On the influence of zirconium on the damping capacity of Mn – 40 % Cu alloy in the field of amplitude-independent damping

Автор: Naumov S.B., Ginne S.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 4 vol.23, 2022 года.

Бесплатный доступ

The results of the study of the damping capacity of manganese-copper alloys based on the Mn – 40 % Cu alloy with additives (0.5 – 1.5) % zirconium in the field of amplitude-independent damping are present-ed. Mn – Cu alloys with high damping capacity can be effectively used to reduce vibration and noise. Stud-ies on the influence of a number of alloying elements on the magnitude and stability of the damping capaci-ty of Mn – Cu double alloys in the field of small deformations of relative shear are not enough. In the pa-per, the influence of one of these elements, zirconium, was elucidated. Mn – Cu alloys were smelted in an induction furnace. From the ingots cast into cast iron molds, samples for studies with dimensions (11 × 15 × 117) ± 1 mm were obtained by mechanical cutting. The samples were subjected to aging at a temperature of 643 K for 0.5–40 hours. The damping capacity of Mn – Cu alloys (the logarithmic decrement of attenua-tion of oscillations) was studied for longitudinal oscillations of samples in the frequency range 14–17 kHz and the amplitudes of the relative shift (1 ... 3) × 10–6. It has been established that alloying the Mn – 40 % Cu alloy with zirconium from 0.5 % to 1.5 % does not increase its damping capacity in the cast state, as well as in the cast and aged at a temperature of 643 K for 40 hours. It was found that the minimum values of the frequencies of resonant vibrations of samples of Mn – Cu alloys correspond to the maximum levels of the damping capacity of these alloys. Itʼs shown that the high damping capacity of cast and aged alloys at 643 K for 40 hours Mn – 40 % Cu, Mn – 38.5–39.5 % Cu – 0.5–1.5 % Zr after natural aging at 293 K for 7 months decreases by 2.0–2.6 times.

Damping, damping capacity, Mn – Cu alloys

Короткий адрес: https://sciup.org/148329667

IDR: 148329667 | УДК: 669.745 3.018 | DOI: 10.31772/2712-8970-2022-23-4-756-762

Текст научной статьи On the influence of zirconium on the damping capacity of Mn – 40 % Cu alloy in the field of amplitude-independent damping

Modern industry produces and uses mechanisms and machines characterized by high speeds of movement. In this case, vibrations and noises arise, which reduce the reliability of equipment and structures, and worsen working conditions [1–3]. In [4], the causes of vibrations in the electric pump unit of the spacecraft are considered and the use of high damping materials is proposed as one of the ways to reduce it. At the rocket and space plant of Khrunichev State Research and Production Space Cente in several workshops, there is an excess of the AEL in terms of noise levels by 12–33 dBA and vibration by 4–8 dBA, which is created by the operation of stationary press, forging, riveting, drilling and milling machine equipment and manual pneumatic drills, pneumatic brackets, pneumatic grinding machines [5].

High-damping alloys are widely used for noise and vibration protection. High-damping alloys based on Mn – Cu effectively dissipate vibrations and noises at small (about 10-8–10-6 relative deformation) and significant (about 10-4–10-3 relative deformation) deformation amplitudes; have good mechanical properties and satisfactory manufacturability. It is believed that the damping capacity of alloys based on Mn – Cu at low deformation amplitudes (areas of amplitude-independent damping) is due to internal stresses caused by defects in the crystal structure, and at significant deformation amplitudes by the movement of twins of the martensitic face-centered tetragonal (FCT) phase obtained as a result of martensitic FCC – FCT transformations [6; 7]. However, the high damping capacity of Mn – Cu based alloys, obtained by optimal heat treatment, decreases significantly after natural aging at a temperature of 293 K at small and significant amplitudes of relative shear deformations [7–10].

