Получение игольчатого кокса из нефтяного и угольного сырья

Автор: Обухова А. В., Кузнецова Л. И., Каменский Е. С., Кузнецов П. Н., Авид Б.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 6 т.17, 2024 года.

Бесплатный доступ

Игольчатый кокс, углеродный продукт с уникальными физическими свойствами, используется для получения широкого спектра графитовых материалов для важнейших областей техники и технологии. Промышленное производство игольчатого кокса основано на замедленном коксовании полиароматического сырья, локализовано в ограниченном числе стран (в основном в Китае, США, Японии, Корее). В России потребности в игольчатом коксе для динамично развивающихся отраслей промышленности обеспечиваются исключительно посредством импорта. В статье рассмотрены химико-технологические основы формирования игольчатого кокса из нефтяного и угольного сырья, влияние компонентного состава сырья и параметров стадий карбонизации на его качество. Представлен краткий обзор методов получения игольчатого кокса, видов традиционного сырья, используемых для его получения. Приведены данные о способах модифицирования традиционного сырья и возможности использования альтернативных источников, что позволит расширить сырьевую базу для производства игольчатого кокса и повысить его качество.

Замедленное коксование, игольчатый кокс, нефтяной кокс, угольный кокс, ароматические вещества, мезофаза

Короткий адрес: https://sciup.org/146282906

IDR: 146282906 | УДК: 665.777.4:662.749.2

Текст научной статьи Получение игольчатого кокса из нефтяного и угольного сырья

Цитирование: Обухова А. В. Получение игольчатого кокса из нефтяного и угольного сырья / А. В. Обухова, Л. И. Кузнецова, Е. С. Каменский, П. Н. Кузнецов, Б. Авид // Журн. Сиб. федер. ун-та. Техника и технологии, 2024, 17(6). С. 688–711. EDN: BBGDAM

Рис. 1. Внешний вид игольчатого кокса

Fig. 1. Appearance of needle coke его незаменимым при производстве сверхмощных графитированных электродов, которые работают при высокой плотности тока [2]. Он используется также при производстве высококачественного графита, суперконденсаторов, литий-ионных аккумуляторов [3–5].

Большая часть потребления игольчатого кокса (в 2022 г. 75 % [6]) приходится на сегмент графитированных электродов, необходимых для производства высокосортных марок стали в электродуговых сталеплавильных печах. По этой технологии выплавляется свыше 30 % всех производимых сталей [7]. Электродуговой способ плавки прогрессирует во всем мире, в том числе в России, благодаря благоприятным экологическим характеристикам и высокому качеству стали. После предварительной подготовки игольчатый кокс можно использовать также как материал с развитой поверхностью и высокими ёмкостными характеристиками [8].

Важными показателями свойств игольчатого кокса являются коэффициент линейного термического расширения КЛТР, плотность, микроструктура, содержание микропримесей, серы, зольность. Величина КЛТР является показателем качества ИК, характеризующим его способность рассеивать энергию теплового удара при пиковых нагрузках по электрическому току и за счет этого снимать механические напряжения без физической деформации и нарушения структуры. Игольчатый кокс производится трех марок – суперпремиум, премиум и промежуточный. Нормируемые значения показателей качества кокса разных марок приведены в табл. 1 [9].

Мировое производство ИК непрерывно увеличивается. При этом его рынок является высококонцентрированным с неразвитой конкуренцией, основные производственные мощности сосредоточены в ограниченном числе стран [10, 11]: в США (общее производство в 2021 г. более 600 тыс. т), в Японии (4 компании с общим производством 355 тыс. т), Корее (63 тыс. т) и с недавнего времени в Китае (31 компания с общим производством более 760 тыс. т в 2021 г.). Ограниченное предложение на рынке и направленная промышленная политика в Китае привели в последние годы к быстрому развитию производства ИК. Производственные мощности по его получению на основе каменноугольной смолы к 2021 г. достигли 1000 тыс. т в год, объем производства составлял 261 тыс. т; мощности производства на нефтяной основе составляли 1180 тыс. т в год, а объем производства 501 тыс.т. В настоящее время Китай является крупнейшим производителем ИК (44 % от всего мирового производства) [7]. В качестве сырья в Китае, Японии – 690 –

Таблица 1. Показатели качества игольчатого кокса и электродного кокса [9]

Table 1. Requirements for quality indicators of needle coke and electrode coke [9]

Российская Федерация является одним из мировых лидеров по производству стали (четвертое–пятое места), в том числе около 35 % выплавляется в электродуговых печах с углеграфитовыми электродами, которые получают из импортного ИК. Ежегодная потребность в игольчатом коксе (около 100 тыс. т [7]) полностью обеспечивается по импорту. В промышленном масштабе он не производится, хотя опытные работы проводились еще в 1980–х гг. на Красноводском (Туркмения) и Ново–Уфимском нефтеперерабатывающих заводах [12]. В настоящее время активные работы по созданию технологии производства ИК ведутся в Уфимском государственном нефтяном техническом университете, Институте нефтехимпереработки Республики Башкортостан [7], Санкт-Петербургском горном университете [13], в Институте углехимии и химического матераловедения под руководством Исмагилова [14]. По результатам опытно–промышленных пробегов была обоснована возможность создания промышленного производства ИК из отечественного сырья с удовлетворительными эксплуатационными показателями [15, 16]. На Омском НПЗ заканчивается реконструкция установки замедленного коксования (УЗК) для получения ИК по проекту БашНИИ21–10/3М с участием Санкт-Петербургского технологического института и ООО «Газпромнефть» [15, 17]. После запуска установки ежегодно будет производиться около 38,7 тыс. т ИК с выходом около 26 % на сырье. Получаемый кокс полностью соответствует требованиям ГОСТ Р70540–2022 с показателем структуры 5.5 баллов. Планируется также создание промышленной установки на предприятиях Республики Башкортостан мощностью 16 тыс. т ИК в год с выходом по сырью около 20 % [17]. Существующие потребности в ИК на российском рынке составляют от 100 до 150 тыс.т. Поэтому, несмотря на планы по созданию промышленных установок, в ближайшей перспективе импорт игольчатого кокса не только сохранится, но и увеличится из-за возрастающих потребностей.

В настоящей статье представлен краткий обзор состояния проблемы получения игольчатого кокса в России и в мире, типов используемого сырья, химико–технологических основ формирования структуры, влияния состава сырья и технологических параметров процесса на его свойства, рассмотрены подходы к поиску новых источников сырья для получения этого стратегически важного углеродного материала.

Химико-технологические основы формирования игольчатого кокса

В настоящее время производство игольчатого кокса базируется на использовании в качестве сырья нефтяных остатков и каменноугольной смолы [7, 12–15]. В основе технологии лежит сложный процесс замедленного коксования. При термическом разложении тяжелого углеводородного ароматического сырья протекают множество последовательных и параллельных реакций, таких как крекинг, деалкилирование, дегидрирование, поликонденсация. В результате образуются летучие вещества, более легкие, чем исходное сырье, и углеродистые продукты – полукокс или кокс.

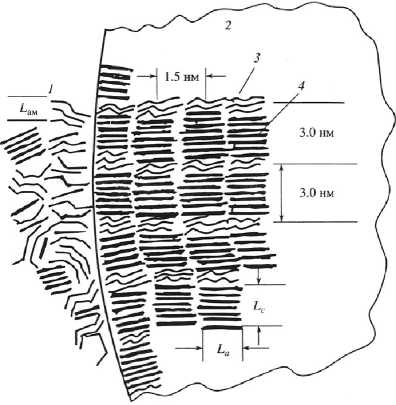

В 1965 г. Тейлор и Брукс [18] впервые показали, что при крекинге каменноугольных и нефтяных пеков в жидкофазной реакционной среде образуется особая промежуточная фаза (мезофаза), которая имеет определенную структурную упорядоченность и подвижность [18, 19]. Такие мезофазные образования в пеках рассматриваются как нематические жидкие кристаллы, состоящие из упакованных в пакеты параллельно друг другу плоских поликонденсированных ароматических молекул (рис. 2).

