Monitoring and protection of sewer tunnels in difficult ground conditions with increasing anthropogenic impact

Автор: Perminov Nikolai Alekseevich

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 4 (102), 2022 года.

Бесплатный доступ

The object of research. Long-term operation of sewer tunnels in difficult engineering and geological conditions creates the danger of violating their structural safety. A long-term study of the changes’ dynamics in the technical state of the tunnels made it possible to establish the patterns of intense anthropogenic and dynamic influences on this process. Method. The developed discrete and continuous diagnostic models of the defects’ development in the tunnels’ structures make it possible to identify potentially hazardous areas subject to the manifestation of critical failures and methods of their localization. On the basis of numerical modeling, the boundaries of defect-free joint operation of the system “source of impact - geo-mass - sewer tunnel” have been determined. Results. With increasing external anthropogenic and dynamic impacts, modeling zones of urban areas with potentially dangerous sections of underground sewage facilities is the basis for the development of regulatory documents on monitoring methods and safe development geotechnical infrastructure.

Monitoring, tunnel, weak soils, anthropogenic impacts, protection

Короткий адрес: https://sciup.org/143179048

IDR: 143179048 | DOI: 10.4123/CUBS.102.5

Текст научной статьи Monitoring and protection of sewer tunnels in difficult ground conditions with increasing anthropogenic impact

With the development of large cities, long-term operated tunnel sewage collectors need special protection from man-induced impacts. As objects related to the structures with a higher level of responsibility, sewer tunnels must meet the requirements for safe operation, excluding the risk of dangerous accidents [1]- [4]. Analysis of the materials on the current technical condition of sewer tunnels in more than ten largest cities in Russia with a developed historical center, with a total length of more than 2.5 thousand km, made it possible to develop a methodology for assessing their technical condition, give a classification and a catalog of defects.

For almost most of the cities under consideration, the network of tunnel collectors has an average value of the physical deterioration degree more than 60% with a development dynamic of 0.6-1.2% per year. It was found that for the cities where the operation of the engineering infrastructure is carried out in complex engineering and geological conditions typical, for example, for St. Petersburg, the degree of the tunnels wear is significantly greater, reaching 83% with a higher development dynamic of up to 1.6-2.1 % per year. Development of a methodology for identifying the potentially dangerous sections of tunnels operated for a long time in difficult soil conditions, with their subsequent modeling and monitoring, will ensure their structural safety with increasing man-induced dynamic impacts.

The most interesting from the point of view of studying potentially dangerous sections of sewer tunnels is the system and network of tunnel collectors of St. Petersburg, which, with an undeveloped redundancy scheme, has a length of about 275 km. The system of sewer tunnels consists of pipelines with a diameter of 1.2 to 5.6 m and a depth of 8 to 70 m. Most (up to 75%) of the waste line length is located in the central historical part of the city in extremely difficult technogenic and engineering-geological conditions. The main part of the territory is covered by a stratum of Quaternary deposits (Q) that are unstable to technogenic impacts. Among the latter, it should be especially noted water-saturated clay soils belonging to lake-sea, lake-glacial and moraine deposits. Up to a depth of 30-120 m, soil strata are represented by silty sands of medium density, water-saturated Е=7-11 МРа, С=0-0.005 МРа, j=27-30°; silty plastic sandy loam Е=3-5 МРа, С=0.01-0.02 МРа, j=12-17°; silty layered fluid plastic loams Е=5-8 МРа, С=0.015-0.025 МРа, j=10-16°. Long-term waste line operation in these conditions negatively affects their technical condition.

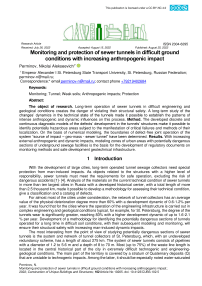

This factor is especially true for the continuously operating tunnel sewer collectors under the conditions of increasing man-induced impacts, first of all, to static from the large-sized complexes under construction in the influence zone with a developed underground part (see Fig. 1) and vibro-dynamic from the construction and transport equipment [5]– [9].

The research is devoted to the development and justification by geotechnical modeling of ways to ensure the safety of tunnel structures and the development of recommendations for use in large cities with difficult soil conditions, with heavily worn and potentially dangerous sections of tunnels. And, as a result, to increase their reliability during long-term operation in the conditions of urban infrastructure development.

