Provision of safety - the priority in the sphere of fundamental and applied research

Автор: Makhutov Nikolay Andreyevich, Abrosimov Nikolay Vasilyevich, Gadenin Mikhail Matveyevich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Russia-belarus integrationas a tool of security strategy

Статья в выпуске: 3 (27) т.6, 2013 года.

Бесплатный доступ

The authors are the members of the working group for the analysis of risks and security issues under the RAS President. The article substantiates the necessity of transition to the new methodological framework and principles, which reduce the country’s strategic risks, ensure and enhance the safety of anthropogenic and natural-anthropogenic spheres of human life and society from negative processes and phenomena. The article studies the issues of establishing a new criteria base for safety, methods, systems of preventing and overcoming threats and risk optimization.

Human life and society, technosphere, risks, disasters, safety

Короткий адрес: https://sciup.org/147223473

IDR: 147223473 | УДК: 338.22

Текст научной статьи Provision of safety - the priority in the sphere of fundamental and applied research

Modern development of the fundamental theory of safety justifies the need to change the existing traditional approaches to ensuring safe operating conditions of potentially dangerous objects of technosphere for new promising ones. They should be based on the standardized risks and safety parameters justified for technological systems according to the criteria of strength, durability, survivability, reliability and security [1, 2]. The key factor in solving this problem is the use of the risk monitoring concept [3, 4] based on the control, diagnostics and monitoring of the basic operating parameters of technosphere objects and the comprehensive analysis of obtained results [2, 5].

Consequently, the development and implementation of large-scale projects in mechanical engineering, defence, energy, oil and gas sphere, transport and other sectors requires fundamentally new views on the problems of ensuring the reliability and safety of designed and operated machines, structures and mechanisms taking into account potential hazards of infrastructure and possible large-scale damage caused by anthropogenic accidents. The basic requirement for such projects and objects is ensuring their safe operation according to the acceptable risks criteria [1, 2, 6].

The results of fundamental and applied research on anthropogenic safety and risks are the basis for the transition from traditional methods and systems of ensuring durability, resource and reliability to the methods of risk assessment and management. One of the important elements in solving fundamental problems of security and risks is the integrated development and use of a comprehensive detection and monitoring system in normal and emergency situations, monitoring of emerging and ongoing risks of its operation at all stages of life cycle and the provision of preventive treatment of emerging threats to such objects on the basis of the risk management concept, as the current operational risks go beyond acceptable and approach the limit [1 – 8].

In the last years of the 20th century and the first decade of the 21st century, two major trends become widely acknowledged on the background of global dynamic processes taking place in the social, economic, natural and technology-related spheres of human life, society, country and mankind [1, 9]:

– desire to implement major international and national projects to improve the quality of life and sustainable environmental conservation;

– increase of a wide range of threats, further sustainable development of humanity and its environment.

These trends are reflected in the known resolutions of the UN, regional organizations and individual states on sustainable development (Rio de Janeiro 1992, Johannesburg 2002, Kobe 2005). However, in the 21st century, humanity has already faced global and regional natural disasters – tsunami in Southeast Asia in 2004, earthquake in China in 2008 and Haiti in 2010, military conflicts in Afghanistan, Yugoslavia, Iraq, Syria, national and international terrorism, the world economic crisis which started in 2008. They all indicate that the proposed strategies for forecasting and management of further development may prove to be insufficient, ineffective and unsafe without direct quantitative account of the everincreasing threats [10].

In this respect, the great importance is attached to national and international basic and applied research on the issues of information security on the basis of risk analysis, aimed to develop and implement the principles of state policy in such strategically important areas as modernization of economy, priorities and priority spheres of technological development, critical and innovation technologies, national and intergovernmental projects [2]. Material and technological basis for the application of the results of such research is found in the objects and infrastructure of civil and military complexes included into a comprehensive social-natural-technological system of life support. This system forms and realizes technological and anthropogenic risks of its development and functioning, the risks of emergencies and disasters involving loss of life, destruction of objects and damage of the natural environment.

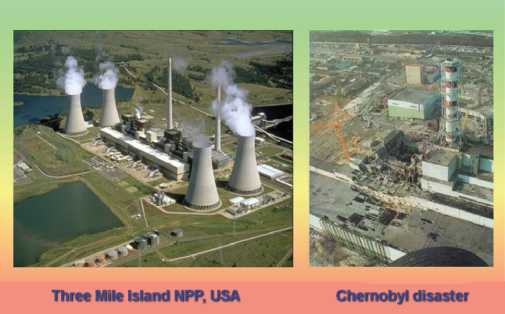

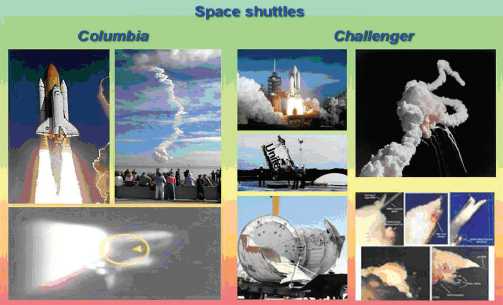

In the second half of the 20th century the largest catastrophes happened [1, 11, 12] in India (Bhopal), USA (the nuclear-powered submarine USS Thresher , the space shuttles Columbia and Challenger , the Three Mile Island nuclear power plant), in the USSR and Russia (the Chernobyl nuclear power plant, the nuclear-powered submarine Komsomolets , the rocket systems Soyuz and N1 , the railways near Ufa, in Arzamas, and Sverdlovsk, at the Sayano-Shushenskaya hydroelectric power station), in Japan, Norway, Canada, Estonia (at the nuclear power station, offshore platforms, the largest tankers and ferries; fig. 1 ).

The above disasters took hundreds and tens of thousands of human lives, resulted in injury and loss of health for tens and hundreds of thousands of people, contaminated vast territories of the regions, states and continents [1, 9, 11]. At the same time, large-scale natural disasters occurred – earthquakes (in Armenia, Iraq, Japan, Central America), floods (in India, China, the USA, some European countries), storms, tsunamis [1, 12]. The damage consisted in numerous losses of human lives, destruction of infrastructure and environment.

These examples demonstrate that serious accidents and disasters become a permanent factor in modern civilization; moreover, they show that, unfortunately, the threats of their occurrence are increasing faster than the ability of scientists, specialists and state structures to predict and prevent man-caused accidents and natural disasters.

For Russia the main documents, defining the key goals of considered fundamental research and developments in the field of safety are the Russian Federation National Security Strategy [13] and the Fundamentals of strategic planning in the Russian Federation [14], elaborated by the Security Council of the Russian Federation and approved by the President of the Russian Federation in 2009.

Ensuring the conditions for safe operation of the objects of technosphere is inseparably linked with the analysis of conditions and risks of potential challenges, dangers, threats and their stage wise implementation [1 – 9]. The theory of safety assumes that the risks R are such combinations of the probability P of occurrence of adverse events (dangerous and crisis phenomena, catastrophes, accidents and emergencies), on the one hand, and the mathematic expectation of losses U generated by them on the other hand, that determine the change in the safety level and the state of the systems of protectability of human, infrastructure and the environment from threats and dangers, both internal and external – man-made, natural, anthropogenic [1, 2, 6]. Integral risks are calculated as the product, sum or integral:

R = PU = VUi = J C ( P ) U ( P ) dP =

= J C ( U ) P ( U ) dU, (1)

where Pi , Ui are probabilities and damage from the main (differentiated) adverse events;

C – weight functions.

