On the choice of some modifiers when creating composite nickel-phosphorus coatings

Автор: Shcherbakov Igor N.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 1 т.15, 2022 года.

Бесплатный доступ

The article considers the issues of choosing some modifiers of composite nickel-phosphorus coatings (CNiPC) using the method of crystal-chemical design in order to create high reliability and durability in the friction units of machines and mechanisms of tribological systems (TS). The paper shows the possibility of improving the tribological and anti-corrosion properties of NiP coatings without modifiers by introducing modifying additives into the coatings - ultradisperse powders of simple and complex metal oxides, oxides with corundum and rutile structures, simple substances with magnesium and tungsten structures, and polytetrafluoroethylene.

Modeling, friction coefficient, linear wear rate, composite coatings, modifiers, tribological system

Короткий адрес: https://sciup.org/146282409

IDR: 146282409 | УДК: 621.793

Текст научной статьи On the choice of some modifiers when creating composite nickel-phosphorus coatings

Цитирование: Щербаков, И.Н. О выборе некоторых модификаторов при создании композиционных никель-фосфорных покрытий / И. Н. Щербаков // Журн. Сиб. федер. ун-та. Техника и технологии, 2022, 15(1). С. 80–87. DOI: 10.17516/1999-494X-0375

Methods and objects of the research

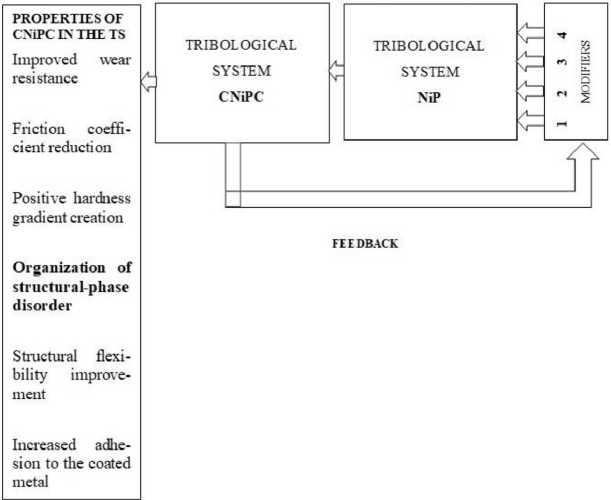

For the creation of CNiPC used in the TS, representing a multi-parameter system, a systematic approach was used in which the TS was considered as the main system, and the modifiers were considered as elements of the subsystem. In turn, the modifiers were studied as basic systems at the molecular and atomic levels. Thus, the construction of the TS of CNiPC was carried out by moving from the particular to the general system by merging its elements (modifiers), which were considered separately.

Due to the fact that the study of TS coatings and structures and the phases of modifiers was carried out at the molecular and atomic level, scientific research and development of compositions were carried out using methods of crystal-chemical design [5–7]. Previously, a crystal-chemical model of CNiPC with various modifiers capable of creating a state of structural-phase disorderedness in the TS was hypothetically developed and theoretically justified [4]. Then, experimental samples of coatings were made, the studies of tribological and other physical and mechanical characteristics were carried out on test equipment that imitated the operation of real friction units and, in case of inadequacy of real models of coatings to the crystal-chemical ones, feedback and a system analysis of errors was used that led to the existing inadequacy.

Figure 1 shows an element of a systematic approach to selecting certain types of modifiers to improve certain characteristics in the CNiPC.

Further, the author considers the results of crystal-chemical studies and experimental tests of CNiPC with modifiers of the following types: Ni – Me 2 O 3 (corundum structure), Ni – MeO 2 (rutile structure), and compositions of these modifiers with ultradisperse metal powders and polytetrafluoroethylene.

Fig. 1. The system for modifiers selection for the formation of the following systems in the CNiPC structure: 1 – Ni – Me 2 O 3 (corundum structure) – Me – P; 2 – Ni – Me 2 O 3 (corundum structure) – Me – polytetrafluoroethylene – P; 3 – Ni – MeO 2 (rutile structure) – Me – P; 4 – Ni – MeO 2 – Me – polytetrafluoroethylene – P

Table 1. Phase composition and tribological characteristics of CNiPC, which form the Ni – Me 2 O 3 – Me – P systems

|

CNiPC components |

Phase composition |

α |

Linear wear rate, I л , microns/h |

Friction coefficient, f |

|

Ni-P |

(s) Ni, Ni 3 P |

0.92 |

5.95 |

0.25–0.27 |

|

(l) Ni 12 P 5 , Ni 2 P |

||||

|

Ni-P (Al 2 O 3 , Al) |

(s) Ni, Ni 3 P, Al 2 O 3 , Ni 3 Al, AlP |

0.89–0.90 |

4.6–4.8 |

0.23 |

|

(l)Ni 12 P 5 , Ni 2 P, Al 3 Ni 2 , Al 3 Ni, AlOOH |

||||

|

Ni-P (Cr 2 O 3 , Cr) |

(s) Ni, Ni 3 P, Cr 2 O 3 , CrNi, Cr 3 P, CrP (l) Ni 12 P 5 , Ni 2 P, CrOOH |

0.89–0.90 |

4.7–5.0 |

0.23 |

(l) – lubricant coating component, (s) – solid coating component.