2 Materials and Methods

To identify the potentially dangerous areas, instrumental surveys of tunnels are carried out using a special technique [10]. Technical instrumental surveys included: full-scale tachymetric survey of the spatial position of the tunnel in the intervals between mines, scanning the inner surface conditions of the tunnel with an assessment of its continuity with a GPR; taking cores and carrying out tests using the pull-off method with scanning to determine the strength characteristics of concrete, taking samples for chemical and biochemical analyzes, assessing the degree of corrosion and reinforcement by nondestructive methods, vibro-dynamic testing of vibrations of internal tunnel structures from external and construction vibration effects [11], [12].

Fig. 1 - Scheme of a potentially dangerous section of a sewer tunnel in the zone with man-induced impacts from a complex under construction in St. Petersburg

The uniqueness of the observation materials for the tunnels’ state lies in the fact that the technical inspection of the structures has been carried out for a long time from the end of the 70s up to the present (2021). During this period, the same reservoir intervals have been surveyed for several times. At the same time, as a rule, after the examination, their conditions were monitored for several years. Thus, it became possible to trace the dynamics of the defects’ development.

The observation time range was divided into 3 periods:

-

а) 70-80s; b) 80-2000s; c) 2000-2020s. The most typical revealed defects affecting the operational reliability and bearing capacity of the tunnel were grouped into 7 classes [13]- [15]: d1 - shrinkage cracks in the concrete jacket; d2 - signs of gas corrosion; d3 - drip leaks; d4 - force cracks in the arch and on the lateral surface of the tunnel; d5 - signs of biological corrosion of concrete; d6 - reinforcement corrosion, tray abrasion; d7- the presence of pressure leaks.

Analysis of the defects’ development manifestation and dynamics structure show that in the initial period of the tunnel collectors’ operation, defects were observed in the form of shrinkage cracks in the concrete jacket with the manifestation of drip leaks and signs of gas corrosion. The nature of the defects prevailing in the first 15-20 years of the tunnels’ operation and their influence on the bearing capacity and operational reliability of structures can be taken as insignificant, and their technological state can be recognized as workable according to the RF “GOST” and “BC” regulations.

The next 20 years of the tunnels’ operation are characterized by the signs of force cracks and a significant increase in concrete defects due to its gas and biocorrosion. However, their technical condition is in the category of limited working capacity.

Of particular interest are the results of the defects analysis, the manifestation of which falls on the period 2000-2020s. It should be noted that it was during this period that the number of defects affecting the bearing capacity of the tunnel structures increased: an almost 40% increase in the number of force cracks in the roof and on the lateral surface of the tunnel; signs of reinforcement corrosion and tray abrasion; the presence of pressure leaks in a tunnel body; an increase in the proportion of defects associated with biological and gas corrosion. Category of technical condition of the waste line structure was classified as “disabled”. This period is especially typical for long-term operating tunnel sewers under the conditions of increasing man-induced impacts, primarily from the additional point static loads during sealing construction and increasing external vibro-dynamic effects [16], [17].

Defect-free waste line functioning in these conditions requires a calculated justification of the structural safety of the tunnel and monitoring its technical condition when choosing a method and a mode of carrying out the measures to restore the bearing capacity and operational reliability of the structure.

Within the framework of this study, we faced the task of the safe level external anthropogenic impacts’ geotechnical provision on the tunnel structure, taking into account its residual bearing capacity.

3 Results and Discussion

The measures to protect potentially dangerous sections of tunnel collectors and ensure their reliability and safety were proposed on the basis of modeling and determining the boundary of the defect-free joint operation of the system “source of impact – geo-mass - sewer tunnel” [18]- [20], but the main requirement that they must certainly meet, is the possibility of preventive use, justified by geotechnical and design calculations [21]- [23].

The results of geotechnical modeling to ensure the waste line structural safety typical for a large city with a developed engineering and transport infrastructure under difficult engineering and geological conditions of construction and operation are presented below (Table 1) as one of the examples [24]- [29].

Table 1. The results of the calculation substantiation of geotechnical measures to protect potentially dangerous sections of tunnels from unacceptable impacts

Character of technogenic impacts

Geotechnical and structural measures of a protective screen made of fixed soil to prevent the foundation pit bottom from elevation

|

Unloading the soil mass when trenching the excavation for the tunnel |

Vertical deformations of the soil mass after the excavation of the construction pit, without preliminary fixing - 37mm |