При получении игольчатого кокса из тяжелого ароматического сырья реализуется следующая схема превращений: пековое сырье → мезофазный пек → зеленый (низкотемпературный) игольчатый кокс → прокаленный (высокотемпературный) игольчатый кокс . В процессе карбонизации можно выделить две основные стадии, ответственные за образование кокса игольча-

Рис. 2. Схематичное изображение мезофазной частицы в пеке [22]: 1 – изотропная фаза; 2 – фрагмент мезофазной частицы; 3 – аморфная фаза; 4 – кристаллиты

Fig. 2. The schematic representation of a mesophase particle in pitch 1 – isotropic phase; 2 – fragment of a mesophase particle; 3 – amorphous phase; 4 – crystallites той структуры. Во-первых, это образование объемной мезофазы низкой вязкости в результате зарождения, роста и слияния мезофазных сфер. Второй этап – одноосная перестройка объемной мезофазы в потоке выделяющихся газов (летучих веществ) [20, 21]. На стадии затвердевания насыщенные соединения становятся источником газовыделения, способствующего пере-упорядочиванию молекул в направлении потока.

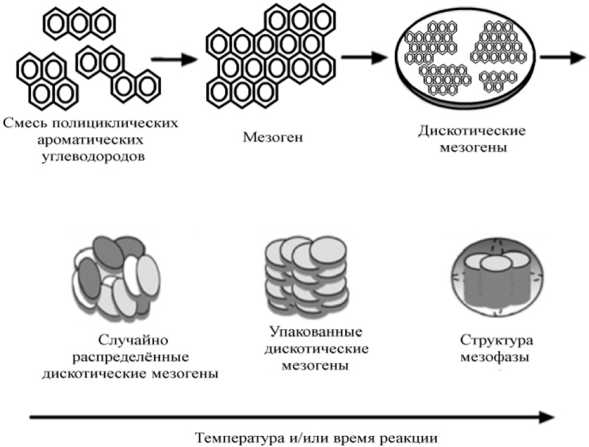

Для реализации последовательности этих превращений необходимы специфичный состав сырья и строго контролируемые условия замедленного коксования, которые обеспечивают формирование мезофазы с анизотропной текстурой. Эволюция аморфной оптически изотропной реакционной массы пеков с переходом в мезофазное состояние при нагревании происходит в несколько стадий, которые ещё сравнительно мало изучены. При нагревании происходит дифференциация структурных фрагментов ароматического сырья, плоские поликонденсиро-ванные ароматические молекулы упорядочиваются в пакеты, образуя в аморфной матрице новую микрофазу (турбостратные двумерные кристаллиты [22]). Стадия зарождения мезофазы начинается в температурной области 350 °С и выше, когда в оптически изотропной среде уже образовалось значительное количество “кристаллической” микрофазы. Образование кристаллических зародышей протекает с меньшей энергией активации (75–135 кДж/моль) и скоростью по сравнению с формированием мезофазы (>200 кДж/моль). Формирование мезофазных структур можно рассматривать как вторичное надмолекулярное упорядочение образовавшихся кристаллических зародышей, при этом между ними сохраняется некоторая прослойка частиц аморфной среды. Схематичное изображение формирования мезофазы показано на рис 3.

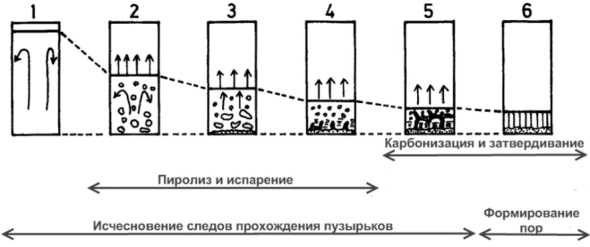

Образование мезофазы и её последующая трансформация являются неотъемлемыми этапами при формировании ИК и определяются как молекулярным составом сырья, так и условиями процесса карбонизации. В работе [21] приведена схема превращения тяжёлого газойля каталитического крекинга в игольчатый кокс в трубчатом реакторе. Процесс формирования игольчатого кокса описан шестью стадиями (рис. 4):

Рис. 3. Предполагаемая схема формирования мезофазы [22, 23, 24]

Fig. 3. The proposed scheme of mesophase formation [22, 23, 24]

Рис. 4. Схема процесса формирования игольчатого кокса из декантойля [21]

Fig. 4. The process formation of needle coke from decantoil [21]

-

1. Выделение лёгкой фракции, объём тяжелой фракции, которая подвергается карбонизации, уменьшается примерно на половину в первые 15 мин.

-

2. Формирование мезофазных сфер, которые начинают увеличиваться в диаметре, и одновременно может начинаться их слияние, при этом продолжается выделение лёгкой фракции и уменьшение объёма сырья, подвергающегося карбонизации.

-

3. Рост мезофазных сфер; начинает формироваться объёмная мезофаза в нижней части реактора, в то время как в верхней части реактора преобладают сферы разного диаметра. В донной части формируется тонкий слой, имеющий мозаичную текстуру.

-

4. Текстуры больших доменов, ориентированные примерно параллельно поверхности дна реактора, осаждаются поверх слоя мозаичной текстуры, в то время как изотропные области, содержащие большое количество мезофазных сфер, все еще остаются в верхней части. На этом этапе происходит коалесценция мезофазных сфер и формируется объёмная мезофаза.

-

5. Рост объёмной мезофазы; начинается перегруппировка текстуры домена в параллельную оси реактора. Отмечено, что домены объемной мезофазы врастают в изотропную матрицу. Вязкость мезофазы на этом этапе постепенно увеличивается.

-

6. Выделение большого количества газа (летучих веществ), подъем пузырьков приводят к перестройке мезофазы в текстуру восходящего потока. Текстура потока, параллельная оси реактора, начинает преобладать во всем реакционном объеме перед затвердеванием. При затвердевании образуется игольчатый кокс.

Ключевыми этапами формирования игольчатого кокса являются зарождение и развитие объемной мезофазы и выделение газа, сопровождаемые перестройкой объемной мезофазы и её затвердеванием. Такая трансформация обеспечивает трехмерную структуру кокса, которая определяет его структурные изменения на стадии обжига и физико–химические характеристики готового продукта.

Фракции, направляемые на процесс замедленного коксования, должны иметь определённый углеводородный состав. Присутствие в сырье ароматических соединений способствует формированию мезофазы с низкой вязкостью, что обеспечивает благоприятные условия для диффузии мезофазных сфер, последующего их слияния и роста. Для формирования анизотропной структуры наиболее благоприятны тетра– и трициклические ароматические соединения с короткими боковыми заместителями [25, 26]. Они содействуют формированию жидкокри-– 694 – сталлической фазы – мезофазы, образование и рост которой в дисперсионной среде является предпосылкой будущей упорядоченной (в идеале игольчатой) структуры кокса.

Нафтеновые углеводороды оказывают благоприятное влияние на развитие мезофазы [27, 28] вследствие их способности донировать водород, который, стабилизируя радикальные частицы, препятствует их рекомбинации. В результате сохраняется низкая вязкость реакционной массы, что способствует диффузии и слиянию частиц мезофазы [29].

Во многих работах [30–32] установлено отрицательное влияние асфальтенов в сырье на формирование мезофазы. В статье [30] показано, что с увеличением доли асфальтенов от 0 до 3 мас.% объемная доля мезофазы в получаемых пеках уменьшалась, а доля мозаичной структуры увеличивалась.

Олефиновые углеводороды являются реакционноспособными компонентами, при нагревании они легко вступают в реакции, увеличивают долю высокомолекулярных углеводородов и общую вязкость системы, что затрудняет слияние мезофазных сфер [30]. При содержании олефинов в сырье 3–5 масс.% образующийся кокс имеет крупнозернистую или мелкозернистую мозаичную текстуру [33].

