Numerical simulation of modifying material distribution during the impulse induction heating of metal surface

Автор: Popov V.N.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 2 т.18, 2017 года.

Бесплатный доступ

Method of improvement of operational properties of surfaces is considered. Under study is the applicability of high- frequency electromagnetic field for metal heating and melting with a view to its subsequent modification. 2D numerical modeling of the processes during the modification of the substrate surface metal layer is carried out. The substrate surface is covered with a layer of specially prepared nano-size particles of refractory compounds, which are active crystallization centers after the penetration into the melt. The distribution of the electromagnetic energy in the metal is described by empirical formulas. The proposed mathematical model is used to consider the processes including heat- ing, phase transition and heat transfer in the molten metal, the nucleation and growth of the solid phase in the presence of a modifier material in the melt. Melting of the metal is considered at the Stephan’s approximation, and during solidi- fication all nano-size particles are assumed to be centers of volume-consecutive crystallization. The flow in the liquid is described by the Navier-Stokes equations in the Boussinesq approximation. The movement of the markers models the distribution of nano-size particles in the melt. According to the results of numerical experiments, the flow structure in the melt was evaluated versus the characteristics of induction heating and the amount of surface-active impurities in the metal. The modes of the induction-pulse action are detected: they promote creating the flows for the homogeneous dis- tribution of modifying particles in the melt. Found that the application of high frequency electromagnetic field for heat- ing and melting of metals allows to modify the metal deeper in comparison with the use of a laser.

Numerical simulation, metal modification, impulse induction heating, heat transfer, nano-size refractory particles

Короткий адрес: https://sciup.org/148177716

IDR: 148177716 | УДК: 19.6:532.517+621.7+669.17

Текст научной статьи Numerical simulation of modifying material distribution during the impulse induction heating of metal surface

Introduction. The use of constructions and their components operated in extreme conditions excluding repair or replacement makes urgent the increase in their properties such as thermo – and wear-resistance, plasticity, durability etc. A perspective way of improvement of details operational properties is modifying of the melt at laser processing of their surfaces by the prepared nanosize particles of refractory compounds (carbides, nitrides, carbonitrides and etc.) that allows to increase the number of the centers of crystallization and to crush structural components of the solid metal, increasing its uniformity [1; 2]. At the same time along with the wide use of the laser during modifying and alloying of metal surface, the use of energy of the high-frequency induction field [3; 4] is also possible. However nowadays possibilities of such technology are insufficiently studied especially regarding the use of nano-size modifiers for material structure improvement [4].

As part of the study of the processes going on in a metal surface affected by a laser impulse it is defined that one of the main factors influencing the efficiency of modifying is thermocapillary convection which under certain conditions can promote homogeneous distribution of the insertion materials which penetrate during submelting into melt [5; 6]. In [7; 8] the influence of surfaceactive substance dissolved in the melt on the nature of convection is considered and defined that the structure of flows in molten metal depends on composition and amount of the present impurities in it. In this regard possible changes in technology of modifying of a surface make necessary a detailed research of the happening processes taking into account perhaps more influencing factors.

In this work with the use of numerical modifying the impact of an impulse of high-frequency electromagnetic field on the distribution of the modifying material penetrating into a substrate from its surface in the presence of surface-active substance in metal is considered. As an object of research iron alloy (Fe) + 0.42 % on carbon weight (C) + 0.001–0.02 % sulfur (S) is used. This system is chosen in view of the existence in literature [9; 10] the thermophysical parameters and physical constants necessary for calculations and analysis of the happening processes. By means of the offered mathematical model describing thermo – and hydrodynamic phenomena, the non-stationary processes including metal heating, its melting, convective heat transfer in the melt and further after the termination of an impulse its solidification are considered. According to the results of numerical experiments the modes of impulse impact on a substrate connected with an amount of surface-active substance in metal and promoting homogeneous distribution of the modifying nano-size particles in the melt are defined.