The main tasks in the direction of providing security based on the concept of risk are [2, 6]:

– formation of the fundamental base of risk analysis R(t) in three main spheres – social ( N ), natural ( O ) and technological ( T ), which constitute a single, complex socio-natural-anthropogenic system “man – nature – infrastructure” and functioning in time t :

R ( t ) =FR { RN ( t ) , RО ( t ) , RT ( t )}; (2)

– construction of the generalized model of the specified complex system with the definition of the roles of its main components N, O, T in terms of the basic parameters of risks R(t) – the probabilities of occurrence P(t) of adverse processes and events (dangers, challenges, threats, crises, catastrophes) and associated damages U(t) :

R ( t ) =FR { P ( t ) , U ( t )}; (3)

Figure 1. Examples of grave disasters at the objects of technosphere

P ( t ) =FP { РN ( t ) , РО ( t ) , РT ( t )}; (4)

U ( t ) =FU { UN ( t ) , UО ( t ) , UT ( t )}; (5)

– creation of scenarios of the emergence and development of adverse events in the complex system and quantitative risk assessment R(t) through the parameters of the main initiating and damaging factors – hazardous energy E(t) substances W(t) and information flows I(t) :

R ( t ) =FR { E ( t ) , W ( t ) , I ( t )}. (6)

On the basis of the relations (1) – (6) the fundamentals of rating emergency situations, high-risk facilities and dangerous processes according to the values of risks R(t) .

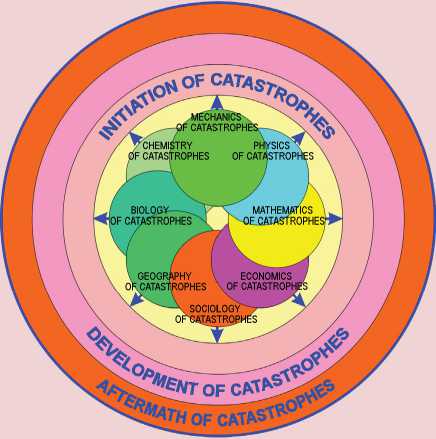

Risks, as an interdisciplinary scientific basis for assessing integrated security, including the analysis of the initiating factors, the conditions of development and the nature of the consequences of accidents and disasters, are based on the patterns, methods, equations, and the criteria obtained in the fundamental fields of knowledge: mathematics, physics, chemistry, mechanics, informatics, engineering science, biology, geology, geophysics, physics of atmosphere and ocean, geography, economics, law, philosophy, sociology, psychology, physiology (fig. 2) [2, 6].

The developed theories of system analysis, theories of chaos and order, management theories, theories of catastrophes and creating protection, methods of mathematical and simulation modelling, forecasting, mathematical statistics, methods and systems for diagnostics and monitoring are generalizing for the analysis of integrated risks.

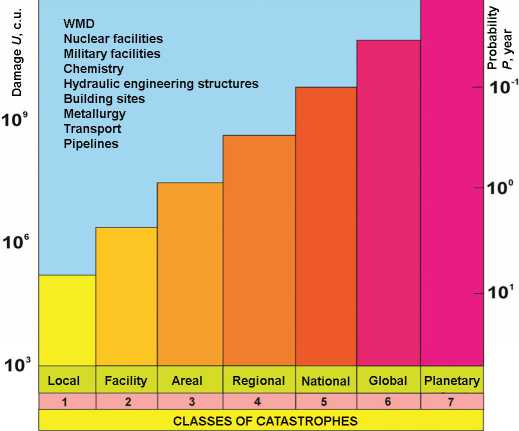

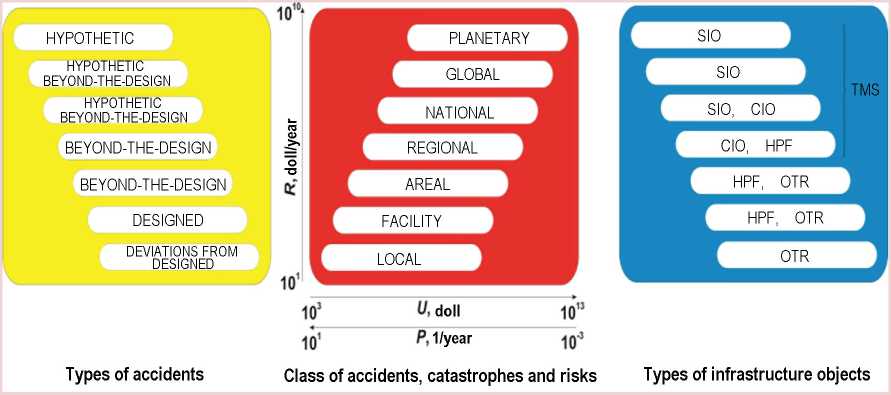

Accidents and disasters, depending on the severity of their consequences (damage) and the observed frequency of their occurrence are divided (fig. 3) into planetary, global, national, regional, areal, facility and local [1, 2]. The former create severe socio- economic and environmental consequences for neighbouring countries, the latter affect industrial and sanitary protection areas of the sites.

Accordingly, depending on the scale and consequences of accidents and disasters, seven (1 – 7) their classes are introduced in the risk analysis R(t) [1, 2]:

-

1 class – local ones, occurring on the components of the object (the parts, units, shops, buildings);

-

2 class – facility ones occurring on the territory of the object, which have impact on the object (enterprise, residential and industrial complexes, dams, hydroelectric stations, transport facilities and complexes);

-

3 class – areal ones occurring on the object of infrastructure and environment, which have impact on the territories, population and facilities, municipal entities (enterprises, transport, energy, municipal systems, landscape and natural sites);

-

4 class – regional ones occurring on large objects of natural, man-made and social sphere, with negative consequences;

-

5 class – national ones occurring during the disasters on the unique objects of infrastructure during natural and anthropogenic emergencies and on vital objects during natural disasters, as well as in case of terrorist acts and military conflicts with severe socio-economic and environmental consequences for a number of regions and the country in general;

-

6 class – global ones occurring during the disasters on the objects of technosphere and during anthropogenic and natural disasters in the environment with severe socio-economic and environmental consequences for the country and a number of adjacent states;

-

7 class – planetary ones occurring under extreme impact of the military, anthropogenic or natural character with severe consequences for the countries, continents and the planet in general.

Figure 2. Structure of the fundamentals of the catastrophe theory and the analysis of their development scenarios

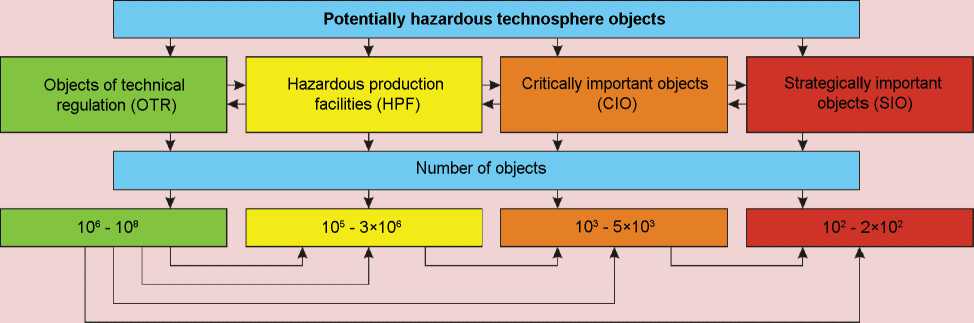

According to the level of potential hazard (fig. 3) , in compliance with the legislation and taking into account the risk of accidents and catastrophes, the objects of technosphere can be divided (fig. 4) in four main groups [1, 2], which have the following safety requirements:

-

– objects of technical regulation (OTR), the safety of operation of which is ensured by the law on technical regulation, their number is measured in millions and tens of millions;

– hazardous production facilities (HPF), the safety of operation of which is ensured by the law on industrial safety, their number is measured in hundreds of thousands;

– critically important objects (CIO), the safety of operation of which is ensured according to the decision of the Security Council of the Russian Federation, their number is measured in thousands;

– strategically important objects (SIO), safety of operation of which influences the country’s national security, their number is measured in hundreds.

The data in fig. 3 and 4 show that at present the most relevant is the risk analysis of severe accidents (5 – 7 classes according to fig. 3) for critically (CIO) and strategically important objects (SIO).

