Production of PVC-films with specific properties

Автор: Maskova Albina Rafitovna, Aminova Guliya Karamovna, Faizullina Svetlana Radikovna, Faizullina Galiya Fatyhovna, Mazitova Aliya Karamovna

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Разработка новых полимерных материалов

Статья в выпуске: 4 т.10, 2018 года.

Бесплатный доступ

When developing polymeric materials with specified properties special compounds such as fungicides are used alongside traditional chemical additives (plasticizers). Usage of fungicides are determined by negative influence of mold fungi, bacteria and other microorganisms on polyvinyl chloride (PVC) material. The present work focuses on the possibility to implement octylphenoxypropyl phthalates (OPOPP), proposed as plasticizers, and derivatives of 3-mercapto-1,2,4-triazinon-5, proposed as fungicides, in PVC films. The first additive was produced by esterification of phthalic anhydride by oxypropylated phenols and 2-ethylhexanol, the second additive - by cyclocondensation of alpha-keto acids with thiosemicarbazide. Having analyzed the results of experiments the authors found out that compositions obtained with the use of new additives - octylphenoxypropyl phthalates and derivatives of 3-mercapto-1,2,4-triazinone-5, acquire high performance properties that leads to increased service life. At the same time such important characteristics as strain at elongation, ultimate tensile stress, thermostability and funginertness are enhanced.

Funginertness, dioctyl phthalate, tension at elongation, octylphenoxypropyl phthalate, ultimate tensile stress, pvc film, plasticizers of polyvinyl chloride, thermostability, fungicide

Короткий адрес: https://sciup.org/142217080

IDR: 142217080 | УДК: 678 | DOI: 10.15828/2075-8545-2018-10-4-102-115

Текст научной статьи Production of PVC-films with specific properties

M achine - readable information on CC- licenses (HTML- code ) in metadata of the paper

Production of PVC-films with specific properties by Maskova A.R., Aminova G.K., Faizullina S.R., Faizullina G.

F., Mazitova A.K. is licensed under a ...

olymeric materials are used in different fields of industry. One can notice the increasing number of the works devoted to polymers with specified characteristics, as well as advanced requirements to be met by these materials.

At the present time polyvinyl chloride (PVC) is the most widely used polymer. Pure polyvinyl chloride is difficult processed, for this reason PVC is mixed with different additives. The main role of chemical additives is to facilitate polymeric mixtures processing and giving the necessary properties to finished products. A wide range of physical and mechanical properties of plastics are obtained by using additives, that makes it possible to produce a wide variety of products – from very soft, gel-like to elastic, rigid materials. Thus chemical additives expand the field of PVC applica-

DEVELOPMENT OF NEW POLYMER MATERIALS tion and allow it to be considered as a multicomponent system and the most easily compounded thermoplastic polymer [7–12].

More than 12 million tons of polymeric additives are produced every year in the world and plasticizers are the major part of them. Partial use of PVC in plasticized form are determined by characteristics of its chemicals structure – low elasticity, a significant temperature range of plastic deformation, and insufficient frost resistance [2, 5–7, 11, 12]. For this reason, intensification of manufacturing process and expansion of PVC application fields and providing wide variety of its properties, are connected to a large extent with the successful solution of the problem of creating effective plasticizers.

As known, phthalates are widely used as plasticizers in polymer industry. Dioctyl phthalate (DOP) is the main representative of phthalate plasticizers and it still remains the most widespread ester plasticizers of PVC. DOP possesses the optimal combination of properties, it is comparatively cheap, but DOP doesn’t provide necessary service properties especially funginertness [11].

In this connection it is advantageous to produce the following additives: octylphenoxypropyl phthalates (OPOPP), which are proposed as plasticizers and derivatives of 3-marcapto-1,2,4-triazinone-5, which are proposed as fungicides. It is of great interest to study their properties and the possibility to develop PVC-materials that could meet the advanced operation requirements with the use of them.

We have produced new ester compounds – octylphenoxypropyl phthalates (OPOPP) with hydroxypropylation degree of phenol 1.0–2.1, that present slightly hygroscopic, oily liquids of yellowish color, highly soluble in organic solvents. OPOPP were obtained by the methods previously developed by us, by the esterification of phthalic anhydride by oxypropylated phenols and 2-ethylhexanol [13–27]. The physicochemical properties of proposed plasticizers are shown in table 1.

To determine the efficiency of suggested plasticizers the changing of Shor A hardness from the concentration of plasticizer were investigated (plasticizer: PVC – 1:100) [2-6]. On the base of calculation of quantitative substitution factor (SF) it was determined that 1,0-OPOPP is very similar to DOP by plasticization efficiency (table 1).

