New technological shape of basic branches of RF industrial regions

Автор: Romanova Olga Aleksandrovna, Sirotin Dmitrii Vladimirovich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Socio-economic development strategy

Статья в выпуске: 5 (41) т.8, 2015 года.

Бесплатный доступ

The article emphasizes the increasing importance of industry in the economic development of both developing and developed countries. It highlights the decisive role of basic industries of the RF industrial regions in ensuring the level of their socio-economic development. The work substantiates the possibility to develop basic industries of some industrial regions as the ones that are knowledge-intensive, high-tech and can meet the requirements of new industrialization. The authors propose their understanding of new industrialization in terms of inclusive development. The article introduces a term “repositioning of the regional industrial complex” as a gradual process of interdependent technological, economic, social- institutional, environmental and organizational change based on innovation. It proves that this complex should be viewed as a network of competitive and structurally balanced productions, satisfying individualized needs of the high-tech sector in knowledge-intensive goods and services and increased quality needs of traditional industries...

Industrial region, bibliometric modelling, patent analysis, foresight, priorities, repositioning, technological shape, scenario approach

Короткий адрес: https://sciup.org/147223770

IDR: 147223770 | УДК: 338.2 | DOI: 10.15838/esc/2015.5.41.2

Текст научной статьи New technological shape of basic branches of RF industrial regions

Industry is a backbone of the Russian economy. It is a key factor of economic growth. Despite the fact that in the period of serious market transformations the role of industry in shaping the country’s GDP, tax revenues, employment and other macroeconomic indicators narrowed, it still occupies the leading place in the economy, creating necessary conditions for economic growth. However, today Russia addresses the challenge of new industrialization, involving the update of the technological, socio-economic base of economy and the change of the ways to manage the country’s economic complex. During the formation of new industries and infrastructure there is a mismatch between techno-economic and socio-institutional spheres. There are also internal contradictions in the economic system between new and old technologies. The process of their overcoming is socio painful, difficult and long-term. Therefore, in our view, new industrialization affects management and organization not only at the level of individual firms, industries and sectors, but also the entire system of social and political regulation. Successful implementation of new industrialization requires fundamental changes in investment behavior, technological solutions and organizational models. These changes will improve the efficiency of decision-making, promote positive changes in the mentality of society and the institutional environment, supporting and regulating the desired economic and social processes.

It appears that new industrialization should focus on inclusive economic growth, which is manifested not only in the growth rates of macroeconomic indicators, but also in the improved distribution of growth results and the extension of equal opportunities for all society members [21, 17]. Thus, new industrialization can be interpreted as a synchronous process involving not only the creation of new high-tech sectors, but also the effective and innovative update of its traditional sectors as a result of agreed quality changes between techno-economic and socio-institutional spheres, carried out on the basis of inclusive development principles through interactive, technological, social, political and administrative changes.

The successful experience of new industrialization in Europe shows that it is the modern diversified industrial sector that determines rapid and qualitative economic growth. The reason is that of all sectors the industry ensures the highest growth rates of labor productivity and has a high multiplier effect on other economic sectors.

Repositioning of basic industries under new industrialization . The RF industry forms about 35% of the country’s GDP. Among federal districts we can single out the Ural Federal District, as the share of industry in GRP amounts to more than 55% ( tab. 1 ). The share of the Ural Federal District in the Russian industry ranged from 19 to 21% over the last decade (2004–2014).

The technological shape of any industrialized country and its regions characterizes not so much the industry in general as the level and the quality of development of manufacturing industries.

By GDP amount Russia ranks the 6th in the world, but by share of value added in the manufacturing sector – the 17th, lagging behind South Korea by 3 times and the U.S. by 24 times.

As mentioned above, the qualitative structure of the industry is largely determined by the share of manufacturing in its composition. The Sverdlovsk and Chelyabinsk oblasts are in the lead in the Ural Federal District; there the share of manufacturing activities exceeds 82% ( tab. 2 ). It can be noted that in the Middle Urals the level of industrial production concentration exceeds the national average by 4 times.