Насыщенные соединения в виде парафинов с прямыми цепями, а также длинные алкильные заместители ароматических молекул в условиях коксования подвергаются деструкции, летучие продукты деструкции формируют в реакционной массе направленный поток, который способствует одноосной перестройке объемной мезофазы на стадии затвердевания [34]. По данным [27], оптимальное соотношение насыщенных длинноцепочечных углеводородов к ароматическим составляет 5 к 100. При увеличении содержания парафиновых молекул возрастает разница в молекулярной массе компонентов сырья, что может приводить к разделению фаз и образованию углеродного материала с мозаичной структурой.

В работах [35, 36] рассматривают влияние хинолин-нерастворимых веществ (α 1 –фракции) на формирование мезофазы. При формировании кокса эти компоненты образуют изотропные включения. Более того, они увеличивают вязкость среды, что неблагоприятно для развития мезофазы. В работе [37] исследовали влияние α1–фракции на формирование мезофазы при карбонизации каменноугольного пека. Установлено, что в каменноугольном пеке, очищенном от α1–фракции, общая частота генерации сфер увеличивается в пять раз, скорость слияния снижается на порядок, линейная скорость роста уменьшается в 2 раза.

Нежелательными компонентами сырья для производства игольчатого кокса являются примеси соединений серы, ванадия и никеля. Повышенное содержание серы в игольчатом коксе, используемом для изготовления электродов, может приводить к растрескиванию электрода в условиях работы при высоких температурах из-за разрыва C-S связей. Это ставит под угрозу целостность электрода и режим его работы [38, 39]. Присутствие примесей соединений ванадия и никеля приводит к ухудшению теплофизических характеристик электродов. Кроме того, ванадий и никель (особенно в присутствии натрия) являются катализаторами реакций окисления углерода кислородом, тем самым они увеличивают расход анода при электролизе. В высококачественном ИК содержание серы не должно превышать 0.6 %, ванадия и никеля не более 10 ppm [27].

Таким образом, для получения высокого выхода кокса определенной заданной структуры, обеспечивающей хорошие механические, тепловые и другие физические свойства, требуемые – 695 – в соответствующей области применения, необходимо иметь не только высокую ароматичность сырья для коксования, но и определенные молекулярно-структурные параметры ароматических углеводородов и минимальное содержание гетероатомных соединений, карбоидов, минеральных примесей.

Методы подготовки сырья, влияющие на структурные свойства игольчатого кокса

Эффективным способом подготовки сырья для процесса коксования является предварительная термическая обработка [40–42]. В работе [43] показано, что термическая выдержка вакуумного остатка мазута приводит к снижению доли реакционноспособных компонентов и повышению стабильности. Нагревание сырья при температуре 400 °C в течение 45 мин при давлении 0,2 МПа приводило к уменьшению вязкости, увеличению доли ароматических соединений с 3–5 кольцами, а также уменьшению длины алкильных заместителей. Такая подготовка сырья благоприятно сказывается на образовании кокса анизотропной структуры [44].

В работах [36, 41, 45, 46] подготовка сырья была направлена на удаление сернистых соединений с применением гидроочистки, вакуумной дистилляции и экстракции растворителем. Гидроочистку осуществляли с применением алюмокобальтмолибденового катализатора [45]. Удаление механических примесей и хинолин-нерастворимых веществ осуществляли методами фильтрации, экстракции, гравитационного осаждения растворителем и центрифугированием [54]. Асфальтены удаляли методом сольвентной деасфальтизации [46].

Одним из наиболее эффективных методов подготовки сырья для производства ИК является его модифицирование различными добавками, содержащими мезогенные компоненты, каталитически активные соединения, другие вещества, способствующие формированию мезофазы [46–49]. В качестве доноров мезогенных компонентов используют полимеры и индивидуальные органические соединения. Эффективными донорами мезогенных компонентов могут служить также полистирол, полиэтилентерефталат [47–49], полиакриловая кислота [49].

Авторы [7] получали игольчатый кокс с использованием в качестве сырья нефтяного де-кантойля с добавлением небольшого количества термопластичного полимера ароматического ряда в качестве модификатора. После коксования полученные образцы прокаливали при 1250– 1300 °С. С применением физических методов были изучены особенности структурных свойств полученных образцов. Результаты анализа методами рентгеновской дифракции и оптической микроскопии приведены в табл. 2. Видно, что в сформированных пачках содержится от 10 до 12 слоев-ламелей. Диаметр пакетов значительно превышает их толщину, что характерно для структуры игольчатого кокса. В целом размеры областей когерентного рассеяния и межплоскостные расстояния типичны для кокса игольчатой структуры. Наиболее качественные высокоструктурированные образцы по показателю текстуры и кристаллической структуры получены при использовании добавки полимерного модификатора в количестве 5–10 %.

В работе [50] использовали бензоилхлорид в качестве модификатора и катализатора для модифицирования свойств каменноугольного пека. Авторы [51] применяли добавки оксидов никеля и кобальта, в результате в готовом продукте увеличивалось соотношение C/H, что указывает на образование более конденсированных структур и уменьшение доли длинных алкильных цепей [52].

Таблица 2. Показатели структурных свойств образцов кокса, полученных при коксовании декантойля в качестве сырья с добавками полимерного модификатора [7]

Table 2. Structural property indices of coke samples obtained by coking decantoil as a raw material with additives of a polymer modifier [7]

|

Показатель |

Количество модификатора, мас.% 0 2,5 5 10 15 |

|

Межплоскостное расстояние, d002, Å Толщина пачки, Lc, Å Диаметр пачки, L a , Å Число слоев в пачке |

3,48 3,48 3,49 3,51 3,49 36,03 36,19 33,33 34,03 36,68 78,44 77,35 82,82 88,76 78,06 11,3 11,4 10,5 10,7 11,5 |

|

Отношение L a /L c |

2,22 2,22 2,50 2,63 2,17 |

|

Балл микроструктуры |

5,40 5,70 6,10 6,15 5,70 |

Модификаторы структуры кокса могут вводиться на стадиях обжига сырого кокса. В качестве таких добавок могут применяться оксид железа, соли щелочных металлов натрия, калия, лития и алюминиевый порошок [53, 54]. Как правило, такие модификаторы обеспечивают улучшенные электротермические свойства продукта за счет внедрения в структуру углеродного материала или образования слоя на его поверхности.

Одним из вариантов улучшения качества получаемого игольчатого кокса является совместная карбонизация различных углеводородных фракций, которые при раздельном использовании малопригодны для получения ИК. В работе [55] при добавлении тяжёлой смолы пиролиза (содержащей значительное количество реакционноспособных ненасыщенных углеводородов) в каменноугольный пек наблюдали уменьшение скорости карбонизации, что способствовало образованию и развитию мезофазы. По данным [56], модифицирование нефтяного вакуумного остатка добавками тяжёлого газойля каталитического крекинга приводило к уменьшению реакционной способности сырья, скорости карбонизации и оказывало положительное влияние на развитие мезофазы.

Технологии и сырье для получения игольчатого кокса

Для производства анизотропного (в идеале игольчатого) кокса необходимо использовать только специально подготовленное сырье – малосернистое, с низким содержанием металлов, высокоароматизованное с определенной структурой ароматических углеводородов, которые должны содержать конденсированные циклы с короткими боковыми заместителями [57].

