Preventive control taking into account of an operational condition power equipment and flowing path of hydropower plant

Автор: Sekretarev Yuri A., Mitrofanov Sergey V.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 1 т.6, 2013 года.

Бесплатный доступ

In this paper the methodology of preventive control on hydropower plant is considered. Object of control – operationa l conditio n o f hydr o aggregates, bloc k transformer s an d flowin g pat h o f hydr o power station. In article possibility of creation on the basis of the given methodology of a decision-making support subsystem is considered. The given subsystem will allow operation personnel to obtain the data about an equipment condition in the form convenient for perception and to make correction or change of an operating mode of the given equipment for the purpose of prevention of damage and maintenance of station normal work.

Hydropower plant, preventive control, maintainability, fuzzy sets theory, membership function

Короткий адрес: https://sciup.org/146114716

IDR: 146114716 | УДК: 621.311.21

Текст научной статьи Preventive control taking into account of an operational condition power equipment and flowing path of hydropower plant

Today hydropower plant represents difficult system. Effectiveness of the given system depends on many social, technical and economical factors. One of primary factors in this list is the operational condition of the basic power equipment of hydropower station.

The basic power equipment of hydropower station make: the hydro turbine, the hydro generator, the block transformer, and the flowing path of the hydro turbine if high-head hydropower plant are considered. Realization depends on non-failure operation of the given elements shown to a mode of hydroelectric power station of requirements: reliability and quality of an electrical supply, and also the maximum profitability of an operating mode of station.

Principles of operating modes control of the basic power equipment

There are two ways of normal modes control of hydropower station:

-

• Automatic regulation;

-

• Operational control.

-

© Siberian Federal University. All rights reserved

Automatic regulation is carried out in rate of production by means of automatic devices, at a deviation of parameters of a mode from the established values. It also serves as an intermediate link between decision-making system and performance of this decision on object of control.

The operational control is carried out by the duty personnel of power station and down to control of technological streams in the process of production, transformation and transmission of energy [1].

As operational control means normal modes oversail:

-

• Short-term planning (control according to plan);

-

• Updating of the plan up to fact;

-

• Preliminary updating of a planned mode (preventive control);

Short-term planning is carried out beforehand with the account of schedules of power consumption and limitations. Restrictions are imposed because of features of the station work, and also higher levels of a power supply system. Result of short-term planning is the dispatching schedule.

However, high dynamics and variability of situations at station lead to deviations from the made plan. In this case updating of the plan up to fact. It is carried out basically by automatic control means, when values of regime parameters appear near to emergency.

Use of preliminary updating of modes for the account of preventive control allows to trace and liquidate developing deviations of parameters at early stages. It is possible thanks to the forecast of change of parameters.

However at realization of preventive control the person making decision (PMD) deal with variety of difficulties. Particularly:

-

• Huge volume of the arriving information. This problem also becomes complicated information heterogeneity (various units of parameters measure) and various character of its representation (Determined, probabilistic, stochastic);

-

• Subjective interpretation of the information arriving to the person (Underestimation of one situations and revaluation of others which can lead to infringement of reliability and profitability of the working equipment).

Besides there are three additional factors of hydropower plant present at an operational control:

-

• Constant presence of “time trouble” at PMD at decision-making;

-

• Private responsibility of PMD for the made decision;

-

• The High material and social payment for unreasonably made decision.

In such conditions on shoulders PMD fell difficult problem of decision-making on control of modes of the power equipment and station as a whole lays down.

Introduction in a contour of an operational control of decision-making support intellectual system (DMSIS), carrying out function of “adviser”, allows to lower process of pressure of the specified factors on PMD.

General provisions of a methodology of an assessment of an operational condition

Today reception of exact values of an operational condition is connected with a range of difficulties. In particular, parameters on which control is carried out, are rather numerous and have various dimension, and also various ranges of measurements:

Rr = (Rt, Rvib, Ral, Rlev, Rfpt, Rect), where Rt, Rvib, Ral, Rlev, Rfpt, Rect – parameters of temperature, vibrating, electric conditions, the parameters characterizing a deviation of water levels and oil, pressure of air, parameters of a flowing path of the hydro turbine etc.

Therefore formation of the generalized criterion which could characterize an operational condition of all hydro block is necessary. This problem demands development of special procedures of bringing of parameters to uniform dimension, and also their ranging, as parameters have various importance for decision-making in a control contour.