Table 2. Phase composition and tribological characteristics of CNFPS, which form the Ni – Me 2 O 3 – Me – P – PTFE systems

|

CNiPC components |

Phase composition |

α |

Linear wear rate, I l , microns/h |

Friction coefficient, f |

|

Ni-P |

(s) Ni, Ni 3 P |

0.92 |

5.95 |

0.25–0.27 |

|

(l) Ni 12 P 5 , Ni 2 P |

||||

|

Ni-P (PTFE) |

(s) Ni, Ni 3 P |

0.90 |

5.0 |

0.20 |

|

(l) Ni 12 P 5 , Ni 2 P, PTFE |

||||

|

Ni-P (Al 2 O 3 , Al, PTFE) |

(s) Ni, Ni 3 P, Al 2 O 3 , Ni 3 Al, AlP |

0.85–0.75 |

3.8 4.1 |

0.20 0.17 |

|

(l) Ni 12 P 5 , Ni 2 P, Al 3 Ni 2 , Al 3 Ni, AlOOH, PTFE |

||||

|

Ni-P (Cr 2 O 3 , Cr, PTFE) |

(s) Ni, Ni 3 P, Cr 2 O 3 , CrNi, Cr 3 P, CrP |

0.850.75 |

4.0 4.4 |

0.21 0.17 |

|

(l) Ni 12 P 5 , Ni 2 P, CrOOH, PTFE |

(l) – lubricant coating component, (s) – solid coating component

Table 1 shows the phase composition and tribological characteristics of the experimental CNiPC samples modified with:

– simple oxides with Me 2 O 3 composition, where (Me – Al, Cr) with a corundum-type structure (sp.gr. R ¯3c (3));

Table 2 shows the phase composition and tribological characteristics of the experimental CNiPC samples modified with the modifiers from Table 1 with the addition of PTFE nanopowders.

Table 3 shows the phase composition and tribological characteristics of the experimental CNiPC samples, modified with:

– simple oxides with MeO2 (Me – Ti, Zr,) composition with a rutile-type structure (sp.gr. P4 2 /mna (2));

– ultradisperse metal powders: Me – Ti, Zr with a hexagonal magnesium -type structure (sp.gr. P6 3 /mmc (2)).

Table 4 shows the phase composition and tribological characteristics of the experimental CNiPC samples modified with the modifiers specified in Table 3 with the addition of PTFE nanopowders.

Table 3. Phase composition and tribological characteristics of CNiPC, in which the systems Ni – MeO 2 – Me – P are formed

|

CNiPC components |

Phase composition |

α |

Linear wear rate, I l , microns/h |

Friction coefficient, f |

|

Ni-P |

(s) Ni, Ni 3 P |

0.92 |

5.95 |

0.25–0.27 |

|

(l) Ni 12 P 5 , Ni 2 P |

||||

|

Ni-P |

(s) Ni, Ni 3 P, TiO 2 , Ni 3 Ti, NiTi 2 , Ti 3 P |

0.89–0.90 |

4.6–4.8 |

0.24 |

|

(TiO 2 , Ti) |

Ni 12 P 5 , Ni 2 P, |

|||

|

Ni-P |

Ni, Ni 3 P, ZrO 2 , |

0.89–0.90 |

4.5–4.7 |

0.23 |

|

(ZrO 2 , Zr) |

Ni 12 P 5 , Ni 2 P, Ni 10 Zr 7 , |

Table 4

|

CNiPC |

Components and phase composition |

α |

Linear wear rate, I l , microns/h |

Friction coefficient, f |

|

Ni-P |

(s) Ni, Ni 3 P |

0.92 |

5.95 |

0.25–0.27 |

|

(l) Ni 12 P 5 , Ni 2 P |

||||

|

Ni-P |

(s) Ni, Ni 3 P |

0.90 |

5.0 |

0.20 |

|

(PTFE) |

(l) Ni 12 P 5 , Ni 2 P, PTFE |

|||

|

Ni-P |

(s) Ni, Ni 3 P, TiO 2 , Ni 3 Ti, NiTi 2 , Ti 3 P |

0.85 |

3.9 |

0.21 |

|

(TiO 2 , Ti, ПТФЭ) |

(l) Ni 12 P 5 , Ni 2 P, PTFE |

0.75 |

4.3 |

0.17 |

|

Ni-P |

(s) Ni, Ni 3 P, ZrO 2 , |

0.85 |

3.8 |

0.22 |

|

(ZrO 2 , Zr, PTFE) |

(l) (Ni 12 P 5 , Ni 2 P, Ni 10 Zr 7 , PTFE |

0.75 |

4.1 |

0.18 |

(l) – lubricant coating component, (s) – solid coating component

The main equations for determining the tribological characteristics of the experimental CNiPC samples were the following equations [4]:

Linear wear rate –

Iл = αt Il, t + (1 – αтв) Il, s + Δβ (Iл, тв – Il, s) (1) Friction coefficient – f = αt ft + (1 – αt) fs – Δβ (ft – fs) (2) where: α, β – interrelated coefficients, that take into account (volume or mass fraction) of components exhibiting solid (s) or lubricant (l) properties of the coating subject to the synergy of their action [2,3]. The calculation of these coefficients is considered in [4].

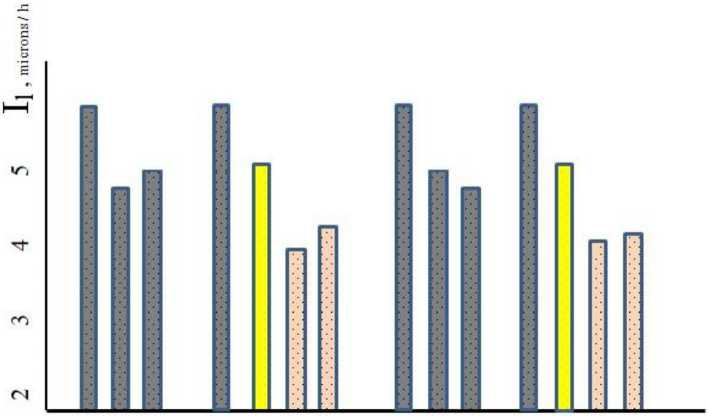

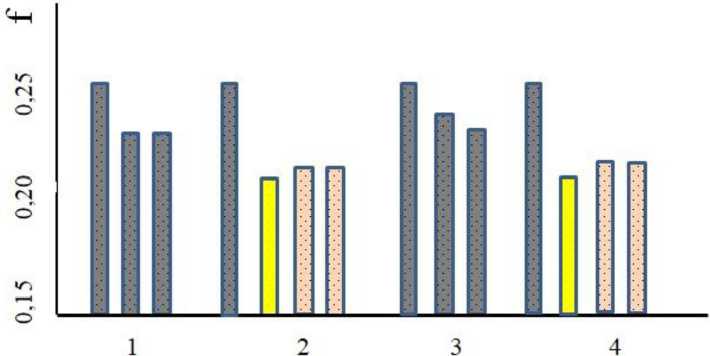

Figures 2, 3 show the CNiPC tribological characteristics, the characteristics obtained as a result of testing experimental samples on a friction machine [8]. Load P = 1MPa, friction velocity 0.048 m/s, friction pair – steel St45

The discrepancy between the values of the tribological characteristics calculated in accordance with the above-mentioned equations and the test results was in the range of 2–3 %.

Fig. 2. Linear wear rate of CNiPC with the modifiers of the systems shown in Tables 1–4

Fig. 3. Friction coefficient of CNiPC with the modifiers of the systems considered in Tables 1–4

Discussion of the results and conclusion

First of all, from the results of the conducted research, it is obvious that:

-

– the modifiers, that were hypothetically selected in the process of crystal-chemical design, increase the tribological characteristics of the NiF coating;

-

– in our case, the PTFE introduced into the coating, as in the general case, increases its wear resistance. At the same time, when the above-mentioned modifiers are in the composition of the coating, the effectiveness of the polymer increases by 20–40 %;

-

– the so-called coefficient α is of great importance for the tribological characteristics of CNiPC, which takes into account (the volume or mass fraction) of the components that exhibit solid (s) or lubricant (l) properties of the coating, taking into account the synergism of their interaction, and, consequently, the influence of the crystal-chemical state of the TS surfaces.

The above-mentioned conclusions are based primarily on the special state of the TS, the so-called structural-phase disorder of the system. This state is achieved due to the formation and simultaneous existence in the TS system of pseudophases that are in an energetically favorable structural state.

Therefore, it is the crystal-chemical design at the atomic and molecular level that allows you to choose from a huge mass of substances the necessary elements for the CNiPC TS.

The article considers some modifiers from the standpoint of crystal chemistry that can form a state of structural-phase disorderliness in the TS. These substances are recommended as CNiPC modifiers.

