Получение ПВХ-пленок, обладающих специфическими свойствами

Автор: Маскова Альбина Рафитовна, Аминова Гулия Карамовна, Файзуллина Светлана Радиковна, Файзуллина Галия Фатыховна, Мазитова Алия Карамовна

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Разработка новых полимерных материалов

Статья в выпуске: 4 т.10, 2018 года.

Бесплатный доступ

При разработке полимерных материалов, обладающих специфическими свойствами, наряду с применением традиционных химических добавок (пластификаторов) используются также и такие специальные вещества, как фун гициды. Применение последних обусловлено негативным воздействием на поливинилхлоридные (ПВХ) материалы плесневых грибов, бактерий и других микроорганизмов. В настоящей работе исследована возможность практического применения октилфеноксипропилфталатов (ОФОПФ), предложенных в качестве пластификаторов, и производных 3-меркапто-1,2,4-триазинонов-5, предложенных в качестве фунгицидов, в ПВХ-пленках. Первая добавка получена этерификацией фталевого ангидрида оксипропилированными фенолами и 2-этилгексанолом, вторая – циклоконденсацией альфа-кетокислот с тиосемикарбазидом. На основании проведенных экспериментов было установлено, что композиции, полученные с использованием новых добавок, а именно октилфеноксипропилфталатов и производных 3-меркапто-1,2,4-триазинонов-5, приобретают высокие эксплуатационные свойства, что приводит к увеличению срока их службы. При этом улучшаются основные показатели: напряжение при удлинении, разрушающее напряжение, термостабильность и грибостойкость.

Грибостойкость, диоктилфталат, напряжение при удлинении, октилфеноксипропилфталат, разрушающее напряжение, ПВХ-пленка, пластификаторы поливинилхлорида, термостабильность, фунгициды.

Короткий адрес: https://sciup.org/142212209

IDR: 142212209 | УДК: 678 | DOI: 10.15828/2075-8545-2018-10-4-102-115

Текст научной статьи Получение ПВХ-пленок, обладающих специфическими свойствами

M achine - readable information on CC- licenses (HTML- code ) in metadata of the paper

Production of PVC-films with specific properties by Maskova A.R., Aminova G.K., Faizullina S.R., Faizullina G.

F., Mazitova A.K. is licensed under a ...

olymeric materials are used in different fields of industry. One can notice the increasing number of the works devoted to polymers with specified characteristics, as well as advanced requirements to be met by these materials.

At the present time polyvinyl chloride (PVC) is the most widely used polymer. Pure polyvinyl chloride is difficult processed, for this reason PVC is mixed with different additives. The main role of chemical additives is to facilitate polymeric mixtures processing and giving the necessary properties to finished products. A wide range of physical and mechanical properties of plastics are obtained by using additives, that makes it possible to produce a wide variety of products – from very soft, gel-like to elastic, rigid materials. Thus chemical additives expand the field of PVC applica-

DEVELOPMENT OF NEW POLYMER MATERIALS tion and allow it to be considered as a multicomponent system and the most easily compounded thermoplastic polymer [7–12].

More than 12 million tons of polymeric additives are produced every year in the world and plasticizers are the major part of them. Partial use of PVC in plasticized form are determined by characteristics of its chemicals structure – low elasticity, a significant temperature range of plastic deformation, and insufficient frost resistance [2, 5–7, 11, 12]. For this reason, intensification of manufacturing process and expansion of PVC application fields and providing wide variety of its properties, are connected to a large extent with the successful solution of the problem of creating effective plasticizers.

As known, phthalates are widely used as plasticizers in polymer industry. Dioctyl phthalate (DOP) is the main representative of phthalate plasticizers and it still remains the most widespread ester plasticizers of PVC. DOP possesses the optimal combination of properties, it is comparatively cheap, but DOP doesn’t provide necessary service properties especially funginertness [11].

In this connection it is advantageous to produce the following additives: octylphenoxypropyl phthalates (OPOPP), which are proposed as plasticizers and derivatives of 3-marcapto-1,2,4-triazinone-5, which are proposed as fungicides. It is of great interest to study their properties and the possibility to develop PVC-materials that could meet the advanced operation requirements with the use of them.

We have produced new ester compounds – octylphenoxypropyl phthalates (OPOPP) with hydroxypropylation degree of phenol 1.0–2.1, that present slightly hygroscopic, oily liquids of yellowish color, highly soluble in organic solvents. OPOPP were obtained by the methods previously developed by us, by the esterification of phthalic anhydride by oxypropylated phenols and 2-ethylhexanol [13–27]. The physicochemical properties of proposed plasticizers are shown in table 1.

To determine the efficiency of suggested plasticizers the changing of Shor A hardness from the concentration of plasticizer were investigated (plasticizer: PVC – 1:100) [2-6]. On the base of calculation of quantitative substitution factor (SF) it was determined that 1,0-OPOPP is very similar to DOP by plasticization efficiency (table 1).

As known, plasticized PVC materials can be exposed to various microorganisms including fungus under unfavorable conditions which adversely

DEVELOPMENT OF NEW POLYMER MATERIALS affected on the visual appearance of plastic compounds and reduce their service life. One of the way to protect PVC materials from negative influence of mold fungi is to introduce fungicides into compositions [11, 28].