As mathematical apparatus for realization of these principles the fuzzy sets theory as they possesses a range of advantages in comparison with traditional methods can be accepted. Namely:

-

• Possibility of processing and comparison of a considerable quantity of the diverse information, by means of their reduction to uniform dimensionless units;

-

• Possibility of ranging of diverse parameters on degree of their superiority;

-

• Possibility of representation of results in shape which is convenient for perception of the person making decision.

Procedure of assessment of controllable parameters should be realized in some stages.

In a general view all process of formation of assessment of an operational condition is presented on the scheme represented on Fig. 1.

-

1 Stage: calculation of “base” assessments of operational parameters.

In the beginning for an assessment and comparison of operational parameters of the hydrounit and a flowing path of the hydro turbine of their value are represented in the form of fuzzy intervals.

It is the form of representation of values of parameters allows to consider simultaneously and a nominal range of values (a nucleus of an fuzzy interval), and a range of deterioration of a condition of parameter beginning from the moment of operation of the precautionary alarm system and up to

Data of sensors and Monitoring systems of a parametres current condition of the hydrounit

constraint tables of automatic control devices of an operational condition of the hydroblock

The module 1. Calculation of «base» assessments of an operational condition of the hydrounit b k (П i )

The module 2. Calculation of assessments of a current operational condition of the hydrounit t k (П i )

The module 3. Calculation of resultant assessments of parametres j k (П i )

Fig. 1. The scheme of formation of resultants of assessment of an operational condition

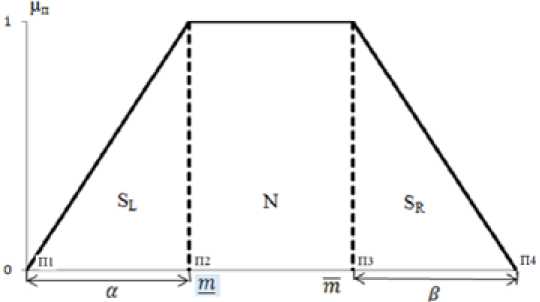

Fig. 2. The General view of an fuzzy interval; N – a nuclear of an fuzzy interval (parameter rating values), SL, SR - the left and right carriers of an illegibility (a zone of deterioration of parameter), m , m - the bottom and top borders of a nuclear of an fuzzy interval

Fig. 3. Types of fuzzy intervals value of emergency switching-off (the left and right carriers of an illegibility). The general view of an indistinct interval is presented on (Fig. 2).

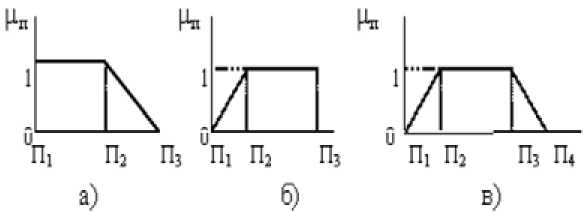

On an axis of abscises values of parameter (degrees, amperes, meters, relative units etc.) settle down. On an axis of ordinates values of membership function of values of parameters settle down. It is possible to present all controllable parameters in the form of fuzzy intervals of three types (Fig. 3).

The indistinct interval (Fig. 3a) represents process of control over increase by value of parameter П to its maximum value after which there is an automatic switching-off of the hydrounit. The parametrical description of this interval is N = ( m, m,a, 0). The fuzzy interval (Fig. 36) characterizes process of control over fall of value of parameter П to its minimum value. The parametrical description following N = ( m, m, 0 , в ). The fuzzy interval (Fig. 3в) characterizes process of maintenance of controllable parameter in a normal range. Control is carried out behind decrease and parameter increase. The parametrical description of this type of an fuzzy interval is N = ( m, m, а , в ).

Each of controllable parameters has both various dimension, and a various range of change of controllable parameter values.

For reduction of values of parameter to uniform dimensionless units for an fuzzy interval of the first type it is necessary to use following formulas:

m * = П 1 .100%, m* = П 2 •100%, a = П 3 • 100% - m *

П 1 П 1 П 1

For an interval of the second type of the formula of reduction will look as follows:

m * = П 2 •100%, m* = П 3 • 100%,в* = m * - П • 100% П3 П3 П3

The interval of the third type is represented as set of intervals of the first and second types. Formulas of the unified recalculation for an interval of the second type remain the same, and for an fuzzy interval of the first type in the basic expression following corrective amendments are introduced:

П , = П 2 , П 2 = П 3 , П 3 = П 4 ;

The base assessment turns out on the basis of comparison of indistinct intervals and characterizes importance of controllable parameter in relation to another. Also it defines a measure of possibility of deterioration of parameter.