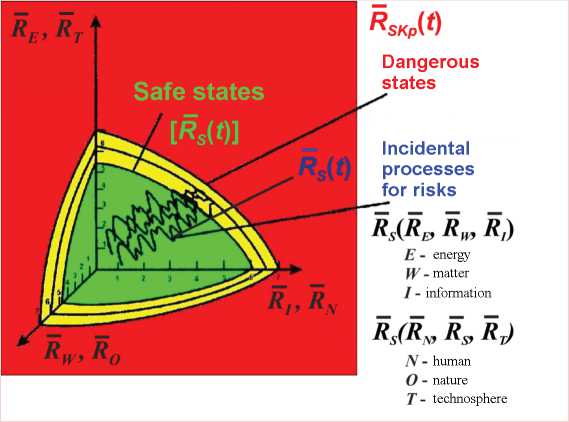

In the cases when for the considered object of technosphere in accordance with the expression (2) the r el ative (per unit period of time) systemic risks RS are defined (respectively for the pop u lation RN , for the objects of t e chnosphere RT and for the environment RO ), then the surface areas of safe, dangerous and threshold conditions RS can be created [2, 6] for the object using these data in terms of relative systemic risks can be constructed (fig. 5) :

Rs = RNI + R 2 + Ro2 . (7)

However, if we plot the above-mentioned classes of accidents and catastrophes 1 – 7 by t h e i n crease i n their severity along the scales RT , RN and RO , it will be possible to perform a quantitative assessment of the degree of safety of the considered object and any of its components on risk criteria. Such an assessment is characterized by the position of the radiusve c tor o f th i s object in three-dimensional space “ R T - R N - R O ”.

Figure 3. Types of accidents and disasters with the probabilities of their occurrence and possible damage

Figure 4. Structural scheme of analysis and categorization of potentially hazardous objects

Figure 5. Areas of dangerous and safe conditions according to the indicators of relative risks

In order to transfer the object to the safe condition along with the use of the risk s of t he above mentioned risk components RN , RT , RO , and the systemic risk in general (see fig. 5) it is necessary to reduce the possibility of parameters of uncontrolled outputs of potentially hazardous substances W , energy E and information flows I on the corresponding components of the risk (8). These parameters condition the risks according to the expression (6):

R = ^R W + r2 + r2 . (8)

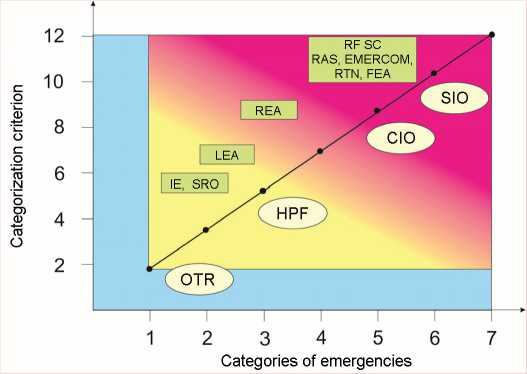

It follows that the analysis of conditions of safe operation of the objects of technosphere can be based on the indicators (classes, categories) of possible emergency situations (see fig. 2), or, on the other hand, the indicators categorizing potentially dangerous objects themselves (see fig. 4). The latter can be represented in the form of quantitative values (fig. 6) , determined by the ratio of the corresponding relative risk values for human lives, technosphere and the environment according to the expression (7). For the quantitative categorization of hazardous processes and objects, the expression (8) s h ou l d b e used for the components of the risk R W , R E , R I .

When changing the above-mentioned components of the systemic risk, that are changing in the range from 1 (local emergency situation) to 7 (planetary catastrophic s ituations), the relative value of systemic risk R S ( t ) will vary from 1.86 (local accident) to 12.12 (planetary catastrophe).

If we accept t h at e v en one maxim u m c o mponent out of RN , R T , RO and RW , RE , R I , of the systemic risk R S ( t ) corresponds to this class of emergency, and the other components correspond to the lower class of the dangerous situation, the boundary values of relative risks will be in accordance with the expressions (7) and (8) the following: for local emergencies – from 1.86 to 2.45; for facility emergencies – from 2.46 to 3.16; for areal emergencies – from 3.17 to 4.24; for regional emergencies – from 4.25 to 5.19; for national emergencies – from 5.20 to 6.16; for global emergencies – from 6.17 to 7.14; planetary catastrophes – from 7.14 to 12.12.

The determination of appropriate indicators of categorization of hazardous objects by the values of risks and management of these indicators should be effected with the participation of administrative and supervisory bodies for different types of objects relevant to their jurisdiction, including for the

Figure 6. Categorization of the objects according to the values of risks

objects of OTR type they can be (see fig. 6) industrial enterprises (IE) or a self-regulatory organizations (SRO) for the objects of HPF type – local executive authorities (LEA), or regional executive authorities (REA), for the objects of CIO and SIO types – the Security Council of the Russian Federation (RF SC), the Russian Academy of Sciences (RAS), the Ministry of Emergency Situations (EMERCOM), the Federal Service for Ecological, Technological and Nuclear Supervision (Rostekhnadzor, RTN), federal executive authorities (FEA).

Considering the aforementioned, we can conclude that the integral economic risks, determined by the product of individual risks on the number of objects, are comparable for both global and facility-level disasters. The damages from single disasters of a global and on-site scale differ by 8 – 10 orders, risks differ by 4 – 6 orders and integral damages – by 1 – 3 orders at the seven classes of anthropogenic and natural-man-made disasters according to fig. 3, 5 and 6.

For the entire set of technosphere facilities of the types OTR, HPF, CIO and SIO, the types of accidents and disasters, the level of their safety, and related operational risks during the transition from normal operation to emergency can be characterized [2, 6] by the definitions according to fig. 7 as follows:

– normal situations, occurring in the functioning of the objects within the established norms and rules; the risks for them are controlled and the security is increased;

– regime emergencies, occurring in a deviation from the normal operating conditions during the normal functioning of potentially dangerous objects; their consequences are foreseeable, the risks – regulated, the safety – sufficient;

– designed accidents, which occur if the object goes beyond the regular functioning modes with predictable and acceptable consequences; the risks are analyzed, and safety is partial;

– accidents beyond the designed ones, which occur due to the irreversible damage of the critical elements of the object with high damage and loss of life and with the necessity of subsequent recovery works; the risks are increased, and the safety is insufficient;

– hypothetic accidents may occur under unexpected options and development scenarios with maximum possible damage and victims; they are characterized by high risks, the protection against them is low, the direct restoration of objects is not possible.

Thus, the overall structure of the analysis and management of potentially dangerous technosphere objects according to risk criteria includes the classification of types of emergencies and disasters, the definition of accidents and disasters by the levels of possible risks and damages, as well as the description of the types of potentially dangerous objects (fig. 8) .

In the considered structure, the characteristics of the types of accidents and disasters, shown in the left part of fig. 8, the related risks

Figure 7. Types of emergences and the degree of objects’ safety

|

№ п/п |

Emergencies |

Safety |

Risks |

|

1. |

Normal operating conditions |

Increased |

Controlled |

|

2. |

Deviations from normal conditions (regime emergences) |

Sufficient |

Regulated |

|

3. |

Designed accidents |

Partial |

Analyzed |

|

4. |

Beyond-the-design accidents |

Insufficient |

Increased |

|

5. |

Hypothetic accidents |

Low |

High |

Figure 8. The overall structure of the analysis and management of objects according to risk criteria

and the degree of safety of the objects during the transition from their normal operation conditions to emergency conditions are presented in fig. 7.

The classification of types, objects and infrastructure (fig. 4 – the right part) is linked with the categories and classes of accidents, catastrophes (fig. 4 – central part), and levels of risks for the arising emergencies and disasters, and it can be elaborated according to the estimates of the degree of their severity and inflicted damage, as well as the parameter estimates of the probability of their occurrence and the levels of potential human and material losses. In this case, the situations of the positions 1 – 3 according to fig. 7 are analysed for OTR and the HPF, for CIO, respectively, the situations 1 – 4, for SIO – the situations 1 – 5.