Получение игольчатого кокса из нефтяного сырья

Промышленным нефтяным сырьем для получения игольчатого кокса методом замедленного коксования обычно служат остаточные фракции первичных и вторичных процессов переработки нефти и нефтяных фракций: дистиллятные крекинг-остатки, тяжелые газойли каталитического крекинга, смолы пиролизного производства олефинов. Типичные характеристики их состава и свойств приведены в табл. 3. Процесс осуществляют на установках замедленного коксования (УЗК) с получением целевого продукта кокса, а также побочных дистиллятных светлых фракций и газа [58, 59]. Важной особенностью процесса замедленного коксования яв- – 697 –

Таблица 3. Типовые показатели состава и свойств тяжелых нефтяных остаточных фракций, используемых при получении игольчатого кокса [16]

Table 3. Typical indicators of the composition and properties of heavy petroleum residual fractions used in the production of needle coke [16]

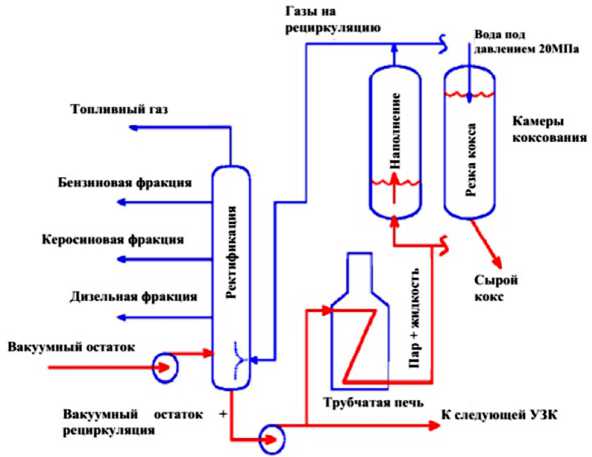

При получении игольчатого кокса параметры работы УЗК существенно отличаются от традиционной технологии замедленного коксования: i) величиной давления, ii) кратностью рециркуляции (Кр), iii) продолжительностью коксования и iiii) использованием более качественного сырья. Предварительно нагретое до высокой температуры (480–520 °C) сырье закачивается в необогреваемые реакторы, где проводится коксование за счет аккумулированного сырьем тепла. Процесс осуществляется под давлением (0,3–0,5 МПа). В состав одной УЗК входят две необогреваемые камеры коксования, ректификационная колонна, трубчатая печь, насосы, вспомогательное оборудование (рис. 5) [60, 61].

Камеры коксования работают поочередно: одна камера заполняется сырьем, вторая – разгружается и чистится. Таким образом, камеры работают периодически, а трубчатая печь и ректификационная колонна непрерывно. В процессе замедленного коксования получают сырой кокс, который перед вовлечением в дальнейшее производство проходит прокаливание при 1100–1300 °C в восстановительной атмосфере, в результате чего из него удаляется влага, летучие вещества, происходит усадка и уплотнение структуры, формируется кристаллическая решетка, значительно повышается тепло- и электропроводность.

Авторы [60] приводят следующие условия получения игольчатого кокса на установке УЗК из дистиллятного крекинг-остатка: температура сырья на выходе из печи 507 °С, давление в реакторе 0,35 МПа, коэффициент рециркуляции К р 2,08. Отмечается, что высокие значения К р – 698 –

Рис. 5. Технологическая схема процесса замедленного коксования [60, 61]

Fig. 5. Diagram of the delayed coking process [60, 61]

улучшают структуру кокса и повышают его выход на первичное сырье. Важной особенностью режима работы УЗК при получении игольчатого кокса является значительное удлинение цикла коксования (до 36 ч, вместо 24 ч при традиционном коксовании). Повышение давления коксования позволяет более полно использовать потенциал коксообразующих компонентов, приводит к существенному увеличению выхода кокса [23]. При повышенном давлении замедляется испарение компонентов сырья, что увеличивает их концентрацию в жидкой фазе, где они вовлекаются в процесс жидкофазного коксования. По данным [62], повышение давления от 0,1 до 0,6 МПа увеличивает выход кокса на 35–40 %. Увеличение температуры коксования приводит к уменьшению выхода кокса и росту выхода дистиллята [23]. На основе анализа литературных данных авторы [20] привели требования по составу нефтяного сырья, обеспечивающие формирование игольчатого кокса (табл. 4).

Варианты технологических схем подготовки нефтяного сырья для обеспечения требуемых свойств при получении игольчатого кокса представлены ниже [60, 61]:

-

I. Термический крекинг дистиллятов малосернистых нефтей – замедленное коксование крекинг-остатка.

-

II. Гидроочистка вакуумного газойля сернистых нефтей – термический крекинг – замедленное коксование крекинг-остатка.

-

III. Смешение дистиллятного крекинг-остатка со смолой пиролиза – замедленное коксование смеси.

-

IV. Смешение дистиллятного крекинг-остатка с газойлем каталитического крекинга – замедленное коксование смеси.

-

V. Смешение газойля каталитического крекинга со смолой пиролиза – замедленное коксование смеси.

Таблица 4. Параметры нефтяного сырья, обеспечивающие образование ИК [20]

Table 4. Parameters of petroleum feedstock that ensure the formation of NC [20]

|

Параметры |

Значение |

|

1. Групповой состав: |

|

|

Насыщенные, мас.%, в т.ч. |

8,0–28,0 |

|

нафтеновые |

*80,0–85,0 |

|

парафиновые |

*15–20 |

|

Ароматические вещества |

61,4–86,0 |

|

Асфальтены |

не более 3 мас.%. |

|

Смолы |

1,0–13,9 %мас. |

|

Олефины |

1–2 мас.% |

|

2. Содержание золы |

0,0013–0,018 мас.% |

|

3. Содержание серы |

не более 0,7 мас.%. |

|

4. Содержание ванадия |

не более 10 ppm |

– процент от общей доли насыщенных углеводородов.

С конца 1960-х гг. отечественными специалистами ведущих институтов по нефтепереработке (ВНИИНП, БашНИИ НП, УНИ), а также в области электродной промышленности (ГосНИИЭП, НИИГрафит) проводились исследования по разработке теоретических основ получения и применения ИК из нефтяного сырья, отрабатывались технологические схемы производства кокса [16]. Были получены опытные партии ИК (до 20 тыс. т) и графитированных электродов, проведены их испытания на электрометаллургических предприятиях с положительными результатами. По проекту ООО «Газпром нефтехим Салават» в качестве сырья использовали смесь тяжелой смолы пиролиза и тяжелого газойля каталитического крекинга. Получены ИК с выходом около 20 %, бензиновая фракция (около 19.2 %), газойлевая фракция (34,5 %) и газ (25 %) (табл. 5). В 2015–2021 гг. опытно-промышленные испытания проводились ПАО «Газпромнефть». При коксовании утяжеленного газойля каталитического крекинга выход ИК при коэффициенте рециркуляции Кр=1.9 составлял 26,3 % [62].

Вместе с тем проблема создания отечественных мощностей по промышленному производству ИК, остро необходимого в первую очередь для производства графитированных электродов для прогрессивно развивающегося в России производства стали и других применений, пока не решена. В рамках опытно-промышленных пробегов его получают только из низкосернистого тяжелого газойля каталитического крекинга.

Получение игольчатого кокса из угольного сырья

Базовым угольным сырьем, который используется для получения ИК, служит каменноугольная смола, которая в качестве побочного продукта в небольшом количестве (не более 4–5 %) образуется в процессе высокотемпературного коксования каменных углей. Целевым продуктом этого процесса является металлургический кокс, который незаменим в технологии доменной плавки чугуна. На первой промышленной установке получения ИК в Японии ис- – 700 –

Таблица 5. Материальный баланс процесса получения игольчатого кокса по технологии ООО «Газпром нефтехим Салават» мощностью 16 тыс.т кокса в год [16]

Table 5. Material balance of the process of obtaining needle coke using the technology of Gazpromneftekhim Salavat LLC with a capacity of 16 thousand tons of coke per year [16]

Каменноугольная смола является уникальным, не имеющим аналогов сырьевым источником, покрывающим в настоящее время более 95 % мировой потребности в конденсированных ароматических и гетероциклических соединениях. Смола имеет сложную физико-химическую природу, характеризуется широким температурным интервалом кипения [64, 65]. Выход дистиллятных фракций обычно составляет около 50 % и столько же нелетучего остатка – пека. Из дистиллятных фракций преобладает высокотемпературная антраценовая с температурами

Таблица 6. Типовые показатели химического состава каменноугольной смолы [64]

Table 6. Typical indicators of the chemical composition of coal tar [64]

Являясь продуктом глубокого термического разложения органической массы угля, смола состоит из термодинамически наиболее стабильных соединений разных классов, преимущественно поликонденсированных ароматических углеводородов, а также гетероциклических соединений. Содержание парафиновых и циклопарафиновых углеводородов и ароматических углеводородов с длинными алкильными заместителями невелико. Сравнительно мало также соединений с функциональными группами, в частности фенолов. Типичные содержания основных индивидуальных компонентов в каменноугольных смолах приведены в табл. 7.

