Parameters of rocket engine chambers, obtained by selective laser melting

Автор: Zhuravlev V.Y., Manokhina E.S., Shikarev M.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 1 vol.25, 2024 года.

Бесплатный доступ

When designing and testing a low-thrust rocket engine (LTRE), one of the most important tasks is to ensure the quality of materials, which, in turn, affects the reliability of the product. Currently, additive technologies for manufacturing parts from metals are actively developing. This direction is relevant for rocket and space technology products to reduce weight and increase the reliability of products. The article presents the results of studies of the chemical composition and mechanical characteristics of the material of the low-thrust rocket engine demonstrator chamber, manufactured by selective laser melting from metal powder. The properties of products made from Inconel 718 metal powder were studied. Samples were made and the chemical, mechanical and structural characteristics of the material were studied. Based on the test results, two LTRE samples were printed. LTRE chambers were tested for vibration loads, strength and tightness. Increased porosity and roughness of the test material of the engine chamber were noted. When analyzing a number of parameters of the selective laser melting technology, an experimental selection of printing parameters was carried out and the most significant factors affecting the print quality (surface roughness and porosity) were identified. Based on the results of the work carried out, four groups of controlled printing parameters were identified that affect the properties of the resulting material. The work also provides recommendations on printing modes and characteristics to obtain the highest quality parts.

SLM-printing, Inconel 718, testing, analysis, mechanical properties of the material, analysis of printing parameters

Короткий адрес: https://sciup.org/148329727

IDR: 148329727 | УДК: 620.181.5 | DOI: 10.31772/2712-8970-2024-25-1-106-114

Текст научной статьи Parameters of rocket engine chambers, obtained by selective laser melting

High quality requirements are imposed on the products of the rocket and space industry. At all stages of aircraft engines (AE) development, parameters are evaluated based on the efficiency of design solutions, the quality of materials used, design development of prototypes, and the results of product tests during production and operation [1].

The development of additive technologies (AT) in comparison with traditional production in the future will significantly reduce the time and cost of manufacturing products as a result of improving manufacturability, reducing the number of parts of assemblies, obtaining structural materials with improved properties [2]. The differences in the material properties of parts produced using additive technologies and those produced by traditional molding methods have already been revealed. Currently, the use of 3D printing in the production of rocket engines is constrained by insufficient development of technology parameters.

The purpose of the research is to study the properties of the material obtained by SLM printing method, experimental development of printing modes and identification of controllable parameters affecting the physical and mechanical characteristics of products operating at high temperatures.

Description of selective laser metal melting technology

The Reshetnev Siberian State University of Science and Technology together with industrial partner LLC "Polychrome" are conducting research on the development of technology for the production of low thrust rocket engine chamber by selective laser melting (SLM) of Inconel 718 material.

Inconel 718 is a heat-resistant, high-quality alloy that was developed for the reliable operation of products at temperatures up to 980 °C. Almost immediately after its creation, it became highly demanded and already in the 70s of the last century it accounted for more than 50% of the total gross production of industrial heat-resistant alloys in the USA. Inconel 718 is now considered one of the most sought-after materials in the Inconel group.

This alloy has high impact toughness and strength up to a temperature of 900 °C, and at low temperature (–78 °C) Inconel has no sensitivity to notching. Inconel alloys are resistant to oxidation and corrosion. When heated, Inconel forms a thin stable passivating oxide film protecting the surface from further destruction. Inconel maintains its strength over a wide temperature range and is therefore a universal material used in many industries.

Initially, experiments were conducted to identify controllable laser parameters and to work out printing modes of the printer from Inconel 718 powder of PR08-HN53BMTU grade. Then experimental samples were printed to determine the porosity, chemical composition, mechanical properties of the obtained material (Fig. 1).

Рис. 1. Образцы для механических испытаний

Fig. 1. Samples for mechanical testing

A part of samples was manufactured without heat treatment. A part of the samples was heat-treated according to the following regime: hardening at 980 ± 10 °C, holding for 1 hour, cooling in air (argon), aging at 720 ± 10 °C, holding for 8 hours, cooling in the furnace to 620 °C for 2 hours, then holding for 8 hours at 620 ± 10 °C, cooling in air (argon). The obtained samples were subjected to studies to determine the chemical composition, structure, and mechanical properties of the material. The density of Inconel 718 alloy is 8.19 g/cm3.