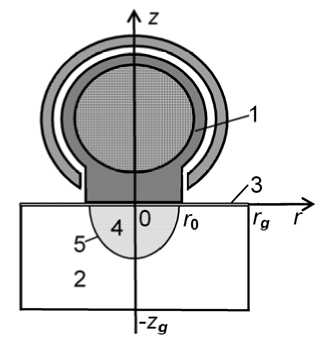

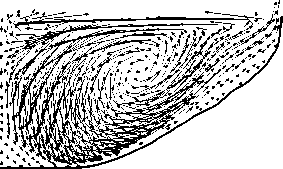

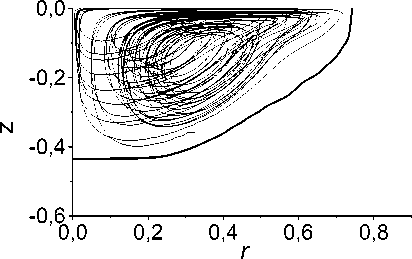

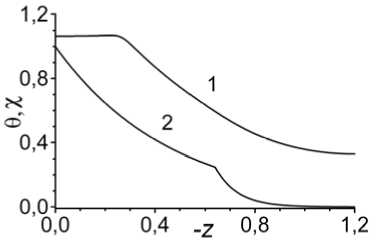

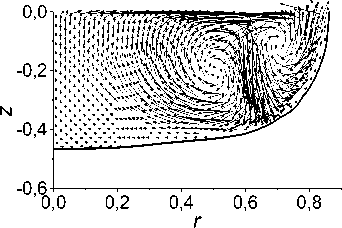

Mathematical model and algorithm of realization. The impact of an impulse of the high-frequency electromagnetic field on a metal substrate is considered. The scheme of the process is illustrated in fig. 1. Duration of impulse tH . The cylindrical head of the electromagnetic field inductor is located over the flat surface of an iron alloy sheet. Induction influence is carried out through r0 radius spot. The distribution of electromagnetic energy in metal is described by the empirical formulas used in engi- neering thermal calculations of induction heaters [11]. The surface of a substrate is covered with a layer of specially prepared modifying nano-size particles of refractory compounds which serve as active centers of crystallization after penetration into the melt [2]. Affected by energy metal is heated and melted. Phase transition happens at a substrate material melting temperature Tm. In the fluid cavity formed and increasing over time the convection under the influence of capillary and thermogravitational forces develops. The moistened particles under the influence of convective flows penetrate into the melt depth. On the border of a phase transition sticking conditions are satisfied. After completion of an impulse due to heat exchange to the environment and heat removal in not warmed material of a substrate the cooling of the melt and its volume-consecutive crystallization occurs in the assumption that all penetrated modifying particles are its centers.

Fig. 1. Scheme of an inductive impulse influence: 1 – an inductor with the covering ferrite magnetoscreen; 2 – a metal substrate and particles of the modifying material (3) on a surface; 4 – the melt; 5 – border of the melted zone; zg and rg – depth and radius of the considered area in a substrate

Рис. 1. Схема воздействия индукционного импульса:

-

1 – индуктор с охватывающим ферритовым магнитоэкраном; 2 – металлическая подложка и частицы модифицирующего материала (3) на поверхности; 4 – расплав; 5 – граница проплавленной зоны; zg и rg – глубина и радиус рассматриваемой области в подложке

For simplification of the task it is considered that thermal characteristics of fluid, solid and two-phase mediums are identical and do not depend on temperature. The mass particles mp content penetrating into the melt is not enough (mp < 0.05 %), their diameter dp is much less than reference size of the fluid cavity and influence of inclusions on physical parameters of the melt can be neglected. The quantity of the dissolved components in the melt is not considerable so it is possible not to consider their influence on phase transition temperature supposing Tm = const. Melting of metal is considered at the Stefan’s approximation with the use of efficient thermal capacity [12]. It is supposed that at the considered heating modes small rates of convective speeds cause flatness of the free surface of liquid [13]. Borders rg, zg of the considered area are chosen so that their position does not affect the studied processes.

