellulose quality and the increase of the production profitability. For the realization of the plans on modernization and expansion of the basic manufacture in the years 2010 – 2015 public corporation “Kondopoga” 741 million rubles are required. By 2013 it is planned to finish the program on reconstruction and expansion of the Segezha pulp-and-paper plant within the framework of the project “Polar Bear”. The volume of investments will make about 1 billion euro. The feature of “Polar Bear” is that the birch will be used as raw material for manufacture, instead of coniferous breeds of trees. This wood resource in the region now remains practically unclaimed by the timber industry enterprises. After the completion of the Segezha plant’s enhancement it will begin to release the whitened cellulose which is the basic raw material for manufacture of the enamel-paper. Thus, holding “InvestLesProm” owning the Segezha plant becomes the first supplier of the enamel-paper in Russia. The further development of the enterprises should be under the production construction with the high added cost: sanitary-and-hygienic products, enamel-paper, and packages.

As a result of the analysis of the forestry complex development under the influence of various groups of interests it is possible to tell, that three directions of the branch development connected with modernization were generated.

The first is the enhancement at the external interest and accordingly to the external investments. In the result is the fast growth of the labor productivity. This direction is typical for timber cuttings, in which development and modernization Finnish wood-processing enterprises were interested. Now in this branch a high level of work mechanization and workers’ qualification can be observed. Due to the development of the sorting technologies in Karelia (in Petrozavodsk and Medvezhyegorsk) the service enterprises appeared, they began to release the harvester under the brand “Chetra” on the basis of technologies of the Danish company “Silvatec”. Thus, it is possible to tell, that the technical modernization in timber cuttings has already taken place.

The second direction is the enhancement due to the internal resources (at gradual occurrence of the external ones) which was typical for the pulp-and-paper enterprises. In the result was the recession of the labor productivity in 1990s and the growth gradually accelerated in 2000. The nonsuccessful experience of the Swedish company “Assidomen” at the Segezha plant considerably lowered the investment rating of the Republic. Just before the beginning of 2000s the enterprise of the branch developed with some help from the Republican authorities. From the middle of the 2000s the enterprise on manufacturing cellulose, paper, cardboard and products of them became very attractive to the Russian investors. Holding “InvestLesProm”, which bought the Segezha plant in 2006, began to invest actively into the complex’ enhancement.

The third direction is the modernization at insignificant interest of proprietors and consumers. In the result is considerable recession in 1990 and slow growth in 2000s. The mentioned variant describes the development of the wood-processing enterprises in Karelia.

The problems which were faced by the Karelian woodworkers in 1990s, did not allow them to find means for the complex enterprises’ enhancement. Foreign investors, basically the Finnish ones, were not interested in this branch’s development in Karelia. Even the enterprises which appeared not long ago with the foreign participation on the territory of Karelia pursue the purpose not directed to the development of deep wood processing, but to fastening the enterprise to the resource base. Nowadays the majority of enterprises make production with the low added cost. The transition to a deeper wood processing is necessary for the branch’s development. There are certain successes which are already reached: the growing demand for plywood and window blocks resulted in the occurrence of the modern equipment on their manufacturing in Karelia. As to 90% of all saw-timbers are used in the construction, the leader of the branch’s enhancement should be the development of the wooden housing construction.

Theoretically the fourth direction is possible, it is the state support, when federal (or regional) authorities within the framework of the enhancement program invest budgetary funds, create the system of privileges for the external investors’ attraction and render the necessary support to the enterprises, helping in this way to solve arising problems.

Список литературы Modernization trends of forestry complex in the region (the Karelia Republic's case)

- Forestry complex of the Karelia Republic: stat. coll./KareliaStat. -Petrozavodsk, 2010. -61 p.

- Druzhinin, P.V. The analysis of economic conditions of the timber industry complex’ development in Karelia/P.V. Druzhinin//Problems of Forecasting. -2003. -№ 1. -Pp. 108-117.

- Forestry complex in the Karelia Republic: conditions and ways of development/E.G. Nemkovich, A.F. Kozlov. -Petrozavodsk, 2006. -171p.

- Timber industry complex in the Karelia Republic (1990 -1999)/E.G. Nemkovich, A.M. Tsypuk, A.I. Shishkin. -Petrozavodsk: Publishing house PetrGu, 2000. -164 p.

- Wood processing enterprises in Karelia: It’s too far to former heights//LesPromInform. -2010. -№ 3. -Pp. 20-22.

- Shishulina, Z.I. The development of the timber industry complex of the Karelia Republic: Tendencies and Prospects/Z.I. Shishulina//Economic and social changes: facts, tendencies, forecast. -2008. -№ 3. -Pp. 32-39.

- Statistical yearbook of Finland/Tilastokeskus. -Helsinki, 2009. -713 p.

- Forestry /Forestry Statistics Service Tilda. http://www.forestindustries.fi/.Statistics/Tilastokuviot/Basics/Forms/AllItems.aspx.free (date of the reference: 23.11.2010).