Prospects for bioenergetics

Автор: Grachyov Victor Vasilevich, Markov Roman Borisovich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Environmental economics

Статья в выпуске: 4 (8) т.2, 2009 года.

Бесплатный доступ

The article considers possibilities of energy production increasing through forest resources rational use. This important case organizing experience, which characterizes its development prospects on the materials of the Vologda region is presented in the article.

Energy resumption, complex timber processing, wood pellets production, cost-effectiveness

Короткий адрес: https://sciup.org/147223161

IDR: 147223161 | УДК: 620.95

Текст научной статьи Prospects for bioenergetics

The article considers possibilities of energy production increasing through forest resources rational use. This important case organizing experience, which characterizes its development prospects on the materials of the Vologda region is presented in the article.

Energy resumption, complex timber processing, wood pellets production, cost-effectiveness.

Victor V.

GRACHYOV

Head of Forestry Department of the Vologda region, Deputy governor of the Vologda region

Roman B.

MARKOV

Head of investment development administration,

Deputy head of Forestry Department of the Vologda region

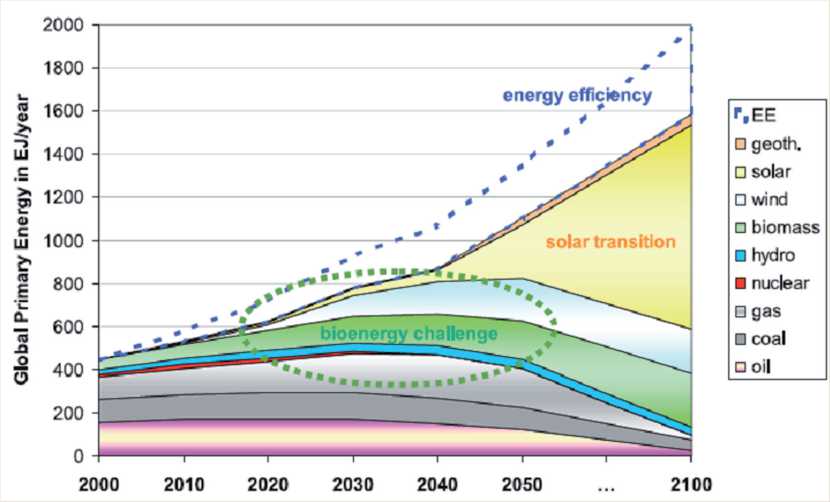

Global economic development demands a significant increase in energy production. Meanwhile, traditional fuel reserves, such as natural gas, oil and coal, have been gradually exhausting. That is why there has been a lot of research programs done in the world aimed at finding alternative kinds of fuel (fig. 1) .

As can be seen in figure 1, the world share of bioenergy (renewable energy) will grow in future.

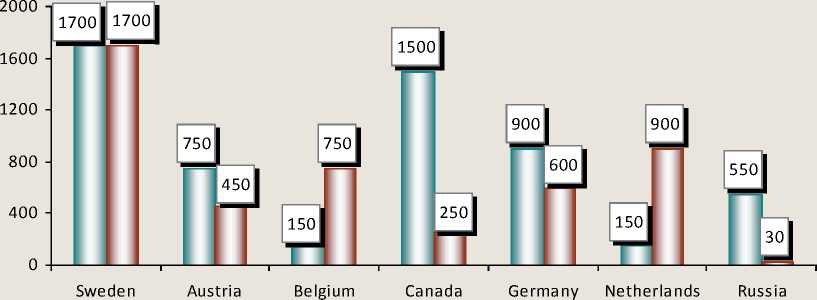

Today the developed countries have reached a 10 – 15% share of renewable energy. And in some countries, such as Austria, Sweden, Finland the share of renewables makes up almost 25% of total energy production (fig. 2) .

And at the same time the largest share of bioenergy comes from biofuel and it means that timber resources are the source materials for this kind of energy.

Meanwhile, Russia, having the largest timber resources, produces less than 1% of bioenergy.