Distribution of a temperature profile in solid and fluid material of a substrate is described by the equations of convective heat transfer in a cylindrical coordinate frame ( r , z ) which have the following form for the dimensionless variables:

c ef [ 6 1 + ( V- u ) 6 ] = A6 + Ki- X (r , Z ),

Pr Pr

0 < r < Гд, - Zg < z < 0, 0 < t < tH, at influence of an inductor;

6 1 + ( V- u ) 6 = -1 A6 + St ( f ) t ,

0 < r < Гд, - Zg < z < 0, t > tH, after completion of warming up. Here 6 - temperature; t -time; Pr = v / a - Prandtl’s number, v - kinematic viscosity of the melt, а – thermal diffusivity; u – a speed vector in molten metal with components u, w in radial (r) and vertical (z) directions respectively (in solid metal u = 0, w = 0); St = k/ (cpTm) - the Stefan’s number, к - specific heat of melting; cp - specific thermal capacity; fs - a part of a solid phase in material (0 < fs < 1); Ki = (p0r0) / (XTm) - Kirpichyov’s number, X - a thermal conductivity, p0 – the specific capacity absorbed by unit of a surface of the heated body. The efficient thermal capacity considering the latent heat of a phase transition of к is described by a ratio cef = 1 + 6(6)St where 5(6) = 1 at 6e [1-A6/2,1 + A6/2] and 6(6) = 0 if 6 g [1 - A6 /2,1 + A6 /2], A6 - a temperature band where the phase boundary “is smeared”. The dimensionless parameters are defined with the help of the reference size r0, speed v0 =v / r0, time 10 = r0 / v0 and temperature Tm: r = r / r0, z = z / r0, u = u / v0, w = w / v0, t = t /10, 6= T / Tm .

At impact of a high-frequency electromagnetic field on a substrate an apparent density of internal sources of heat w 0 according to [11] is described by a ratio

W q ( r , z ) = — X ( r , z ). r 0

Here x ( r , z ) - the dimensionless function depending only on coordinates, r 0 – the reference size, in our case the radius of a spot of inductive impact on a substrate surface, p 0 – the specific power absorbed by a unit of a heating body surface.

Assuming that the central point of “the spot” of inductive influence of radius r 0 is located in a point (0, 0) . In this case the distribution of energy release over the sheet thickness can be described with the dependence:

X(r, z) = eZ/A1 , r < r0, z < 0, where A1 - current penetration depth in material (m), i. e. skin layer thickness, A1 = 503^/pe 1 / (p1 f) , pe 1 - specific electrical resistance, p1 - the relative magnetic conductivity when warming up of metal is lower than the temperature of magnetic transformations (Curie point), f – working frequency of the generator of the field, Hz. At the achievement of magnetic transformations temperature the relative magnetic conductivity decreases to value μ2 = 1 and specific electrical resistance increases up to size pe2, consequently the current depth of penetration in material becomes A2 = 503^pe2 / (p2 f) and energy distribution over the depth of a substrate is described by expressions

X ( r , z )

eZ / A2, — zk (r) < z < 0, e - zK / A2 e(z+zK)/A1, z <— zk (r), r < r0,

where zK ( r ) – distance from a substrate surface to a point with a temperature of magnetic transformations ( T = T k ).

At transition to the dimensionless variables we get

X ( r , Z ) = eZ / A 1 , 6 ( r ,0) <6 K , r < 1, Z < 0;

[ eZ / A 2 , - zk ( r ) < z < 0,

X ( r Z ) = < , K , , | e - z k / a 2 e ( Z + z k )/ A 1 , z <- zk ( r ),

6 ( r ,0) >6 к , r < 1;

where A =A / r ,, A =A 2 / r ,, z k = z k / r 0 , 6 к = T K / T m .

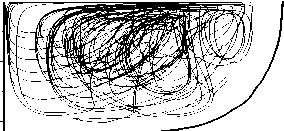

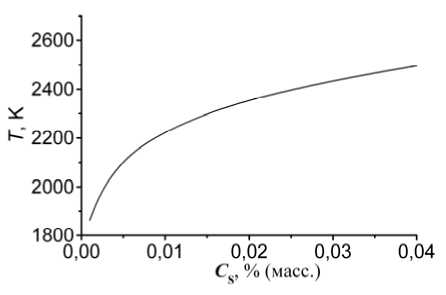

Boundary conditions for the equations (1), (2) are the following. On an axis of symmetry

