Plasmotron for coating internal surfaces of component parts

Автор: А. E. Mikheev, A. V. Girn, I. O. Yakubovich, M. S. Rudenko

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.21, 2020 года.

Бесплатный доступ

Plasma spraying is one of technologically appropriate, productive and effective methods of applying protec-tive coatings to component parts produced by aerospace, metallurgical and other industries, objects exposed to high temperatures, dynamic loads, aggressive media, etc. Plasma spraying makes it possible to apply quite a va-riety of materials, such as metals, oxides, carbides, nitrides, etc. to different surfaces. Certain problems may arise, though, in applying protective coatings to the inner surfaces of cylinders and complex parts of small size (about 100 mm). These complexities depend on the dimensions of the plasma generator proper. There are no home-produced small-size plasma torches, they are all imported from other countries. That causes certain prob-lems with delivery, to say nothing of very high commercial price. One of the ways to improve the situation is to develop small-size plasmatrons capable of applying high-quality coatings to the internal surfaces of limited-size parts; that may significantly reduce expenses through import substitution. The effectiveness of the proposed device is in working out a method of applying high-quality coatings to the inner surfaces of orifices as small as 60 mm in diameter (operating a plasmatron of smaller size), as well as in significant cost reduction due to domestic production. Sample calculations show that the price of that plasma-tron type will not exceed 0.5 million rubles.

Plasmatron, plasma spraying, internal surface coating.

Короткий адрес: https://sciup.org/148321746

IDR: 148321746 | УДК: 621.793 | DOI: 10.31772/2587-6066-2020-21-2-274-278

Текст научной статьи Plasmotron for coating internal surfaces of component parts

Introduction In many industries, such as aerospace, metallurgy, oil production, etc., there are increasing requirements for reliability, durability and safety of products operated in extreme conditions (exposure to high temperatures, dynamic loads, aggressive media, etc.). These requirements create a demand for special protective coatings. One of the most effective methods of applying such coatings is plasma spraying, and the application of the method is growing from year to year [1–17]. The problems arising in application of protective coatings to the inner surfaces of cylinders and complex parts of small size (about 100 mm), refer to the dimensions of the plasma torches in use – there is not enough space for them in the sprayed area. Small-size plasma torches are not produced in Russia, they are all imported; that involves problems of shipment and delivery, of paying high commercial prices. One of the ways to avoid these problems is to develop home-produced small-size plasmatrons capable of applying high-quality coatings to the inner surfaces of limited-size parts – import substitution means considerably reduced prices.

The model currently used most widely is F1 plasma torch, intended for applying various high-quality coatings by the method of plasma-powder spraying to inner surfaces of orifices as small as 70 mm in diameter [18]. The manufacturer is “Innatech” company (Dinse – , АМТ – . The drawbacks of the plasmotron are the limited period of plasma torch operation (not more than 50 hours) and the unit’s high cost – more than 1.5 million rubles. This article presents a comparison of capacities demonstrated by the F1 plasma torch and the currently developed small-size plasmatron PM-2, capable of applying coatings to inner surfaces of orifices as small as 60 mm in diameter.

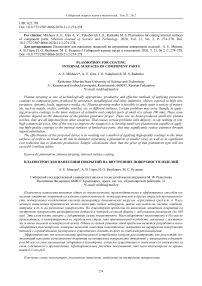

Experimental parameters. The proposed plasma torch make comprises coaxially and sequentially mounted cathode assembly, insulating bushing, anode assembly, working (plasma forming) gas and cooling water supply systems, injector for supplying powder under the nozzle edge. In the developed plasmatron design, the nozzle with the sealing gaskets is removed from the anode assembly; its function is overtaken by water-cooled anode assembly, into which a tungsten insert is pressed to increase the endurance of the nozzle. The cathode and anode assemblies have separate cooling systems. The cooling channels are formed by covers soldered to the cathode and anode assemblies – that eliminates the need for gaskets, which often wear out. These changes allow smaller dimensions of the plasma torch. The insulating bushing is installed between the cathode and anode assemblies, and these are held together with three screws in insulating cover.

Fig. 1 is the cross section view of the plasmotron construction.