-

2 Stage: Reception of “current” assessment of operational parameters.

As “flowing” understand an assessment characterizing degree of operational reliability of the unit during the moment.

T (П i ) = ( R r , I = 1…k ) ;

As information source about a flowing condition of parameters of operational reliability indications of systems of monitoring and control automatics serve.

-

3 Stage: Calculation of resultants of assessment of operational parameters.

Resultants of assessment of operational reliability of the hydro unit can be received by imposing of “current” assessments on “base” assessments of controllable parameters.

J (П , ) - ( RH,B (П , ) T (П , ) I = 1_n ) ;

-

4 Stage: Formation of the generalized criterion of operational reliability.

As the generalized criterion of reliability one of resultants parameters of the hydro unit which values are closest to the emergency gets out.

L Vk j = 1 – max( J k (П i ))

Application of a methodology of an assessment of an operational condition on an example of hydrounits and flowing path of Sajano-Shushenskaya hydropower plant

The assessment of a condition of hydrounits. As the initial information for calculation of base estimations of operational parameters of units tables of limiting values of hydrounit SSHHPS are used.

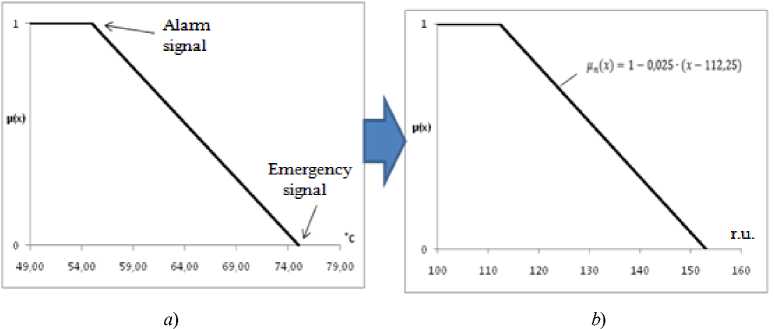

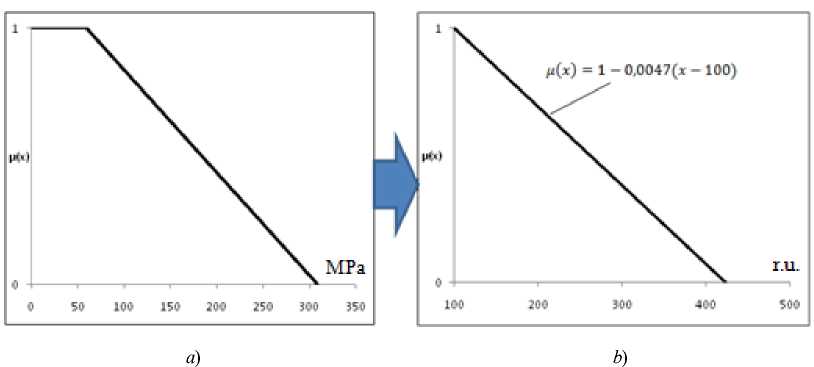

Fig. 4. Reception of membership function to increase in temperature of a stator winding the generator: a ) in nominal units (°С), b ) in relative units

а)

b)

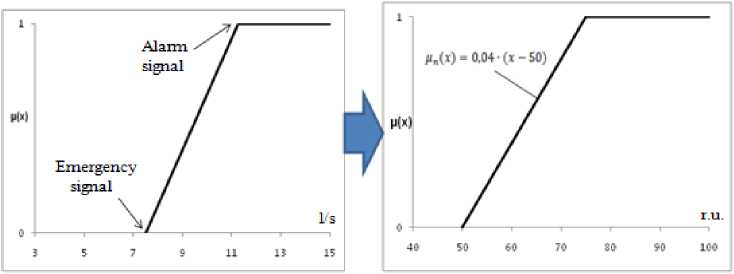

Fig. 5. Reception of function of an accessory to fall of the expense of water on cooling of the thyristor converter: а) in nominal units (l/s), b) in relative units

As a result of the analysis more than 100 parameters have been selected 50 which values can be used for construction of fuzzy intervals and reception of membership functions.

During consideration of the received data it has been defined that 39 parameters can be presented fuzzy intervals of the first type (not increasing interval) and 11 parameters are presented by fuzzy intervals of the second type (not decreasing interval). As an example of not increasing interval temperature control of a stator winding the generator (Fig. 4) can be presented.

As not decreasing interval the parameter of control of fall of the consumption of water on cooling of the thyristor converter (Fig. 5) can be presented.