^^ = 0, r = 0, -zg dr On the external side border of calculated area |^ = 0, r = rg , - zg < z < 0.(4) dr On the upper bound ( z = 0). When heating from a source t< tH — = a(6 c-6), 1 < r < rg.(5) dz After completion of an impulse (t > tH) ■^6 = a(6c-6), 0 < r < rg .(5а) On the lower bound of calculated area d6 = 0, 0 < r < r , z = -z .(6) dz g g Here a = a0r0 / X , a0 = sg0 (T2 + Tc2)(T + Tc), g0 -a Stefan-Boltzmann constant, s - degree of blackness of material of a substrate, Tc – environment temperature (6c = Tc / Tm ) . When melting material speed vnfor each point of the border “melt - solid phase” Z(r, z, t) is defined by a condition Pr Stvn = d6/dn| 6=i_-a6/an| e=1+ where n – a unit vector of a normal. During solidification it is supposed that all nano-size particles are crystallization centers, then the portion of a solid phase fs in the two-phase melt zone is defined according to [14] of a ratio fs = 1 - exp {- QNp} where 4л г Q(r,z,t-У = — rp + KvJ(Tm -T)dZ 3 L § _ the volume of the growing nucleus which arose in an instant t =Z , Np - number of nanoparticles in the unit of melt volume, rp = dp /2, Kv - an empirical constant. fs = 0.95 corresponds to the end of solidification. When melting metal in the area 6 > 1 with the border “melt - solid phase” Z(r, z, t) the flow in liquid is described by the Navier–Stokes equations in the Boussinesq approximation u t + (V- u)u = -Vp + V2u + kGr (6-1), (7) V-u = 0. Here p - pressure (p = p / P0, P0= pv2, p - substrate material density), Gr = Ppgr0Tm / v2 - Grasgof’s number, g - a free fall acceleration, Pp- coefficient of a cubic thermal expansion of a melt, k – unit vector along a coordinate axis of z. Boundary conditions for the equations (7) are the following. On the surface “melt - solid phase” Z(r, z, t) u = 0, w = 0 . (8) On an axis of symmetry r = 0, -if (t) < z< 0 (-zf (t) - coordinate of the border of phase transition) u = 0, dw dr On the surface of liquid z = 0 , 0 < r< rf (t) du Mn d6 — =--n , w = 0 , dz Pr dr where rf (t) – radius of the cavity of molten metal on the free surface. In the presence of surface-active substance in the melt, for the description of the interfacial tension the empirical formula [9] is used 0 = 00 - ko(T-Tm)-TRГs ln(1 + KCs), K = Sl exp[-AH0/(RT)], where o0 - the interfacial tension in clear metal at melting point; ko = -do / dT - for clear metal; R - universal gas constant; Cs – concentration of surface-active substance impurity on a melt surface; Sl – the constant corresponding to an entropy of segregation; AH 0 - standard absorption heat; Гs - excess of impurity in the surface layer per unit area, then do d T = - ko - RГ ln(1 + KC)--s--s-----, (11) s s 1 + KCs T from where are defined Mn = -koTmr0 /(pva) - Maran-goni’s number and n П = 1 + R rs ln(1 + KCS) / kc + KCsГ s AH . s s o1 + KCs Tko Initial conditions for the heat transfer equation (1) 6 = 60, (12) for (7) in just melted metal u = 0, w = 0 . (13) It is supposed that well moistened modifying nanosize particles under the influence of convective flows penetrate into the depth of the melted cavity. Movement and distribution of nanoparticles in the melt was estimated by means of M markers which initial position is described by coordinates (rm, z^), 0 < rm< 1, z^ =-rp, m = 1, ...,M. Markers move according to locally average speeds in the closest vicinity of everyone. At realization of model (1)–(13) which includes the equations of Navier–Stokes and convective heat transfer the finite-difference algorithm was applied. Discretization of dimentional calculated domain was carried out on I x K cells. Step т along a temporary variable is constant. Distribution of temperature was described by values in grid clusters. Systems of difference equation were under construction by means of implicit approximation of the balance ratios received by an integration of the equations (1), (2), (7) taking into account the corresponding boundary conditions. At approximation (7) in the field of the melted material, by analogy with MAC and SIMPLE methods [15; 16], components of velocity u, w, were defined in the middle of lateral faces of cells, and pressure p – in the centers of cells. The algorithm of each temporary step has the following operations procedure. Initially the temperature profile in a substrate at influence of energy of a high-frequency electromagnetic field was calculated. After occurrence of the fluid cavity on each temporary step the border of phase transition was established. Substitution