О положительном опыте применения ферросплавов при микродуговой химико-термической обработке

Автор: Домбровский Юрий Маркович, Степанов Макар Степанович, Давидян Левон Варужанович

Журнал: Advanced Engineering Research (Rostov-on-Don) @vestnik-donstu

Рубрика: Машиностроение и машиноведение

Статья в выпуске: 4 (87) т.16, 2016 года.

Бесплатный доступ

Целью исследований являлось изучение возможности ускоренного формирования высокотвердого карбидного покрытия на поверхности стальных изделий. Предложено использование технологии микродуговой химико-термической обработки. Стальное изделие погружается в порошок каменного угля и нагревается пропусканием электрического тока. Образование микродуговых разрядов в порошковой среде приводит к насыщению поверхности углеродом, а одновременная диффузия металла позволяет формировать высокотвердый карбидный слой. Установлена возможность применения ферросплавов в качестве источника карбидообразующего металла при образовании высокотвердого покрытия с помощью микродуговой химико-термической обработке. Электропроводность ферросплавов выше, чем химических соединений, и это позволяет достичь ускорения диффузионного насыщения за счет интенсивного образования активных атомов металлов под действием микродуг. Применение ферросплавов более выгодно с энергетической точки зрения, так как восстановление оксидов металлов до атомарного состояния требует дополнительных энергетических затрат. При использовании феррохрома, ферромолибдена и ферровольфрама образуется поверхностный карбидный слой толщиной до 160 мкм и микротвердостью до 18 ГПа.

Поверхностное упрочнение, микродуговая химико-термическая обработка, формирование высокотвердого карбидного слоя на поверхности стальных изделий

Короткий адрес: https://sciup.org/14250250

IDR: 14250250 | УДК: 621.793 | DOI: 10.12737/22158

Текст научной статьи О положительном опыте применения ферросплавов при микродуговой химико-термической обработке

Introduction. The modern mechanical engineering imposes increased requirements to reliability and durability of the used materials. In many cases these requirements can be provided with increase of details of machines and the tool blanket properties. Chemical heat treatment changes a chemical composition and structure of a material surface and allows to increase the hardness, wear resistance, corrosion resistance, heat resistance and other mechanical and physic- chemical properties of responsible details [1]..

The methods of chemical heat treatment applied in the industry are based on diffusion saturation of metals and alloys blankets by one element or a complex of elements that allows obtaining the required properties on a surface of the processed product [1-3]. Usually it is necessary to form very hard surface coatings. For example, to apply a saturation of the surface with chromium, molybdenum and tungsten in powder mixtures. Treatment is performed within several hours in the pressurized containers in the protective atmosphere or in vacuum [1].

However, these methods have a number of shortcomings including: the long duration of saturation process, surface decarburization, a possibility of a layer without carbide phase formation, dependence of layer hardness on duration and temperature of diffusion. Insufficient sealing of containers accelerates depletion of the saturating mixture, and it worsens stability of results and can cause powder agglomeration. Besides, it is difficult to automate such methods of treatment and therefore they require application of a manual work.

The purpose of the work. The aim of this work is to study the possibility of accelerated formation of a very hard carbide layer on the surface of steel products.

Research results and discussion. To accelerate the formation of the surface carbide coating is proposed to use the method of microarc chemical heat treatment. The product is plunges into the container with coal powder and is exposed to high-speed heating by a transmission of electric current through the powder environment and a product. As a result the surface layer is saturated with carbon. To saturate the other elements, a coating consisting of a conductive gel and powder containing saturating element is applied on the surface. This method allows intensifying process of chemical heat treatment: saturation of a material surface continues 3-4 minutes [4].

Application of this method has allowed receiving positive results in case of superficial saturation of steel products both carbon [4], and the carbide forming metals [5-7]. As sources of these metals chemical compounds were used: oxides of these metals. In processing course formation of active atoms of metals which defuse in a surface of a saturable product is resulted by chemical reactions. Simultaneous diffusion of carbon leads to formation of carbides of these metals. The possibility of formation of carbide coverings is confirmed with the thermodynamic analysis [6-8].

Further research have shown a possibility of obtaining of highly rigid carbide coverings on a surface of steel products when using as sources of saturating elements of metals alloys with iron (ferroalloys). A possibility of ferrochrome, ferrotungsten and ferromolybdenum usage was studied.

Higher conductivity in comparison with chemical compounds of elements is positive property of the ferroalloys applied to saturation of a surface. Therefore the use of ferroalloys allows reaching acceleration of diffusive saturation due to intensive formation of active atoms of metals under the influence of microarcs which temperature reaches 4000-7000ºС. This process is more expedient from the energy point of view in comparison with the use of oxides of metals which reconstruction to an atomic condition requires additional energy costs.