An effective way to improve the physical and mechanical properties of alloys is their alloying [11; 12]. In this regard, the purpose of this work is to study the effect of 0.5–1.5% zirconium on the damping capacity of the double alloy Mn – 40% Cu in the cast state, after casting and aging at a temperature of 643 K for 40 h, natural aging at 293 K for 7 months.

Experimental methodology

In order to clarify the effect of zirconium doping on the damping ability of the base alloy Mn – 40% Cu, its concentrations from 0.5 to 1.5% were taken. The table shows the composition of the studied alloys based on Mn – 40% Cu alloy.

Composition of alloys based on Mn – Cu Состав сплавов на основе Mn – Cu

|

Alloy |

Chemical composition by charge (%, by mass) |

||

|

Mn |

Cu |

Zr |

|

|

1 |

60 |

40 |

– |

|

2 |

60 |

39,5 |

0,5 |

|

3 |

60 |

39,3 |

0,7 |

|

4 |

60 |

39,0 |

1,0 |

|

5 |

60 |

38,8 |

1,2 |

|

6 |

60 |

38,5 |

1,5 |

Electrolytic manganese Мр0 and Мр1, cathode copper М0, zirconium in copper ligature Cu – 30% Zr were used as the charge material. Manganese-copper alloys were smelted in an induction furnace under a layer of cryolite. The pouring of the melt was carried out from the temperatures of 1673–1723 K from above into flat cast iron molds heated to temperatures of 423–473 K and lubricated with rosin. Ingots weighing 5 kg were milled and cut into samples with dimensions (11 × 15 × 117) ± 1 mm. The samples were aged in a muffle furnace at a temperature of 643 K for 0.5–40 h.

The damping capacity (the logarithmic damping decrement of vibrations) was studied during longitudinal vibrations of the samples on the Elastomat installation in the frequency range of 14–17 kHz and relative shift amplitudes of 1–3 × 10-6. Relative scattering ψ (attenuation) was determined by formula (1):

ψ= 2 δ⋅ 100 %, (1)

where δ – is a logarithmic decrement.

The measurement error by this method was 2–4 %.

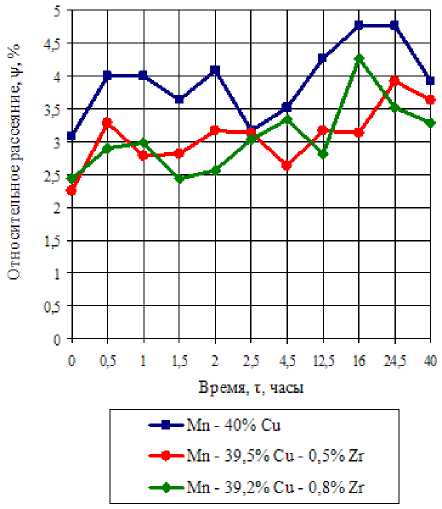

Figure 1 shows the dependences of the damping ability of the Mn – 40% Cu double alloy and alloys based on it, alloyed with 0.5–1.5% zirconium after casting into cast iron molds, aging at a temperature of 643 K for 0.5–40 h and cooling in air. It can be seen that the Mn – 40% Cu double alloy in the cast state has a higher level of damping ability (ψ = 3.2%) than alloys containing zirconium (ψ = 2.2–2.7%).

Aging of the studied alloys at 643 K for 0.5–1.0 h increases their damping capacity up to 3–4%. At the same time, the highest level of damping (ψ = 4%) shows a double alloy Mn – 40% Cu. After aging at 673 K for 2–2.5 h in this alloy, there is a slight decrease in the damping ability to ψ = 3–3.5%. At the same exposure in zirconium–doped alloys, the damping level remains the same as it was obtained after 0.5–1.0 hours of exposure at 643 K. Subsequent exposures at 643 K to 4.5–12 h reduce the level of damping capacity in zirconium–doped alloys.