of the found values of temperature in momentum equations made possible the determination of the field of velocities components. Further, with the use of a method of simulated compressibility [17] pressure was culculated. Several iterations were performed to coordinate found pressure distribution and speeds before realization of inequality max ∇⋅u ≤ γ where γ – the given small number. The solution of the algebraic systems received at approximation of motion equations and a heatmass transfer was carried out by iterative methods. By means of ratios rmn=rmn-1+umnτ, zmn=zmn-1+vmnτ, m= 1, ...,M, new coordinates of markers rmn , zmn on a n-temporary step were calculated. Here umn , vmn – speeds of particles movement, defined according to locally average speeds in the nearest neighborhood of each of them. Calculations were carried out on spatial grids I × K from 120×150 to 240×300. Value of a temporary step τ = 10–4, γ = 10–4, Δθ = 0.001, M = 25. After completion of an impulse the solution of a task proceeded until disappearance of overheat in molten metal of a substrate. Convective redistribution of markers occurred only in the melt, and in the solid area the last calculated coordinates were fixed. Results of numerical experiments. Numerical researches were conducted at the following parameters: r0 = 0.001 м, zg = 0.0012 м, rg = 0.0015 м; tH = 70 мс; Tс = 300 K; T0 = 300 K; p0 = (6.5–7.0)⋅108 Вт/м2; f = 1200 кГц; Кv = 2.5⋅10–5 м/(с⋅K); dр = 5∙10–8 м; Np = 2.0⋅1015 1/м3. Properties of metal [9–11]: ρ = 7065 кг/м3, cp = 787 Дж/(кг⋅K), λ = 27 Вт/(м⋅K), κ = 2.77⋅105 Дж/кг, ν = 8.5⋅10–7 м2/с, kσ= 4.3∙10–4 Н/(м⋅K), βρ= 1.18⋅10–4 1/K, R = 8314.3 Дж/(моль∙K), Sl = 3.18 × × 10–3, Γs = 1.3∙10–8 моль/м2, ΔH0 = –1.88∙108 Дж/моль, Tm = 1775 K, ε = 0.7, σ0 = 5.7⋅10–8 Вт/(м2⋅K4), TK = 1141 K, µ1 = 14, ρe1 = 5.2⋅10–7 Ом⋅м, µ2 = 1, ρe2 = 1.0⋅10–6 Ом⋅м. The considered sulphur load in iron is Cs = 0.001–0.04 % of weight. In fig. 2, 4 regarding calculated area adjacent to a zone of molten metal in the dimensionless coordinates, the structure of flows, trajectories of movement and distribution of the modifying particles at surface-active substance in the melt 0.002 % of weight for various characteristics of an impulse are displayed. Arrows in drawings specify the direction, and their length characterizes intensity of a flow. Fig. 2 shows the results received at p0 = 6.5⋅108 W/sq.m, tH = 70 ms. Fig. 2, а illustrates the field of speeds in the melt at the time of completion of inductive influence. From the submitted data it appears that by the time of the impulse termination a big whirlwind with the direction of a flow near the free surface of liquid from border of a phase transition to the center of the cavity with the strong downflow in this area is formed. The similar structure of a flow exists from the moment of emergence of the melt to the completion of an impulse on condition of a small overheat of its surface regarding phase transition temperature. It leads to the fact that the modifying particles penetrate into the central part of the cavity in the considerable depth, and then are evenly distributed by the dispersing flow on all melt volume (fig. 2, b). A small local whirlwind in the central part of the cavity at the free surface does not have any influence on markers movement. The depth of melt penetration is about 450 microns that is 2-3 times more than at laser processing by a beam with the close values of radius and power [7]. It should be noted that slight overheat of a surface of molten metal promotes preservation of its flatness and allows to avoid the subsequent after-treatment. After completion of an impulse the melt cools down and solidifies that is promoted by heat removal from its surface and in not warmed material. Movement of nano-size particles happens as long as the molten metal exists. -0,2- N -0,4- 0,01 -0,6-1--------■--------1111--------1--------1--------1—0,0 0,2 0,4 0,6 0,8 r а b Fig. 2. The field of speeds (а), trajectories and distribution of markers (b) in the melt at q0 = 6.5⋅108 W/sq.m , tH = 70 мs Рис. 2. Поле скоростей (а), траектории и распределение маркеров (б) в расплаве при q0 = 6.5⋅108 Вт/м2, tH = 70 мс Fig. 3 illustrates distribution of the dimensionless temperature and the χ function over substrate thickness from its surface in a point of the maximal warming up (r = 0). It follows from the presented results that the depth of penetration of current does not exceed the thickness of the