-

1. Me2O3 (Me – Al, Cr) with a corundum-type structure (sp.gr. R ¯3 c (3)) or ultradisperse metal powders: Me – Cr, Mo, W, V, with a cubic tungsten-type structure (sp.gr. Im3m (2)), Me – Ti, Zr with a hexagonal magnesium-type structure (sp.gr. P63/mmc (2)) [1, 5–7]. In the corundum-type structure (aAl 2 O 3 ) Al3+ cations occupy octahedral positions in the hexagonal close arrangement of anions. Along the direction [001] of the hexagonal cell, pairs of AlO6 – octahedrons are combined into octahedral dimers through common faces and shortened distances of the type due to bonds of a predominantly covalent nature. The structural corundum type compounds belong to octahedral structures based on partial filling (2/3) of octahedral voids in the HCA and belong to the following series of structural types: Mg (P63/mmc(2)) → FeCl3 (P3112(6)) → TiO2 (P42/mna(2)) → αAl2O3 (R ¯3c(3)) → NiAs (P63/mmc(2)) [6].

-

2. MeO2 (Me – Ti, Zr, Ce) with a rutile-type structure (sp.gr. P42/mna (2)) and ultradisperse metal powders: Me – Ti, Zr with a hexagonal magnesium-type structure (sp.gr. P6 3 /mmc (2)) or Me – Cr, Mo, W, V, Ta with a cubic tungsten-type structure (sp.gr. Im3m (2)) [5–7]. In the rutile-type structure (TiO2) Ti2+ cations occupy octahedral positions in the hexagonal close arrangement of anions. The frame structure consists of the chains of TiO6 – octahedrons, in which each octahedron is connected to its neighbor by two opposite edges. These chains are joined together by the vertices of octahedrons. Rutile structural type compounds belong to octahedral structures based on partial filling of (1/2) octahedral voids in the HCA and belong to the following series of structural types: Mg (P6 3 /mmc(2)) → FeCl 3 (P3 1 12(6)) → TiO 2 (P4 2 /mna(2)) → αAl 2 O 3 (R ¯3c(3)) → NiAs (P6 3 /mmc(2)) [6, 7–10].

Thus, with the use of the above mentioned substances, the following is possible:

-

– the formation of pseudophases that form a state of structural-phase disorder in the TS;

-

– the optimization of the composition of solid and lubricant components of CNiPC;

-

– the formation of intermetallic phases, which can not only improve the tribological characteristics of CNiPC, but also increase the adhesion of the coating to the coated metal.

The use of the above mentioned system approaches allowed the author to create a number of CNiPC with increased tribological characteristics.

Список литературы On the choice of some modifiers when creating composite nickel-phosphorus coatings

- Kutkov A. A. Iznosostoikie i antifriktsionnye pokrytiya, 152 p. (1976).

- Ivanov V. V., Ivanov A. V., Shcherbakov I. N., Bashkirov O. M. Sinergicheskiy effekt v kompozitsionnykh materialakh pri trenii i iznose. University News. North-Caucasian Region. Technical Sciences Series, 3, 46-49 (2005).

- EDN: HQLLJF

- Ivanov V. V., Shcherbakov I. N., Bashkirov O.M, Loginov V. T. Analiz sinergicheskogo effekta v kompozitsionnykh Ni-P-pokrytiyakh na stali. University News. North-Caucasian Region. Technical Sciences Series, 4, 42-44. (2005).

- EDN: HQLLJF

- Ivanov V. V., Shcherbakov I. N. Modelirovanie kompozitsionnykh nikel'-fosfornykh pokrytiy s antifriktsionnymi svoystvami. University News. North-Caucasian Region, 112p. (2006).

- Bregg U., Klaringbull G. Kristallicheskaya struktura mineralov, 390p. (1967).

- Urusov V. S. Teoreticheskaya kristallokhimiya, 276p. (1987).

- Uells A. Strukturnaya neorganicheskaya khimiya: V 3-kh t. Vol. 1. 408p. (1987/88).

- Shcherbakov I. N. Razrabotka kompozitsionnogo nikel'-fosfornogo pokrytiya, modifitsirovannogo nitridom bora i politetraftoretilenom. PhD diss. (2003).

- EDN: NMOOVP

- Shcherbakov I. N., Ivanov V. V., Korotkiy A. A. Elaboration and Investi-gation of Metallic Coating with Inclusion of Potassium Polytitanate, Solid State Phenomena, 284, 1140-1143, (2018).

- EDN: ORVSWN

- Shcherbakov I. N., Korotkiy A. A., Egelskaya E. V. Formation and Properties of Multilayer Composite Solid Lubricant Coating. Proceedings of the 5th International Conference on Industrial Engineering (ICIE2019). ICIE2019. Lecture Notes in Mechanical Engineering. Springer, Cham. 1279-1285 (2019).