The global trends of industry development indicate high growth rates of high-tech, environmentally-friendly industries,

Table 1. Share of industry in GRP of RF federal districts, 2013

|

Federal District |

Share of industry in GRP |

|

Central Federal District (CFD) |

24.5% |

|

Northwestern Federal District (NWFD) |

33.1% |

|

Southern Federal District (SFD) |

23.7% |

|

North-Caucasian Federal District (NCFD) |

14.5% |

|

Volga Federal District (VFD) |

44.1% |

|

Ural Federal District (UrFD) |

55.7% |

|

Siberian Federal District (SFD) |

38.2% |

|

Far Eastern Federal District (FEFD) |

37.5% |

Table 2. Share of manufacturing in the structure of industry in the UFD regions, 2013

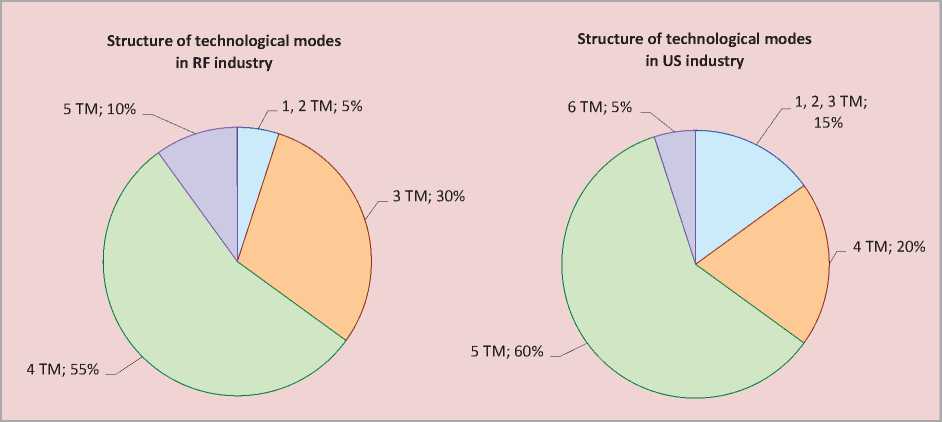

The quality of the industry technological structure in any country is characterized by the structure of formed technological modes (TM). If in the US industry 5 TM dominates and the elements of 6 TM are being actively formed, in the Russian industry the technologies of lower modes are functioning ( fig. 1 ) [6].

Figure 1. Structure of technological modes (TM) in the industry of the Russian Federation and the USA

The current pace of changes in global market conditions, uncertainty, geopolitical transformations and, at the same time, the formation of a domestic economy development vector on the basis of new industrialization principles lead to the fact that the successful development of the Middle Urals industrial complex can be focused not so much on addressing the needs of traditional industries as new high-tech ones. The complex development should involve market prospects and realization of competitive advantages. In this regard, under new industrialization further development of the Urals industrial complex is connected with the new development priorities, unique repositioning of the old industrial region into the region with the strong scientific-technological and production base that meets modern requirements of world standards. The key objectives of this transformation are the following: creation of new markets aimed at high-tech consumption sectors and satisfaction of increasing quality demands of traditional customers of industrial products.

The uncertainty of conditions and factors determining the repositioning of the regional industrial complex involves the need for a uniform approach to understanding of the term “repositioning”. We carried out the research in the conceptual framework concerning the interpretation of this term suggested by domestic economists, identified their similarities and differences. It helped propose the author’s definition of this term in relation to a regional industrial complex (RIC). We understand RIC repositioning as a gradual process of interrelated technological, economic, social-institutional, environmental

and organizational changes based on innovation, helping due to the achieved indicators of best available technologies and the implemented principles of “green economy” to generate a new technological shape of the industrial complex as a network community of competitive, structurally balanced production, meeting individualized needs of the high-tech sector in knowledge-intensive goods and services and increased quality demands of traditional branches of the economy.

The conducted studies [7, 11, 13, 15] identified the preconditions indicating real possibilities for repositioning of basic industries and the formation of their new, modern, technological shape. Person, his/her creativity and entrepreneurial activity is a defining resource of this repositioning. The importance of such traditional resources, as mineral, scientific-technological, industrial, institutional, is not diminished. However, the requirements to their quality are changed dramatically, considerable attention is paid to the possibilities of varying the combination of resources used. This combination helps increase “recombination potential” and contributes to the achievement of new industrialization goals.