considered sheet, and the main energy release occurs in the metal layer heated higher than the temperature of magnetic transformations of z = –0.65. As a result, the temperature accepts maximal values on the processed surface and monotonically decreases in the process of removal from it, and the substrate warming up through all thickness does not occur. Fig. 4 shows the results received at p0 = 7.0⋅108 W/sq.m, tH = 70 ms, that is at higher specific power absorbed by a surface unit of the heated body. It follows from the submitted data that by the time of the termination of a laser impulse in the melt two toroidal-shaped whirlwinds determined by the parameter ∂σ/ ∂T which accepts both positive, and negative values are formed. That is a surface temperature increase changes the structure of molten metal. Near the free surface a flow from the border of a phase transition to the center of the cavity occurs (fig. 4, a) promoting that the modifying particles do not penetrate into the depth of the melt on its periphery (fig. 4, b). Also near the surface a flow dispersing from the center which appears at collision with the counter flow, an intensive downflow is formed. As a result chaotic movement of the particles which got into molten metal in the field of intensive whirlwinds appears. In the central part of the cavity the modifying additives penetrate into the considerable depth only at the beginning of melting, and further when the considerable overheat of the melt is formed, upward movement of liquid obstructs it. In general it turns out that particles are not distributed in all volume of molten metal, are absent in the central part and on peripheries of the melt and the considered processing mode of the surface layer is impossible to be called efficient. On completion of an impulse temperature gradients in liquid decrease, intensity of a convection decreases, metal cools down and solidifies (13–15 ms) that is promoted by the low initial temperature of material. After overheat decrease in the melt there takes place a volume-consecutive crystallization in the direction to a substrate surface. By results of numerical calculations it is defined that homogeneous nucleation of crystals in the presence of highly activated nano-size particles in the melt does not happen and does not affect crystallization kinetics as at the existing cooling rates conditions necessary for this are not reached. Fig. 3. Change of temperature θ (1) and χ (2) function in a substrate at r = 0 for q0 = 6.5⋅108 W/sq.m, tH = 70 ms Рис. 3. Изменение температуры θ (1) и функции χ (2) в подложке при r = 0 для q0 = 6.5⋅108 Вт/м2, tH = 70 мс а 0,0 -0,2 -0,4 ■ 0,6-1-------■-------■-------•-------■-------•-------■-------■-------- 0,0 0,2 0,4 0,6 0,8 r b Fig. 4. The field of speeds (a), trajectories and distribution of markers (b) in the melt at q0 = 7.0⋅108 W/sq.m, tH = 70 ms Рис. 4. Поле скоростей (а), траектории и распределение маркеров (б) в расплаве при q0 = 7.0⋅108 Вт/м2, tH = 70 мс Fig. 5. The maximal values of melting temperatures at various concentration surface-active substance in metal for receiving homogeneous distribution of the modifying particles Рис. 5. Максимальные значения температур расплава при различных концентрациях ПАВ в металле для получения гомогенного распределения модифицирующих частиц By results of the analysis of a formula (11) and numerical experiments for various concentration surfaceactive substance in metal (0.001 % <Cs ≤ 0.04 %) maximum temperatures of warming up of the free surface of the melt are determined (fig. 5) at which the steady flow near it is formed with the direction from border of phase transition to the center of the cavity similar to the presented in fig. 2, а. Conclusion. By results of numerical modeling the possibility of the use of inductive processing for modification of molten metal by the nano-size particles of refractory compounds allowing to improve its structural components when solidifying is determined. The results of calculations show that the existence of surface-active substance in the melt significantly influences physical processes during modifying and in particular the flow in the melt. To improve the processing quality of the metal layer surface it is necessary to take into consideration its structure and accounting it to choose the modes of an impulse of a high-frequency inductive field. The use of optimum modes can promote the homogeneous distribution of the modifying particles in full volume.

