Optimizing process of producing tomato paste using fuzzy logic

Автор: Mojtaba Nouri, Leila Shaghaghi, Mohammad Moghadasi Incheh Keykanloo, Ali Abhari Segonbad, Mahsa Tabrizi, Mohammad Ali Shariati

Журнал: Биология в сельском хозяйстве @biology-in-agriculture

Рубрика: Актуальные исследования иностранных авторов

Статья в выпуске: 1 т.2, 2014 года.

Бесплатный доступ

The aim of this study is to investigate consistency heating (primary Brix) of tomato and mutual influence of different temperatures and brixes on the final consistency of produced paste using fuzzy logic. Tomato paste is the most important products of tomato and improving its properties is of high importance. The results of applying different amounts of these parameters showed that heating tomato in 79 centigrade degrees causes pectin to be preserved better and finally its consistency will be improved and the quality of tomato will be preserved. Increasing temperatures makes the apparent quality to be preserved. Also, the tests of evaluating consistency and color of the product in 70 confirmed the optimization of consistency and parameters L, a and b. Fuzzy logic created the argument-based system for this research so that its application helps us solve the problems of production line and unpredicted conditions through applying other conditions.

Primary brix, temperature, tomato paste, fuzzy, consistency

Короткий адрес: https://sciup.org/14770274

IDR: 14770274 | УДК: 664-404.9

Текст научной статьи Optimizing process of producing tomato paste using fuzzy logic

Tomato paste contains the mixture of separated pericarp cells in transparent serum and acquiring proper consistency and stability depend on different factors especially variety, geographical location, care and processing conditions. Tagor et el. found that during crushing the enzymes of pectinolitic are released and act rapidly. So even in the best conditions of heating crushed product, 100% retention of pectic products will not be possible and the pectin of tomato will decrease 20-30%. Chiyang (1995) placed complete tomatoes in hot water with 85 centigrade’s for 2 minutes in primary heating. Due to the permeability of heating area the enzymes of pericarp will not be inactivated (the central heating of tomato reached 24 centigrade degrees in this case). Therefore, for complete elimination of enzymes the crushing process in 85 centigrade’s was used.

Jerhard Jones et al. (2001) dealt with the quality of tomato using fuzzy logic and obtained the best quality in terms of size, color, shape, fracture, etc. and regarding to factors such as consumption aspects and the needs of con- sumer, so that it is possible to provide the best quality with changing the expectations of consumers. Harris used fuzzy logic for ranking raw milk on the basis of quality and health properties. This method makes more clear and comprehensive evaluation than existing methods (Har-ris,1998) .

Sinksi et al. (2001) used fuzzy logic in order to model the quality and health properties of sea systems. On the basis of conventional methods it is possible for them not to be proper for these systems in relation with high levels of unreliability in measuring feasibility and design steps of solution. In contrast, the fuzzy logic using the rules of “if, then” can model quality aspects of human knowledge and processing reason and theorem without measuring careful quality analysis (Sing sii ,et al ,2001)

In this research it is tried to investigate the influences of primary product on final Brix and consistency of the product through investigation of data obtained by brix of primary product and different temperatures while using the opinions of experts and elite researchers. We intend to obtain more careful results using fuzzy logic and drawing graphs. Regarding the heating processes and high costs of energy consumption and also defined standard in the field of tomato paste in Iran we became closer to the aim of production with considered quality and decreasing the cost of energy consumption. Finally the best range was selected.

-

2- Materials and Methods

Preparing tomato paste: paste is prepared in constant conditions by crushing in 85 centigrade degrees and concentrating in vacuum with the method of batch. First input brix was measured daily and temperature of process was controlled and recorded in the time of concentration and this act was repeated for 30 days. The results have been indicated in table 1. For measuring consistency of final product the tomato paste was diluted by distillated water to brix 12 and it was measured by consistency meter in 20 centigrade degrees and the results were recorded. Consistency is in fact the criterion of fluid resistance against flow and is one of the important properties in accepting many products especially tomato paste. So, the quality of consistency can have main influence on marketability of the product. This study investigates this issue that regarding primary brix of the product before process, which temperature has the best consistency and quality and if each of factors changes due to probable problems, which parameter should be changed so that the consistency of final product has the least fluctuation. Fuzzy logic helped us in this regard (Falahi, 2005).