Vertical deformations of the soil mass after excavation of a construction pit with soil fixing above the collector using Jet Grouting technology (3.0 m thick) - 3.2 mm |

|

|

' l^^^jjj^^^l |

1 |

||

|

Calculation option |

Construction stage |

Collector deformation, mm. |

|

|

Without Propping |

- |

+37 |

|

|

Propping the foundation pit using Jet Grouting technology. Power 2.0m. |

soil reinforcement |

-2.1 |

|

|

excavation |

+10.1 |

||

|

Propping the foundation pit using Jet Grouting technology. Power 3.0m. |

soil reinforcement |

-3.0 |

|

excavation |

+3.6 |

|

|

Propping the soils above the collector using Jet |

soil reinforcement |

-2.6 |

|

Grouting technology. Power 2.0m. |

excavation |

+8.3 |

|

Propping the soils above the collector using Jet |

soil reinforcement |

-2.9 |

|

Grouting technology. Power 3.0m. |

excavation |

+3.2 |

Structural waste line reinforcement winding technology to increase the maximum permissible tunnel displacements

General calculated displacements during General calculated displacements during excavation under the excavation with the device of a geotechnical barrier protection of sheet piling

Increasing the zone of maximum permissible waste line displacements with one-sided unloading

of the soil mass during

the

embankment

reconstruction.

Additional horizontal deformations of the collector were 54mm

Additional horizontal deformations of the collector were 7mm

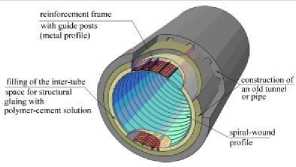

Structural waste line reinforcement by lining and spiral-wound technology to restore the bearing capacity of the tunnel to the design level

Increase in static and dynamic loads on waste line from the action of heavy vehicles and trams

Condition of a potentially dangerous waste line area before renovation

Structural scheme and solution to strengthen the tunnel section

Technical condition of the tunnel after restoration and repair

The second example of the numerical implementation of measures to protect the collector from external influences is the potentially hazardous area noted above (see Fig. 1).

The customer set the task to ensure the safe operation of a sewer collector located in soft soils, near which the construction of a high-rise building had started.

The modeling task was to determine the permissible horizontal displacements of the tunnel sections when performing work near the structure.

For normal operation of the collector tunnel, it is necessary to exclude the formation of cracks in the structure of the lining caused by its displacement towards the pit during the work.

The criterion for the structure safety is the maximum permissible tensile stresses of concrete at the characteristic points of the lining.