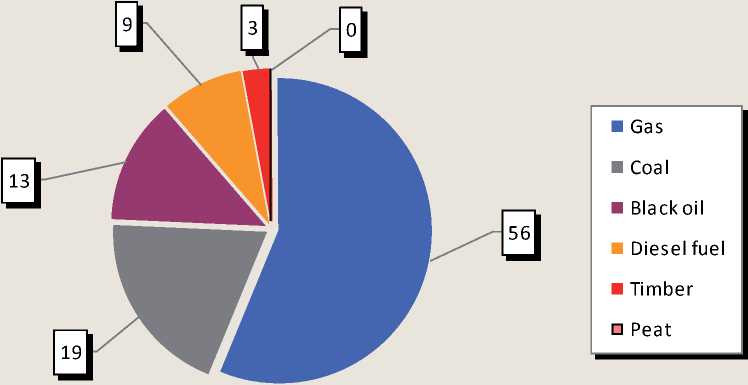

In the North-West the share of use of timber resources in fuel and energy balance counts for 3%, and it is extremely insufficient and does not correlate with its potential use (fig. 3) .

Accepting all challenges that are offered to our country by the world economy, the Government of the Russian Federation began to pursue a new policy aimed at increasing the use of renewable energy sources.

Figure 1. Global energy production by fuel type

Source: IEA (2007), IPCC (2007), UNPD (2004) and WBGU (2003).

Figure 2. The proportion of energy production from renewable resources in some countries, %

Figure 3. The structure sheme of fuel and energy balance of the North-West federal district, %

For example, an the beginning of January 2009, the Russian Federation Government adopted the resolution provided that in 2010 Russia will get 1.5% of total energy from renewable sources and 4.5% by the year of 2020.

The issues of bioenergy development, taking into account the problem of integrated timber processing, have been discussed at all levels of authority, including the Council for Forest Sector Development under the Russian Federation Government.

The vital task for today is to create and implement efficient technologies of biofuel production from different kinds of biological sources. And wood resources are of particular interest here.

At the same time bioenergy does not confine itself to the problem of fuel production, the field of bioenergy deals also with modern technologies for production of biofuel-generated heat and electricity (fig. 4) .

At present, wood is one of the most common types of raw materials for production of biofuel and bioenergy (tabl. 1) .

Table 1 presents wood in traditional types of fuel, such as firewood, sawdust, wood chips, wood shavings, bark, as well as in modern fuels – briquettes and granules (pellets).

The use of compressed dried wood fuel (briquettes and granules) is widespread in the world because of its energy properties and pellets became the most widespread form of compressed fuel due to the simple technology of combustion.