The article considers metallurgy as an example of a typical basic industry of the Ural industrial region. It discloses preliminary estimates of resource potential of new industrialization and identifies technological and economic prerequisites for the formation of its new technological shape [8, 9, 10].

In the Middle Urals industry the decisive role in the region’s economic development is played by the metallurgical complex, whose share in the structure of manufacturing industries amounts to more than 55%. The region provides more than 10% of Russia’s production of metal-roll. Before the geopolitical crisis that began in the 2nd half of 2014 the export of the Sverdlovsk Oblast metallurgical enterprises covered 86 countries near and far abroad. Due to a number of large-scale investment projects, implemented in 2010–2014, the Middle Urals metallurgy set up production of new high-tech steel products [16]. There is no open-hearth steelmaking (3 TM), and steelmaking capacities are distributed between converter (4 TM) and electric furnace (5 TM) production methods. The achieved technological production level gives an opportunity to manufacture high quality metal which corresponds to the modern requirements of high-tech industries.

Methodological approach to the change in the technological mode of the basic industry. The formation of new markets, focused on high-tech industry consumption, and the increased competition on the construction materials market actualizes the need to develop methodologies identifying the priorities of technological development of metallurgy and contributing to the change in its technological shape. The Institute of Economics, the Ural Branch of RAS developed a methodological approach to the identification of priorities of metallurgy technological development, applied to the Middle Urals metallurgy. The first stage of this approach involved the construction of the bibliometric model revealing interaction of metallurgy with related research activities. During bibliometric modeling we built the information model on the basis of different flows of documentation taking into account their specificity. The study highlights the main areas of nanoscience as the key discipline of the 6 TM kernel having strong relations with iron and steel production, involved in the development of high-tech industries. We also studied the state and the speed of elaboration of the promising directions.

The analysis of nanoscience development revealed the high growth rate and the dynamics of publication activity of the works devoted to nanomaterials. This suggests that materials take one of significant places in the structure of the scientific base of the latest TM. There is a relatively strong correlation among academic disciplines, proposing the idea of nanomaterials (nanostructured materials; bulk nanomaterials, obtained by hardening from the melt and severe plastic deformation; powder nanomaterials, etc.) and fundamental metallurgical disciplines (metal science; technology of foundry processes, etc.). As a result of the bibliometric analysis we selected materials and processing methods that are shared in nanotechnology and metallurgy and, thus, formed the basis for further analysis.

In accordance with the developed methodological approach we identified the scientific areas appropriate to the headings of the International Patent Classification (IPC). The attribution of the selected research areas to the relevant IPC headings allowed us to single out 4 main subgroups of metallurgy and 4 separate directions, using the opportunities of nanotechnology. Having determined the directions of technological development of the scientific base of high-tech industries and metallurgy we found points of their intersection ( tab. 3 ). The study was conducted on the basis of analyzed databases of the European Patent

Table 3. Correlation of the directions of technological development of the scientific base of high-tech industries and metallurgy in accordance with the International Patent Classification (IPC 8th edition)

|

Directions of nanosciences |

Directions of metallurgy |

||

|

IPC code |

Designation |

IPC code |

Designation |

|

B82B |

Nanostructures, their fabrication and processing |

C21 |

Metallurgy of iron |

|

B01J |

Chemical or physical processes, e.g. catalysis, colloid chemistry; tools to carry them out |

C22 |

Metallurgy; alloys of ferrous or nonferrous metals; treatment of alloys or non-ferrous metals |

|

B81B |

Microstructural devices or systems, e.g. micromechanical devices |

C23 |

Coating metallic material; coating other materials with metallic material; chemical surface treatment; etc. |

|

C09 |

Dyes, paints, varnishes, etc. |

C25 |

Electrolytic methods of production, recovery or refining of metals, and coating; devices therefor (scope – non-ferrous metallurgy) |

Office and the Federal Institute of Industrial Property. So, at the first we built a process map of world metallurgy development in the conditions of 6 TM and also specified a scientific vector of the Russian metallurgy development.