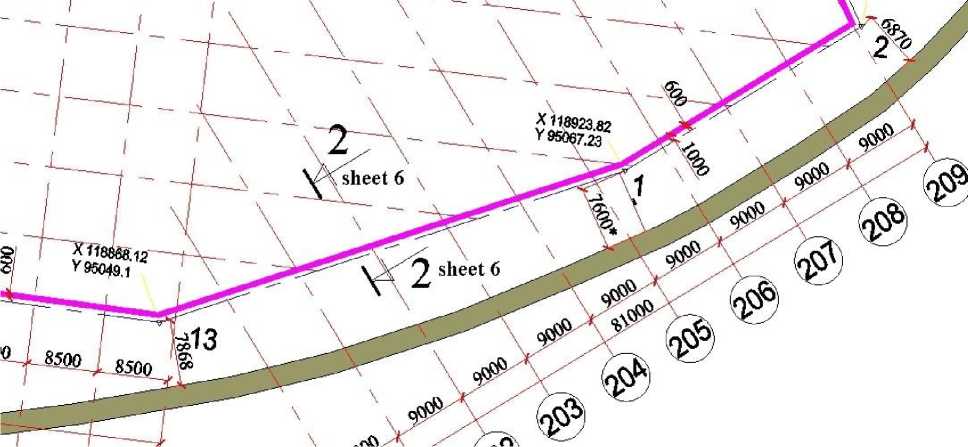

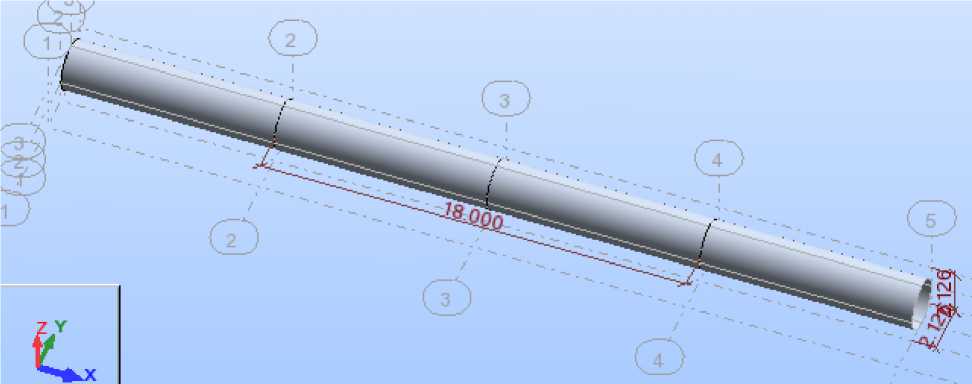

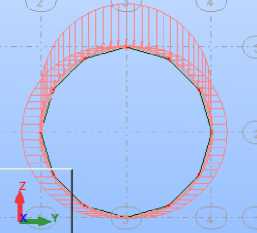

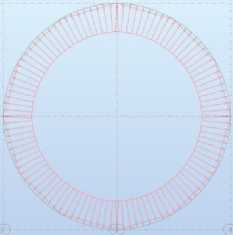

The design of the collector tunnel lining is a two-layer cylinder. The outer layer is a prefabricated reinforced concrete structure made of tubing. The inner layer is a monolithic reinforced concrete jacket (see Fig. 2).

Fig. 2 - Design of the collector tunnel potentially dangerous section’s lining

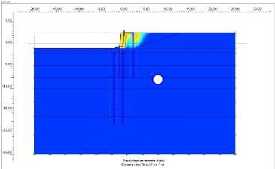

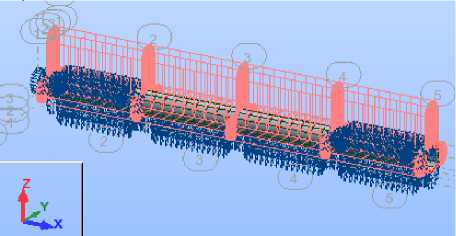

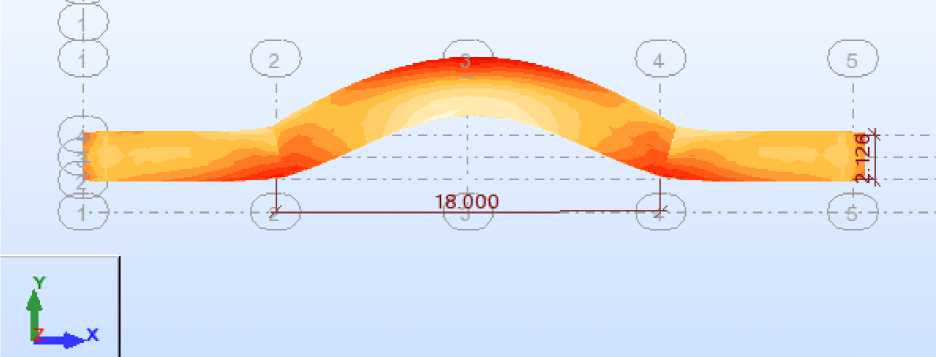

The tunnel sections with different lengths of the influence zone and the structure reinforcement degree were modeled (see Fig. 3). Geotechnical calculations simulated the measures to reduce the impact on the displacement of the tunnel using a wall in the ground between the tunnel and the wall under construction in the ground made of low-modulus material [25], [26].

а)

b)

Fig. 3 - Fragment of the calculated potentially dangerous section of the collector with a length of 18 m: a) with loads and elastic rebound;

b) the transcendent SSS tunnel zones: 1 - in the middle; 2 - at the ends of the displacement section

Numerical calculations were used to obtain the permissible displacement values of the lining, taking into account the presence of a screen made of low modulus material and depending on the tunnel deformable section length. Carrying out of work related to man-induced impacts, the project provided monitoring the tunnel and geo-massif structure [27]- [29].