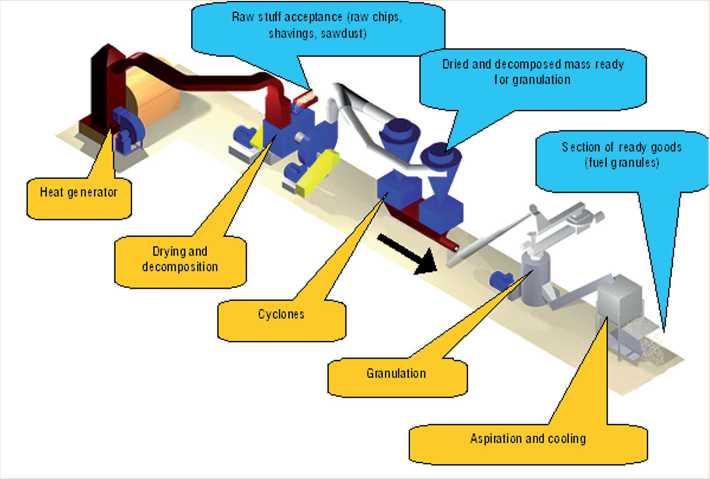

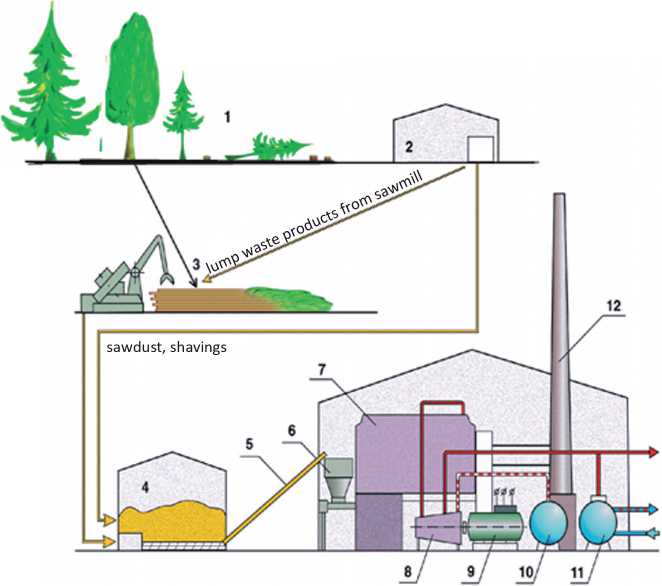

The structure scheme of pellet production or technological scheme is shown at figure 5 :

At present in Europe fuel granules are used mainly for heat production by heat and power plants. Before that the heating plants used coal to produce heat. The process of combustion of dust-like coal was replaced by the process of combustion of dust-like wood fuel.

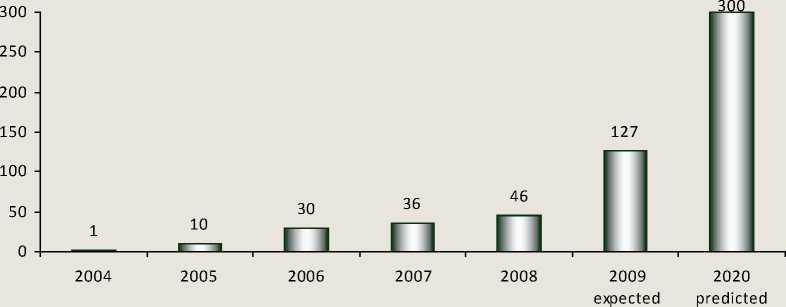

The world production and consumption of wood granules is about 8 – 10 million tons per year and grows at 15% annually (fig. 6) .

The world’s biggest pellet producers are Sweden, the USA and Canada. In Russia the pellet production increased from 10,000 tons in 2003 to 500,000 tons in 2009.

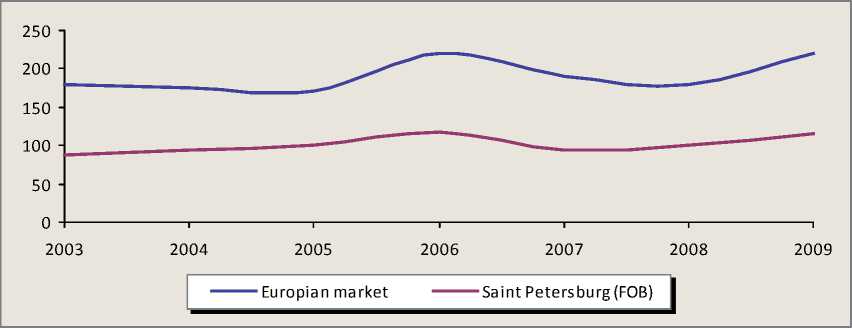

European countries are the main markets for Russian pellet production. Pellet prices remain stable and show a tendency to grow (fig. 7) .