According to the content of alloying elements, the material of samples corresponds to Inconel 718 grade. According to the structure, the material of the samples has increased porosity [3; 4]. The surface of the samples has increased roughness.

To investigate the mechanical characteristics, the material of standard samples of the chamberdemonstrator was tested for tensile properties and microhardness was determined by the Vickers method. As a result of the studies, the values of yield strength, strength, tensile strain and hardness of the material were obtained [5].

After processing the test results, the values of residual material deformations and elastic moduli for heat-treated samples and samples without heat treatment were obtained (Table 1).

Table 1

Inconel 718 alloy test results at room temperature

|

Sample number |

Modulus of elasticity (E), MPa |

Permanent strain at break (δост), % |

|

1. With heat treatment |

0,214·105 |

5,27 |

|

2. With heat treatment |

0,209·105 |

5,38 |

|

3. With heat treatment |

0,176·105 |

5,95 |

|

4. With heat treatment |

0,156·105 |

6,95 |

|

5. Without heat treatment |

0,139·105 |

6,51 |

|

6. Without heat treatment |

0,139·105 |

6,43 |

|

7. Without heat treatment |

0,116·105 |

8,7 |

|

8. Without heat treatment |

0,113·105 |

5,23 |

Heat treatment of the samples led to an increase in their strength characteristics, hardness, and a decrease in elasticity and plasticity. The obtained stress characteristics are close to the results of [6], while the strain characteristics are significantly lower (Table 2).

Table 2

Mechanical properties of Inconel 718 alloy at room temperature

|

Characteristics |

Inconel 718 (after heat treatment) |

|

|

With heat treatment |

Without heat treatment |

|

|

Tensile strength σв, MPa |

1400 |

1380 |

|

Yield strength σ0,2, MPa |

1150 |

1240 |

|

Relative elongation δ, % |

15 |

18 |

Затем были напечатаны две камеры и смесительные головки ракетного двигателя (рис. 2).

The two chambers and mixing heads of the rocket engine were then printed (Fig. 2).

а

б

Рис. 2. Напечатанные камера ( а ) и смесительная головка ракетного двигателя ( б )

Fig. 2. Printed rocket engine chamber ( а ) and mixing head ( b )

To confirm their performance, a whole range of tests was carried out. First, vibration tests of the chambers were successfully carried out. Then strength and tightness tests using a special device were carried out.

According to the technological requirements for test devices, the test device must ensure tightness, simulate and withstand the loads that the product experiences in real operation. For testing the strength and tightness of the engine chamber, a special device was designed (Fig. 3). It was manufactured by the company Variant-999 Ltd.

Рис. 3. Приспособления для испытаний

Fig. 3. Test devices

According to OST 92-4291-75 the following types of tests were chosen: for strength by pressure test (using distilled water), for tightness by «aquarium» method (using air). Tightness test is performed immediately after the strength test using the same special device. Test modes were developed (Table 3).

Parameters of tightness test modes

Table 3

|

Parameter |

Strength |

Tightness |

|

Pressurization pressure, kg/sm2 |

11,2 |

12,65 |

|

Pressurization duration, min |

5 |

5 |

|

Test pressure, kg/sm2 |

12,75 |

11,5 |

|

Test duration, min |

5 |

3 |

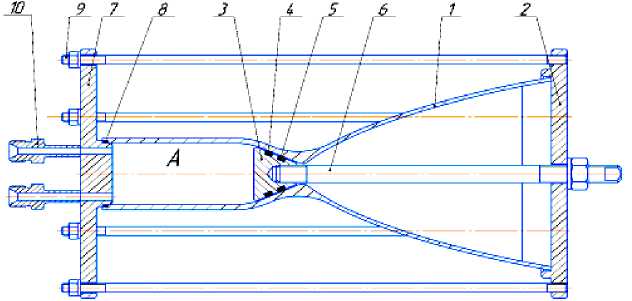

The main requirement for test devices is that they must ensure tightness and withstand the loads that the product is subjected to in actual operation. Therefore, all elements of the device operating under loads were designed on the basis of calculations carried out under the condition of strength. The scheme of the test fixture is shown in Fig. 4.