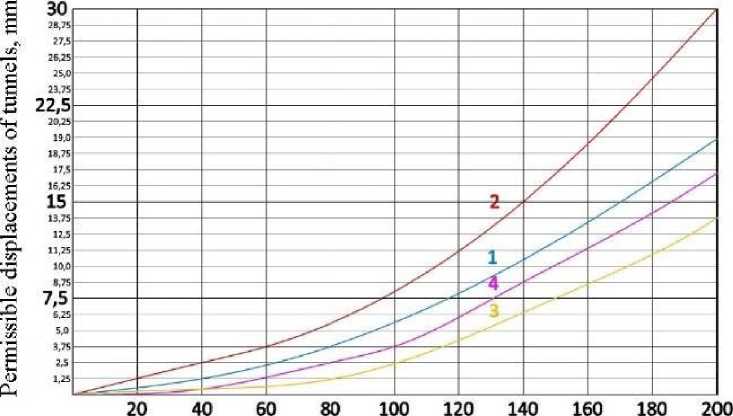

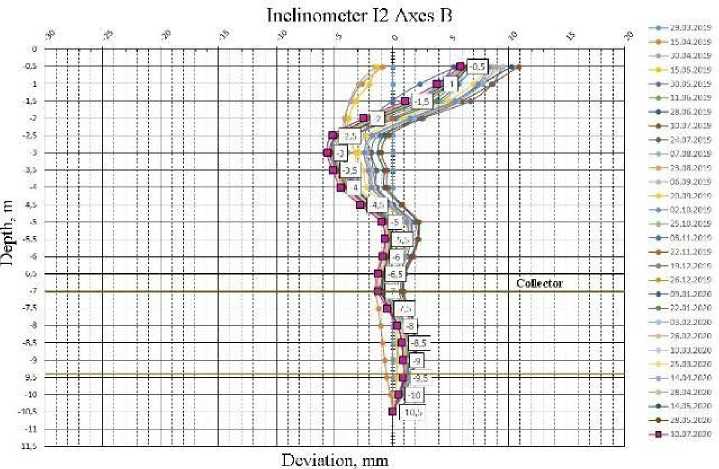

The calculation substantiation of geotechnical protective measures was carried out according to the algorithm [30]- [33]: collection of loads and impacts, determination of physical and mechanical characteristics, determination by geotechnical calculations of the permissible level of external anthropogenic impacts on the tunnel, taking into account its residual bearing capacity. Figure 4.a shows fragments of the tunnels’ maximum permissible displacements computational modeling results (before the application of protective measures and after the implementation of protective measures) and Figure 4.b shows the data of monitoring observations.

a)

b)

The length of the deformable section of the tunnel, m

Fig. 4 - Maximum permissible displacement of a tunnel falling into the zone of man-induced influences:

a) calculated values of the maximum permissible displacement of sewer tunnels D=1.5 and D=2.5 before (1.3) and after (2.4) strengthening the structure using winding technology; b) data of monitoring control by the inclinometers readings to prevent exceeding the maximum permissible displacement of the tunnel D=2.5m with the length of the deformable section 70m.

To ensure the bearing capacity of the tunnel, the SATURN winding method was used, developed and adapted for the specific conditions of St. Petersburg: intervals between mines up to 1000m and more; irregularity of the working section along the length of the collector associated with the dynamic influences and subsidence of the tunnel in weak thixotropic soils. The tunnel collector on Tovarishchesky Avenue with intervals and diameters of D = 2.5 m and D = 1.5 m at a depth of 1274 m was in operation for more than 40 years and, according to the survey results, had a wear rate of more than 79%, subsidence at the intersection of streets up to 25 mm. Based on the GPR scanning results, it was found everywhere that the concrete jacket was peeled off from the tubing lining with the formation of pressure Perminov, N.

Monitoring and protection of sewer tunnels in difficult ground conditions with increasing anthropogenic impact;

leaks. The scope of work operations included: tunnel cleaning and surface preparation; structural bonding of the concrete jacket and tubing lining by injecting SikaDur; reinforcement of the surface of the vault with structural reinforcement with SikaWrap carbon fiber; lining the surface of the tunnel with a winding profile made of PVC; polymer cement mortar injection (P comp =65MPа) into the annular space for structural bonding of the shell made of PVC with tunnel construction.

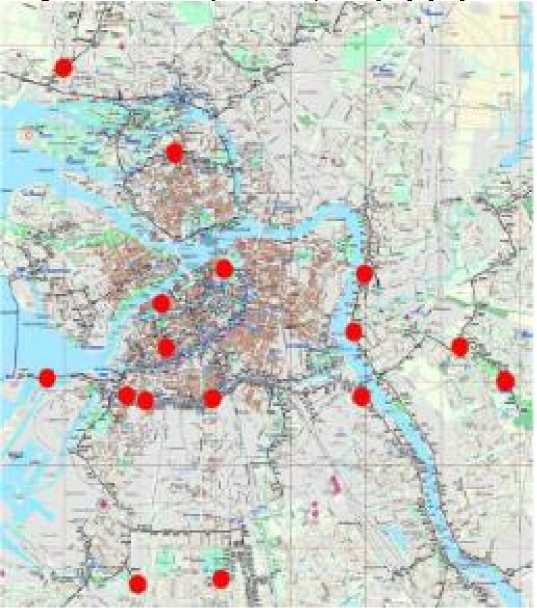

Using this technique, potentially dangerous sections of tunnels that have been operated for a long time in difficult soil conditions were identified (see Fig. 5), which, using numerical modeling, made it possible to choose rational methods of geotechnical protection of these sections and ensure their structural safety under increasing man-induced dynamic impacts [34]- [37].