The second stage of the developed methodological approach presupposes the identification of scientific and technological potential of the Middle Urals in terms of the requirements of best available technologies to steel products. We formulated a hypothesis on the consideration of the patent granting dynamics as one of the factors justifying the choice of priority directions to improve the quality of domestic products. In our view, the growth in patent activity can be a characteristic of innovative activity. Under this hypothesis relying on the previously selected promising areas of metallurgy development we had an additional stage of patent analysis, which specified the regional identity of potentialities, the date of receipt and the status of the patent.

To test the method we studied the patent database according to the RF registered patents referring to materials, technical equipment and methods for increasing the quality of steel. On the basis of the patent classification we determined the intersection points of the search headings of metallurgical specializations and the nanoscience practical application sections that helped narrow down the selection of priority metallurgical directions. Then we considered the following areas: treating molten steel in a ladle (IPC code C21C7 ladle treatment); high-pressure metal processing, with/without heat treatment (IPC code C21D8; C21D9); coating using molten and solid coating material (IPC code C23C); and obtaining rare earth metals (IPC code C22B59) (tab. 4). The analyzed period equaled to 12 years (2003–2014). The detailed analysis made it possible to trace the development of each selected area at the international, federal and regional levels.

The combination of the selected areas forms the technological base boundaries, reflecting the specific requirements of the best available technologies to steel products. We analyzed the granted patents by basic perspective directions of industry development

Table 4. Dynamics of granting patents by RF federal districts by promising areas of metallurgy development, units

|

Federal district |

Year of patent publication |

||||||||||||

|

2003 |

2004 |

2005 |

2006 |

2007 |

2008 |

2009 |

2010 |

2011 |

2012 |

2013 |

2014 |

Total for 12 years |

|

|

Total in Russia |

57 |

44 |

33 |

37 |

33 |

51 |

56 |

48 |

54 |

66 |

58 |

65 |

602 |

|

CFD |

25 |

16 |

12 |

15 |

15 |

23 |

29 |

16 |

35 |

26 |

31 |

37 |

280 |

|

of these, number of foreign right holders |

7 |

3 |

5 |

8 |

4 |

11 |

4 |

8 |

19 |

14 |

7 |

5 |

95 |

|

NWFD |

12 |

6 |

4 |

5 |

3 |

2 |

6 |

2 |

10 |

10 |

5 |

15 |

80 |

|

of these, number of foreign right holders |

2 |

1 |

1 |

2 |

1 |

2 |

1 |

10 |

|||||

|

SFD |

1 |

1 |

1 |

3 |

2 |

1 |

3 |

2 |

1 |

1 |

16 |

||

|

NCFD |

2 |

1 |

3 |

||||||||||

|

VFD |

7 |

4 |

7 |

7 |

3 |

6 |

4 |

8 |

1 |

5 |

3 |

4 |

59 |

|

UFD |

9 |

17 |

7 |

7 |

4 |

12 |

12 |

13 |

3 |

18 |

16 |

3 |

121 |

|

SFD |

2 |

3 |

2 |

5 |

4 |

4 |

6 |

3 |

6 |

2 |

5 |

42 |

|

|

FEFD |

1 |

1 |

|||||||||||

Compiled by the data provided by the public registers of the Federal Institute of Industrial Property. Available at: portal/Registers/

in the world and found out a steady, positive trend in this indicator in Russia, similar to the global one.

At the federal level active granting of patents considered as promising is conducted through the Central Federal District (with about 37% of the grant receivers in this district being foreigners). The Ural Federal District, where patent owners are concentrated mostly in the Chelyabinsk and Sverdlovsk oblasts, lags behind only the Central Federal district by development of perspective directions and steel occupies the leading position by development of technologies for liquid steel processing.

To clarify the development priorities, agreed at the previous stages, we conducted further research based on the Foresight methodology, which fully conforms to modern scientific approaches and existing practices of making long-term forecasts [2, 18, 20, 22].