As it has already been mentioned, the fundamental scientific research of the characteristics of safe operation of the technosphere objects according to the parameters of the risks of emergencies occurrence include, first of all, the study on criteria of strength, durability, survivability and security of considered machines and constructions with the analysis of the conditions for achieving the threshold state in the process of exploitation at different stages and modes of life cycle [2, 6, 8, 15]. The system of such criteria of the mechanics of deformation and destruction at different stages of the research and development of appropriate calculation methods in this field consistently included analysing and defining the basic characteri-stics of mechanical properties of materials, determining the conditions of reaching the threshold state in the increasingly complicated operating conditions, requiring the use of special approaches to the implementation of the relevant calculations, the highest degree of which is the definition of security, risk and safety parameters of the considered technosphere objects [8, 15].

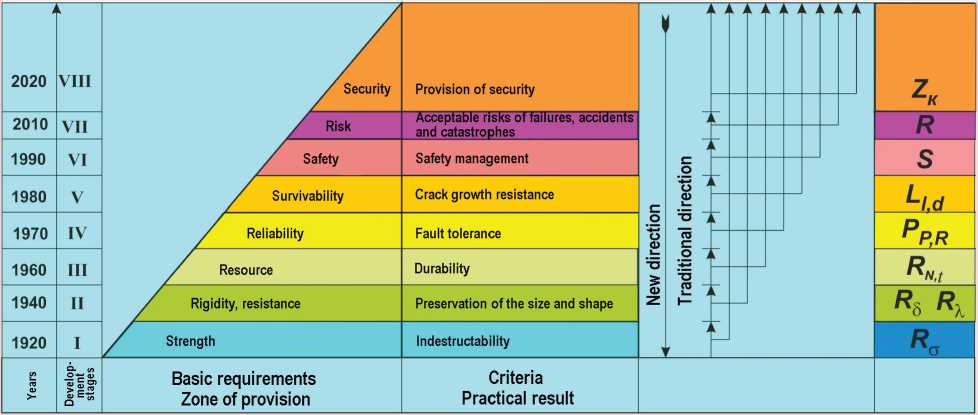

Figure 9 presents the time scale beginning from the 1930s to the second decade of the 21st century, which shows the sections of fundamental scientific research of strength R σ ,, resource RN , τ , reliability PP,R , survivability Ll , d , safety S , risk R and protection Z for the various types of technosphere objects.

In the historical and scientific-technological terms, this direction has a stable chain of traditionally resolved and above mentioned problems [2, 6]:

R σ → RN, τ → PP,R → Ll,d → S → R → Z → Z (9)

The protection of the object Z is defined by the ability of equipment to fight the occurence and development of accidents in regular and emergency conditions and is described by the relevant functional from the basic criteria parameters of strength, durability, survivability, safety and risk:

Z (т) =F z { R (т) , S (t) ,L u (t) , P pR (t) , R№(t) , R c (t)} . (10)

As follows from fig. 9, each subsequent step or stage in the development of science and technology uses the previous ones and is based on them. At that, the basic parameters of operational impacts Pэ are the equivalent operating stress σ э , deformation eэ , the number of cycles Nэ , time τ э , temperature tэ , the external environment Φ э (radiation, corrosion, electromagnetic field), stress intensity factors and deformation intensity КIэе factors КIэе :

Р э = { a э , е э , N э , т э , t э , Ф э , К , К Э } . (11)

The basic characteristics of mechanical properties include the limits of fluidity σ T , the ultimate strength σ B , the endurance limits σ -1, the long-term strength σ дп , tear resistance Sк ; the ultimate plasticity ψ к , the critical stress intensity factors KIc and deformation intensity factors K :

Iec

Ra = F { a T , ^ B , a- 1 , a dn , S k , V k , K Ic , Klee } (12)

The derivatives of the characteristics of the mechanical properties of the material, constructive forms and the loading conditions of the object are such characteristics as stress rupture ductility ψ к τ , efficient stress concentration factors K σ , sensitivity to the absolute sizes εσ and cycle asymmetry ψσ , variation coefficient υσ , crack growth by the number of cycles dl / dN and time dN / d τ , sensitivity to the external environment β с . Then the conditions of strength are written in the form:

Р э < R a{ ^ k T , Ka , £a , ¥a , v„ , dl / dN , dl / dT , в с } . (13)

To ensure the resource (in the cycle, time dimensions, or in the parameters of resistance to environment), the following requirement should be met:

Rnt , p < R N , T = { Nэ / Nc , тэ Itc , Фэ / Ф с } , (14)

where R NN, T is the critical (limit) value of resource, expressed through critical (destructive) cycles Nc ,, time τ с or exposure to the environment Φ с .

Durability parameters PP,R according to the criteria of strength R σ and resource are determined by the expressions (10) – (14), with the introduction of probabilistic characteristics of strength, plasticity, operational loading taking into account the variation coefficient υ of these characteristics:

P p , R = F { Рэ , Ra , Rn , t , Ф , v } . (15)

In accordance with the expression (15), mechanical testing of samples of the construction material for defining the scattering parameters (including the variation coefficient υ ) becomes extremely labour-intensive. In some cases, to establish the distribution curves of the basic characteristics of mechanical properties σ B , ψ к , σ -1 , σ дп , the tests of 10 up to 2000 samples were conducted at one of loading modes.

When assessing the survivability, the major attention is focused on determining the level of accumulated damage d that is measured by the above relative parameters Nэ / Nc , τ э / τ c , Φ э / Φ c , or crack (defects) growth from the initial sizes l 0to the current lэ and critical lс . This crack growth is determined by their speeds dl / dN , dl/d τ , which, in turn, depend on the scale of stress intensity factors Δ KI or deformation intensity factors Δ KIe . Once this limit condition is achieved, the conditions of destruction according to the criteria of linear ( KIс ) and nonlinear ( KIec ) fracture mechanics.

Figure 9. Development stages of calculation methods and criteria of strength, resource, durability, survivability, safety, risk and security

|

Z^R,U,P^ R,U,P |

Security (potentially hazardous objects) |

||||||||||

|

r^u,p^ U,P |

Risk (potentially hazardous objects) |

||||||||||

|

Vo3,e\N\t\i3^max {o т ,ct B ,ct A,KIc,KIec,dl / dN ,dl / с/т} max |

Safety of machines (potentially hazardous objects) |

||||||||||

|

a\e\l\N\t\T\K3,Kl^c ст t,ct B,dl / dN ,dl kh |

Survivability of machines (thermonuclear power, reactor engineering) |

||||||||||

|

G3,e\l3,Ki,Kl,t3 h’Rlc^Iec |

Fracture mechanics (reactor engineering) |

||||||||||

|

g 3,e3 ,g -N,vo G^G^G.^K^S^ ,\Va,Vc, |

Reliability and resource of machines (general engineering) |

||||||||||

|

G3,e3,t3,T3 ^ т ’^ в ’^ дп ’Ч^ кт ’ ^"lec’ ^t |

Creep and long-term strength (aviation, power engineering) |

||||||||||

|

G3,e3,N3,t3 GT,Gb,m,^k,mp,me |

Low-cyclic fatigue (thermal power, petrochemistry) |

||||||||||

|

G3,N3,t3 Gi’°B’SOT |

Low-temperature strength (northern, cryogenic engineering) |

||||||||||

|

G3,N3 <7 , ,CTB,CT.| |

Fatigue and durability (aviation, transport, hydraulic engineering) |

||||||||||

|

CT 3 gt,gb,E |

Dynamics and strength of machines (agricultural machines, automobiles, technological equipment) |

||||||||||

1930 1940 1950 1960 1970 1980 1990 2000 2010 2020

Then the survivability Ld,l of the objects taking into account the damage d and crack growth l will be estimated by the condition:

Ld , l = F { рэ , R^ , RN т , Ф } = F { d , dl I dT, dl I dN } < < F { Nэ I Nc ,T Itc , Фэ IФс , KI I Kic , Kle IKiec } . (16)

If statistical parameters are introduced in the expression (16), the characterisation of survivability Ld,l acquires a probabilistic character. This task requires mechanical testing of large series of samples for verification regimes of loading in determining, primarily the parameters dl / dN , dl/d t, K Ic , K Iec .