Fig. 5 - The potentially dangerous sections of sewer tunnels identified in St. Petersburg, requiring structural safety protection

According to the monitoring carried out on the restored potentially dangerous sections of the tunnel, it was established: vibration dynamic tests of the tunnel before and after repair showed the changes in the period of natural collector vibrations of 0.54 s. up to 0.19 s. so, by 58%, and the amplitude of natural vibrations decreased from A = 300 µm to A = 15 µm, i.e., by almost double. This indicates the structure integrity restoration and the joint work of its layers during continuous operation.

4 Conclusions

-

1 .Difficult engineering and geological conditions and the increasing influence of technogenic factors have led to the wear of long-operated tunnel collectors in large cities of Russia up to 66%. For St. Petersburg, characterized by vibration-resistant enclosing waste line massifs of soils, the level of wear reaches 83% with a high dynamic of development up to 1.5 hours 2% per year.

-

2 .Potentially dangerous sections of the tunnels have been identified by the methods of diagnostics and modeling of technical conditions. Proposed and geotechnically sound waste line protection methods, including technologies of structural reinforcement and rehabilitation in the conditions of wastewater transportation, accompanied by a monitoring system, ensure structural waste line safety and their operational reliability.

-

3 .Methods for ensuring structural safety developed and substantiated by waste line geotechnical modeling are recommended for use in large cities with difficult soil conditions, with heavily worn-out sewers with potentially dangerous sections of tunnels and, as a result, to increase their reliability during long-term operation in conditions of urban infrastructure development.

Список литературы Monitoring and protection of sewer tunnels in difficult ground conditions with increasing anthropogenic impact

- Salemi A, Mikaeil R, Haghshenas SS. Integration of Finite Difference Method and Genetic Algorithm to Seismic analysis of Circular Shallow Tunnels (Case Study: Tabriz Urban Railway Tunnels). KSCE J Civ Eng 2018; P. 1978–90. https://doi.org/10.1007/s12205-017-2039-y.

- Alexeev M.I., Baranov L.A., Ermolin Yu.A. Risk-based approach to evaluate the reliability of a city sewer network // Water and Ecology: Problems and Solutions. 2020. №3 (83). P. 3-7. DOI: 10.23968/2305-3488.2020.25.3.3-7.

- Perminov A., Perminov N. Geotechnical and geo ecological fundamentals of sustainable life cycle of unique long-operated underground structures of water disposal systems in difficult soil conditions (the experience of St. Petersburg) // Geotechnics fundamentals and applications in construction: new materials, structures, technologies and calculations Proceedings of the International Conference on Geotechnics Fundamentals and Applications in Construction: New Materials, Structures, Technologies and Calculations, GFAC 2019. P. 231-234. DOI: 10.1201/9780429058882-45.

- Dashko R.E., Shashkin A.G., Shashkin K.G. Analysis of causes of deformations in historic buildings on weak clay soils // Geotechnics fundamentals and applications in construction: new materials, structures, technologies and calculations Proceedings of the International Conference on Geotechnics Fundamentals and Applications in Construction: New Materials, Structures, Technologies and Calculations, GFAC 2019. P. 231-234. DOI: 10.1201/9780429058882-64.

- Voznesensky E.A., Sentsova E.A., Nikitin M.S. 2019. Sandy soils dynamic strength parameters according to triaxial tests // Engineering Geology. 2019. №2. Т.14. P. 24-33. DOI: 10.25296/1993-5056-2019-14-2-24-33.

- Il'ichev V.A., Nikiforova N.S. Methods for the determination of curvatures and the difference between the slopes of foundations as the criteria of deformation of the basements of buildings and structures // Soil Mechanics and Foundation Engineering. 2018. Т. 55. № 3. P. 168-172. DOI: 10.1007/s11204-018-9521-5.

- Dashko R.E., Аlekseev I.V. Main features of engineering-geological and geotechnical research of microbiota influence on hard rocks in the urban underground space // Conference Proceedings. 19th International Multidisciplinary Scientific Geoconference Sgem. 2019. P. 369-376. DOI: 10.5593/sgem2019/1.2/S02.047.