Under this methodology we worked out an expert questionnaire reflecting the specifics of engineering support of the metallurgical complex in the Middle Urals. This study was focused not only on forecasting, but also on forming a coherent vision of innovative development prospects among “key players” of metallurgy in the region. The representatives of regional authorities, large industrial enterprises, business, science and education were involved in the solution of this problem. We held a number of meetings with experts, compiled a preliminary list of promising technology areas, conducted a survey, made conclusions and published results [14].

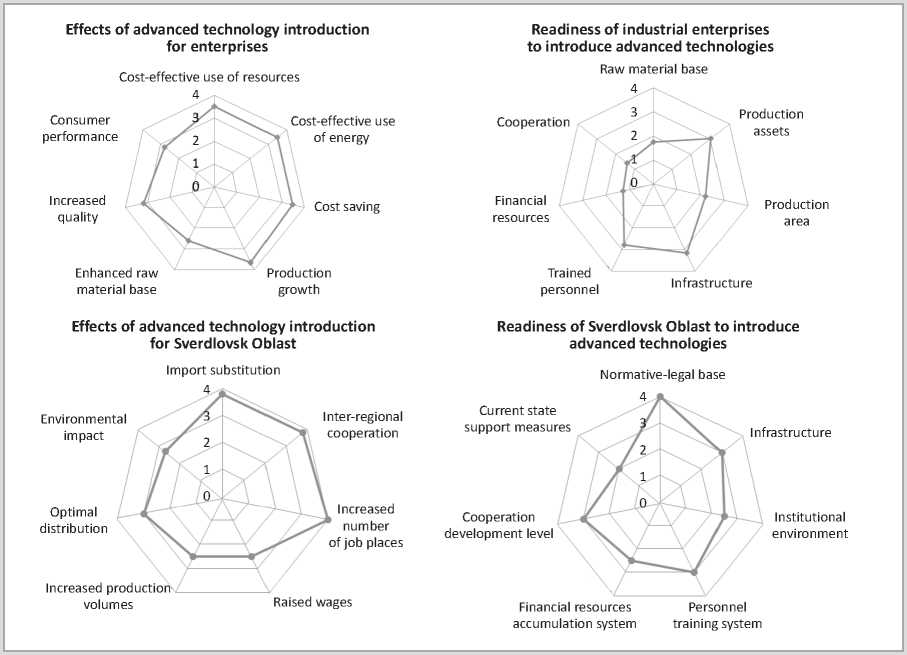

We proposed to assess the identified priority areas in terms of the timeliness of implementation and achievement of a positive effect for business and economy of the Middle Urals, in general ( fig. 2 ).

Figure 2. Expert evaluation of possibilities and effectiveness of perspective technologies implementation at metallurgical enterprises of the Sverdlovsk Oblast [14, pp. 242-243]

According to the research results (see fig. 2), the Sverdlovsk Oblast is not fully prepared for the introduction of advanced technologies, primarily due to the weak government support and the immature legal framework. Regional infrastructure and the staff training system are other obstacles. Financial resources, inadequate cooperation and insufficient provision with certain raw materials are key constrains for industrial enterprises to introduce advanced technologies.

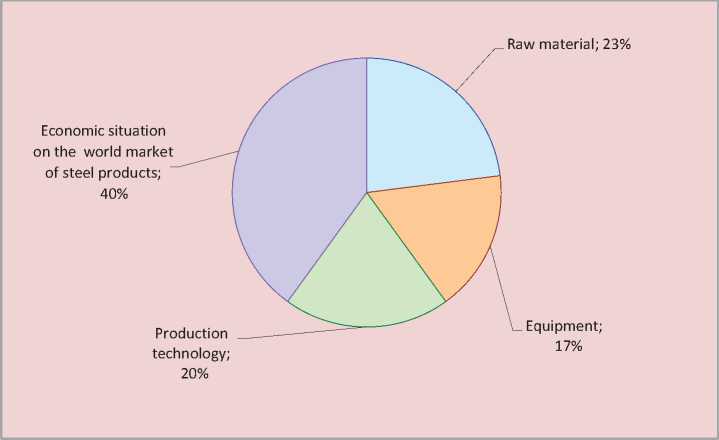

The expert panels also take into account the main risk factors accompanying the introduction of new technologies of steelmaking. Both the probability of their occurrence and the impact on a manufacturer are considered (fig. 3).