In recent years the safety S of civil and military objects, technical systems, machines, structures, products and materials has become one of the defining parameters of industrial production, economy and life.

For a long time, requirements for the safety S have remained mostly qualitative or have been related to production safety. However, after a number of the largest man-made and natural-anthropogenic catastrophes and disasters at the atomic and thermal power engineering facilities, petrochemical complexes, rocketspace systems, nuclear-powered submarines, it has become evident that safety S should be a quantitatively defined, controlled and adjustable parameter. As it was mentioned above, to achieve this goal, it was proposed to use the quantitative characteristics of risks R . On the basis of the expressions (1) and (2), the risks R(t) for assessing the safety S of technosphere facilities are understood as the functional FR , depending on the probability P(t) of anthropogenic accidents or disasters according to the criteria of strength and resource and the mathematical expectation of consequences (damages) U(t) , generated by these accidents and disasters [1, 2, 6].

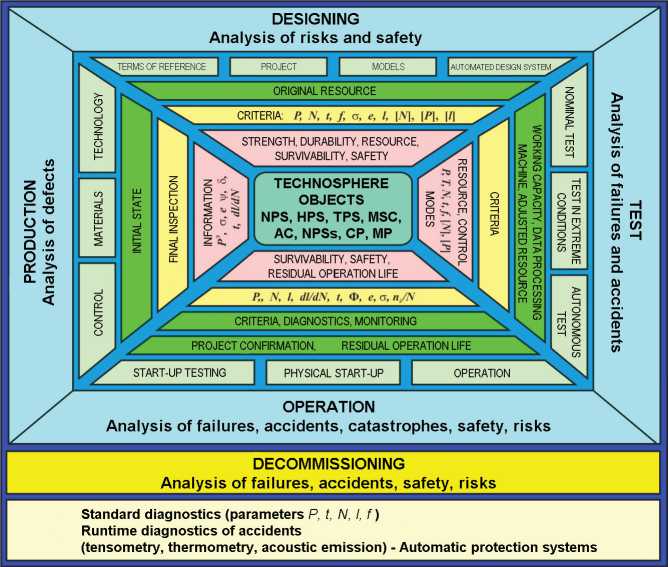

In turn, the risk parameters P(t) at the stage of designing high-loaded machines and constructions of various purpose (nuclear (NPS), hydro (HPS), thermal (TPS) power stations, missile and space complexes (MSC), aircrafts (AC), nuclear-powered submarines (NPSs), chemical productions (CP), main pipelines (MP), etc.) are determined by the expression (15) in the form of the functional of operational loading Pэ, fracture resistance Rσ, resource and their scattering characteristics υ (fig. 10). For the stages of manufacture, tests and operation, in addition to the expression (15), the analysis of the likelihood of accidents or disasters is supplemented with survivability characteristics Ld,l according to (16). Standard systems of diagnostics and monitoring of these parameters must ensure operation of the objects within the permissible values of these parameters and the automatic protection systems must activate them when these diagnosed parameters go beyond the permissible limits. Decommissioning of potentially dangerous objects should also be accompanied by the analysis of the whole complex of parameters determining the safety of this process and preventing their going beyond the established limits.

Damage U(t) associated with non-compliance of the terms of strength and resource depends on the type of ultimate state, attained by the object in operation. The most significant damage (for the life and health of operators, personnel, population, for the damage of the objects themselves and the environment) U ( t ) in the expressions (1), (3) and (5) occurs in those cases when there are extensive brittle fractures, the global loss of stability, gliding fractures after growth of cracks during the cyclic and sustained loading.

In-depth analysis of the largest man-made and natural-technogenic catastrophes of the last years shows the necessity of improving the scientific, engineering, technological, regulatory, supervisory and legal solutions in the field of ensuring the safety and security of engineering objects with high levels of risks. One of the ways of such improvement can be a detailed consideration of the considered (see fig. 9) historically established sequence of forming the fundamental scientific foundations for the development of engineering methods of calculation and testing, creation of norms and rules of designing and manufacturing the technosphere facilities, ensuring their functioning within the set limits of design modes and parameters in the direction of its application to the tasks of regulating the relevant characteristics (fig. 11) .

The basic, gradually increasing, demands to the standard (normal) operation and design parameters of functioning for the high risk

Figure 10. Structural scheme of the analysis of durability and safety of technosphere facilities at various stages of life cycle

Figure 11. Hierarchical structure of the criteria ensuring the operability of equipment

technosphere facilities at all the stages of their life cycle (see expression (9)) at present are as follows “strength → rigidity → resistance → resource → reliability → survivability → safety → risk → security”. At that, the following definitions, which are included in this sequence (see fig. 11), can be assumed:

R σ – strength, determined by the resistance of supporting elements of the equipment to the damage during normal and emergency actions;

R λ – resistance, determined by the resistance to the loss of initial forms λ of load-bearing elements of the equipment under normal or emergency load;

R δ – rigidity, determined by the resistance of the load-bearing elements of the equipment to the achievement of inadmissible deformations δ under normal or emergency load;

RN, τ – resource (service life), determined by the time τ or number of cycles N before the destruction or loss of stability;

PP,R – reliability, which is determined by the ability of the equipment to perform specified functions in a normal or corrupted condition, under the specified loads R or resource RNτ ;

Ll,d – survivability, which is determined by the ability of the equipment to function to a limited capacity under the injuries d and sizes of defects (cracks) l, inadmissible according to the standards;

S – safety, which is determined by the ability of the equipment to not go into the emergency or catastrophic state with the infliction of considerable damage to the population, technosphere and natural environment;

R – risk, defined as the probability of occurrence of adverse situations on the equipment with possible damages from these situations in normal and emergency conditions;

Zк – security, defined by the ability of the equipment to counteract the emergence and development of adverse situations in normal and emergency conditions.

The above-mentioned operability parameters are functions of time τ , and the last one of them, i.e. security Zк ( τ ), is the most important for extremely loaded high-risk equipment (see fig. 10).

The diagram shown in figure 11 highlights the periods and main stages of development (I – VIII), basic requirements, the main practical results and sequences of implementation of the considered approaches. It is clear that each upstream element relies on downstream elements as the foundation. This means that the solution of security, risk and safety problems should fully rely on the solution of the problems of “survivability → reliability → resource → rigidity → resistance → strength” going through the traditional stages of their interaction. It should be emphasized that the fundamental results of determining and ensuring strength (stage I) were obtained in their present-day form at the beginning of the 20th century, and the closed analysis of rigidity and resistance (stage II) ended in the mid-1990s. In the 20th century the theory and practice of ensuring “resource → reliability → survivability” were formed (stages III, IV, V). Recently, the fundamental problem of analysing and providing safety and risk (stage VI) was formulated for all potentially dangerous objects with the transition (phase VII) to security managing according to risk criteria. The requirement for ensuring safety was set forth as a crucial one, which required the development of a new direction in promoting the operability of anthropogenic infrastructure “VII→I” as a promising one to ensure the conditions for its safe functioning. In accordance with the Russian Federation National Security Strategy [13, 14], ensuring the safety and security of the country’s infrastructure is one of the objectives of the state science and technology policy, in this connection the task of ensuring the safety and security of high-loaded, potentially hazardous objects against accidents and catastrophes of natural and anthropogenic origin (phase VIII) is put forward as a new and urgent one at the present stage.