- Voznesensky E.A., Usov A.N., Chernov M.S., Sokolov V.N. Variation in the Microstructure of Clay Soil during Deformation under Triaxial Compression with Consideration of the Occurrence of Deformation Instability // Moscow University Geology Bulletin. 2018. №1. P. 83-86. DOI: 10.3103/S014587521801012X.

- Ponomaryov A.B., Kaloshina S.V., Zakharov A.V., Bezgodov M.A., Shenkman R.I. and Zolotozubov D.G. Results of geotechnical modeling of the influence of construction of the large foundation ditch on the existing historical building Japanese // Geotechnical Society Special Publication: the 15th Asian Regional Conf. on Soil Mechanics and Geotechnical Engineering: Geotechnical Heritage. Part 2 (TC 301/ATC 19 Session) 2015. Vol№ 78. P. 2676-2679. DOI:10.15593/2224-9826/2014.4.18.

- Perminov N. Unsteady interaction simulation of a large rc shell with heterogeneous soil milieu for a gradually increasing caisson structure // IOP conference series: materials science and engineering Institute of Physics Publishing. 2018. P. 012059. DOI: 10.1088/1757-899X/456/1/012059.

- Perminov N. Simulation of defectless lifecycle of unique underground structures of the sewage system at the stage of their construction in difficult soil conditions // International Journal for Computational Civil and Structural Engineering Publishing House ASV, LTD (Moscow). 2019. Т. 15. № 1. P. 119-130. DOI: 10.22337/2587-9618-2019-15-1-119-130.

- Voznesensky E.A., Kushnareva E.S. Methodological aspects of experimental evaluation of dynamic stability of sands in geotechnical survey // Article in the proceedings of the conference. Saint Petersburg 2008: Geosciences - From New Ideas to New Discoveries. 2008. DOI:10.3997/2214-4609.20146895.

- Mangushev R.A., Osokin A.I. The experience of the underground construction for the complex of buildings on a soft soil in the center of St. Petersburg // International Journal for Computational Civil and Structural Engineering. 2020. Т. 16. № 3. P. 47-53. DOI: 10.22337/2587-9618-2020-16-3-47-53.

- Merzlyakov V.P., Vlasov A.N. Effect of polygonal crack nets on the deformation characteristics of rocks // Soil mechanics and foundation engineering. 1993. № 30(3). P. 85-91. DOI: 10.1007/BF01712792.

- Frolov, Y.S., Konkov, A.N., Larionov, A.A. Scientific Substantiation of Constructive-technological Parameters of St. Petersburg Subway // Underground Structures Procedia Engineering, 189. 2017. PP 673-680. DOI: 10.1016/j.proeng.2017.05.107

- Ledyaev, A., Kavkazskiy, V., Vatulin, Y., Svitin, V., Shelgunov, O. Mathematical modeling of aerodynamic processes in railway tunnels on high-speed railways // E3S Web of Conferences, 157, 6017 (2020). DOI: 10.1051/e3sconf/202015706017.

- Karasev M.A., Tai Tien N., Vil'ner M.A. Forecast of the stress-strain state of the prefabricated lining of underground tunnels of curvilinear cross-section // Bulletin of the Ural State Mining University. 2019. № 4 (56). P. 90-97.DOI: 10.21440/2307-2091-2019-4-90-97.

- Perelmuter A.V., Fialko S.Y. Inelastic analysis of reinforced concrete structures in SCAD // International Journal for Computational Civil and Structural Engineering Publishing House ASV, LTD (Moscow). 2019. Т. 15. № 1. P. 54-60. DOI: 10.22337/2587-9618-2019-15-1-54-60.

- Protosenya A.G., Karasev M.A., Belyakov N.A., Lebedev M.O. Geomechanics of low-subsidence construction during the development of underground space in large cities and megalopolises // International Journal of Mechanical and Production Engineering Research and Development. 2019. Т. 9. № 5. P. 1005-1014. DOI: 10.24247/ijmperdoct201989.

- Barabash M., Bashinsky Y., Korjakins A. Stress-strain state of the structure in the service area of underground railway // In the collection: IOP Conference Series: Materials Science and Engineering. 2017. P. 012100. DOI: 10.1088/1757-899X/251/1/012100.

- Mikaeil R, Bakhshinezhad H, Haghshenas SS, Ataei M. Stability analysis of tunnel support systems using numerical and intelligent simulations (case study: kouhin tunnel of qazvin-rasht railway). Rud Zb 2019; 34:1–11. https://doi.org/10.17794/rgn.2019.2.1

- Jalilvand P, Haghshenas SS, Haghshenas SS, Javan MH. Evaluation of Dynamic Resistance of the Toyserkan Doolayi Tunnel by Rock Bolt and Reinforced Shotcrete Composite System. Tunneling Undergr. Constr., Reston, VA: American Society of Civil Engineers; 2014, p. 376–84. https://doi.org/10.1061/9780784413449.037.