Для коксования чаще всего используют остаток перегонки каменноугольной смолы – каменноугольный пек. В качестве сырья для получения ИК можно использовать также смолу полукоксования и продукты технологической переработки смол коксования и полукоксования. Авторы [37, 49, 52, 66] изучали влияние состава каменноугольного пека и смесей на его основе на процесс формирования и качество ИК. Было установлено, что для получения кокса игольчатой структуры степень ароматичности сырья должна находиться в диапазоне от 0,95 до 0,98. По данным [20], каменноугольный пек должен отвечать показателям, приведенным в табл. 8.

Таблица 7. Типичное содержание основных компонентов в каменноугольной смоле [64, 65]

Table 7. Typical content of the main components in coal tar [64, 65]

|

Компоненты, мас.% |

0 кип , |

Содержание, мас.% |

|

Бензол |

80 |

0,1–0,3 |

|

Толуол |

111 |

0,1–0,2 |

|

Фенол |

182 |

0,35–0,4 |

|

о -Крезол |

191 |

0,1–0,2 |

|

Инден |

183 |

1–1,2 |

|

Нафталин |

218 |

8–12 |

|

Хинолин |

237 |

1,0–1,2 |

|

Метилнафталины |

241 |

1,8–2,5 |

|

Аценафтен |

279 |

1–2 |

|

Флуорен |

294 |

1–1,8 |

|

Дибензофуран |

287 |

1,1–1,3 |

|

Антрацен |

340 |

1–1,8 |

|

Фенантрен |

338 |

4–5 |

|

Карбазол |

355 |

1,2–1,5 |

|

Флуорантен |

382 |

1,6–3 |

|

Пирен |

393 |

1–2 |

|

Хризен |

448 |

0,4–2 |

|

Пицен |

519 |

1,3–2,2 |

|

Бензфлуорантен |

481 |

2,2–2,5 |

|

Коронен |

525 |

0,3–1,1 |

Таблица 8. Параметры каменноугольного пека, обеспечивающие образование ИК [20]

Table 8. Parameters of coal tar pitch that ensure the formation of NC [20]

|

Параметры |

Значение |

|

0,95–0,98 7–16 0–0,7 0,004–0,09 42–60 57–86 |

Для получения качественного угольного сырья требуется предварительная подготовка, которая может включать процессы ректификации, гидрирования и очистки. При оценке качества каменноугольного сырья особое внимание уделяют таким показателям, как зольность, содержание серы и азота, а также групповому составу. Значительное негативное влияние на микроструктуру получаемого ИК оказывает присутствие в сырье нерастворимой α1-фракции, чем больше ее содержание в сырье, тем более изотропным получается кокс.

В Институте нефтехимпереработки (Республика Башкортостан) при подготовке каменноугольных пеков к коксованию были применены различные способы очистки, метод экстракции позволял более полно удалять из сырья нежелательные компоненты [61]. По полученным данным была разработана технология коксования утяжеленной каменноугольной смолы, включающая стадию ее экстракции смесью алифатического и ароматического растворителей с последующим коксованием выделенного экстракта, выход ИК составлял 14.8 % [61].

Авторы [14] по методу избирательного растворения из промышленного среднетемпературного пека выделяли толуол-нерастворимую, но растворимую в хинолине фракцию (α 2 -фракции). По результатам анализа, выделенная α2-фракция содержала смесь ароматических углеводородов и небольшое количество гетероатомных соединений. При её карбонизации при температурах от 300 °С до 600 °С получен кокс с высокой плотностью с содержанием углерода 90–93 %. При повышении температуры до 1200 °С содержание углерода увеличивалось до 97 %, а структура приобретала слоистое строение с выраженной анизотропией, близкой к игольчатому коксу «премиум класса».

По данным [66], добавление антраценового масла к каменноугольному пеку уменьшает вязкость жидкофазной среды карбонизации, что способствует формированию кокса преимущественно с волокнистой структурой (около 86 %).

Температурный режим и давление при карбонизации являются важными параметрами, позволяющими регулировать соотношение скоростей различных конкурирующих реакций и, соответственно, структуру формирующихся коксов [67, 68]. Для каждого типа сырья подбирается оптимальное соотношение режимных параметров. Уменьшение температуры карбонизации до 480 оC и давления до 0,4 МПа приводит к улучшению текстуры кокса. Для карбонизации пека с высокой ароматичностью благоприятна повышенная температура (500 °C) в сочетании с давлением до 4 МПа [67, 68].

Расширение сырьевой базы для получения игольчатого кокса

В настоящее время для всей мировой нефтеперерабатывающей промышленности характерно устойчивое увеличение доли высокосернистых тяжелых нефтей [7, 20]. При их использовании требуется дополнительная ароматизация, очистка от серы, асфальтенов и деметаллизация образующихся остатков, что значительно увеличивает стоимость конечного продукта. При этом выход остатков не превышает 1–2 % и их качество зависит от марки перерабатываемой нефти.

Ресурсы коксохимической смолы также ограничены, так как ее выход в процессе коксования угля не превышает 4–5 %, а объемы производства в последнее десятилетие неуклонно снижаются из-за необратимого уменьшения потребности металлургической промышленности в дорогостоящем коксе, а также из-за ужесточения требований по экологической безопасности доменного и коксохимического производств. Отмеченные факторы стимулируют поиск новых источников полиароматического сырья для производства игольчатого кокса.

Перспективным и надёжным видом сырья могут стать полиароматические продукты, образующиеся в процессах сольвентной переработки углей (растворения, гидрогенизации), вместо высокотемпературного коксования [63, 69, 70]. В работе [63] изучена возможность получения ИК с использованием в качестве сырья остатка продуктов каталитической гидрогенизации угля, производимого в Китае на заводе Shenhua. Из остатка выделяли толуол- и пиридин-растворимые фракции, их состав был изучен методом хромато-масс-спектрометрии. По результатам испытаний в процессе коксования было установлено, что толуольный экстракт с повышенным содержанием мезогенных нафтен-ароматических молекул образовывал мезофазу, из которой при высокой температуре формировался ИК с высокими индексами анизотропии и низким коэффициентом линейного термического расширения. Кокс, полученный в тех же условиях из пиридинового экстракта, отличался мелкой мозаичной структурой. Авторы [66] в качестве сырья для получения ИК использовали пековый остаток ожижения угля с добавлением антраценового масла. Установлено, что добавки антраценового масла улучшают качество сырья и качество получаемого из него ИК (увеличивается плотность, степень анизотропии и уменьшается доля мозаичных структур).

Для получения полиароматических веществ значительный интерес представляют процессы низкотемпературного растворения углей. В Японии предприятия Kobe Steel Co. Ltd. и Mitsubishi Chemical Co. совместно разрабатывают процесс термического растворения угля для получения пекоподобного обеззоленного продукта «Гиперуголь» [71, 72], который рассматривается как исходное сырье для получения различных углеродных материалов, в том числе графитированных. В США в Университете Кентукки разработаны методы термического растворения угля для получения полиароматических продуктов, пригодных для производства электродов [73], игольчатого кокса [74], других углеродных и композиционных материалов. Считается, что полиароматические молекулы с тремя-пятью конденсированными кольцами с небольшим числом коротких заместителей, а также нафтеноароматические производные, содержащиеся в сырье, являются активными мезогенными компонентами, участвующими в образовании анизотропных мезофазных структур.