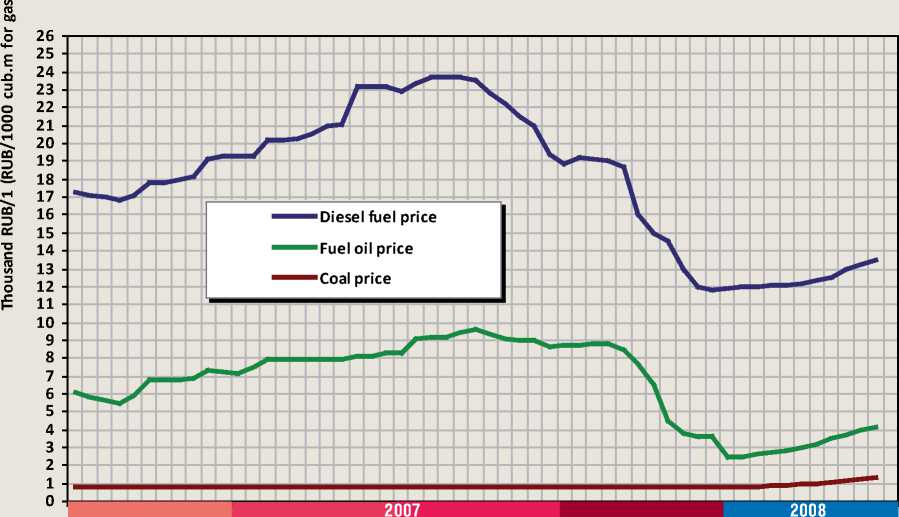

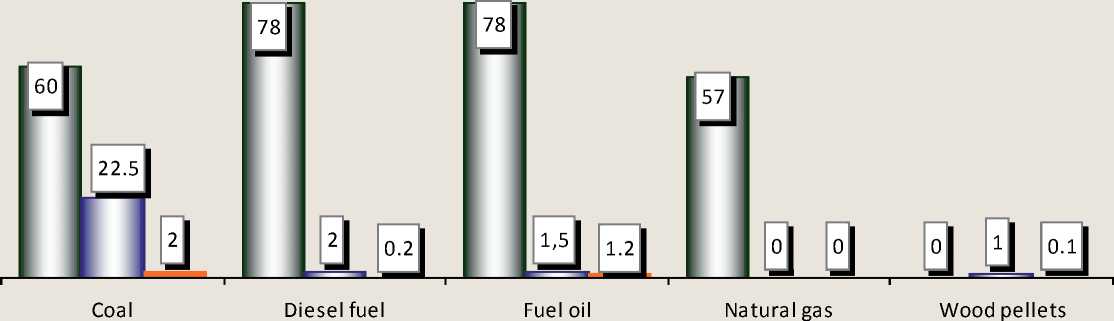

Analyzing pellet prices one should take into account fuel prices. Price changes for different kinds of fuel are shown at figure 8 .

Figure 4. Bioenergy, the classification of biomass

BIOFUEL

Solid fuel (wood, wood chips, sawdust, briquettes, granules)

Liquid and gas fuel (biodiesel, bio

Non-combustible items

Table 1. Properties of biofuel from wood raw materials

|

Type of Biofuel |

Moisture content, % |

Ash content, % |

Sulfur content, % |

Specific gravity, kg/m3 |

|

Sawdust, wood chips |

8-60 |

0.4-0.6 |

0-0.3 |

200-350 |

|

Granules, briquettes |

9-10 |

0.4-0.8 |

0-0.3 |

550-700 |

|

Tops and branches |

35-55 |

1-5 |

0.02-0.05 |

200-350 |

|

Bark |

21-65 |

2-6 |

0-0.1 |

300-550 |

|

Foliferous wood |

20-40 |

0.3-1.7 |

0.01-0.04 |

440-580 |

Figure 5. The stucture scheme of wood fuel granules and pellets production

Figure 6. The production and consumption of wood fuel granules (pellets), thous. tons