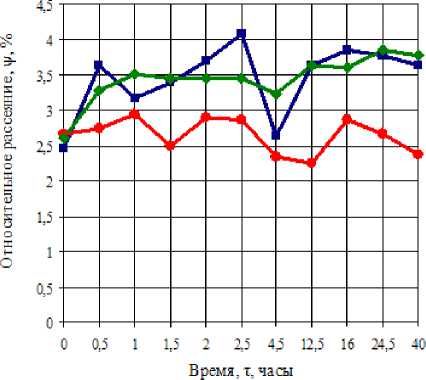

Further aging at 643 K over 12.5 h increases the level of damping ability of Mn – 40% Cu alloy to ψ = 4.7% and alloys with 0.5, 0.8 and 1% zirconium to ψ = 3.9 %, ψ = 4.2% and ψ = 3.8%, respectively. Aging at 643 K for 40 h causes a decrease in the damping ability of Mn – 40% Cu alloy, alloys with 0.5, 0.8 and 1.2% zirconium. At the same time, the aging of alloys with 1 and 1.5% zirconium at 643 K for 12.5–40 hours does not lead to a decrease in the previously achieved level of damping ability (ψ = 3.7%).

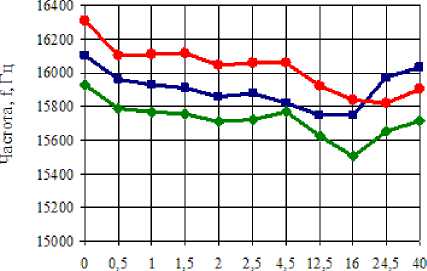

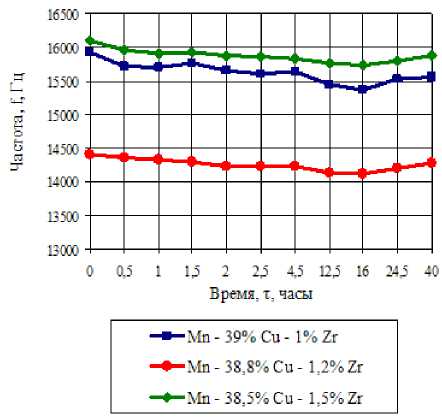

Figure 2 shows the changes in the resonant vibration frequencies of cast alloys Mn – 40% Cu, Mn – 38.5–39.5% Cu – 0.5–1.5% Zr. From Fig. 2 it can be seen that the aging of alloys based on Mn – 40% Cu at 643 K for 0.5–40 h leads first to a certain decrease in the resonant oscillation frequencies, and then to their increase. At the same time, the minimum values of resonant vibration frequencies for all alloys based on Mn – Cu are observed after 16 hours of aging at 643 K.

Fig. 1. Dependences of the damping capacity, ψ, of the cast Mn – Cu alloys on the aging time, τ, at a temperature of 643 K

-■-Мп -39% Cu- l%Zr

-•-Мп- 38,8%Си- l,2%Zr

—♦-Мп- 38,5%Си- l,5%Zr

Рис. 1. Зависимости демпфирующей способности, ψ, литых сплавов Mn – Cu от времени старения, τ, при температуре 643 К

Время, т, часы

-■-Мп - 40% Си

-•-Мп - 39,5% Си - 0,5% Zr

-♦-Мп - 39,2% Си - 0,8% Zr

Fig. 2. Change of the frequency of resonant oscillations, f, of the cast Mn – Cu alloys on the aging time, τ, at a temperature of 643 K

Рис. 2. Изменение частоты резонансных колебаний, f, литых сплавов Mn – Cu от времени старения, τ, при температуре 643 К