As known, plasticized PVC materials can be exposed to various microorganisms including fungus under unfavorable conditions which adversely

DEVELOPMENT OF NEW POLYMER MATERIALS affected on the visual appearance of plastic compounds and reduce their service life. One of the way to protect PVC materials from negative influence of mold fungi is to introduce fungicides into compositions [11, 28].

Table 1

Physicochemical properties of octylphenoxypropyl phthalates

|

Characteristics |

1,0-OPOPP |

1,5-OPOPP |

2,1-OPOPP |

|

Yield, % |

89 |

87 |

84 |

|

Ester number., mg КОН/g |

269 |

251 |

232 |

|

Molecular mass, found |

416 |

446 |

481 |

|

Flash point, оС |

199 |

198 |

198 |

|

Substitution factor |

1,019 |

1,043 |

1,052 |

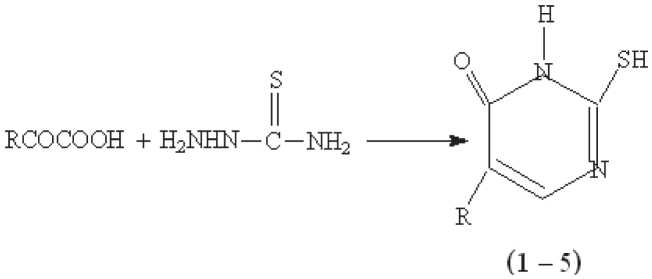

To realize this we obtained derivatives of nones-5 (scheme 1):

3-mercapto-1,2,4-triazi-

,

where R = СН3 (1), i-C3H7 (2), i-C4H9 (3), t-C4H9 (4), C6H5 (5).

Scheme 1

Compounds of the heterocyclic series were obtained by cyclocondensation of alpha-keto acids with thiosemicarbazide.

At the beginning, the reagents were loaded in the following order: water 100 ml (solvent), sodium hydrogen carbonate 0,01 mole (cyclizing

DEVELOPMENT OF NEW POLYMER MATERIALS agent), alpha-keto acid 0,1 mole, thiosemicarbazide 0,1 mole. The reaction was performed at 100оС for 3 hours then cooled to 10оС and neutralized with concentrated hydrochloric acid to pH = 6,0. The obtained precipitate was filtrated, washed with water and dried on the air.

For obtaining 3-mercapto-1,2,4-triazinon-5 with the maximum yield, the filtrate was treated with a concentrated solution of sodium hydroxide and kept under synthesis conditions for 1 hour. The resulting precipitate was filtered off, washed with water and air-dried.

3-Mercapto-1,2,4-triazinones-5 are solids, from white to orange colour, soluble in many organic solvents.

Physicochemical properties and spectral characteristics of the synthesized compounds are presented in table 2.

Physicochemical properties and spectral characteristics of 3-mercapto-1,2,4-triazinones-5

Table 2

|

Characteristics |

3-Mercapto-1,2,4-triazinones-5 |

||||

|

1 |

2 |

3 |

4 |

5 |

|

|

Yield, % |

80 |

80 |

74 |

79 |

80 |

|

Melting point, оС |

217–219 |

132–134 |

160–162 |

280–282 |

255–257 |

|

IR-spec-trum, sm–1 |

1670,1270, 1520 |

1675,1270, 1540 |

1690,1260, 1390 |

1675,1260, 1520 |

1670,1260, 1540 |

|

UV-spec-trum, nm |

190,275,310 |

195,280,319 |

190,270,315 |

192,270,320 |

220,290,330 |

Preliminary investigations have shown that derivatives of 3-mercap-to-1,2,4-triazinon-5 possess high fungicidal activity [29, 30].

Next the produced compounds were tested in the PVC-films. Physical and mechanical properties of obtained PVC-films were analyzed according to standards: thermostability – according to GOST 14041-91, melt flow index – according to GOST 11645-73, funginertness – according to GOST 9.049-91, method 1.