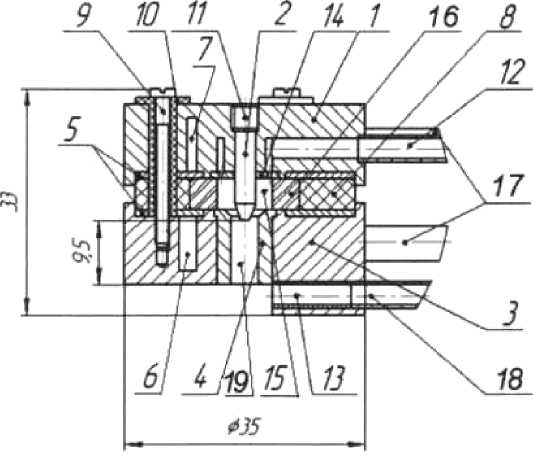

Fig. 2 is a 3D graphic presentation of the cathode 1 and anode 3 assemblies with cooling channels 6 and 7 .

The proposed plasmotron design comprises cathode assembly 1 with cathode 2 and anode assembly also performing the nozzle function 3 , into which a tungsten insert 4 is pressed to increase the endurance; covers 5 are soldered to the cathode and anode assemblies to form cooling channels 6 and 7 ; electrical insulator 8 separating the cathode assembly from the anode assembly; tungsten cathode 8 ; three screws 9 in insulating covers 10 to hold the cathode and anode assemblies together; plugs 11 for fixing the cathode; feeder 12 of the working (plasmaforming) gas to channel 13 in the cathode assembly body, to the gas distribution ring 14 installed at the entrance to discharge chamber 15 comprising cathode assembly 1 , ceramic ring 16 and anode assembly 3 (that provides uniform distribution of the gas inside); tubes 17 to feed cooling water to channels 6 and 7 ; injector 18 for feeding the spraying powder, and orifices 19 in insert 4 for the plasma jet.

Fig. 1. Plasmotron PM-2

Рис. 1. Плазмотрон ПМ-2

Fig. 2. Cathode and anode assemblies

Рис. 2. Катодный и анодный узел

Comparative characteristics of the plasmotrons

|

Parameter |

Plasmotron F1 (GTV) |

Plasmotron PM-2 |

|

Maximum power, kW |

25 |

20 |

|

Arc current, А |

Up to 500 |

Up to 400 |

|

Immersion length at spraying, mm |

500 |

600 |

|

Min diameter of the orifice for spraying, mm |

70 |

60 |

|

Max plasmotron overall size, mm |

50 |

35 |

|

Operation time at medium current, hr |

50 ≤ |

50 ≤ |

|

Type of cooling |

Water |

Water |

|

Technological powder |

Metal, composite, ceramic |

Metal, composite, ceramic |

The plasma torch works as follows: water is fed through cooling tubes 16 , plasma-forming gas is fed to tube 12 , and an electric arc is initiated between cathode 2 and tungsten insert 4 pressed into the anode assembly. The working (plasma-forming) gas is fed through the inlet channel 13 and gas distribution ring 14 into plasmotron discharge chamber 15 (fig. 1), formed by cathode assembly 1 , ceramic ring 16 and anode assembly 3 ; the gas gets ionizes and escapes through orifice 18 of insert 6 at high speed, producing a jet of plasma, into which the powder material is fed through injector 11 , mounted in anode assembly 3 .

In the developed design of the plasma torch (PM-2), the overall dimensions are minimized: 33 mm vertically, 35 mm in diameter. The plasma torch is capable of applying coatings inside smaller orifices (as small as 60 mm in diameter). The make allows to adjust the immersion length at spraying by installation of longer nozzles.

The operational parameters of two small-size plasmo-trons are compared in table.

Tests were carried out to check the adherence of coatings applied by the plasmatrons at their maximum power. The strength of the coating adhesion to the substrate was determined by pull-off method (adhesive binding, VK-9 glue) according to GOST (State standard specification) 209-75 with the use of Eurotest T-50 universal test machine. The obtained data showed that the adhesion strength of aluminum oxide coating applied to steel sam- ples by the experimental plasmotron PM-2 comes between 8 and 10 MPa, which is close to the results of plasmatron F1 (GTV) coating strength tests, showing 9-10.5 MPa. But the min diameter of the orifice for spraying allowed by plasmatron F1 is 70 mm – the limit determined by the overall plasmotron dimensions (see table).

Conclusion. The efficiency of the proposed plasmo-tron design is in the potential of applying high-quality coatings to the inner surfaces of orifices as small as 60 mm in diameter by reducing the overall dimensions of the plasma torch; the cost of the device can also be significantly reduced. Sample calculations show that the price of the plasmotron will not exceed 0.5 million rubles.

Список литературы Plasmotron for coating internal surfaces of component parts

- Khasuy A. Tekhnika napyleniya [Spraying technique]. Moscow, Mashinostroyeniye Publ., 1975, 288 p.