Table 1- Amounts of Initial BX , Tem, Final Bx in Tomato Paste

|

Initial oBx |

TEM o C |

Final oBx |

|

36 |

74 |

4/7 |

|

36/2 |

77 |

5/3 |

|

36 |

75 |

4/9 |

|

36/2 |

75 |

5/5 |

|

36/1 |

76 |

5/4 |

|

35/8 |

80 |

5/8 |

|

36/1 |

74 |

6/7 |

|

36 |

71 |

5/1 |

|

35/5 |

74 |

5/9 |

|

36/1 |

72 |

5/9 |

|

36/4 |

72 |

5/3 |

|

36/4 |

72 |

4/8 |

|

35/9 |

75 |

6/2 |

|

36/3 |

79 |

7/2 |

|

35/9 |

73 |

4/7 |

|

35/7 |

68 |

6 |

|

36 |

71 |

5/4 |

|

36/1 |

71 |

5/6 |

|

36/1 |

72 |

5/2 |

|

36/1 |

72 |

6/1 |

|

36 |

73 |

5/6 |

|

36/1 |

71 |

3/8 |

|

36 |

72 |

4 |

|

36/1 |

71 |

5/2 |

|

36/3 |

71 |

4/9 |

|

35/6 |

71 |

4 |

|

36 |

73 |

4/7 |

|

35/8 |

73 |

5/4 |

|

36 |

70 |

5/9 |

|

28/7 |

74 |

5/6 |

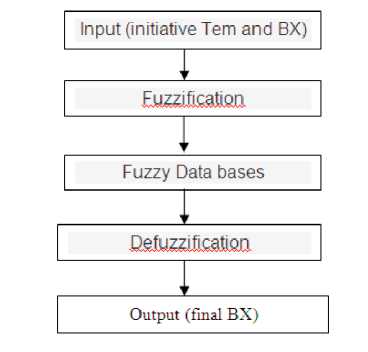

Figure-1 Fuzzy Inference System for optimizing Tem and Thickening of tomato

2-2 Fuzzy Set

Fuzzy set is a set without definite member the boundary of which is defined clearly. This set can indicate all elements of main set only with a relativity degree. In other word, fuzzy set is defined as a set of ordered pairs as follows (Jahns et al , 2001):

D = {(x, Ц D (X)) x e X , |IdM e [0,1]}

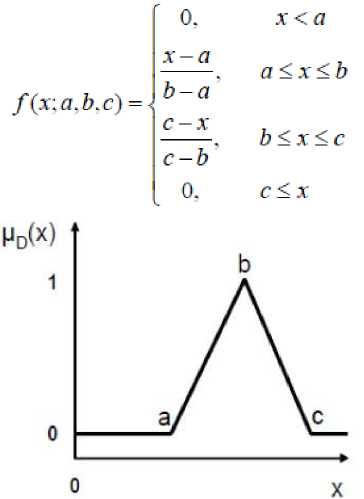

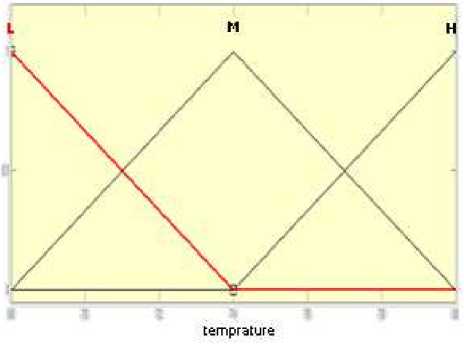

In which x is an element of natural set. The belonged functions have been usually defined for input and output variables and include different kinds such as triangle, trapezoid and Gaussian. For this research the triangular and trapezoid functions have been selected. One triangular function having three points is defined from the change limitations of one variable (figure 2) while for a trapezoid function we need 4 points. Mathematical expression of triangular function has been indicated below (Zimmermann , 1996 and Jahns et al , 2001).

Figure -2 Triangle part Function

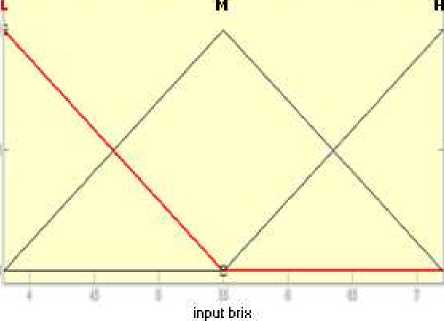

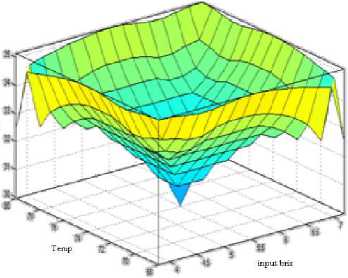

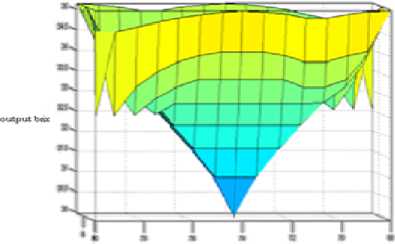

First we have determined minimum and maximum of different data and placed them in software MATLAB so that we can obtain the amounts of a, b and c. In the next step 3 functions in software were defined for each input and output. They are L(little), M (medium) and H (high). Then we determined the place of input data in functions so that we can act on the basis of the above equation. After placing the numbers higher than 0/5 and higher or equal to 1 were obtained. This act is used for the next step called pruning. Then the obtained numbers from each part of input and output were multiplied by each other and the obtained number was less than 1 and equal to 1 in the best case. Then pruning was conducted so that first the data having the same input but different output were specified. Then the answer of multiplying above was determined and the data having higher obtained number were maintained and the others were eliminated. Then, the remaining rules being 7 in total were placed in software and fi-