В наших ранее выполненных исследованиях [75–79] было показано, что полиаромати-ческие вещества – основные строительные единицы многих углеродных материалов с различными структурными модификациями – можно селективно получать из углей путем тер- – 704 –

Таблица 9. Сравнительные показатели состава и технических свойств образцов экстрактивных пеков и промышленных образцов каменноугольного и нефтяного пеков [79]

Table 9. Comparative indicators of the composition and technical properties of extractive pitch samples and industrial samples of coal tar and petroleum pitch [79]

Из результатов анализа видно, что показатели химического и группового состава, основных технических свойств термоэкстрактивных пеков находятся в интервале значений для коммерческих каменноугольного и нефтяного пеков. Важным достоинством экстрактивных пеков, в сравнении с каменноугольным, является более низкое содержание бенз(а)пирена. В целом, по полученным сравнительным данным, продукты растворения углей в мягких условиях (при невысокой температуре и давлении) могут служить надежным альтернативным сырьем для получения ИК, других углеродных материалов с высокой добавленной стоимостью.

Заключение

Игольчатый кокс, углеродный продукт с уникальными физическими свойствами, используется для получения широкого спектра графитовых материалов для важнейших областей техники и технологии. Благодаря уникальным физическим свойствам он незаменим при производстве графитовых электродов с высокими токовыми нагрузками для выплавки высококачественной стали в электродуговых печах.

Для производства ИК требуется высококачественное углеводородное ароматическое сырье с определенным молекулярно-структурным составом, с низким содержанием асфальтенов, нерастворимых в хинолине веществ, гетероатомных соединений, соединений металлов и дру-– 705 – гих примесей. Промышленное производство основано на процессе замедленного коксования сырья, традиционными источниками служат остаточные фракции первичных и вторичных процессов переработки нефти и каменноугольная смола, которая в небольшом количестве (не более 4–5 %) образуется в процессе коксования каменных углей. Указанные типы сырья являются побочными продуктами, их свойства не нормируются, существенно различаются по химическому, групповому, фракционному составу. При их использовании для получения ИК необходима предварительная квалифицированная подготовка с применением сложных методов для придания требуемого состава, что повышает стоимость конечной продукции.

Основные мощности по получению ИК локализованы в ограниченном числе стран. В России производство ИК в промышленном масштабе не производится, что связано как с отсутствием эффективных технологий, так и с ограниченными ресурсами качественного нефтяного и коксохимического полиароматического сырья. Значительные потребности в ИК в отечественной прогрессивно развивающейся сталелитейной промышленности обеспечиваются импортными поставками.

Высокая стоимость ИК, быстро растущий спрос на него в различных отраслях промышленности стимулируют расширение рынка ИК, поиск новых источников качественного полиа-роматического сырья для его производства.

Перспективным и надёжным видом сырья могут стать полиароматические продукты, образующиеся в процессах растворения, гидрогенизации и газификации углей. В последнее десятилетие работы в этом направлении активно проводятся зарубежными исследователями и промышленными фирмами. Значительное развитие получил процесс растворения угля при невысокой температуре, который позволит производить качественное сырье для производства углеродных материалов различного назначения, включая игольчатый кокс.

Список литературы Получение игольчатого кокса из нефтяного и угольного сырья

- Ахметов М. М. К вопросу о механизме формирования структуры игольчатых коксов. Научно-технический журнал «Мир нефтепродуктов». 2015. 4. 29–35. [Akhmetov M. M. On the mechanism of formation of the structure of needle cokes. Scientific and technical journal “World of petroleum products”. 2015. 4. 29–35. (in Rus.)]

- Zhang Z., Chen K., Liu D., Lou B., Li M., Guo S., Yu R., Wu B., Gong X., Li G. Comparative study of the carbonization process and structural evolution during needle coke preparation from petroleum and coal feedstock. Journal of Analytical and Applied Pyrolysis, 2021, 156, 105097

- Cheng J., Lu Z., Zhao X., Chen X., Zhu Y., Chu H. Electrochemical performance of porous carbons derived from needle coke with different textures for supercapacitor electrode materials. Carbon Lett., 2021, 31, 57–65

- Wei F., He X. J., Zhang H. F., Liu Z. D., Xiao N., Qiu J. S. Crumpled carbon nanonets derived from anthracene oil for high energy density supercapacitor. Journal of Power Sources, 2019, 428, 8–12

- Chen G., Jin Y., Zhang Z., Zhao W., Su W., Qing T., Chen J., Li Y. A green phenolic resin/needle coke scrap-based carbon/carbon composite as anode material for lithium-ion batteries. Ionics (Kiel), 2021, 27, 5079–5087

- Global Needle Coke Industry Trends Analysis Report 2024, Forecast to 2032 (Broken Down by Type, End User, Regional Analysis, and Competitive Landscape) [Electronic resourse] – Access: https://www.marketgrowthreports.com/global-needle-coke-industry‑25826630

- Рудко В. А., Габдулхаков Р. Р., Пягай И. Н. Научно-техническое обоснование возможности организации производства игольчатого кокса в России. Записки Горного института, 2023, 263, 795–809 [Rudko V. A., Gabdulkhakov R. R., Pyagai I. N. Scientific and technical substantiation of the possibility of organizing the production of needle coke in Russian. Journal of Mining Institute, 2023, 263, 795–809 (in Rus.)]

- Zhao D., Zhao H., Ye J., Song W., Miao S., Shen H. Oxygen functionalization boosted sodium adsorption-intercalation in coal based needle coke. Electrochim Acta., 2020, 329, 135127

- Sawarkar A. N., Pandit A. B., Samant S. D., Joshi J. B. Petroleum residue upgrading via delayed coking: a review. Canadian Journal of Chemical Engineering, 2007, 85, 1–24

- Needle Coke Market. Analysis of size and share market – growth trends and forecast (2024–2029) [Electronic resourse] – Access: https://www.mordorintelligence.com/ru/industry-reports/needle-coke-market

- Габдулхаков Р. Р., Рудко В. А., Ефимов И. И., Спекторук А. А. Оценка качества игольчатого кокса для производства графитированных электродов металлургических печей. Цветные металлы, 2022, 7, 46–56 [Gabdulkhakov R. R., Rudko V. А., Efimov I. I., Spectoruk A. A. Quality assessment of needle coke used in the production of graphiteelectrodes for metallurgical furnaces. Tsvetnye Metally., 2022, 7, 46–56 (in Rus.)]

- Zaporin V. P., Valyavin G. G., Rizvanov I. V., Akhmetov A. F. Decant-oil coking gasoils for production of industrial carbon. Chemistry and Technology of Fuels and Oils, 2007, 43, 326–329

- Рудко Н. К., Кондрашева, Романовский С. Ю., Кондрашев Д. О. Изучение углеводородного и микроэлементного состава и свойств сырья и продуктов процесса замедленного коксования. Известия СПбГТИ(ТУ), 2017, 38(64), 69–75. [Rudko N. K. Kondrasheva, S. Yu. Romanovsky, D. O. Kondrashev. Study of hydrocarbon and microelement composition and properties of raw materials and products of the delayed coking process. Bulletin of SPbGTI(TU), 2017, 38(64), 69–75 (in Rus.)]

- Созинов С. А., Попова А. Н., Лырщиков С. Ю., Исмагилов З. Р. Термолиз α2 –фракции каменноугольного пека: характеристика структуры кокса. Химия в интересах устойчивого развития. 2022, 30, 553–558 [Sozinov S. A., Popova A. N., LyrshchikovS.Yu., Ismagilov Z. R. Thermolysis of the α2 fraction of coal pitch: characteristics of the coke structure. Chemistry for sustainable development. 2022, 30, 553–558 (in Rus.)]