DEVELOPMENT OF NEW POLYMER MATERIALS

The results of testing of plasticized PVC-films containing 3-mercapto-1,2,4-triazinones-5 as additive

Table 3

|

Characteristics |

Control* |

1,0-ОPOPP + 3-mercapto-1,2,4-triazinones-5 |

||||

|

1 |

2 |

3 |

4 |

5 |

||

|

Strain at elongation 100%, MPa |

11,1 |

11,9 |

11,8 |

12,0 |

12,2 |

12,4 |

|

Ultimate tensile stress, MPa |

21,6 |

22,8 |

22,7 |

22,9 |

23,2 |

23,4 |

|

Breaking elongation, % |

340 |

305 |

305 |

309 |

308 |

310 |

|

Extractability by waters, % |

0,012 |

0,212 |

0,243 |

0,146 |

0,087 |

0,014 |

|

Water absorption, % |

0,195 |

0,312 |

0,315 |

0,294 |

0,207 |

0,201 |

|

Melt flow rate, g/10min |

44,5 |

40,2 |

40,4 |

39,3 |

38,9 |

38,7 |

|

Thermostability at 175оС, min |

165 |

170 |

169 |

172 |

174 |

175 |

|

Funginertness, grade |

Not resistant |

Resistant |

Resistant |

Resistant |

Resistant |

Resistant |

* PVC-film, plasticized with DOP, without 3-mercapto-1,2,4-triazinones-5

As it can be seen from table 3, PVC-films produced by introducing developed octylphenoxypropyl phthalates and derivatives of 3-marcapto-1,2,4-triazinone-5, acquire high performance properties that leads to increased service life of the films. In particular, one should note the improvement of the following indices: strain at elongation, ultimate tensile stress and thermostability. Evaluating funginertness of materials by the degree of fungi it has been found out that composition prepared on the base of PVC with octylphenoxypropyl phthalates and derivatives of 3-marcapto-1,2,4-triazinone-5 acquire high fungi resistance, while compositions prepared with the use of only plasticizer DOP were unstable with respect to microorganisms.

All this indicates the perspective of using octylphenoxypropyl phthalates as plasticizers and derivatives of 3-marcapto-1,2,4-triazinone-5 as fungicides.

DEVELOPMENT OF NEW POLYMER MATERIALS

The performed research has been funded through the government grant «Synthe-sis and investigation of the modern polyvinyl chloride plasticizers» according to the Decree of the Government of the Republic of Bashkortostan of 07.02.2018 № 56 «On providing grants of the Republic of Bashkortostan to young scientists and groups of young researchers in 2018».

Список литературы Production of PVC-films with specific properties

- Воскресенский В.А., Орлова Е.М., Абрамов Е.И., Прохорова Н.С. Пластификация полимеров//Успехи химии. -1971. -Т. 15, № 1. -С. 142-159.

- Штаркман Б.П. Пластификация ПВХ. -М.: Химия, 1975. -248 с.

- Минскер К.С., Федосеева Г.Т. Деструкция и стабилизация поливинилхлорида. -М.: Химия, 1979. -272 с.

- Аскадский А.А., Матвеев Ю.И. Химическое строение и физические свойства полимеров. -М.: Химия, 1983. -248 с.

- Уилки Ч., Саммерс Дж., Даниелс Ч. Поливинилхлорид. -СПб.: Профессия, 2007. -728 с.

- Гроссман Ф. Руководство по разработке композиций на основе ПВХ. -М.: Научные основы и технологии, 2009. -550 с.

- Маслова И.П. Химические добавки к полимерам. Справочник. -М.: Химия, 1981. -264 с.

- Мазитова А.К., Аминова Г.К., Нафикова Р.Ф., Дебердеев Р.Я. Основные поливинилхлоридные композиции строительного назначения. -Уфа, 2013. -130 с.

- Мазитова А.К., Нафикова Р.Ф., Аминова Г.К. Пластификаторы поливинилхлорида//Наука и эпоха: монография. -под общей ред. проф. О.И. Кирикова. -Воронеж, 2011. -С. 276-296.

- Маскова А.Р. Поливинилхлоридные композиции строительного назначения, пластифицированные фталатами оксиалкилированных спиртов: дис.. канд. техн. наук. -Уфа, 2012. -143 c.

- Барштейн Р.С., Кириллович В.И., Носовский Ю.Е. Пластификаторы для полимеров. -М.: Химия, 1982. -196 с.

- Тиниус К. Пластификаторы. -М.: Химия, 1964. -915 с.