□ Production □ Consumption

Figure 7. Pellet price movement, euro/tons

Figure 8. Price changes for fuels competing with pellet prices

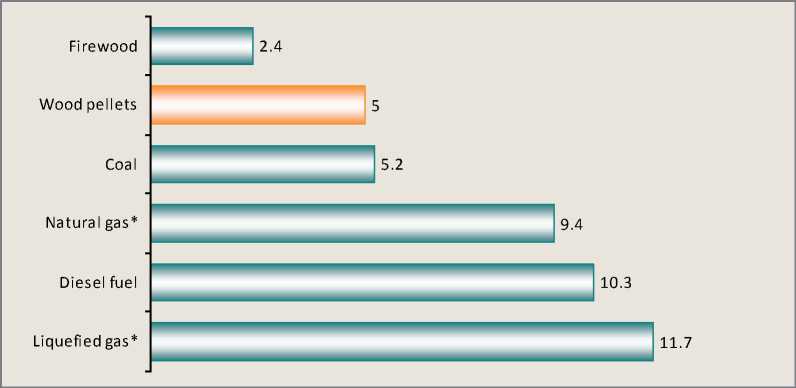

Figure 9. The calorific value of different types of fuel, kWh/kg

*kWh/cu.m.

The calorific value of wood pellets is close to that of coal and is much higher than the calorific value of firewood (fig. 9) .

The amount of carbon dioxide released during the combustion of wood pellets does not exceed the amount of emissions if wood was left to decompose through natural process. The amount of ash from wood pellet burning is 15 – 20 times less than that of the coal burning (fig. 10) .

In the Vologda region due to investments the volume of timber processing has been constantly growing. At present there are 8 priority investment projects concerning forest development in our region. One of the first fully implemented projects in Russia became the project of “Cherepovetz Plywood and Furniture Plant”.

The volumes of forest harvesting will certainly grow and at the same time a big amount of low-quality wood will be logged, that’s why

Figure 10. The amount of emissions released during the combustion of different types of fuel, %

Sulfurs

□ Carbon dioxide

□ Ashes

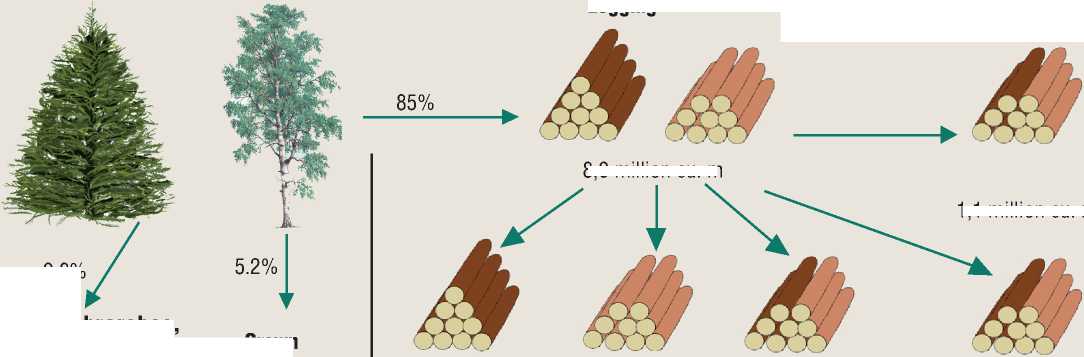

Figure 11. The balance of wast use from wood harvesting and processing in the Vologda region

Logging

Firewood

8,9 million cu. m

9.8%

Crown

Veneerlog

Palpwood

3.1 million cu. m

1.6 million cu. m

Balkraw materials 0.9 million cu. m

Coniferous sawlog

2.2 million cu. m

Batchirg, brarches, tops

1,1 million cu. m

Not used

Batchirg

Used as fuel

Sawmilling and wood processing

Sawduct,shavings, chips, lamp waste

830 thous. cu. m

Pulp and paper plant

Pulpchips

Used as fuel

360 thous. cu. m

cormbasted in heat boilers for pellet production about 210 thous. cu. m about 320 thous. cu. m

resources for use about 300 thous. cu. m

one should realize that it is necessary to utilize waste materials that remain after mechanical wood processing. The Government of the Vologda region is implementing a strategic and integrated approach to bioenergy development.