Table 1

Physicochemical properties of octylphenoxypropyl phthalates

|

Characteristics |

1,0-OPOPP |

1,5-OPOPP |

2,1-OPOPP |

|

Yield, % |

89 |

87 |

84 |

|

Ester number., mg КОН/g |

269 |

251 |

232 |

|

Molecular mass, found |

416 |

446 |

481 |

|

Flash point, оС |

199 |

198 |

198 |

|

Substitution factor |

1,019 |

1,043 |

1,052 |

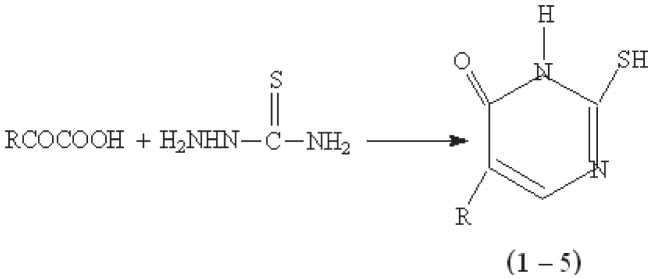

To realize this we obtained derivatives of nones-5 (scheme 1):

3-mercapto-1,2,4-triazi-

,

where R = СН3 (1), i-C3H7 (2), i-C4H9 (3), t-C4H9 (4), C6H5 (5).

Scheme 1

Compounds of the heterocyclic series were obtained by cyclocondensation of alpha-keto acids with thiosemicarbazide.

At the beginning, the reagents were loaded in the following order: water 100 ml (solvent), sodium hydrogen carbonate 0,01 mole (cyclizing

DEVELOPMENT OF NEW POLYMER MATERIALS agent), alpha-keto acid 0,1 mole, thiosemicarbazide 0,1 mole. The reaction was performed at 100оС for 3 hours then cooled to 10оС and neutralized with concentrated hydrochloric acid to pH = 6,0. The obtained precipitate was filtrated, washed with water and dried on the air.

For obtaining 3-mercapto-1,2,4-triazinon-5 with the maximum yield, the filtrate was treated with a concentrated solution of sodium hydroxide and kept under synthesis conditions for 1 hour. The resulting precipitate was filtered off, washed with water and air-dried.

3-Mercapto-1,2,4-triazinones-5 are solids, from white to orange colour, soluble in many organic solvents.

Physicochemical properties and spectral characteristics of the synthesized compounds are presented in table 2.

Physicochemical properties and spectral characteristics of 3-mercapto-1,2,4-triazinones-5

Table 2

|

Characteristics |

3-Mercapto-1,2,4-triazinones-5 |

||||

|

1 |

2 |

3 |

4 |

5 |

|

|

Yield, % |

80 |

80 |

74 |

79 |

80 |

|

Melting point, оС |

217–219 |

132–134 |

160–162 |

280–282 |

255–257 |

|

IR-spec-trum, sm–1 |

1670,1270, 1520 |

1675,1270, 1540 |

1690,1260, 1390 |

1675,1260, 1520 |

1670,1260, 1540 |

|

UV-spec-trum, nm |

190,275,310 |

195,280,319 |

190,270,315 |

192,270,320 |

220,290,330 |

Preliminary investigations have shown that derivatives of 3-mercap-to-1,2,4-triazinon-5 possess high fungicidal activity [29, 30].

Next the produced compounds were tested in the PVC-films. Physical and mechanical properties of obtained PVC-films were analyzed according to standards: thermostability – according to GOST 14041-91, melt flow index – according to GOST 11645-73, funginertness – according to GOST 9.049-91, method 1.

DEVELOPMENT OF NEW POLYMER MATERIALS

The results of testing of plasticized PVC-films containing 3-mercapto-1,2,4-triazinones-5 as additive

Table 3

|

Characteristics |

Control* |

1,0-ОPOPP + 3-mercapto-1,2,4-triazinones-5 |

||||

|

1 |

2 |

3 |

4 |

5 |

||

|

Strain at elongation 100%, MPa |

11,1 |

11,9 |

11,8 |

12,0 |

12,2 |

12,4 |

|

Ultimate tensile stress, MPa |

21,6 |

22,8 |

22,7 |

22,9 |

23,2 |

23,4 |

|

Breaking elongation, % |

340 |

305 |

305 |

309 |

308 |

310 |

|

Extractability by waters, % |

0,012 |

0,212 |

0,243 |

0,146 |

0,087 |

0,014 |

|

Water absorption, % |

0,195 |

0,312 |

0,315 |

0,294 |

0,207 |

0,201 |

|

Melt flow rate, g/10min |

44,5 |

40,2 |

40,4 |

39,3 |

38,9 |

38,7 |

|

Thermostability at 175оС, min |

165 |

170 |

169 |

172 |

174 |

175 |

|

Funginertness, grade |

Not resistant |

Resistant |

Resistant |

Resistant |

Resistant |

Resistant |

* PVC-film, plasticized with DOP, without 3-mercapto-1,2,4-triazinones-5

As it can be seen from table 3, PVC-films produced by introducing developed octylphenoxypropyl phthalates and derivatives of 3-marcapto-1,2,4-triazinone-5, acquire high performance properties that leads to increased service life of the films. In particular, one should note the improvement of the following indices: strain at elongation, ultimate tensile stress and thermostability. Evaluating funginertness of materials by the degree of fungi it has been found out that composition prepared on the base of PVC with octylphenoxypropyl phthalates and derivatives of 3-marcapto-1,2,4-triazinone-5 acquire high fungi resistance, while compositions prepared with the use of only plasticizer DOP were unstable with respect to microorganisms.

All this indicates the perspective of using octylphenoxypropyl phthalates as plasticizers and derivatives of 3-marcapto-1,2,4-triazinone-5 as fungicides.

DEVELOPMENT OF NEW POLYMER MATERIALS

The performed research has been funded through the government grant «Synthe-sis and investigation of the modern polyvinyl chloride plasticizers» according to the Decree of the Government of the Republic of Bashkortostan of 07.02.2018 № 56 «On providing grants of the Republic of Bashkortostan to young scientists and groups of young researchers in 2018».