Рис. 4. Схема приспособления для испытаний:

1 – камера; 2 – кольцо упорное; 3 – прижим; 4 , 5 , 8 – уплотнительные кольца;

6 – шток; 7 – фланец; 9 – шпилька; 10 – штуцер

Fig. 5. The scheme of the device for testing:

1 – chamber; 2 – thrust ring; 3 – clamp; 4 , 5 , 8 – sealing rings;

6 – rod; 7 – flange; 9 – stud; 10 – fitting

The working body for testing is fed into the cavity «A» through the inlet fitting 10 and removed through the outlet fitting. The tightness of the cavity is ensured by sealing rings 4, 5, 8 . Therefore, special requirements on roughness and dimensional accuracy are imposed on the mating surfaces of the chamber-demonstrator 1 , as well as flange 7 and clamp 3 with rings. For uniform pressing of the sealing ring 8 to the surfaces of the flange 7 and the demonstrator chamber 1 , six studs 9 arranged evenly around the circumference are used. Pressing of sealing rings 4 and 5 from the side of critical section is provided by means of rod 6 . The strength calculation of the loaded elements of the device showed the necessary safety margin for the test.

During engine chamber tightness testing, increased porosity and leaking of the chamber material was found.

Analysis of identified parameters of selective laser melting technology

As a result of working out the technology of printing samples and rocket engine chambers on a particular printer, the following features were revealed [7]:

– printed products have isotropic mechanical properties;

– low printing speed;

-

– internal porosity of the obtained product;

-

– shrinkage of the product after heat treatment [8];

-

– possibility of warping of the product after heat treatment;

-

– necessity of post-processing of the product surface to reduce roughness [9-14];

-

– limitation of the product size by the dimensions of the space of the printing device;

-

– high cost of powder.

Further, by changing the printing modes of the engine chambers, satisfactory results were achieved to improve the quality and reliability of the products in strength and tightness tests.

Based on the results of this work, four groups of controllable SLM printing parameters affecting the properties of the resulting product material can be identified:

-

1. laser characteristics F л :

-

– laser power N л;

-

– print spot temperature T ;

-

– print spot size d л;

-

2. Properties of the melted layer F с:

– powder granularity d з;

– height of the melted powder layer h [15];

F л ( N л , T , d л ).

-

– the amount of overlap of the beam edges when printing with the next laser pass in the layer Δ d ;

-

3. Printing time parameters Ft :

– speed of laser movement during printing v ;

– laser return time when printing with the next pass in the layer t ;

-

4. Geometric parameters of the product Fr :

F с ( d з , h , Δ d ).

Ft ( ν , t ).

-

– transverse dimension of the product b ;

-

– product wall thickness δ;

-

– angle in the horizontal plane between the product and the laser beam direction α ;

F r ( b , δ , α ) .

Conclusion

According to the results of the conducted researches the following conclusions can be formulated:

-

– the technology of selection of printer parameters for SLM printing, which allows to obtain products with the necessary mechanical properties of the material, has been experimentally worked out;

-

– recommendations on control tests of products manufactured by 3D printing method have been developed;

-

– the properties of products manufactured by 3D printing method were investigated and the differences from the products manufactured by traditional methods were revealed;

-

– controlled parameters of SLM printing affecting the properties of the product material were systematized.

To implement new technology in production, it is necessary to study the influence of various factors on individual physical and mechanical properties of materials in the form of functional or statistical dependencies Fi ( F л, F с, Ft , Fr ). First of all, this applies to such characteristics of printers as the ability to control the laser parameters, shape and size of the printed product. This will make it possible to develop theoretical bases for new production technologies, significantly reducing the experimental development of the manufacturing technology for each new product [16-18].

Список литературы Parameters of rocket engine chambers, obtained by selective laser melting

- Kolpishon E. Y., Dubh A. V., Razumov N. G. et al. [Criteria for the application of additive technologies in energy and heavy engineering products]. Additivnye tehnologii. 2022, No. 3, P. 33–37 (In Russ.).

- Komarov V. A. [Design of power additive structures: theoretical foundations]. Ontologiya proektirovaniya. 2017. Vol. 7, No. 2(24), P. 191–206 (In Russ). Doi: 10.18287/2223-9537-2017-7-2-191-206.

- Zhigurova E. E., Mumber K. E., Kazakov R. A. et al. [Metalographic analysis of a camera made by 3D printing]. Reshetnevskie chteniya: materialy XXVI Mezhdunarodnoy nauchno-prakticheskoy konferencii [Reshetnev readings: materials of the XXVI International Scientific and Practical Conference]. Krasnoyarsk, 2022, Part 1, P. 175–177 (In Russ.).

