Numerical simulation of the effect of baffle on heat transfer performance of shell-and-tube heat exchanger

Автор: Guo Zhengyang, Shan Jingwei, Li Jun, Levtsev Aleksei

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 1 т.7, 2021 года.

Бесплатный доступ

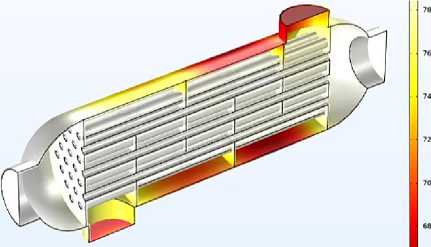

Baffle heat exchanger is widely used in various production activities because of its simple design and strong adaptability, so the structural optimization of baffle heat exchanger is of great significance to engineering practice. COMSOL software was used to simulate the shell-and-tube heat exchanger with baffles. By comparing and analyzing the simulation results, we find that the temperature field and pressure field of baffle plate are distributed evenly; The existence of baffles leads to the transverse flow of air, which increases the heat exchange area. Another advantage of using baffles is that vibration due to fluid flow can be reduced.

Comsol, shell and tube heat exchanger, baffle plate, numerical simulation

Короткий адрес: https://sciup.org/14117930

IDR: 14117930 | УДК: 621.565.95 | DOI: 10.33619/2414-2948/62/24

Текст научной статьи Numerical simulation of the effect of baffle on heat transfer performance of shell-and-tube heat exchanger

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 621.565.95

Yu Jiuyang designed a variety of opening schemes, combined with the advantages of large tube hole baffle and bow baffle, the flow resistance and heat exchanger were tested. According to the experimental results, Expand the opening of the baffle plate, helps to enhance heat transfer efficiency and reduce shell flow resistance, Heat transfer and flow performance of shell side have been significantly improved [6]. Xie Guoxiong designs 5 kinds of opening schemes on the single bow baffle and carries on the experiment inquiry, A proper number of holes in the proper part of the bow baffle plate is found to be beneficial to improve the heat transfer efficiency of the heat exchanger and reduce the flow resistance [7] of the shell side. J. Taborek in the process of studying the tube - shell heat exchanger, it is found that the relationship between the diameter of the shell of the tube-shell heat exchanger and the distance between the baffle plate, the better heat transfer effect of 0.2~1 time shell diameter is [8]. With the development of numerical heat transfer (NTH) and computational fluid dynamics (CFD) research, Numerical simulations and calculations of heat transfer have also developed rapidly, and widely used in practical engineering, among them, it is very important to explore the numerical simulation of shell side of tube-shell heat exchanger. S. V. Pakanter and D. B. Spalding in the process of numerical simulation of shell side of tube-shell heat exchanger, put forward the idea of distributed resistance, Hydraulic tube-shell heat exchanger is used for numerical simulation [9]. W. T. Sha based on our predecessors, Introducing the concept of surface permeability, and successfully use the model to complete the two-dimensional numerical simulation [10] of the shell side. Chao Zhang et al. target the power plant condenser, by means of mass conservation equation, momentum conservation equation and fractional air mass conservation equation, the error of simulation results and test data is small, Data are consistent [11].

Methodology and shell-and-tube heat exchanger geometry

The flow and heat transfer process of tube-shell heat exchanger follow the law of mass conservation, energy conservation and momentum conservation. Because the shell flow of tubeshell heat exchanger usually belongs to turbulent state, the standard model is selected according to the basic heat transfer equation and fluid flow law. A standard κ-ε model [12] is as follows:

d k d k

P--+ PU; --- dt dx{

_d_ dxj

L L+ —

dk

+ Gk + Gb - p- - YM + Sk

dk ds dp — + pui — = — dt dx. dx,

ij

Lt I dLl ++ C.

& d x, 1

1 -

- (Gk + G,fib)-C2ep — + S k 3— b 2—1- -

In the formula, the turbulent dissipation rate is - ; G k is the turbulent kinetic energy generation term caused by the average velocity gradient; YM is the effect of compressible turbulent pulsation expansion on the total dissipation rate; t is time, unit is s ; L is turbulent viscosity in units kg / (m ’ s) ;

3 G = 1.44 C = 1 Сц 0.09 и p is fluid density in units kg / m , The empirical constant is 1s , 3— , L ; k is turbulent kinetic energy, ui is speed, unitm / s , ut is turbulent viscosity in units Pa ’s .

Results and discussion

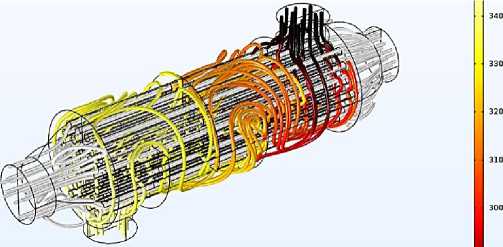

The heat exchanger is made of structural steel. Two fluids flow through the heat exchanger. The first fluid Water flows through the tube, and the second fluid (air) flows in the shell of the heat exchanger. The initial temperature is different when flowing into the heat exchanger, but after cycling in the heat exchanger, the temperature of the two is close to a balance Temperature. The presence of baffle plates leads to lateral flow of air, which increases the heat exchange area. Other using baffles one advantage is that vibration due to fluid flow can be reduced.