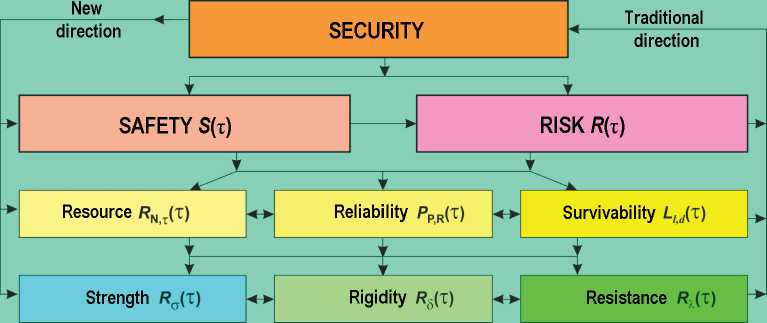

The basic algorithm for analysing and providing the security of equipment from adverse situations (fig. 12) taking into account the expression (10) consists in the implementation of the main above mentioned approaches to the substantiation of their operational safety in regular, emergency and catastrophic situations.

New perspective direction to ensure the security of high-risk of technosphere facilities from adverse situations is the one (the left branch in fig. 12), which initially forms the

Figure 12. Traditional and promising algorithms of analysing and providing security of technosphere facilities

level of security Zк ( τ ) and defines all the main groups of requirements [1, 2, 6]:

– safety S ( τ ) and risks R ( τ );

-

– resource RN τ (τ), reliability PPR ( τ ), survivability Lld ( τ );

-

- strength R σ (τ), rigidity R δ (τ), resistance R λ (τ) .

In the framework of the traditional approach, the following groups of requirements are initially provided: strength → rigidity → resistance; resource → reliability → survivability; safety → risks. Each of the traditional “I→VIII” and new “VIII→I” (fig. 11) stages corresponded to a practical result in scientific research, design, creation and operation of technosphere objects: “indestructability → preservation of the size and shape → durability → fault tolerance →crack growth resistance → safety → acceptable risks → protectability against failures, accidents and catastrophes”.

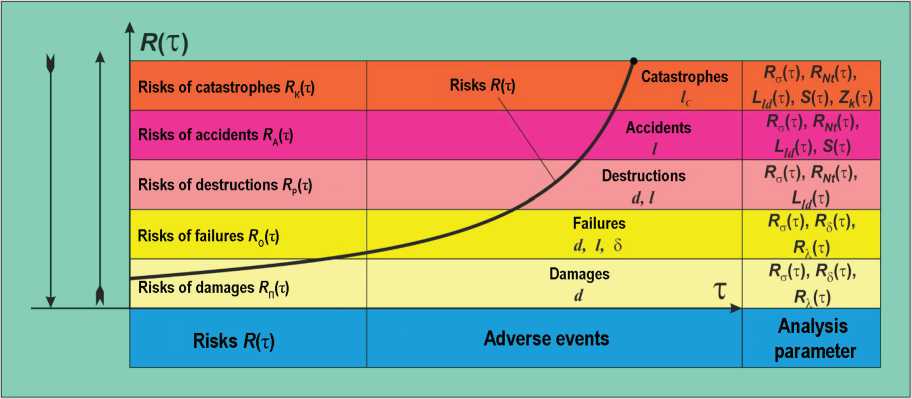

The specified sequence of adverse events causing damage to objects and leading to a catastrophe, may have a different view (fig. 13) , characterized by the increase in time t of risks R(t) , characterized in their analysis by the relevant parameters considered above.

The presence of a potential hazard with regard to a given object is not always accom- panied by its negative impact on the object’s most important elements. The realization of danger requires the fulfilment of at least three conditions: the danger actually works (is present); the object is in the danger zone; the object doesn’t have a sufficient level of security Zк(t). In the latter case the new requirements, criteria and methods should be applied in order to enhance the security up to the specified level.

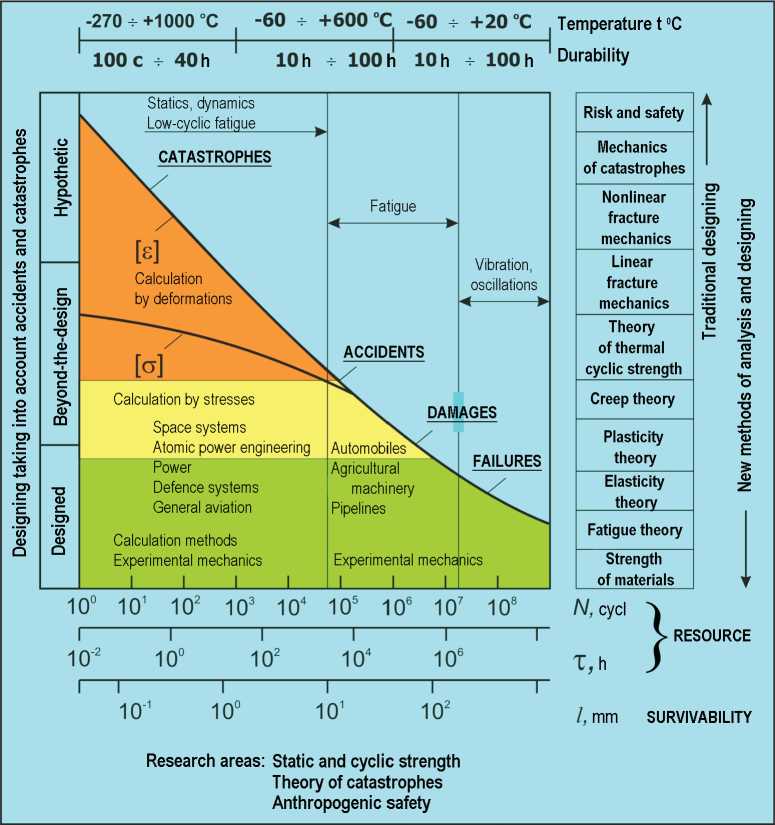

Generally, a comprehensive analysis of safe operation conditions of technosphere objects by the criteria of strength and resource on the basis of the results of the corresponding fundamental and applied research was proposed to be conducted using a generalized diagram of strength, static, cyclic and temporary resource, survivability and safety (fig. 14) taking into account the impact of the corrosion environment, radiation, vibration, fatigue, dynamics and statics of loads application [1, 2, 6, 16 – 18].

The analysis of strength, resource and safety based on this diagram has been performed using the relevant provisions concerning the resistance of materials, theory of elasticity, fatigue, plasticity, creep, linear and nonlinear fracture mechanics, mechanics of catastrophes and theory of risks. In accordance with this

Figure 13. The algorithm for the analysis of damage to the objects and the corresponding risks

Figure 14. Generalized diagram of hazardous and extreme states for technosphere facilities

approach, the durability of structures ranging from 100 seconds to hundreds and thousands of hours at temperatures t from -270°С to 1000 degrees°С, at the numbers of cycles N from 100 to 109 – 1010, temporary resource τ from 10-2 to 106 hours, at the linear dimensions of defects l from 10-2 to 103 mm.

This comprehensive analysis includes routine, emergency and catastrophic situations (designed, beyond-the-design, and hypothetical). At that, the traditional rules of calculations and design prove sufficient for routine situations; emergency and catastrophic situations require new methods of analysis and design. As we move from routine to emergency and catastrophic situations, the calculations of the permissible stress [ σ ] turn out to be not sensitive enough to variable parameters ( N, τ , l ) due to the development of plastic deformation and creep deformation, and this circumstance requires the transition from the calculations of permitted stress [ σ ] to the calculations of the permitted deformations [ ε ]=[ е ].