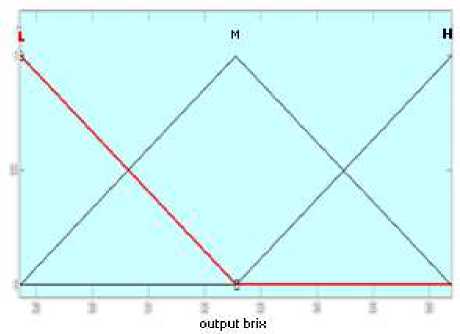

nally the 3-dimensional shape was obtained. For input and output functions 5 little, medium and high belonged functions were considered. These functions have been indicated in figures 3 and 4 (Jahns et al , 2001).

Figure-3 Triangle Part Function for Input variables of Fuzzy System (Input BX and TEM)

Figure-3 Triangle Part Function for Input variables of Fuzzy System (Final BX)

Figure-5 Control level of Sum of the Rules for initial Consistency Tem and Final consistency

We change output variable to a definite number through making non-fuzzy. This process contains different methods such as gravity, maximum average of maximum centers and the first maximum. In this study the method of maximum centers has been used. This method is one weight degree of the area below produced curves for that degree considered in output functions.

Figure-6 Control level of Sum of the Rules for Tem and Final Consistency

Table 2- Desired Level for Fuzzy System Rules

|

г |

L |

M |

H |

|

L |

H |

H |

|

|

M |

H |

L |

H |

|

H |

H |

H |

Conclusions

-

1- As indicated, heating tomato in 79 centigrade degrees causes pectin to be preserved better. Consistency of paste will be improved too. Increasing the temperature makes decrease of coefficients related to color of the product and apparent quality. In fact, temperature higher or less than this range is unacceptable in terms of economic and quality of final product. Final brix in terms of Iran standard is 28 and the numbers higher or less than this are variable regarding the final price of product and standard of target countries. In primary brix of input raw material more heating is necessary with decreasing brix and also with increasing heating in input

brix in desirable range the consistency of the product will increase too.

-

2- The results of this study show that different parameters in producing final crop can be controlled. For example, if the aim is to produce with fewer prices and more volume we can obtain necessary standard with decreasing heat in order to prevent energy cost through compensating other parameters. Applying this system indicates that in most cases we can solve the problems of production line or unpredictable problems with applying other conditions. It means that we create constant conditions through correcting other parameter in the process of production. These conditions should not be far from the standard of considered product.

Список литературы Optimizing process of producing tomato paste using fuzzy logic

- Barreiro J.A., Milano M., Sandoval A.J. Kinetics of colour change of double concentrated tomato paste during thermal treatment, 1997, Journal of Food Engineering, 3-4, 359-371.

- Eerikäinen T., Linko, P., Linko, S., Siimes, T., Zhu, Y.H. Fuzzy logic and neural network applications in food science and technology, 1993, Trends in Food Science & Technology, 8, 237-242.

- Flahi M.(2005).Tomato paste Processing Industries.Marzedanesh Publication,Iran.P 30-85.

- Fuzzy Logic Toolbox, for use with Matlab©7010.0 User’s Guide, 2010, The Math works Software, 30-59.

- Jahns, G., Nielsen, H. and Paul, W. (2001).Measuring image analysis attributes and modeling fuzzy consumer aspects for tomato quality grading, Computers and Electronics in Agriculture, 31, 17-29.

- Harris, J. (1998).Raw milk grading using fuzzy logic, International Journal of Dairy Technology. 51: 52-56.

- Kavdir, I. and Guyer, D.E. Apple Grading Using Fuzzy Logic. 2003, Turkish J. of Agric, 27, 375-382.

- Sing sii, H., Ruxton, T. and Wang, J. (2001).A fuzzy-logic-based approach to qualitative safety modeling for marine systems. Reliability Engineering and System Safety, 73:19-34.

- Zimmermann H. J. (1996).Fuzzy Set Theory and It’s Applications, Kluwer Academic Publishers. Boston, Dordrecht, London, P 435.