The figure shows that in the crisis conditions of economic development the relevance of risk-based assessment of the world situation is increasing.

The research helped reveal and systematize the list of priority regional directions of technological development of metallurgy and assess the degree of influence of production and socio-economic risk groups. The technological development of steel industry is largely determined by the rising share of

Figure 3. Production and socio-economic risks of steelmaking, %

high-tech metal products, which volatility depends on the development of consumption sectors. The results allowed us to construct a steelmaking development vector relative to the changes on the consumer market ( fig. 4 ).

Such a significant change in the share of the high-tech metal products market, shown in the figure, is caused by the idea to form an optimal variant of its growth following the programs to develop metallurgy and steel consuming industries by 2050. The experience of European metallurgy, implementing best available technologies, is taken into account. By key indicators European metallurgy exceeds the domestic by 60–70%.

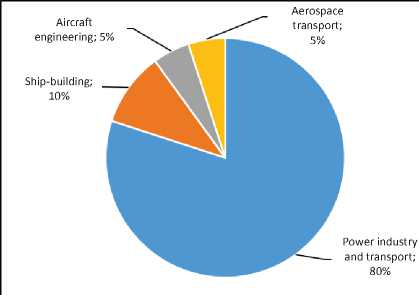

To identify the expected metal consumption structure we analyzed the normative-legislative base defining the Strategy for the development of the domestic industry, including ferrous metallurgy of Russia [3, 4, 12]. Besides, we considered existing and planned investment projects and specified the structure of the high-tech metal products consumers for the period up to 2050 (fig. 5).

Though the proportion of high-tech metal products consumers has risen from 17 to 70%, the structural changes are forecasted. The figure indicates that by 2050 the consumer segment of energy and transport will reduce by more than 2 times, the consumption of steel products by aircraft-and shipbuilding industries will grow by 10% and new consumption sectors will appear: biotechnology (7%) and information and communication (5%).

Scenario approach to the metallurgical complex development in the Middle Urals. Steel industry is greatly influenced by many external and internal factors, that is why it is difficult to single out quantitative parameters for forecasting. In this regard it is rational to apply a scenario approach [19]. We elaborated 4 scenarios for metallurgy development in the

-

Figure 4. Steelmaking development vector relative to changes in the consumer market

-17%

Market share

Рigh-tech metal products сonsumers: power industry and transport; construction; machine-building; car manufacturing and transport

-83%

Traditional customers: construction; machine-building; car manufacturing and transport

Prospective customers: aircraft engineering; aerospace transport; biotechnologies; ship-building; information and communication technologies; power industry and transport

Provision of traditionalconsuming industries with metal products: construction; machinebuilding; car manufacturing and transport

Market share

-70%

-30%

-

Figure 5. Structure of high-tech metal products consumers of the Middle Ural

Aircraft engineering; 18%

Aerospace transport; 15%

Biotechnologies;

7%

Information and communication technologies; 5%

Ship-building;

20%

Power industry and transport; 35%

Middle Urals: negative, inertial, innovative and “image of the future”. The scenario “image of the future” is essentially of qualitative nature. It is based on the elaborated predictive tools, the metallurgical complex development programs and the analytical generalizations of development trends in the steel consuming industries on global and domestic markets.

While working out the scenarios as initial parameters to characterize the stages of regional metallurgical complex repositioning, we singled out the indicators in accordance with the ones adopted in metallurgy of developed countries, the strategy for domestic industry development and the forecast of socially-economic development of the Sverdlovsk Oblast. To specify them, we, using the method of principal components, systematized the indicators forming the critical directions of repositioning. As a result, we had 3 main components (F1, F2, F3) defined by the set of dependent variables ( tab. 5 ).

The selection of the most significant factors that influence metallurgy repositioning in the region helped identify the guidelines for decision making in the changing socioeconomic and political conditions. We worked out the scenarios of metallurgical complex development in the Middle Ural for the period up to 2030, such as negative; inertial and innovative.