- Бородин Е. В., Ведерников О. С., Головачев В. А., Клейменов А. В., Лаврова А. С., Петин А. А. Новый способ получения нефтяного игольчатого кокса с термополиконденсацией сырья. Нефте Газо Химия, 2023, 2, 5–7 [Borodin E. V., Vedernikov O. S., Golovachev V. A., Kleymenov A. V., Lavrova A. S., Petin A. A. New method for obtaining petroleum needle coke with raw material thermopolycondensation. Oil & Gas Chemistry, 2023, 2, 5–7 (in Rus.)]

- Валявин Г. Г., Запорин В. П., Габбасов Р. Г., Калиммулин Т. И. Процесс замедленного коксования и производство нефтяных коксов, специализированных по применению. Территория Нефтегаз, 2011, 8, 44–49 [Valyavin G. G., Zaporin V. P., Gabbasov R. G., Kalimmulin T. I. The process of delayed coking and the production of petroleum cokes specialized in application. Territory of Neftegaz, 2011, 8, 44–49 (in Rus.)]

- The project of a plant for the production of oil needle cokes (Republic of Bashkortostan). [Electronic resourse] – Access: https://www.fbacs.com/images/Игольч.КОКС%20кратко%202019 %20Ишимбай%20(В‑2).pdf

- Brooks J. D., Taylor G. H. Formation of graphitizing carbons from liquid phase. Nature, 1965, 206, 697–699

- Weinberg V. A., White J. L., Yen T. F. Solvent fractionation of petroleum pitch for mesophase formation. Fuel, 1983, 62, 1503–1509

- Gabdulkhakov R. R., Rudko V. A., Pyagay I. N. Methods for modifying needle coke raw materials by introducing additives of various origin (review). Fuel, 2022, 310, 122265

- Mochida I., Oyama T., Korai Y. Formation scheme of needle coke from FCC‑decant oil. Carbon, 1988, 26, 49–55

- Skripchenko G. B. Results of basic investigation carried out by institute for solid fossil fuels on development of scientific foundations of the technology of coal graphite materials. Solid Fuel Chemistry, 2005, 39, 1, 54–67

- Лаврова А. С. Исследование процесса получения игольчатого кокса из нефтяного сырья, дис.канд. техн. наук. Санкт-Петербург, 2024, 117 [Lavrova A. S. Investigation of the process of obtaining needle coke from petroleum raw materials, Thesis cand.of tech. Sci. Saint-Petersburg, 2024, 117 (in Rus.)]

- Wang M., Yang B., Yu T., Yu X., Rizwan M., Yuan X., Niecand X., Zhou X. Research progress in the preparation of mesophase pitch from fluid catalytic cracking slurry. RSC Adv., 2023, 13, 18676–18689

- Mondal S., Yadav A., Pandey V., Sugumaran V., Bagai R., Kumar R. Dissecting the cohesiveness among aromatics, saturates and structural features of aromatics towards needle coke generation in DCU from clarified oil by analytical techniques. Fuel, 2021, 304, 121459

- Zhang Z., Du H., Guo S., Lou B., Yu R., Gong X. Probing the effect of molecular structure and compositions in extracted oil on the characteristics of needle coke. Fuel, 2021, 301, 120984

- Halim H. P., Im J. S., Lee C. W. Preparation of needle coke from petroleum byproducts. Carbon Lett, 2013, 14, 152–61

- . Eser S., Jenkins R. G. Carbonization of petroleum feedstocks and mesophase development. Carbon, 1989, 27, 877–887

- Liu D., Lou B., Li M., Qu F., Yu R., Yang Y. Study on the preparation of mesophase pitch from modified naphthenic vacuum residue by direct thermal treatment. Energy Fuels, 2016, 30, 4609–4618

- Anchita J. HYDRO-IMP Technology for upgrading of heavy petroleum. J Min Inst., 2017, 224, 229–234

- Guo A., Lin X., Liu D., Zhang X., Wang Z. Investigation on shot-coke-forming propensity and controlling of coke morphology during heavy oil coking. Fuel Process Technol, 2012, 104, 332–342

- Eser S., Jenkins R. G. Carbonization of petroleum feedstocks II: Chemical constitution of feedstock asphaltenes and mesophase development. Carbon NY, 1989, 27, 889–897

- Jiao S., Guo A., Wang F., Chen K., Liu H., Ibrahim U-K. Effects of olefins on mesophase pitch prepared from fluidized catalytic cracking decant oil. Fuel, 2020, 262, 116671

- Mochida I., Oyama T., Korai Y., Fei Y. Q. Study of carbonization using a tube bomb: evaluation of lump needle coke, carbonization mechanism and optimization. Fuel, 1988, 67, 9, 1171–1181

- Fernandez-García L., Alvarez P., Perez-Mas A.M., Blanco C., Santamaría R., Menendez R. Role of quinoline insoluble particles during the processing of coal tars to produce graphene materials. Fuel, 2017, 206, 99–106

- Cao Q., Xie X., Li J., Dong J., Jin L. A novel method for removing quinolone insolubles and ash in coal tar pitch using electrostatic fields. Fuel, 2012, 96, 314–318

- Moriyama R., Hayashi J‑i., Chiba T. Effects of quinoline-insoluble particles on the elemental processes of mesophase sphere formation. Carbon NY, 2004, 42, 2443–2449

- Mochida I., Korai Y., Fei Y. Q., Oyama T. Optimum carbonization conditions needed to form needle coke. Oil Gas J, 1988, 86, 18, 73–76

- Didchenko R., Lewis I. C. Method of forming an electrode from a sulfur containing decant oil feedstock. US Patent US 5167796 A (1992). n.d.

- Lin C., Wang J., Chen S., Wang Z., Liu H., Chen K. Thermal treatment of fluid catalytic cracking slurry oil: determination of the thermal stability and its correlation with the quality of derived cokes. J Anal Appl Pyrolysis, 2018, 135, 406–14

- Jiao S., Guo A., Wang F., Yu Y., Biney B. W., Liu H. Sequential pretreatments of an FCC slurry oil sample for preparation of feedstocks for high-value solid carbon materials. Fuel, 2021, 285, 119169

- Zhang Z., Du H., Guo S., Chen Z., Wen F., Shi N. The effect of heat pretreatment of heavy oil on the pyrolysis performance and structural evolution of needle coke. J Anal Appl Pyrolysis, 2021, 157, 10517

- Eser S., Derbyshire F. J., Karsner G. G. Development of coke texture by thermal pretreatment of petroleum residua. Fuel, 1989, 68, 9, 1146–1151

- Zhu Y., Zhao X., Gao L., Lai S., Lv J. Study on the Pyrolysis Characteristic and the Microstructure of the Pyrolysis Products of β Resins from Different Coal Tar Pitch. Journal Chem Soc Pakistan, 2018, 40, 2, 343–353

- Samano V., Rana M. S., Ancheyta J. An easy approach based on textural properties to evaluate catalyst deactivation during heavy oil hydrotreating. Catal Commun., 2020, 133, 105823

- Хайрудинов И. Р., Судтанов Ф. М., Теляшев Э. Г. Современные процессы сольвентной деасфальтизации нефтяных остатков. Уфа: Издательство ГУП ИНХП РБ, 2011. 208. [Khairudinov I. R., Sudtanov F. M., Telyashev E. G. Modern processes of solvent deasphalting of oil residues. Ufa: Publishing house of GUP INHP RB, 2011. 208].

- Cheng X., Zha Q., Li X., Yang X. Modified characteristics of mesophase pitch prepared from coal tar pitch by adding waste polystyrene. Fuel Process Technol., 2008, 89, 12, 1436–1441

- Machnikowski J., Machnikowska H., Brzozowska T., Zieli´nski J. Mesophase development in coal-tar pitch modified with various polymers. J Anal Appl Pyrolysis, 2002, 65, 2, 147–160.