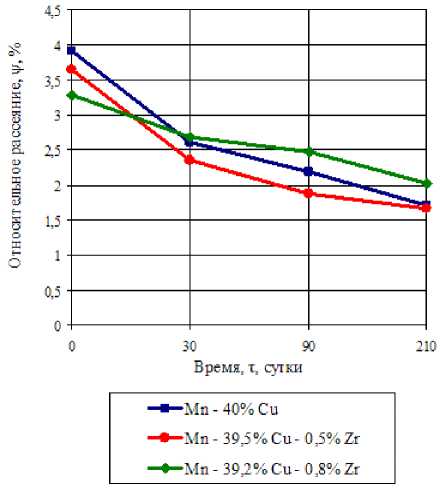

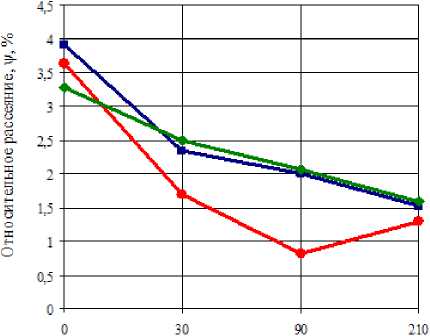

Figure 3 shows the dependences of the change in the damping capacity of the studied alloys based on the Mn – 40 % Cu alloy during natural aging for 7 months. Figure 3 demonstrates that the damping capacity of alloys cast aged at 643 K for 40 hours decreases during natural aging over 7 months by 2– 2.6 times.

Fig. 3. Change of the damping capacity, ψ, of the Mn – Cu alloys, which were cast and aged at 643 K within 40 hours, at natural aging, τ

Время, т, сутки

-■—Мп - 39% Си - 1% Zr

-•—Мп- 38,8%Си- lZ%Zr

—•—Мп - 38,5% Си- 1,5%Zr

Рис. 3. Изменение демпфирующей способности, ψ, сплавов Mn – Cu, литых и состаренных при 643 К в течение 40 ч, при естественном старении, τ

Research results

The study revealed that alloys Mn – 40% Cu, Mn – 38.5–39.5% Cu – 0.5–1.5% Zr, cast into cast iron molds and then aged at a temperature of 643 K for 0.5–40 h show different damping capacity values. A higher level of damping capacity ψ = 4–4.7% was obtained in cast alloys aged at a temperature of 643 K. The damping capacity of cast alloys was ψ = 2.2–2.7%. There is a trend in the level of damping capacity of manganese–copper alloys, which is obviously due to the fact that when these alloys are cooled in cast iron molds, the separation of the γ-solid solution Mn – Cu into regions enriched and depleted in manganese is delayed, which further leads to the formation of a martensitic FCT phase responsible for high damping in alloys based on Mn – Cu [6; 7]. Aging of cast alloys based on the Mn – 40% Cu alloy at 643 K leads to a greater degree of delamination of the Mn – Cu γ-solid solution and, consequently, to a higher level of damping capacity.

The dependences of the change in the damping ability of cast alloys Mn – 40% Cu, Mn – 38.5– 39.5% Cu – 0.5–1.5% Zr on the aging time at a temperature of 643 K (Fig. 1) show intermittent (not monotonic ) increase of damping capacity level. A slight decrease in the damping capacity after 0.5 h, several hours of aging at 643 K is not associated with “overaging”, but, apparently, is a consequence of the inhomogeneity of the samples under study, which is typical for the cast state of alloys based on Mn – Cu [7].

It is known that the oscillation frequency is related to the modulus of normal elasticity, the minimum of which in alloys based on Mn – Cu precedes the maximum of their damping capacity [7; 8]. The dependences of the change in the frequency of resonant oscillations on the aging time at 643 K of the studied alloys based on the Mn – 40% Cu alloy (Fig. 2) show minima that precede the maximum levels of the damping ability of these alloys.

The dependences of the change in the damping ability of cast and aged alloys at a temperature of 643 K Mn – 40% Cu, Mn – 38.5–39.5% Cu – 0.5–1.5% Zr (Fig. 3) show that alloying zirconium does not contribute to a significant stabilization of the level of damping capacity of the double alloy Mn – 40% Cu.