Further, on the basis of the received fuzzy intervals base assessment of parameters have been calculated. In Table 1 ten most priority parameters of an operational condition are presented.

Process of formation of resultants of assessments of an operational condition is presented in Table 2. As current assessments of operational reliability 3 casual values for parameter «pressure in ring oil cooler of the generating bearing » have been simulated.

Table 1. «Base» assessment of parameters of operational reliability

|

№№ |

The parameter name |

Unit of measure |

Alarm value |

Emergency value |

The parametrical description of an indistinct interval, r.u. |

Base assessment, POSб-Вп |

|

1 |

Pressure in ring oil cooler of the generating bearing |

MPa |

3 |

3,5 |

N (100;600,0;100) |

0,847 |

|

2 |

Relative radial vibration displacement of a arbor around the turbine bearing in a direction of the left bank |

mkm |

440,0 |

540,0 |

N (100;236,56;0;53,76) |

0,625 |

|

3 |

The water consumption through arbor consolidation |

m3/s |

3 |

2,5 |

N (49,2;100;8,2;0) |

0,618 |

|

4 |

Control of the consumption of water on cooling step-bearing |

m3/s |

40 |

20 |

N (66,67;100;33,34;0) |

0,382 |

|

5 |

Absolute vertical vibration displacement of the turbine bearing from downstream |

mkm |

56,0 |

70,0 |

N (100;224;0;56) |

0,375 |

|

6 |

Relative radial vibration displacement of a arbor around the turbine bearing in a direction downstream |

mkm |

440,0 |

540,0 |

N (100;218,9;0;49,75) |

0,349 |

|

7 |

Protection against partial breakdown of isolation of high-voltage inputs of the transformer |

А |

0,056 |

0,186 |

N (100;800,0;1857,14) |

0,330 |

|

8 |

Absolute radial vibration displacement of the turbine bearing to a direction of the left bank |

mkm |

56,0 |

70,0 |

N (100;215,38;0;53,85) |

0,303 |

|

9 |

Control of the water consumption on bearing greasing in the turbine |

m3/s |

50 |

30 |

N (65,53;100;26,21;0) |

0,287 |

|

10 |

Protection against fall of The water consumption on cooling the thyristor converter |

m3/s |

11,25 |

7,5 |

N (75;100;25;0) |

0,286 |

Further the resulted values of current assessments are defined by means of substitution of the specified values in the equation of membership function µ(х) = 1- 0,01*(x-600). The given procedure is necessary for reception of values of uniform dimension. It will allow to generate further a resultant an assessments as product of a «base» and «current» estimation.

Greatest of resultants of assessments will characterize the generalized criterion of reliability of the hydrounit.

Features of an assessment of an operational condition of a flowing path Sajano-Shushenskaya hydropower plant. The flowing path of hydro turbine of SSHHPS represents composite structure. It can be divided into three basic parts is water conduit, anchorage bearing and the spiral chamber. In each part it is possible to allocate four basic elements is a steel cover, an armature inside layer, an external layer of reinforcement and concrete.

Table 2. Reception of a resultant of assessments of an operational condition

|

Condition parameter |

Type of membership function |

Base assessment, (POSб-Вп), r.u. |

current assessment, T |

Resultant assessment J= B*T |

||

|

Actual value х , MPa |

resulted value x, r.u. |

Т=1-µ( х ) |

||||

|

Pressure in ring oil cooler of the generating bearing |

µ( х ) = 1- 0,01* *( x -600) |

0,847 |

3,183 |

636,6 |

0,366 |

0,310 |

|

3,281 |

656,2 |

0,562 |

0,476 |

|||

|

3,44 |

688 |

0,88 |

0,745 |

|||

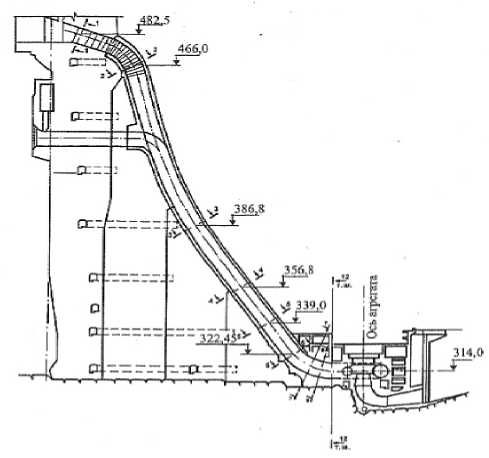

Fig. 6. The Cross-section of flowing path of Sajano-Shushenskaya hydropower plant

Flowing path of Sajano-Shushenskaya hydropower plant represents an extended design. For control of its condition on all length 11 sections (Fig. 6) are chosen. In these sections at building the control equipment (KE) has been put.