The negative scenario assumes the industry development in the face of rising foreign risks, capital outflows and instability of the national currency system. Oil contracts can dip to 40 U.S. dollars per barrel. In this situation the slowdown of the national economy will affect the sectors, such as metallurgy, machine building and construction. In this case the key risks are the following: dependence on world prices; preservation of economic policy aimed at selling products of first processing stages. The reduced investment in the complex will lead to the growth of material and energy intensity of production, the slowdown in the rate of fixed assets renewal and the decrease in product competitiveness. It will hamper repositioning of the metallurgical complex in the Urals, in general, maintaining the existing trends. This scenario does not involve significant investment in the industry.

The inertial scenario simulates the situation in the metallurgical complex, when the crisis impact on the Russian economy is not excessive, the national currency is weakened and the current trends in the national economy are preserved. The price of a barrel of Brent crude oil remains not below 50 U.S. dollars. Major institutional and organizational changes and critical deterioration of the situation are not expected. This scenario is characterized by the following risks: probability of macroeconomic instability, either directly or indirectly affecting the Russian economy; formation of long-term budget deficit; emergence of crisis phenomena in the banking system. No technological change in metallurgy of the Middle Urals is expected. On the other hand, during the period of active demand on the world market metallurgy was restructured, it has certain capabilities to maintain an acceptable technological level. The sector’s upgrade follows the principles of further modernization of traditional industries and search for the ways to promote development

Тable 5. Formation of principal components and interpretation of solutions

The innovative scenario involves the establishment of the modern high-tech complex with high labor productivity that meets the requirements of sustainability, energy and resource saving production and gives an opportunity to speak about the possibility to form a new technological image of metallurgy. The feasibility of this scenario presupposes technological, institutional, economic and organizational changes. The functioning of innovative industries and the creation of business climate to boost investment activity contribute to the development of public-private partnership. The growth of investment activity in the sector, including at the expense of small and medium-sized regional enterprises, is expected. The application of the innovative scenario is possible if the price of a barrel of Brent crude oil is not below 60 U.S. dollars, the sanctions are lifted, the business activity are improved, the situation on the world metal market is enhanced and the investment in the real sector is increased. The implementation of the innovative scenario indicates the repositioning process of metallurgy. Investors, business communities and the society in the territories where the metallurgical enterprises are located perceive the industry as modern and high production with advanced network interactions.

Conclusion

Thus, the metallurgical complex repositioning is the process of gradual generation of the new technological shape of the basic sector in the region, changing the perception of steelmaking as a “dirty industry”. The formation of the new technological basis, meeting and in some areas exceeding the requirements of the best available technologies and the green economy, the shift towards knowledge-intensive production and satisfaction of individualized needs of the high-tech sector of economy and the radical change in the qualification structure of labor resources will characterize the defining features of the new technological shape of the regional metallurgical complex.

Список литературы New technological shape of basic branches of RF industrial regions

- Boikova M.V., Salazkin M.G. Forsait v Germanii . Forsait , 2008, no. 1, pp. 60-69.

- Gaponenko N.V. Forsait. Teoriya. Metodologiya. Opyt: monografiya . Moscow: Yuniti-Dana, 2008. 239 p.

- Gosudarstvennaya programma Rossiiskoi Federatsii “Razvitie promyshlennosti i povyshenie ee konkurentosposobnosti na period do 2020 goda” . Available at: http://innovation.gov.ru/sites/default/files/documents/2014/11065/2561.pdf (Accessed: August 25, 2015)

- Gosudarstvennaya programma Rossiiskoi federatsii “Ekonomicheskoe razvitie i innovatsionnaya ekonomika” . Available at: http://economy.gov.ru/minec/about/structure/depStrategy/doc20130408_01 (Accessed: August 21, 2015)

- Evropeiskaya parlamentskaya set' otsenki tekhnologii: novye tekhnologii i gosudarstvennye resheniya: sbornik materialov. Sovet federatsii . Moscow, 2014, p. 36.

- Koblov E.N. Kursom v 6-i tekhnologicheskii uklad . Sait o nanotekhnologiyakh № 1 v Rossii . Available at: http://www.nanonewsnet.ru/articles/2010/kursom-v-6-oi-tekhnologicheskii-uklad (Accessed: September 8, 2015)

- Romanova O.A., Bryantseva O.S., Pozdnyakova E.A. Resursnyi potentsial reindustrializatsii staropromyshlennogo regiona . Ekaterinburg: Institut ekonomiki UrO RAN, 2013. 251 p.