We calculated a balance of use of wastes that remain in the process of forest harvesting and wood processing taking into account the exist- ing provision of firewood to the population, the provision of wood to the municipal boiler houses, firing of wastes in utilizing boilers at timber industry plants and wood chips supply to wood-based panels production plants and pulp and paper industries. We estimated the volume of wastes from wood processing production and low-quality wood (fig. 11).

As a result, the main directions for the development of biofuel production and use of wood for heat and power technology were determined.

The first step is the production of wood granules and briquettes.

In 2003 the program for the development of biofuel production was worked out and now it is being implemented successfully.

According to the program 9 biofuel manufacturing plants are constructed in the Vologda region and their total manufacturing capacity is more than 200 thous. tons pellet/year. During the current year despite difficult financial conditions their wood pellet output has increased more than 2 times. And due to the rise in demand for wood pellets, current market prices and increase in euro exchange rates against ruble this branch of forest industry became the most profitable one (fig. 12) .

Nowadays we are completing the construction of a large wood processing plant in the town of Babayevo jointly with Krasnodar company “Altbiot”. Except wood processing the project stipulates the construction of bio fuel production plant with 100,000 tons capacity.

On the territory of Cherepovetz district we are implementing a joint project with a Polish company “Barlinek” on wood processing and bio fuel production as well as construction of some other industries.

The enterprises that specialize in production of wood pellets and their manufacturing capacity are shown in the table below (tabl. 2) .

At the same time pellet production is oriented mainly towards export, because the cost of wood pellets fluctuates between 2.5 – 3 thous. rub./tons (tabl. 3) .

A number of measures are put into practice aimed at involving the wastes from wood working into the process of production.

In our region micro-combined heat and power plants (micro-CHP) for heat and electricity production are being constructed rapidly (fig. 13) .

The first industrial micro-combined heat and power plant “Bely Ruchey” , a subsidiary of OAO “Territorial Generating Company-2”, was constructed in 2005. It is situated in the settlement of Depo of the Vytegra ditrict. The installed electrical generating capacity is 6 MW and the useful heat output is 29 thous. gigacalories per year. By processing of low quality wood and wood wastes the micro-CHP provides heat and electricity to a large woodworking enterprise ZAO “Bely Ruchey” and to the social facilities of the settlement.

In 2006 the second micro-combined heat and power plant using waste wood fuel was put into operation at OAO “Veliky Ustyug Plywood Plant Novator” with the capacity of 3 MW . The launch of the plant enabled to provide 68% of the production of own electricity and to provide recycling of 7 thous. solid cu. m of wood waste per month.

Figure 12. Wood granules and briquettes production in the Vologda region, thous. tons

Table 2. Wood fuel granule (pellet) production enterprises in the Vologda region

|

Enterprise |

Location |

Capacity, thousand tonnes per year |

|

OOO “Vologdabioexport” |

Veliky Ustug |

50 |

|

ZAO “Vologda Wood Chemical Plant” |

Vologda |

20 |

|

OOO “Major” |

Cherepovetz |

18 |

|

OOO “Terry” |

Semenkovo of Vologda district |

8 |

|

OOO “PelletMaxGroup”, |

Sokol |

7 |

|

ZAO “Bioenergy Fuel Company” |

Kadnikov |

50 |

|

OOO “Lespromsever” |

settlement of Verkhovazh’ye |

30 |

|

OOO “Bi.Drev” |

settlement of Babushkin |

8 |

|

OOO “Vologda Biofuel Technologies-2” |

Babayevo |

30 |

Table 3. The cost structure of wood fuel granules (pellets) production

|

Expenses |

Cost, RUB |

Share, % |

|

Labor and taxes |

512.78 |

16.7 |

|

Electricity |

461.32 |

15.1 |

|

Gas |

148.74 |

4.8 |

|

Depreciation |

449.37 |

14.5 |

|

Raw materials |

653.05 |

21.2 |

|

Fuel |

102.02 |

3.3 |

|

Fixed assets repair |

388.25 |

12.6 |

|

Payroll taxes |

125.93 |

4.1 |

|

Other |

233.61 |

7.7 |

|

Total |

3075.07 |

100 |

Figure 13. The production scheme of heat and electricity from wood fuel

-

1. Firewood

-

2. Sawmill and woodworking workshops

-

3. Chip fuel production line

-

4. Fuel storehouse

-

5. Conveyor

-

6. Service bunker

-

7. Steam boiler

-

8. Steam turbine

-

9. Electric generator

-

10. Condenser

-

11. Heater

-

12. Smokestack

The government of the Vologa region is planning to construct a number of similar projects.