Conclusion

A study of the effect of alloying with zirconium on the damping ability of the Mn – 40% Cu alloy showed that 0.5–1.5% zirconium does not increase the level of damping ability of this alloy in the cast state, as well as in the cast and aged at a temperature of 643 K for 40 h state and does not contribute to a significant preservation of high damping during natural aging in the region of small deformation amplitudes 10–6–10–5 relative shear – areas of amplitude-independent deformation. High damping capacity of cast and aged alloys at 643 K for 40 h Mn – 40% Cu, Mn – 38.5–39.5% Cu – 0.5–1.5% Zr after natural aging at 293 K within 7 months decreases by 2.0–2.6 times.

Список литературы On the influence of zirconium on the damping capacity of Mn – 40 % Cu alloy in the field of amplitude-independent damping

- Sergienko V. P., Buharov S. N. [Vibration and noise in non-stationary friction processes]. Vi-braciya i shum v nestacionarnyh processah treniya. Minsk, Belorusskaja nauka, 2012, 347 p.

- Mindrin V. I., Pachurin G. V., Rebrushkin M. N. [Types and causes of vibration of power ma-chines]. Sovremennye naukoyomkie tehnologii. 2015, No 5, P. 32–36 (In Russ.).

- Pirogov D. A., Shljapugin R. V., Jel'nashar E. A. [Investigation of vibration and noise of the heald frame of a metal loom]. Fundamental'nye issledovaniya. 2017, No 11-1, P. 114–118 (In Russ.).

- Judina Z. A., Sinichenko M. I., Ladygin A. P., Sin'kovskij F. K., Usmanov D. B. [Causes of vi-bration in the electric pump unit of the spacecraft and ways to reduce it]. Kosmicheskie apparaty i tehnologii. 2021, Vol. 5. No 2, P. 63–76 (In Russ.). Doi: 10.26733/j.st/2021.2.01.

- Vorozhejkina T. S., Goldobin V. N., Gubareva S. P., Zaozjorskaja S. L., Malyshev S. V., Savi-cheva N. M., Fedoseeva G. N., Filippov A. A., Carjova L. G. [Evaluation of the impact of noise and vibration on the health status of workers at the Federal State Unitary Enterprise «GKNPts im. M.V. Khrunichev»]. Medicina yekstremal'nyh situaciy. 2015, No 3 (53), P. 87–90 (In Russ.).

- Vitek J., Warlimont H. On a metastable miscibility gap in Mn – Cu alloys and the origin of high damping capacity. Met. Sci. and Eng. 1976, Vol. 4, Р. 7–13.

- Favstov Ju. K., Shul'ga Ju. N., Rahshtadt A. G. Metallovedenie vysokodempfirujushhih splavov [Metal science of high-damping alloys]. Moscow, Metallurgiya Publ., 1980, 272 p.

- Udovenko V. A., Markova G. V., Rostovcev R. N. Splavy sistemy Mn – Cu. Struktura i svojstva [Alloys of the Mn – Cu system. Structure and properties]. Tula, Grif i K Publ., 2005, 152 p.

- Naumov S. B., Nemirovskij V. V., Rozenberg V. M. [Damping stability of manganese-copper alloys]. Cvetnye metally. 1984, No 10, P. 66–67 (In Russ.).

- Naumov S., Ginne S. Features of the damping capacity of Mn – Cu alloys. MATEC Web of Conferences 344. 2021, 01012. Available at: https://doi.org/10.1051/matecconf/202134401012.

- Zhang Y., Li N., Fu X., Liu W.B., Liu Y., Zhao X.C. Effect of the precipitated second phase during aging on the damping capacity degradation behavior of M2052 alloy. Adv. Mater. Res. 2014, No. 873, P. 36–41.

- Liu W., Li N. Zhong Z., Yan J., Li D., Liu Y., Zhao X., Sci S.. Novel cast-aged MnCuNiFeZ-nAl alloy with good damping capacity and high usage temperature toward engineering application. Materials and Design. 2016, No. 106, P. 45–50.