- Romanova O.A., Selivanov E.N., Korovin G.B. Formirovanie novogo tekhnologicheskogo oblika metallurgicheskogo kompleksa regiona . Ekaterinburg: UrO RAN, 2014. 234 p.

- Romanova O.A., Sirotin D.V. Novyi tekhnologicheskii oblik metallurgii Urala: ekonomicheskii aspekt . Vestnik Zabaikal'skogo gosudarstvennogo universiteta , 2014, no. 7, pp. 105-112.

- Romanova O.A., Sirotin D.V. Ekologicheskaya bezopasnost' v usloviyakh innovatsionnogo razvitiya metallurgii Urala . Ekologicheskaya bezopasnost' promyshlennykh regionov: Trudy mezhdunarodnogo ekologicheskogo kongressa . Ekaterinburg: SOO OO-MANEB, Institut ekonomiki UrO RAN, UGGU, 2015, pp. 247-251.

- Sirotin D.V. Mezhregional'naya integratsiya otraslevykh rynkov v usloviyakh novoi industrializatsii . Vestnik Zabaikal'skogo gosudarstvennogo universiteta , 2014, no. 12, pp. 144-153.

- Strategiya razvitiya chernoi metallurgii Rossii na 2014-2020 gody i na perspektivu do 2030 goda: utv. prikazom Ministerstva promyshlennosti i torgovli RF ot 5 maya 2014 g. № 839 . Available at: http://www.garant.ru/products/ipo/prime/doc/70595824/(Accessed: August 20, 2015)

- Strukturnaya i prostranstvenno-vremennaya dinamika regional'nykh sotsial'no-ekonomicheskikh sistem: kol. monogr. . Under general editorship of RAS Corresponding Member V.I. Suslov, Doctor of Economics O.A. Romanova. Ekaterinburg: Institut ekonomiki UrO RAN, 2013. 400 p.

- Tatarkin A.I., Romanova O.A., Akberdina V.V. Promyshlennost' industrial'nogo regiona: potentsial, prioritety i dinamika ekonomiko-tekhnologicheskogo razvitiya . Ekaterinburg: Institut ekonomiki UrO RAN, 2014. 632 p.

- Tatarkin A.I., Romanova O.A., Akberdina V.V. Tekhnologicheskie i prostranstvennye vozmozhnosti novoi industrializatsii promyshlennykh regionov . Federalizm , 2014, no. 3, pp. 45-56.

- Tatarkin A.I., Romanova O.A., Korovin G.B., Chenchevich S.G. Ural'skii vektor innovatsionnogo razvitiya rossiiskoi metallurgii . EKO , 2015, no. 3, pp. 79-97.

- Amitai Etzioni Reindustrialization of America. Review of Policy Research, 1983, no. 5, pp. 677-694. Available at: http://ideas.repec.org/a/bla/revpol/v2y1983i4p677-694.html (Accessed: 14.08.2015)

- Habegger B. Strategic Foresight in Public Policy: Reviewing the Experiences of the UK, Singapore and the Netherlands. Futures, 2010, February, vol. 42, issue 1, pp. 49-58.

- Kahn H., Wiener A. The Year 2000: A Framework for Speculation on the Next Thirty-Three Years. The Hudson Institute, 1967. 431 p.

- Miles I. The Development of Technology Foresight: A Review. Technological Forecasting and Social Change, 2010, November, vol. 77, issue 9, pp. 1448-1456.

- Aryeetey-Attoh S., Lindquist P., Muraco W., Reid N. Northwestern Ohio: Re-Industrialization and Emission Reduction. Cambridge University Press, 2009. Available at: http://ebooks.cambridge.org/chapter.jsf?bid=CBO9780511535819&cid=CBO9780511535819A015 (data obrashcheniya: 13.08.2015).

- Vecchiato R., Roveda C. Foresight in Corporate Organizations. Technology Analysis and Strategic, 2010, January, vol. 22, issue 1, pp. 99-112.