Nowadays almost all woodworking plants have boiler houses that use by-products of sawmilling and wood working. The boilers produce heat for industrial premises heating and drying room maintenance. The biggest utilizing boilers are installed at the sawmills of OAO “Belozersky Lespromhoz”, ZAO “Chere-povetz FMK”, OAO “Sokolsky DOK”, OOO “Premiumles”, OOO “Kharovsklesprom”, OOO “Novatorsky LPK”, OAO “Veliky Ustug Plywood Plant Novator”.

For example, OAO Sokolsky DOK (a city forming enterprise, which along with production activity produces heat for the majority of social facilities in Sokol) installed 2 boilers KM-10 (made in Russia) run by wood waste (sawdust, shavings, bark, unconditioned wood chips) and decreased the annual gas consumption at the plant from 16,000 cu. m to 9,000 cu. m (by 44%). The annual gas savings are estimated at 12.6 million rub. The purchase price and installation of boilers were paid off within 3 years.

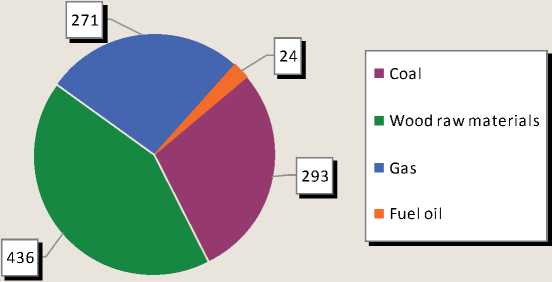

More than 400 municipal boiler houses located in the districts of our region use firewood or wood waste (wood chips and sawdust) as fuel (fig. 14) .

In 2008 2 new boiler houses with recycling of wood chips and sawdust were put into operation in Ustuzhna and Babushkino districts to supply heat to the social facilities of the districts.

A number of boiler houses is planned to be constructed on the basis of public private partnership.

There are pyrolized boilers for coal production in Kaduy and Syamzha.

Some forest and agriculture enterprises have gas-producer plants that use wood fuel and at present they are undergoing testing.

Therefore, the wastes from wood logging as well as low-grade deciduous wood (faulty aspen), bulk raw materials, sawmilling and wood processing wastes are involved into the process of production with the help of modern engineering technologies that can provide integrated wood recycling process. Such approach results in a significant economic efficiency in forest industry.