Список литературы Numerical simulation of modifying material distribution during the impulse induction heating of metal surface

- Surface treatments by laser technology/M. A. Montealegre //Contemporary Materials. 2010. Vol. 1. P. 19-30.

- Плазмохимический синтез ультрадисперсных порошков и их применение для модифицирования металлов и сплавов/В. П. Сабуров . Новосибирск: Наука, 1996. 312 с.

- Марусин В. В. Высокочастотная импульсная закалка (ВИЗ) деталей//Обработка металлов (технология, оборудование, инструменты). 2004. № 2. С. 14-15.

- Комбинированные технологии получения перспективных порошковых материалов, нанесения покрытий и упрочнения поверхностных слоев с регулируемой нано-и микроструктурой/О. П. Солоненко //Тяжелое машиностроение. 2007. № 10. С. 10-13.

- He X., Fuerschbach P. W., DebRoy T. Heat transfer and fluid flow during laser spot welding of 304 stainless steel//J. Phys. D: Appl. Phys. 2003. Vol. 36. P. 1388-1398.

- Role of surface active elements during keyhole mode laser welding/B. Ribic //Journal of Physics D: Applied Physics. 2011. Vol. 44(48), article № 485203.

- Черепанов А. Н., Попов В. Н. Численный анализ влияния поверхностно-активного вещества в расплаве на распределение модифицирующих частиц и кристаллизацию при обработке поверхности металла лазерным импульсом//Теплофизика и аэромеханика. 2014. Т. 21, № 3. C. 273-281.

- Donghua Dai, Dongdong Gu. Influence of thermo-dynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites//International Journal of Machine Tools & Manufacture. 2016. V. 100. P. 14-24.

- Sahoo P., DebRoy T., McNallan M. J. Surface tension of binary metal-surface active solute systems under conditions relevant to welding Metallurgy//Metall. Trans. B. 1988. Vol. 19B. P. 483-491.

- Ehlen G., Ludwig A., Sahm P. R. Simulation of Time-Dependent Pool Shape during Laser Spot Welding: Transient Effects//Metall. Mater. Trans. A. 2003. Vol. 34A. P. 2947-2961.

- Павлов Н. А. Инженерные тепловые расчёты индукционных нагревателей. М.: Энергия, 1978. 120 с.

- Будак Б. М., Соловьева Е. Н., Успенский А. Б. Разностный метод со сглаживанием коэффициентов для решения задач Стефана//Журн. вычисл. матем. и матем. физ. 1965. Т. 5, № 5. С. 828-840.

- Marangoni Convection during Free Electron Laser Nitriding of Titanium/D. Höche //Metall. Mater. Trans. B. 2009. Vol. 40, No. 4. P. 497-507.

- Баландин Г. Ф. Основы теории формирования слитка. М.: Машиностроение, 1979. 335 с.

- Harlow F. H., Welch J. E. Numerical calculation of time-depend viscous incompressible flow of fluid with free surface//Phys. Fluids. 1965. Vol. 8. P. 2182-2189.

- Patankar S. V., Spalding D. B. A Calculation Procedure for Heat, Mass and Momentum Transfer in Three-Dimensional Parabolic Flows//Int. J. Heat Mass Trans. 1972. Vol. 15. P. 1787-1806.

- Chorin A. J. A numerical method for solving incompressible viscous flow problems//J. Comput. Phys. 1967. Vol. 2. P. 12-26.