Product characteristics forecasting model with support vector machines

Автор: Kovalev I.V., Y Urkov N.S.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 5 (26), 2009 года.

Бесплатный доступ

Numerical models with support vector machines are used for forecasting material's properties depending on their production parameters. The paper includes practical forecasting results.

Forecasting model, vector machines, product characteristics

Короткий адрес: https://sciup.org/148176064

IDR: 148176064

Текст научной статьи Product characteristics forecasting model with support vector machines

Creation of materials with prespecified properties is currently one of the most challenging research areas. Solution of such tasks to some extent could give more freedom for designers from limits of available material properties and would disclose additional way of improving the designed machinery.

Preliminary author’s research [1] has shown good prospects for numerical models of material’s properties depending on their production technology at the example of wrought aluminium alloys’ mechanical properties (hardness, elongation at break) dependence on their chemical composition.

As a next step in developing this idea a following problem was considered: the object of research was limited to alloys of Al-Mn and Al-Mg systems, while the sourcing database was extended by introduction of strain-hardening parameters.

Research area. Increasing the strength of aluminium alloys could be achieved not only with adding various alloying elements, but also mechanically with strainhardening of cast slabs (peening, drawing) and heat treatment (tempering, ageing). This introduced the classification of alloys between thermally hardened and non-hardened [2].

Non-thermally hardened wrought alloys typically have relatively low strength (not far from pure aluminum’s strength), high plasticity and corrosion resistance. They are used for products which require high plasticity – produced with forming operation.

Above mentioned group of alloys include Al-Mn alloys (domestic designation AMc, international 3XXX series) and Al-Mg alloys (domestic designation AMg, international 5XXX series). The alloys are supplied in form of sheets and also rolled and formed material, in annealed (soft) condition, or after strain hardening [2].

Problem statement. It is well-known that plastic strain of metal castings increases ultimate strength, while relative elongation decreases.

International standard EN 515–1993 [3] summarizes several existing strain-hardening modes used to achieve the desired mechanical properties of thermally non-hardened wrought aluminium alloys (tab. 1).

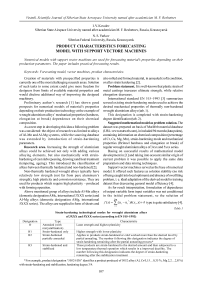

This designation is completed with strain-hardening degree identification (tab. 2).

Suggested mathematical model as problem solution. The dataset was prepared on basis of MatWeb material database (URL: , in included 94 records (data points), containing information on chemical composition (percentage of Cr, Cu, Mg, Mn), strain-hardening mode and mechanical properties (Brinnel hardness and elongation at break) of regular wrought aluminium alloys of 3xxx and 5xxx series.

Basing on successful results of mathematical model development in [1] and taking into account similar origin of current problem it was possible to apply the same data preparation and data mining techniques.

Support vector machines served as the base of numerical model. It offered such features as solution stability (no risk of being caught into local optimum) and absence of overfitting problem, i. e. ideal adaptation of the derived model to training dataset thus decreasing general model efficiency [4].

As for result interpretation, formulation of dependence of output variable form input variables was not conditioned in the initial problem statement, so the solution of

N f (x) = ^ (a, - a*) k (xi, x) + b type is quite satisfactory [4].

i = 1

Table 1

Strain-hardening technological modes for wrought aluminium alloys of 3XXX and 5XXX series (according to EN 515–1993)

|

Designation |

Type |

Characteristic |

|

O |

Annealed (with recrystallization) |

Least strength and highest plasticity |

|

H1 |

Strain-hardened only |

Higher strength with lower plasticity |

|

H2 |

Strain-hardened partially annealed |

Applies to products strain-hardened or cold worked more than the desired level by partial annealing. The number following this designation indicates the degree of strain hardening remaining after the partial annealing process* |

|

H3 |

Strain-hardened and stabilized |

These products are strain-hardened to the desired amount and then subjected to a low temperature thermal operation which results in a improved ductility. The number following this designation indicates the degree of strain-hardening remaining after the stabilization treatment |

*For example, product designation “5052-H36” identifies a product produced of 5052 alloy (Al, Cr 0,15…0,35 %, Mg 2,2…2,8 %) with strain-hardening and stabilization, hardening degree 3/4.

Mathematical apparatus of support vector machines, including its application to the problem of multiple non-linear regression, is well described in book [5] and paper [1], so it is not given here in detail.