- Smelov V. G., Sotov A. V., Agapovichev A. V. [Investigation of the structure and mechanical properties of products obtained by the SLS method from 316L steel powder]. Сhyornye metally. 2016, No. 9, P. 61–65 (In Russ.).

- Zhigurova E. E., Mumber K. E., Kazakov R. A. et al. [Analysis of the mechanical characteristics of the body material of a low-thrust rocket engine demonstrator camera made by 3D printing]. Reshetnevskie chteniya: materialy XXVI Mezhdunarodnoy nauchno-prakticheskoy konferencii [Reshetnev readings: materials of the XXVI International Scientific and Practical Conference]. Krasnoyarsk, 2022, Part 1, P. 172–174 (In Russ.).

- Gryaznov M. Yu., Shotin S. V., Chuvildeev V. N. [Physico-mechanical properties and structure of the Inconel 718 alloy obtained by the technology of layered laser fusion]. Vestnik Nizhegorodskogo universiteta im. N. I. Lobachevskogo. 2014, No. 4–1, P. 46–51 (In Russ.).

- Gu D. D., Meiners W., Wissenbach K., Poprawe R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. International Materials Reviews. 2012, No. 57 (3), P. 133–164.

- Lichtner A. C. [Practical study of shrinkage of 3D-printed ceramic parts made by DLP process]. Additivnye tehnologii. 2023, No. 2, P. 12–15 (In Russ.).

- Krasnova E. V., Saushkin B. P., Slyusar I. A., Smeyan S. V. [Electrochemical processing of additive manufacturing products from metals and alloys]. Additivnye tehnologii. 2023, No. 2, P. 49–57 (In Russ.).

- Zhao Chenhao, Qu Ningsong, Tang Xiaochuan. Removal of adhesive powders from additive manufactured internal surface via electrochemical machining with flexible cathode. Precision Engineering, 2021, Vol. 67, P. 438–452. Doi: 67.438-452.10.1016/j.precisioneng.2020.11.003.

- Nandwana P., Kirka M., Okello A., Dehoff R. Electron beam melting of Inconel 718: effects of processing and post-processing. Materials Science and Technology. 2018, Vol. 34, P. 1–8. Doi: 10.1080/02670836.2018.1424379.

- Mu Jierui, Sun Tengteng, Leung Chu Lun Alex et al. Application of electrochemical polishing in surface treatment of additively manufactured structures. Progress in Materials Science. 2023, Vol. 136, P. 103. Doi: 10.1016/j.pmatsci.2023.101109.

- Mulla Mahaboob Basha, Shaik Mahaboob Basha, Jain V. K., Sankar M. R. State of the art on chemical and electrochemical based finishing processes for additive manufactured features. Additive Manufacturing. 2022, Vol. 58. Doi: 10.1016/j.addma.2022.103028.

- An Linchao, Wang Dengyong, Zhu Di. Combined electrochemical and mechanical polishing of interior channels in parts made by additive manufacturing. Additive Manufacturing. 2022, Vol. 51. Doi: 102638.10.1016/j.addma.2022.102638.

- Sufriyanov V. Sh., Popovich A. A., Borisov E. V. [Influence of the thickness of the construction layer during selective laser melting of inconel 718 alloy on microstructure and properties]. Cvetnye metally. 2016, No. 1(877), P. 81–86 (In Russ.).

- Krasnova Е. V., Saushkin, B. P., Shandrov B. V. Pre-production engineering in additive manufacturing. Lecture Notes in Mechanical Engineering. Proceedings of the 7th International Conference on Industrial Engineering (ICIE 2021). 2021, Vol. 2. P. 261–268.

- Eugenov A. G., Korolev V. A., Shurtakov S. V. [Prospects for the development of highperformance modes of selective laser fusion of nickel-based heat-resistant alloys for the manufacture of gas turbine engine parts]. Additivnye tehnologii: nastoyashhee i budushhee: Sbornik dokladov III Mezhdunarodnoy konferencii [Additive technologies: Present and Future: Collection of reports of the III International Conference]. 2017, P. 23.

- Demchenko A. I., Maksimov A. A., Andreiko A. I., Marshov V. S. [Joint production of parts by 3D printing in Grankom LLC and TSAT JSC]. Additivnye tehnologii. 2022, No. 3, P. 8–10 (In Russ.).