As key parameters on which control of an operational condition is conducted, mechanical stress on sites of a flowing path is considered. As at excess of admissible limits there can be a break of pressure head front that will lead to serious failure at station.

In all elements control of axial stress on compression and a stretching is carried out.

For elements of a flowing path there are no settings limit cards in which maximum permissible values are specified. Therefore as limiting mechanical stress in each element values of a yield stress of a material as at excess of yield stress there come irreversible deformations are accepted.

During the analysis of the data parameters of control of mechanical pressure have been excluded from consideration in facing concrete water as on service conditions concrete is not proof to flaw formation. It supposes in it occurrence of cracks. On sites where has occurred flaw formation, all load is redistributed on a metal cover.

-

16 parameters of control of ring pressure in a steel cover and ring armature on which the estimation of an operational condition will be made have been selected. The top border of a nominal interval accepts settlement ring pressure at a mark top бьефа equal НПУ. Calculation of stress was made under the formula:

R

-

о = p ■ —

d where p – internal pressure, MPa; R – ring radius, m; d – a thickness of a ring, m.

Also it is necessary to take into consideration that in the course of work elements of a flowing path are exposed to long loadings. Therefore at calculation of the maximum values of stress there was an account of factor of reliability on working conditions:

О , = <5™ - к dam 0,02 r , , where σdam yield strength of a material, κr reliability factor on construction working conditions.

In article «the mode deformation of head path elements of Sajano-Shushenskaya hydropower station turbines» [4] is specified that in ring elements stretching stresses prevail. Compressing stresses in a normal operating mode are not observed. Or they are insignificant so that they can be neglected at interval modeling. The obtained data is tabulated in Table 3.

The received values can be used for construction of fuzzy intervals of the first type and definition of membership functions, controllable parameters (Fig. 7).

Further calculation of an operational condition of parameters is made according to the methodology described above.

Formation of the generalized criterion of operational reliability

The received assessments of an parameters operational condition of the basic power equipment and flowing path can be used for control of operating modes within the limits of each unit. However for

Fig. 7 Reception of membership function to parameter of increase of mechanical ring stresses of a cover water conduit in section 1-1: a) in nominal units (MPa), b) in relative units

Table 3. Parameters of control of ring stresses in a steel cover and ring armature of water conduit

It is possible to name such criterion: operational reliability criterion of the hydrounit. Its assessment is formed on the basis of the generalized assessments of an operational condition of the hydrounit and a flowing path.

LVk = (LVk HU+ LVk FP)/2, where, LVk HU – the generalized estimation of an operational condition of the hydrounit, LVkFP – the generalized estimation of an operational condition of a flowing path, LVk – an estimation of operational reliability of the hydro block.

Conclusion

Summing up on the done work it is possible to formulate following conclusions:

-

1. The operation personnel while in service hydropower plant equipment often faces situations when parameters of a normal operating mode leave admissible limits. Great volume of the information not always allows once infringements that result to considerable deterioration of an operating mode of the equipment and station.

-

2. Use of the fuzzy sets theory as mathematical apparatus for methodology realization allows to lead all set of parameters of an operational condition to uniform measures and to represent the information in the form convenient for the person making decision.

-

3. As object for research carrying out Sajano-Shushenskaya hydropower station is chosen. As a result of engineering specifications processing (operative instructions and tables of settings) 50 parameters of hydrounits and 16 parameters of the flowing path characterizing an operational condition of station elements have been selected.

-

4. As a result of the spent calculations assessments of an operational condition of the hydropower plant equipment have been received. Representation of assessments in the form of fuzzy intervals gives the evident description of change process of parameter values and possibility of the forecast of its condition in the future.

-

5. The generated resultants and the generalized assessments can be used for control in frameworks of automated control system of technologic processes of hydropower plant at once at two levels:

Creation of an estimation system of the operational condition, working in a mode of «adviser», will allow to raise quality of station control and will give a mathematical substantiation to the decisions accepted by operation personnel.

-

• Control at the bottom «aggregate» level is carried out mainly by operation personnel in a machine hall of station within the limits of a condition control of hydro blocks. Resultants of an assessment of a condition of parameters will be mainly considered in this case.

-

• Management at the top «station» level is carried out by the shift engineer of station on the central control panel. Use of the generalized estimations of a condition of all hydro block for a choice the shift engineer of station of optimum station unit’s composition is present possible.