- Li M., Liu D., Lou B., Hou X., Chen P. Relationship between Structural Modification of Aromatic-Rich Fraction from Heavy Oil and the Development of Mesophase Microstructure in Thermal Polymerization Process. Energy Fuels, 2016, 30, 10, 8177–8184

- Cao Q., Guo L., Dong Y., Xie X., Jin L.-E. Autocatalytic modification of coal tar pitch using benzoylchloride and its effect on the structure of char. Fuel Process Technol., 2015, 129, 61–66

- Kumar S, Srivastava M. Catalyzing mesophase formation by transition metals. J Anal Appl Pyrolysis., 2015, 112, 192–200

- Zhu Y., Zhao C., Xu Y., Hu C., Zhao X. Preparation and Characterization of Coal Pitch-Based Needle Coke (Part I): The Effects of Aromatic Index (f a) in Refined Coal Pitch. Energy Fuels, 2019, 33, 3456–3464

- Alcántara R., Lavela P., Ortiz G. F., Tirado J. L., Stoyanova R., Zhecheva E. Modification of Petroleum Coke for Lithium-Ion Batteries by Heat-Treatment with Iron Oxide. J Electrochem Soc., 2004, 151, 12, A2113

- Bazhin V. Y. Structural modification of petroleum needle coke by adding lithium on calcining. Coke Chem., 2015, 58, 4, 138–142

- Mochida I., Fei Y. Q., Korai Y., Oishi T. Co-carbonization of ethylene tar pitch and coal tar pitch to form needle coke. Fuel, 1990, 69, 6, 672–677

- Mochida I., Korai Y., Oyama T., Nesumi Y., Todo Y. Carbonization in the tube bomb leading to needle coke: I. Cocarbonization of a petroleum vacuum residue and a FCC‑decant oil into better needle coke. Carbon NY, 1989, 27, 3, 359–365

- Kapustin V. M., Glagoleva V. F. Physicochemical aspects of petroleum coke formation (review). Petroleum Chemistry, 2016, 56, 1, 1–9

- Капустин В. М. Гуреев А. А. Технология переработки нефти. Ч. 2. – Деструктивные процессы. М.: Колос С, 2007. 334 [Kapustin V. M., Gureev A. A. Oil refining technology. Part 2. Destructive processes. Moscow. Kolos S, 2007. 334 (in Rus.)]

- Сюняев З. И. Производство, облагораживание и применение нефтяного кокса. М.: Химия, 1973. 296 [Sunyaev Z. I. Production, refining and application of petroleum coke. Moscow. Chemistry, 1973. 296 (in Rus.)]

- Хайрудинов И. Р., Тихонов А. А., Ахметов М. М. Перспектива расширения сырьевой базы для получения игольчатого кокса. Башкирский химический журнал, 2011, 18, 3, 103–111 [Khairudinov I. R., Tikhonov A. A., Akhmetov M. M. The prospect of expanding the raw material base for the production of needle coke. Bashkir Chemical Journal, 2011, 18, 3, 103–111 (in Rus.)]

- Теляшев Э. Г., Хайрудинов И. Р., Ахметов М. М. Нефтяной кокс в России – перспективные технологии. Территория Нефтегаз, 2006, 4, 66–71 [Telyashev E. G., Khairudinov I. R., Akhmetov M. M. Petroleum coke in Russia – promising technologies. Territory of Neftegaz, 2006, 4, 66–71 (in Rus.)]

- Запорин В. П., Сухов С. В., Старухин Д. А. Способ получения игольчатого кокса замедленным коксованием. Патент России № 2660008, опубл. 04.07.2018. Бюл. № 19 [Zaporin V. P., Sukhov S. V., Starukhin D. A. Method for producing needle coke by delayed coking. Russian Patent No. 2660008, published 04.07.2018. Bulletin No. 19]

- Cheng X., Li G., Peng Y., Song S. et al. Production of needle coke from coal liquefaction residues. Chemistry Technology of Fuels and oils. 2012. 5. 11–14.

- Павлович О. Н. Состав, свойства и перспективы переработки каменноугольной смолы. ГОУ ВПО УГТУ–УПИ, Учебное издание 2006, Екатеринбург. [Pavlovich O. N. Composition, properties and prospects for processing coal tar. State Educational Institution of Higher Professional Education USTU-UPI, Textbook publication 2006, Yekaterinburg (in Rus.)]

- Blumer G.-P., Collin G., Hoke H. Tar and Pitch. Industrial Carbon and Graphite Materials: Raw Materials, Production and Applications. 2021, 1, 172–210.

- Zhang Y., Liu X., Tian M., Zhu Y., Hua C., Zhao X. Generation and characterization of coal-based needle coke produced by the co-carbonization of coal liquefaction pitch and anthracene oil. RSC Adv, 2022, 12, 25860–25871

- Mochida I., Fei YQ., Oyama T., Korai Y., Fujitsu H. Carbonization of coal-tar pitch coke in a tube bomb into lump needle. Journal of materials science, 1987, 22, 3989–3994

- Krebs V., Eliilaoui M., Mareche J. F., Bertau G. R. Carbonization of coal-tar pitch under controlled atmosphere-part I: effect of temperature and pressure on the structural evolution of the formed green coke. Carbon, 1995, 33, 5, 645–651

- Kuznetsov P. N., Kuznetsova L. I., Buryukin F. A., Marakushina E. N., Frizorger V. K. Methods for the preparation of coal-tar pitch. Solid Fuel Chem, 2015, 49, 213–225

- Rahman M., Pudasainee D., Gupta R. Review on chemical upgrading of coal: Production processes, potential applications and recent developments. Fuel Process Technol, 2017, 158, 35–56

- Hamaguchi M., Okuyama N., Shishido T., Sakai K., Komatsu N., Kikuchi N., Inoue T., Koide J., Kasahara H. Prebaked anode from coal extract (3) – carbonization properties of Hypercoal and its blends with binder pitch. In book: Light Metals. Springer, Cham. 2012, 1219–1221

- Koyano K., Takanohashi T., Saito I. Estimation of the extraction yield of coals by a simple analysis. Energy Fuels, 2011, 25, 6, 2565–2571

- Andrews R. J., Rantell T., Jacques D., Hower J. C., Gardner J. S., Amick M. Mild coal extraction for the production of anode coke from Blue Gem coal. Fuel, 2010, 89, 9, 2640–2647

- Craddock J. D., Rantell T. D., Hower J. C., Whitlow D. T., Wiseman J., Weisenberger M. C. Anode coke from coal – A low cost approach. Fuel, 2017, 187, 229–241

- Kuznetsov P. N., Kamenskiy E. S., Kuznetsova L. I. Solvolysis of bituminous coal in coal – and petroleum derived commercial solvents. ACS Omega, 2020, 5, 24, 14384–14393

- Kuznetsov P.N, Kamenskiy E.S, Kuznetsova L.I Comparative study of the properties of the coal extractive and commercial pitches. Energy Fuels, 2017, 31, 5402–5410

- Kuznetsov P. N., Safin V. A., Avid B., Kuznetsova L. I. et al. Thermal dissolution of coals of the metamorphism series in the anthracene fraction of coking tar: an analysis of correlations with the chemical and technological properties of coals. Solid Fuel Chemistry, 2021, 55, 69–77

- Kuznetsov P. N., Ismagilov Z. R., Kuznetsova L. I., Avid В. et al. The composition and properties of soluble products from the coal thermosolvolysis with hydrocarbon residues and blends as solvents. Eurasian Chemico-Technological Journal, 2022, 24, 183–190

- Kuznetsov P. N., Avid B., Kuznetsova L. I., Obukhova A. V. Alternative anode binders for aluminum electrolysis. Tsvetnye Metally, 2023, 6, 39–45