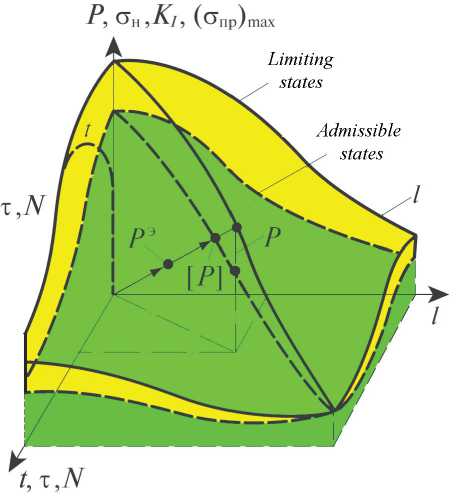

In accordance with the described algorithm, the conditions for achieving the threshold states have been analysed according to the criteria of strength, resource, survivability and safety in general case, taking into account expressions (7) – (16) and by analogy with the approach toward the construction of fig. 5 for limited surfaces of risks.

According to the results of this analysis, it is possible to construct (fig. 15) spatial surfaces of limit and permissible states in a threedimensional coordinate system [2, 6], the axes of which are: the axis of operational loading indicators (force P , nominal stress σ н, stress intensity factors KI , reduced local maximum stress ( σ пр)max, k in the concentration areas); the axis of time-temperature and cyclic operation parameters (temperature t , time τ , the number of load cycles N ); the axis of defectiveness status (sizes of defects l , taking into account their shape and location).

According to this interpretation, the formation of destruction, inadmissible plastic

Figure 15. Scheme for constructing the surfaces of limit and admissible states according to the parameters of strength, resource and survivability

deformations or cracks corresponds to the limit status (surfaces of limit states). Limit load P in this case is the vector going through the origin of the coordinates with angles corresponding to the given state of construction (according to the parameters l, t, τ , N , σ н, KI , ( σ пр)max, k ). If we introduce the required reserves n on the specified parameters into the expressions (11) – (16), then it will be possible to move from the surface of limiting states to the surface of admissible states and admissible load [ P ]. On the basis of the provisions set forth, the strength, resource and survivability can be considered secured, if the vector of operational Pэ load is less than or equal to the vector of permissible [ P ] load ( P э ≤ [ P ]).

Classic (traditional) methods of calculating strength and resource evolved under the assumption that the construction material has no defects ( l =0). In this case, it is possible to move from the limit and admissible surfaces to two-dimensional limit and admissible curves (in the plane “ P , σ н, KI , ( σ пр)max, k – t , τ , N ”) of static (at a given temperature t ), prolonged static (according to the set time τ ) and cyclic (for the given number of cycles N ) strength (see fig. 15). The strength and survivability at the first stages were determined according to the criteria of linear fracture mechanics (static crack resistance) for the plane “ P , σ н, KI , ( σ пр)max, k – l ”.

For modern calculations of strength, durability and survivability with the use of limit and permissible states (see fig. 15) it becomes important to accept the uniform state equations, uniform fracture criteria and uniform complexes of calculated characteristics in the expressions (11) – (16) regardless of the type of construction, properties of structural materials and conditions of operational loading. The most promising, as noted above, is a gradual transition from calculations in stress (that is so far accepted in most of the regulations) to calculations in strains [2, 6].

For more accurate estimates of residual strength, resource, survivability and safety, the basic source equations should include the stress and limit states changing during the operation, taking into account their dependence on the operating conditions, i.e. current characteristics of mechanical properties of materials, the numbers of cycles, time, temperatures, environments [2, 6, 15, 19]. At that, if the statistical characteristics (distribution functions and their parameters) of loading, mechanical properties of materials and the faultiness of details are introduced in the calculations at the stage of design or operation, it will be possible to determine the probability initial characteristics of strength, resource and survivability, resistance, risk and safety of the considered constructions.

A special role in ensuring the safety of operation conditions of technosphere facilities, their reliability and the quality of operation belongs to the systems of diagnostics and monitoring of the actual status of the parts and units of machines and structures according to the parameters specified above [2 – 6, 19, 20] during their use in all the modes and stages of the life cycle (see fig. 10). When using the existing diagnostic systems and developing the new ones in relation to each class of disasters and each type of emergency situations, the following types of measurable characteristics should be defined:

– characteristics of the state of the most important systems of potentially hazardous equipment in normal and emergency situations;

– characteristics of damaging and destructive factors in the emergence and development of accidents;

– characteristics of the continuous change in the state of structural materials and their properties.

The most important diagnosed features and parameters of the state of operated objects are connected with their most loaded ele- ments: stress σ (deformation e), temperature t, dimensions, form and place of occurrence of defects (cracks) l, which can be changed in time τ. These parameters depend on operational loading conditions (pressure p, mechanical, thermal and electromagnetic efforts, velocities, accelerations), geometrical shapes and sizes of structural elements, the properties of construction materials [2, 3, 5, 8, 19].

Since the beginning and development of practically all emergencies starts with the damage of bearing elements (destruction, deformation, decompression, loss of stability), then in the course of diagnostics it is necessary to define the maximum ( σ max, e max, t max) and amplitude values ( σ a , ea , ta ) of the basic parameters – stress σ , deformations e , temperatures t (fig. 16) .

Figure 16. Potential capabilities of the methods of experimental determination of the parameters of strength, resource and safety in diagnostic and monitoring systems

|

METHODS OF RESOURCE DIAGNOSTICS |

|||||||||

|

Parameter Methods |

Stresses |

Temperature |

Defects |

||||||

|

Value |

Cycles N |

Time T |

Value t |

Cycles Til |

Time T |

Size |

Shape a/l |

Place |

|

|

USD |

- + |

- |

- |

- |

- |

+ + |

- + |

- + |

|

|

MPFD |

- |

- |

- |

- |

- |

+ - |

- |

- |

|

|

Vis. contr. |

- |

- |

- |

- |

- |

+ - |

- |

- |

|

|

X-ray |

- + |

- |

- |

- |

- |

- + |

- + |

- + |

|

|

Vibrometry |

+ - |

- |

- |

- |

- |

+ - |

- |

+ - |

|

|

Acoust. contr. |

+ - |

- |

- |

- |

- |

+ - |

- |

+ - |

|

|

Acoust. emiss. |

+ + |

- |

- |

- |

- |

+ + |

+ - |

+ + |

|

|

Photoelasticity |

+ + |

- + |

- |

- + |

- |

+ + |

+ + |

+ + |

|

|

Holography |

+ - |

+ + |

+ - |

+ - |

- |

- |

- |

- + |

+ - |

|

Thermovision |

+ - |

+ - |

+ + |

+ + |

+ + |

+ + |

+ - |

- |

+ - |

|

Tomography |

- |

- |

- |

- |

- |

- |

+ + |

+ + |

+ + |

|

Natur. tens. |

+ + |

+ + |

+ + |

+ + |

+ + |

+ + |

+ - |

+ - |

+ - |

|

CALCULATING RATIOS |

|||||||||

|

N = / (сты,/,т,ЛФ) - naturaltensometry |

|||||||||

|

I = f(ca,N,Tj) - thermovision |

|||||||||

|

АЭ = f^n,ep,Kle,0 - acoustic emission |

|||||||||

|

G= f^o,t,N,T) - holography |

|||||||||

For the measurements in real-time operation or during routine maintenance works with the suspension of work of the objects, it is possible to apply (“+” in fig. 16) widely used and new methods and means of diagnostics – optical, physical, mechanical, electromechanical. These include: external visual control, examination, ultrasonic (USD) and magnetic powder flaw (MPFD) detection, methods of liquid penetrants and photoelasticity, strain metering, vibrometry, thermometry, acoustic emission, thermovision, X-ray radiography, tomography, holography, etc. [2, 6, 19]. It also should be pointed out that there are currently no sign (“–” in fig. 16) universal methods, allowing to conduct simultaneous measurements of all the above-mentioned determining parameters σ , t , l at different stages of the life cycle (according to the time τ and the number of loading cycles N ).

So, in fig. 16 the plus “+” points out the methods, which allow determining the appropriate diagnosed parameter with sufficient accuracy. The minus “ - ” shows the absence of such a possibility in the given method. While a combination of two pluses (+ +) corresponds to a good applicability and credibility in determining the diagnosed parameter by this method, the combination of minus and plus ( - +) corresponds to the reduced possibility of application but good information content, and the combination of plus and minus (+ - ) shows the possibility of using the method, but with reduced information content. Methods of natural tensometry, thermometry, acoustic emission, thermovision and holography, designed and developed for many decades possess the greatest opportunities in this direction.