The results of microarc saturation of cylindrical samples of steel 20 are studied. The studies were carried out using purposely designed experimental equipment [4]. The powder coal with a particle size of 0.4-0.6 mm was applied. The current density was 0.53 A/cm2 [9]. Before the diffusion saturation of the surface of the samples was applied a conductive coating containing powders of the following ferroalloys: ferrochromium FeCr800, ferromolybdenum FeMo60, ferrotungsten FeW70. Results saturation was evaluated by means of microstructural, microhardness and x-ray phase analysis.

The study of the samples surface showed the formation of a very hard carbide layer with the carburized underlayer [58,10].

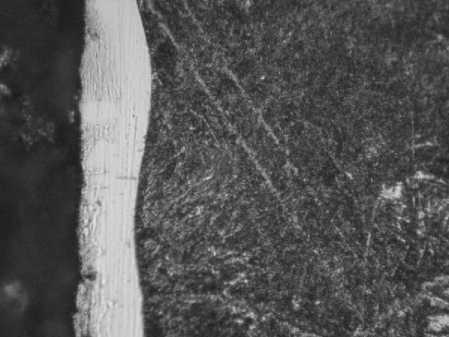

After chromium saturated the surface layer contains carbides of the type (Cr 7 C 3 ), has a thickness up to 90 microns and microhardness about 15 GPA (fig. 1).

Figure 1 - Carbide layer after steel 20 saturation by chrome, x350

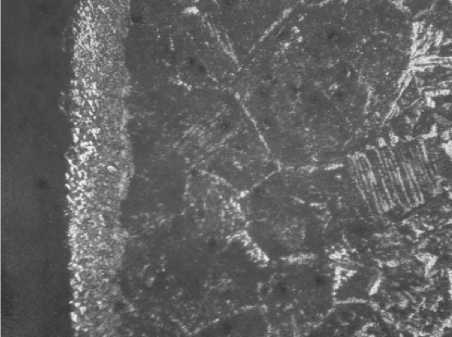

After molybdenum saturated the surface layer contains carbides of the type Mo 2 C, has a thickness up to 150 microns and microhardness about 15 GPA (fig. 2).

Домбровский Ю. М. и др. О положительном опыте применения ферросплавов

Figure 2 - Carbide layer after steel 20 saturation by molybdenum, x200

After tungsten saturated the surface layer contains carbides of the type WC, has a thickness up to 60 microns and microhardness about 18 GPA (fig. 3).

Figure 3 - Carbide layer after steel 20 saturation by tungsten, x350.

Conclusion. The results of the research show the possibility of using technology microarc chemical heat treatment using ferroalloys as a source diffusant for forming very hard surface coating of steel products.

Список литературы О положительном опыте применения ферросплавов при микродуговой химико-термической обработке

- Voroshnin, L.G., Mendeleyeva, O. L., Smetkin, V. A. Teoriya i tekhnologiya khimiko-termicheskoy obrabotki. Moscow: Novoe znanie; Minsk: Novoe znanie, 2010, 304 p..

- Mehrer, H. Diffusion in Solids. Fundamentals, Methods, Materials, Diffusion-Controlled Processes. Springer-Verlag Berlin Heidelberg, 2007, 645 p.

- Antczak, G., Ehrlich, G. Surface diffusion. Cambridge University Press, 2010, 779 p.

- Dombrovsky, Yu.M., Stepanov, M.S. Mikrodugovaya tsementatsiya stal'nykh izdeliy v poroshkovykh sredakh. Strengthening Technologies and Coatings, 2013, no. 12, pp. 25-29.

- Dombrovsky, Yu.M., Stepanov, M.S. Novye vozmozhnosti poverkhnostnogo legirovaniya stali v poroshkovykh sredakh. Vestnik Mashinostroeniya, 2015, no. 8, pp. 79-81.

- Stepanov, M. S., Dombrovsky, Yu.M. Formirovanie karbidnogo pokrytiya pri mikrodugovom khromirovanii stali. Strengthening Technologies and Coatings, 2015, no. 1, pp. 35-38.

- Stepanov, M.S., Dombrovsky, Yu.M. Formirovanie karbidnogo pokrytiya pri mikrodugovom molibdenirovanii stali. Strengthening Technologies and Coatings, 2015, no. 10, pp. 34-38.

- Stepanov, M.S., Dombrovsky, Yu.M. Thermodynamic Analysis of Carbide Layer Formation in Steel with Microarc Saturation by Molybdenum. Steel in Translation, 2016, vol. 46, no. 2, pp. 79-82.

- Dombrovsky, Yu.M., Stepanov, M.S., Davidyan, L.V. K voprosu o tekhnologicheskikh parametrakh mikrodugovoy khimiko-termicheskoy obrabotki (MDKhTO). Izvestia VSTU, 2015, no. 5(160), pp. 130-131 (Series "Problems of materials science, welding and strength in machine building").

- Dombrovsky, Yu.M., Stepanov, M.S. Osobennosti molibdenirovaniya stali v rezhime mikrodugovogo nagreva//Izvestiya VSTU.-2015.-№ 5(160).-pp. 135-138 (Series "Problems of materials science, welding and strength in machine building").