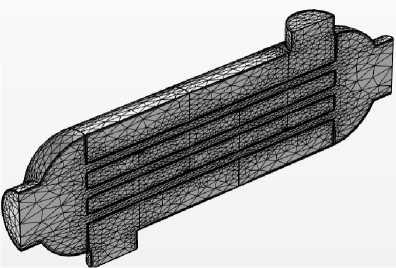

Figure 2 shows the uplift distance of the upper wall. This is the wall lift distance in the tube, which may be the most critical area in terms of grid resolution. It is about 10% of the radius of the tube, which is enough.

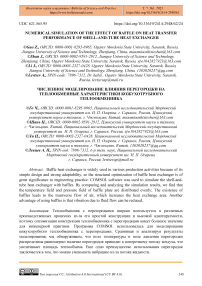

Figure 1. Mesh of tube-shell heat exchanger model.

Figure 2. Wall lifting distance of the tube.

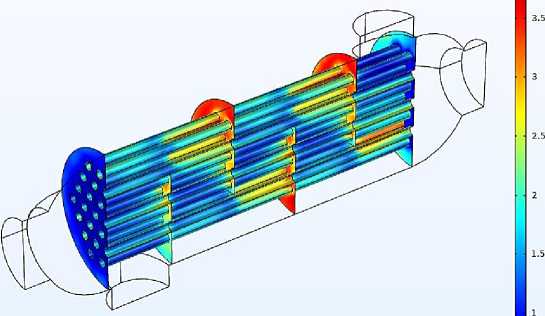

The velocity of the tube path indicates that the velocity distribution in the tube is very uniform. Before the water flows into the pipe, there is a reflux zone. Streamline color indicates the temperature, we can see that the temperature of the two exits is very close.

Figure 3. Streamline diagram.

Figure 4. Temperature on the heat exchanger boundary.

We use several physical quantities to describe the characteristics and efficiency of heat exchangers, one of which is the equivalent heat transfer coefficient, expressed as heq

P

A (T o - T cod )

Among them, where P is the total switching power and A is the surface area through which the h 2

P flows. In this model, the value of eq is 5.5 W /( m ’ K) . The pressure drop of tube side is about 38 Pa, shell side is about 13 Pa.

Conclusion

Based on the numerical simulation of tube-shell baffle with COMSOL software, the following conclusions can be drawn by analyzing velocity field, pressure field and temperature field:

-

1) In the shell flow field of the tube-shell baffle heat exchanger, the back of the baffle is easy to form a retention zone, which results in uneven distribution of temperature, velocity and pressure, which has a certain negative effect on the heat transfer performance of the tube-shell baffle heat exchanger.

-

2) With the continuous improvement of inlet velocity, the retention area of the back of the baffle plate is also increasing. Compared with the open baffle plate, the open baffle plate can effectively reduce the retention area, make the distribution of temperature field and pressure field more uniform, and play a positive role in improving the heat transfer performance of-shell heat exchanger.

Список литературы Numerical simulation of the effect of baffle on heat transfer performance of shell-and-tube heat exchanger

- Chengh. Exploration on the Teaching Reform of Chemistry Major English // Guangdong Chemical Industry. 2013. V. 40. №18. P. 151.

- Xianghua Yang, Xiaoling Cheng, Ming Sun, Hongsheng Luo, Jun He. Teaching reforming practice of Engineering Chemistry course in Civil Engineering major at Guangdong University of Technology // Proceedings of the 2015 3rd International Conference on Management Science, Education Technology, Arts, Social Science and Economics. 2015. DOI: 10.2991/msetasse-15.2015.241

- Cao Baoyue, Wang Shumin, Xu Shan et al. Exploration and Practice on English Teaching Reform of Chemistry Specialty in Local Universities // Guangdong Chemical Industry. 2017. V. 44. №17. P. 222-223.

- Zhou Yun, Chen Rong Practice and Exploration of English Teaching Reform in Chemistry Specialty // Yunnan Chemical Industry. V. 40. №7. P. 101-102.

- Yang Jun, Chen Baodong, Sun Chengjia. Heat Exchanger Performance and Helical Angle Optimization of Heat Exchanger of Helical and Bow-shaped baffle // Journal of Liaoning University of Petrochemical Technology. 2005. V. 25. №2. P. 59-62.

- Yu Jiuyang, Wang Zewu, Feng Xingkui. Experimental Study on the Perforation Performance of Single Bow Refractive Plate // Petrochemical Equipment. 2004. V. 33. №2. P. 4-6.

- Xie Guoxiong, Zhu Bing, Feng Xingkui. Number and layout of openings in single-bow baffle tube bridge // Petrochemical Equipment. 2006. V. 15. №3. P. 1-3.

- Taborek J. Shell and tube heat exchangers. Single phase flow. Heat exchanger design handbook, Section 3.3. Heat exchanger design and theory sourcebook. New York: McGraw Book Company, 1974. P. 155-176.

- Sha W. T., Yang C. I., Kao T. Hemisphere. London: Academic Press, 1972.

- Pakanter S. V., Spalding D. B. A calculation procedure for the transient and steady state behavior shell -and -tube heat ex al. // Multidimensional numerical modeling of heat exchangers. Heat transfer trans ASME. 1982. V. 104(3). P. 417-452.

- Chao Zhang, Bokil A. A quasi -three -dimensional approach to simulate the two -phase fluid flowfe and heat transfer in condensers // International Journal of heat and mess transr. 1997. V. 40. №15. P. 3537-3546.

- DOI: 10.1016/S0017-9310(97)00014-8

- Launder B. E., Spalding D. B. Lectures in mathematical models of turbulence. London: Academic Press, 1972.