The idea of method could be reduced to minimizing structural (expected) risk, apart from empirical one, i.e. developing such regression curve (plane), which will provide the best approximation of not only training dataset (which is normal for many alternative data mining techniques), but also the implied general dataset – all data points, including not yet registered ones.

According to the key SVM idea [6], empirical risk R e s mp should be minimized simultaneously with vector weight coefficients’ sum W 2 , which expresses the dimensionality of the model. Therefore, developing of linear regression hyperplane f ( X , W ) = W T X + b requires minimization of

-

R =-I W I1+ C Six- f ( X - W )l .

-

2 i = 1 s

Parameter C specifies relation between two summands of minimized function (i. e. relation of training error to model dimensionality).

In [5], [1] you can find the derivation of mathematical expression for the best fitted regression hyperplane for the case of non-linear regression:

f (X, W) = W0TX + b = £(ai - a*) k (XX) + b, i=1

where W 0 , b , a i , a i* - parameters of optimal model; k ( Xi , X) -kernel function; X – the array of input variables.

Model verification was done with «leave-one-out» technique, which represents the extreme case of n -fold crossvalidation, where n is the number of data point in the dataset. At every model testing iteration one data point is registered as testing dataset, while the rest – in training dataset.

For the case of regression problem, the average error of n model tests was accepted as general model adequacy [7]. Average model error was determined according to:

n e (X, Y, f ) = - £| f (X *, Y *, P, Xi)- Yi\, П i=1

Xi t X*, Yi t Y *, where X, Y– input and output arrays of dataset; f– verified model; X*, Y* – training dataset at i-step of model verification (not including i data point); P – model parameters.

Such verification method provides the following advantages (for small datasets):

-

1. Intensive usage of the dataset, which increases the possibility of deriving most adequate model.

-

2. This is a determined procedure (since it does not apply random dataset splitting), which allows better estimation of model parameter influence on its adequacy.

Data source and data preparation. MatWeb [4] online material property database was selected as the most relevant source of uniform data, which could provide the biggest dataset with minimal data omissions (due to high sensitivity of mathematical model to data omissions), containing information on standard chemical composition and mechanical properties of the considered aluminium alloy types, taking into account strain hardening.

Dataset preparation from the initial database was done in the same manner as described in paper [1]:

-

– alloying element composition values were derived as the average between high and low percentage margins;

-

– brinnel hardness (dimensionless) and elongation at break (in %) were selected as output variables.

Data preparation procedure was modified according to changes in problem formulation. The quantity of considered alloying element was reduced from 6 to 4 (Cr, Cu, Mg, Mn), since the range of alloying elements in the studied alloy groups (3xxx and 5xxx series) is limited to only these ones.

Additional input variables were introduced to represent strain-hardening mode – 3 Boolean variables. The first one is “true” if strain-hardening is present, second one is “true” only for the condition “strain-hardened partially annealed”, and third one is “true” only for the condition “strain-hardened and stabilized”.

Such scheme allowed interpretation of qualitative factor “strain hardening mode” (4 possible conditions) into Boolean variables without missing its technological origins.

The basic dataset included 94 records (data points).

Practical results. Model parameters were adjusted in accordance with the recommendations in [6], which was used in calculations described in [1].

Gaussian function (radial basis function) of

-

- 1 X - Xi I2

K ( X , X i ) = e 2ct type was chosen as kernel function due to its good compatibility with regression models.

Increasing of regulating parameter C is accompanied with exponential growth of model dimensionality (and corresponding increase in consumed computational power), with simultaneous decrease of model error, which finally stabilizes at a certain level. Due to this fact, this value was fixed at C = 1,000, which enabled single model calculation to fit into sensible time (25…30 per 1 attempt) and provided acceptable level of average model error.

Experiments on forecasting model for “elongation at break” output variable showed no model adequacy changes at C < 100. Parameter s was selected within a frame of 5... 15 % of output variable’s average (different for each model), kernel function shape parameter ( g for this kernel type) - chosen by fitting.

Verification of the derived models for forecasting aluminium alloy’s mechanical properties (considering strain-

Designations of strain-hardening degree (according to EN 515-1993)

Table 2

The study has confirmed efficiency of numerical models for forecasting material’s properties depending on their production parameters. Comparing with previous studies on this topic, the model was significantly extended, now considering two groups of technological parameters of casting production: melt’s chemical composition and casting’s strain-hardening mode.

The paper includes practical forecasting results for 3xxx and 5xxx series wrought aluminium alloys’ properties.

Practical results of the study demonstrate the possibility of creating «inverse» model, i. e. selection of technological parameters for production of materials with predefined properties, which would be of significant practical interest.