- Park J, Chung H, Moon J-B, Choi H, Lee I-M. Overall risk analysis of shield TBM tunnelling using Bayesian Networks (BN) and Analytic Hierarchy Process (AHP). J Korean Tunn Undergr Sp Assoc 2016. https://doi.org/10.9711/ktaj.2016.18.5.453

- Swannell N, Palmer M, Barla G, Barla M. Geotechnical risk management approach for TBM tunnelling in squeezing ground conditions. Tunn Undergr Sp Technol 2016. https://doi.org/10.1016/j.tust.2016.01.013.

- Zare Naghadehi M, Benardos A, Javdan R, Tavakoli H, Rojhani M. The probabilistic time and cost risk analysis of a challenging part of an urban tunneling project. Tunn Undergr Sp Technol 2016. https://doi.org/10.1016/j.tust.2016.04.007.

- Paraskevopoulou C, Boutsis G. Cost overruns in tunnelling projects: Investigating the impact of geological and geotechnical uncertainty using case studies. Infrastructures 2020. https://doi.org/10.3390/INFRASTRUCTURES5090073.

- Wang S, Li L, Cheng S. Risk assessment of collapse in mountain tunnels and software development. Arab J Geosci 2020;13. https://doi.org/10.1007/s12517-020-05520-6.

- Xu Z, Cai N, Li X, Xian M, Dong T. Risk assessment of loess tunnel collapse during construction based on an attribute recognition model. Bull Eng Geol Environ 2021. https://doi.org/10.1007/s10064-021-02300-8.

- Mikaeil R, Shaffiee Haghshenas S, Sedaghati Z. Geotechnical risk evaluation of tunneling projects using optimization techniques (case study: the second part of Emamzade Hashem tunnel). Nat Hazards 2019;97: 1099–113. https://doi.org/10.1007/s11069-019-03688-z.

- Ahmadi S, Moosazadeh S, Hajihassani M, Moomivand H, Rajaei MM. Reliability, availability and maintainability analysis of the conveyor system in mechanized tunneling. Meas J Int Meas Confed 2019. https://doi.org/10.1016/j.measurement.2019.06.009.

- Cao BT, Obel M, Freitag S, Heußner L, Meschke G, Mark P. Real-Time Risk Assessment of Tunneling-Induced Building Damage Considering Polymorphic Uncertainty. ASCE-ASME J Risk Uncertain Eng Syst Part A Civ Eng 2022. https://doi.org/10.1061/ajrua6.0001192.

- Haghshenas SS, Barmal M, Farzan N. Utilization of soft computing for risk assessment of a tunneling project using geological units. Civ Eng J 2016; P:358–64.

- Naderpour H, Nagai K, Fakharian P, Haji M. Innovative models for prediction of compressive strength of FRP-confined circular reinforced concrete columns using soft computing methods. Compos Struct 2019; 215, P:69–84. https://doi.org/10.1016/j.compstruct.2019.02.048.

- Hasanipanah M, Golzar SB, Larki IA, Maryaki MY, Ghahremanians T. Estimation of blast-induced ground vibration through a soft computing framework. Eng Comput 2017. https://doi.org/10.1007/s00366-017-0508-z.

- Wang S, Li L ping, Shi S, Cheng S, Hu H, Wen T. Dynamic Risk Assessment Method of Collapse in Mountain Tunnels and Application. Geotech Geol Eng 2020. https://doi.org/10.1007/s10706- 020-01196-7.

- Nezarat H, Sereshki F, Ataei M. Ranking of geological risks in mechanized tunneling by using Fuzzy Analytical Hierarchy Process (FAHP). Tunn Undergr Sp Technol 2015. https://doi.org/10.1016/j.tust.2015.07.019.

- Hajihassani M, Jahed Armaghani D, Kalatehjari R. Applications of Particle Swarm Optimization in Geotechnical Engineering: A Comprehensive Review. Geotech Geol Eng 2018;36:705–22. https://doi.org/10.1007/s10706-017-0356-z.

- Wu Z, Wu S, Cheng Z. Discussion and application of a risk assessment method for spalling damage in a deep hard-rock tunnel. Comput Geotech 2020. https://doi.org/10.1016/j.compgeo.2020.103632.