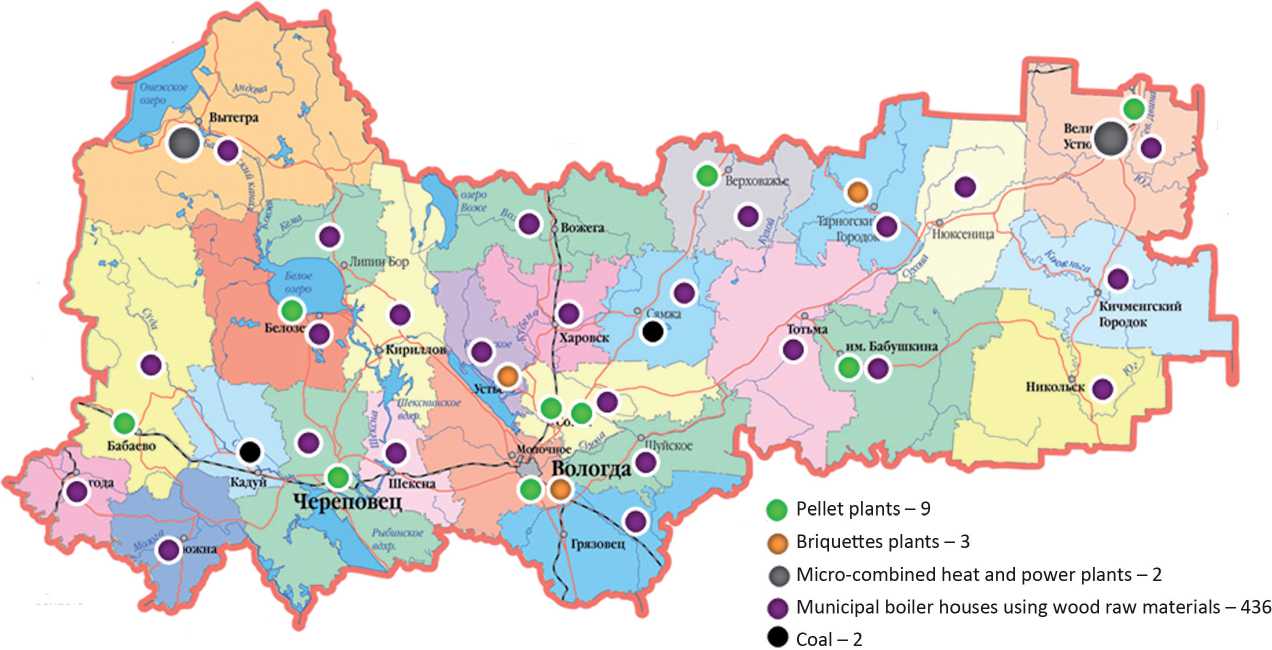

The location of bioenergy plants in the Vologda region is shown below (fig. 15) .

The biofuel production plants that are planned to be constructed according to the program are marked on the map below (fig. 16) .

The implementation of programs aimed to develop bioenergy in the Vologda region will allow to provide the annual production of 300,000 tons of biofuel by the year of 2020, to increase electricity capacity of micro-combined heat and power plants to 22 MWe through the

Figure 14. Boiler houses in municipal districts of the Vologda region using different types of fuel, in numbers

Figure15. Currently operating bioenergy plants in the Vologda region

Figure 16. The projected biofuel plants

Table 4. Prospects by the year of 2020

Table 5. Economic and social efficienceys from fuel briquettes use in housing and communal services of the Vologda region

|

Indicator |

Index |

|

Economic efficienc |

|

|

I. The use of coal fuel |

|

|

1. Price per tonne including transportation costs |

2,700 rub. |

|

2. Calorific Value |

5.2 kWh/kg |

|

3. Efficiency of boilers |

70% |

|

4. Total volume of coal consumption per year |

160,000 tons |

|

5. Total costs |

432 mln. rub. |

|

II. The use of fuel briquettes |

|

|

1. Price per tonne |

3,000 rub. |

|

2. Calorific Value |

5.0 kWh/kg |

|

3. Efficiency of boilers |

90% |

|

4. Necessary volume of consumption |

129,000 tons |

|

5. Total costs |

387 mln. rub. |

|

III. The use of wood wastes |

129,000 tons х 653,000 rub. = 84 mln. rub. |

|

IV. Total efficiency savings |

432 - 387 = 45 (mln. rub.) 45 + 84 = 129 (mln. rub.) |

|

Social efficienc |

|

|

Employment creation |

360 jobs |

|

Additional tax revenue |

30 – 50 million rub. |

As a result of involvement of wood raw materials into the process of production we will have considerable economic and social benefits (tabl. 5) .

In conclusion, it should be noted that it is very timely and important to develop the Federal target program “The use of wood resources for energetic purposes for 2009 – 2012 with the prospects to 2020” in order to provide intensive development of timber processing industry, efficient development of use of wood resources for energetic purposes and to achieve main social and economic goals. We stand ready to take an active part in implementation of the program.