- Файзуллина Г.Ф., Габитов А.И., Маскова А.Р., Ахметова И.И. Пластификация поливинилхлорида новыми пластификаторами//Нефтегазовое дело. -2017. -Т. 15, № 3. -С. 106-111.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Ягафарова Г. Г., Мазитов Р.М. Новые пластификаторы для пвх-композиций строительного назначения//Нанотехнологии в строительстве. -2017. -Том 9, № 4. -С. 48-63. - dx.doi.o DOI: rg/10.15828/2075-8545-2017-9-4-48-63

- Mazitova A.K., Aminova G.K., Maskova A.R., Zentsov V.N., Nedopekin D.V., Rayzer Ju.S. Development of Oil-Benzen-Resistant PVC-Plastics. Journal of Engineering and Applied Sciences, 12: 7865-7869. 2017 DOI: 10.3923/jeasci.2017.7865.7869

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Cабитов И.Н., Недосеко И.В. Новые пластификаторы поливинилхлорида//Нанотехнологии в строительстве. -2017. -Том 9, № 6. -С. 168-180. - dx.doi.o DOI: rg/10.15828/2075-8545-2017-9-6-168-180

- Мазитова А.К., Аминова Г.К., Габитов А.И., Маскова А.Р., Рахматуллина Р.Г. Новые пластификаторы ПВХ-композиций специального назначения//Башкирский химический журнал. -2015. -Т. 22, № 3. -С. 23-26.

- Мазитова А.К., Аминова Г.Ф., Габитов А.И., Маскова А.Р., Хуснутдинов Б.Р., Фаттахова А.М. Разработка новых пластификаторов поливинилхлорида//Нефтегазовое дело. -2014. -Т. 12, № 1. -С. 120-127.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Буйлова Е.А., Недопекин Д.В. Дифеноксиэтилфталаты и бутоксиэтилфеноксиэтилфталаты -новые пластификаторы поливинилхлорида//Нефтегазовое дело. -2015. -№ 5. -С. 376-397.

- Мазитова А.К., Степанова Л.Б., Аминова Г.Ф., Маскова А.Р. Разработка функциональных добавок для поливинилхлоридных композиций строительного назначения//Промышленное производство и использование эластомеров. -2015. -№ 2. -С. 27-31.

- Маскова А.Р., Степанова Л.Б., Аминова Г.Ф., Рольник Л.З., Абдрахманова Л.К. Испытание рецептур ПВХ-композиций строительного назначения на основе новых добавок//Промышленное производство и использование эластомеров. -2015. -№ 3. -С. 11-15.

- Aminova G.F., Gabitov A.I., Maskova A.R., Yagafarova G.G., Rolnik L.Z., Klyavlin M.S. New composite PVC-material for finishing purposes, plasticized by butoxyalkylphenoxy-alkylphthalates//Electronic scientific journal «Oil and gas business». -2013. -№ 5. -P. 353-362.

- Мазитова А.К., Аминова Г.К., Маскова А.Р. Исследование термостабильности фталатов оксиалкилированных спиртов//Нанотехнологии в строительстве. -2018. -Том 10, № 2. -С. 157-170. - dx.doi.o DOI: rg/10.15828/2075-8545-2018-10-2-157-170

- Маскова А.Р., Мазитова А.К., Аминова Г.К., Рольник Л.З., Файзуллина Г.Ф. Исследование реологических свойств ПВХ-композиций, содержащих фталатные пластификаторы//Нанотехнологии в строительстве. -2018. -Том 10, № 3. -С. 127-137. - dx.doi.o DOI: rg/10.15828/2075-8545-2018-10-3-127-137

- Маскова А.Р., Буйлова Е.А., Азнабаев Ш.Т., Мазитова А.К. О некоторых свойствах бутоксиэтилбензоксиэтилфталатов//Промышленное производство и использование эластомеров. -2015. -№ 4. -С. 20-22.

- Мазитова А.К., Нафикова Р.Ф., Аминова Г.Ф., Габитов А.И., Маскова А.Р., Хуснутдинов Б.Р. Поливинилхлоридные композиции изоляционного назначения на основе фталатов оксиалкилированных спиртов//Промышленное производство и использование эластомеров. -2014. -№ 2. -С. 36-39.

- Мазитова А.К., Аминова Г.К., Маскова А.Р., Буйлова Е.А. Новые фталатные пластификаторы для поливинилхлоридного линолеума//Нефтегазовое дело. -2015. -Т. 13, № 3. -С. 83-86.

- Алешин А.А., Панов Ю.Т., Кудрявцева З.А. Биоразрушаемая полимерная композиции//Современные наукоемкие технологии. -2007. -№ 6. -С. 29-31.

- Аминова Г.К., Кудаярова Р.Р., Булдаков А.К., Мазитова А.К. О биологической активности 1,2,4-триазиндионов-5,6//Башкирский химический журнал. -2004. -Т. 11, № 4. -C. 15-16.

- Мазитова А.К, Сухарева И.А., Агзамов Р.Р., Буйлова Е.А., Недопекин Д.В. Химические превращения 3-меркаптопроизводных несимметричных триазинов//Башкирский химический журнал. -2017. -Т. 24, № 2. -C. 75-80.