- Kudinov V. V. Plazmennye pokrytiya [Plasma coatings]. Moscow, Nauka Publ., 1977, 270 p.

- Kudinov V. V, Ivanov V. M. Naneseniye plazmoy tugoplavkikh pokrytiy [Plasma application of refractory coatings]. Moscow, Mashinostroyeniye Publ., 1981, 212 p.

- Borisov Yu. S., KHarlamov Yu. A., Sidorenko S. L., Ardatovskaya E. N. Gazotermicheskiyye pokrytiya iz poroshkovykh materialov: Spravochnik [Gasothermic coating with powder materials: Reference book]. Kiev, Naukova dumka Publ., 1987, 544 p.

- Kopylov V. I, Shatinskiy V. F. [Investigation of processes in plasma spraying contact zone and estimation of their parameters]. Neorganicheskiye i organosilikatnyye pokrytiya. 1975, P. 96– 106 (In Russ.).

- Puzryakov A. F. Teoreticheskiyye osnovy tekhnologii plazmennogo napyleniya [Theoretical Foundations of the Technology of Plasma Sputtering]. Moscow, MGTU im. N. E. Baumana Publ., 2008, 235 p.

- Kharlamov Yu. A. [Factors influencing the adhesion strength of gas-thermal coatings]. Zashchitnye pokrytiya na metallakh. 1988, No. 22, P. 30–34 (In Russ.).

- Polak L. S., Surov N. S. [Investigation of the interaction of powder particles with plasma flow in the nozzle]. Fizika i khimiya obrabotki materialov. 1969, No. 2, P. 19–29 (In Russ.).

- Mikheev A. E., Kolmykov V. A. Povysheniye ekspluatatsionnykh kharakteristik poverkhnostey elementov konstruktsiy letatel 'nykh apparatov. Avtomatizatsiya protsessov obrabotki [Upgrading of operational characteristics of aircraft components’ surfaces. Automation of treatment processes]. Moscow, MAKS Press Publ., 2002, 224 p.

- Mikheev A. E., Statsura V. V., Nikushkin N. V. [Equipment for high-quality gas-thermal coating application]. III otraslevaya nauchno-tekhnicheskaya konferentsiya “Primeneniyye gazotermicheskikh pokrytiy v mashinostroyyenii” [III Industry science and technology conference “Application of gas-thermal coatings in mechanical engineering”]. Moscow, 1990, P. 84–87 (In Russ.).

- Mikheyev A. E., Statsura V. V., Ivasev S. S., Gim A. V. [Processing of refractory oxides in low-temperature plasma]. Sb. nauchnykh trudov Vserossiyskoy nauchno-tekhnicheskoy konferentsii “Materialy i tekhnologii XXI veka“ [Proceedings of Russian science and technical conference “Materials and technologies of the XXI century“]. Penza, 2001, P. 123–125 (In Russ.).

- Donskoy A. V., Klubnikin V. S. Elektroplazmennyyye protsessy i ustanovki v mashinostroyenii [Electroplasma processes and equipment in mechanical engineering], Leningrad, Mashinostroyyeniye Publ., 1979, 221 p.

- Zhukov M. F., Smolyakov V. Ya, Uryukov B. A. Elektrodugovye nagrevateli gaza (plazmotrony) [Electric arc gas heaters (plasmatrons)]. Moscow, Nauka Publ., 1973, 232 p.

- Yavleniya perenosa v nizkotemperaturno-y plazme [Transference phenomena in low- temperature plasma]. Ed. A.V. Lykova et al. Minsk, Nauka i tekhnika Publ., 1969, 248 p.

- Saunin V. N. Elektrodugovoy plazmotron Saunina [Saunin electric arc plasmatron]. Patent RF, No. 2276840, 2006.

- Ivanchenko A. F., Lavrinenko M. Z., Mel'nik B. I., Prisevok A. F., Sannikov V. A., Solovey A. I., Fedo-

- rtsev V. A. Sposob naneseniya pokrytiy na vnutrennie poverkhnosti tsilindricheskikh izdeliy i ustroystvo dlya ego osushchestvleniya [Method of coating inner surfaces of cylinders and device for the coating application]. Patent No. 2009027, 1994.

- BY 8930 U 2013.02.28 Plasmatron for coating internal surfaces of component parts.

- FI plasma torch of innatech.ru (manufacturers: Dinse – www.dinse.eu, AMT www.amt-ag.net).