In the general case, to provide the required parameters of strength, resource, reliability, survivability, risk and safety of technosphere facilities it is possible to use certain ratios of deformable body mechanics and fracture mechanics, to carry out the relevant calculations and obtain the assessments of the technical condition of the object [2, 6, 15 – 19]. At that, basic design parameters are the parameters of stress, temperature and defects, which must in the first place be determined using diagnostic and monitoring systems.

The parameter of stress has the following important characteristics: amplitude, the number of load cycles and the time during which these amplitudes are realised in cycles. The parameter of temperature has such important characteristics as the absolute value of this temperature, the form of heat cycle, the rate of temperature changes and the time of the temperature-time impacts and exposures in operating cycles. The parameter of defects requires the knowledge of their dimensions, shape and location.

When setting the objectives for the multivariate diagnostics of the state of technical systems, of primary interest is the obtaining of operational information about the parameters mentioned above, taking into account all the specifics of functioning of these objects. For the implementation of diagnostics and monitoring of condition during the operation of the objects it is possible to apply certain conventional methods known in the practice of solving such tasks. However, if there is a necessity to have a full set of the considered operational information, it turns out that using certain methods do not always guarantee the obtaining of the entire set of required information in full. The data presented in fig. 16 show that there is no universal method for solving this problem, and if there are any particular special developments, they tend to be very complex, costly and time-consuming in their implementation.

When analysing the state of the considered technical system according to the results of application of diagnostics and monitoring of its dangerous objects, one should bear in mind that only the knowledge of the complete information about the combination of all the required parameters in their direct interaction allows assessing the extent of its damage, and further development of the given defects

Figure 17. Multivolume publication Safety of Russia, 40 volumes (1998 – 2012)

depends on the nature of the damage already occurring. The accounting of such interaction of diagnosed parameters of the objects’ condition is very important, and obtaining objective data reflecting such cooperation is possible only with the comprehensive use of different methods, monitoring their condition. For example, the use of a widely known ultrasonic testing (see fig. 16) allows obtaining sufficiently complete information about the sizes of defects, but the information about their location and configuration is not always sufficient for their reliable identification. And each of the methods analysed in fig. 16, including powder flaw detection, visual inspection, radiography, vibrometry, acoustic testing, acoustic emission, holography, thermovision, tomography and natural tensometry, has its own range of applications and makes it possible, either directly or through corresponding calculated ratios, to receive a specific amount of information on the specific analysed parameters, including the ones considered above, and also on the destroying number of cycles Np, nominal stress σn, factors of the aggressiveness of the environment Φ, presence of plastic deformation zones ep, deformation intensity coefficients KIe. It should be noted that the method of natural tensometry to the greatest extent ensures the comprehensive diagnostics and monitoring of the considered technical system. In a number of cases in routine and emergency situations an increasing importance is attached to the diagnostics of structural states of construction materials and their chemical composition with the use of optical and electron microscopy.

Thus, the solution of the considered fundamental problems of ensuring conditions for safe operation of technosphere facilities lays the scientific foundations for the concept of creating and developing a new perspective integrated approach to the objective assessment (according to the risk criteria) of the country’s existing infrastructure and designed prospective infrastructure projects in the future [1, 2, 6]. Taking into account the aforementioned, the results of fundamental research, already received to date, show the need for a transition to a new methodological framework and principles of providing and enhancing the security of anthropogenic and natural-anthropogenic spheres of human life and society in general from the negative processes and phenomena, decreasing, ultimately, the country’s strategic risks [1, 2, 6, 21]. Their decrease in all the directions is possible on the basis of profound fundamental and applied research of dangerous processes, creating new criteria base for security, methods, systems of counteracting threats and risk optimization.

In accordance to the recommendations of the Security Council of the Russian Federation, the Russian Academy of Sciences, the Ministry of Emergency Situations of Russia and the International Fund “Znanie” in the period from 1998 to 2013, Russia prepared and published 40 volumes of the unique edition of the series

“Russia’s security. The legal, socio-economic and scientific-technical issues” [1], containing the results of relevant studies, conducted by a large group of organizations, experts and scientists on a wide range of fundamental problems of safety and risk analysis (fig. 17).

Список литературы Provision of safety - the priority in the sphere of fundamental and applied research

- Russia’s security. The legal, socio-economic and scientific-technical issues: multi-volume edition. Moscow: IHPF “Znanie”, 1998 -2013. Vol. 1 -40.

- Makhutov N.A. Strength and safety. Fundamental and applied research. Novosibirsk: Nauka, 2008.

- Makhutov N.A., Gadenin M.M. Anthropogenic safety: diagnosis and monitoring of the state of potentially dangerous equipment and risks of its operation. Federal directory: information and analytical edition. Moscow: “Centre for Strategic Partnership”, 2012. Vol. 26. P. 307-314.

- Makhutov N.A., Gadenin M.M. Methods of safety analysis in problems of risks monitoring. Assessment and control of industrial risks and safety: proceedings of the school-seminar, Moscow, 26 -28 October 2011. Saint Petersburg: SVEN, 2012. P. 4-10.

- Gadenin M.M. Structure of the multilevel monitoring of parameters of technosphere and environmental safety. Problems of safety and extraordinary situations. 2012. No. 1. P. 93-102.

- Makhutov N.A. Structural strength, resource and anthropogenic safety: in 2 parts. Part 1: Criteria of strength and resource; Part 2: Substantiation of resource and safety. Novosibirsk: Nauka, 2005.

- Makhutov N.A., Gadenin M.M., Chernyavskiy A.O., Shatov M.M. Analysis of the risk of failures in the functioning of potentially dangerous objects. Problems of risk analysis. 2012. Vol. 9. No. 3. P. 8-21.

- Gadenin M.M. Multivariable analyses of the conditions for safe operation and protection of machines and constructions according to the criteria of strength, resource and survivability. Problems of safety and extraordinary situations. 2012. No. 6. P. 22-36.

- Makhutov N.A., Gratsianskiy Ye.V., Gadenin M.M. et al. Federal scientific technological programme “Safety”. The concept and the results of work for 1991 -1992. Results of science and technology: in 2 volumes. Moscow: VINITI, 1993.

- Makhutov N.A., Kuzyk B.N., Abrosimov N.V. Scientific foundations for prediction and the forecast indicators of socio-economic and scientific-technological development of Russia up to 2030 using the criteria of strategic risks Moscow: INES, 2011.

- Atlas of natural and man-made hazards in the Russian Federation. Ed. by S. K. Shoigu. Moscow: PPI “Design. Information. Cartography”, 2005.

- Natural hazards in Russia. Ed. by V.I. Osipov, S. K. Shoigu. Moscow: Publishing house “KRUK”, 2000 -2003. Volumes 1-6.

- Russian Federation National Security Strategy up to 2020: approved by the Decree of the President of the Russian Federation No. 537 dated May 12, 2009.

- On the framework of strategic planning in the Russian Federation: approved by the Decree of the President of the Russian Federation No. 536 dated May 12, 2009.

- Gadenin M.M. Characteristics of mechanical properties of materials in the analysis of conditions for achievement of limit states. Factory laboratory. Diagnostics of materials. 2012. Vol. 78. No. 2. P. 58-63.

- The study of stresses and strength of nuclear reactors: a series of monographs in 9 volumes. Ed. by N.A. Makhutov and M.M. Gadenin. Moscow: Nauka, 1987 -2009.

- Research of strength in low-cycle loading: a series of 8 books. Ed. by S.V. Serensen, N.A. Makhutov, and M.M. Gadenin. Moscow: Nauka, 1975 -2006.

- Makhutov N.A., Rachuk V.S., Gadenin M. M. et al. Strength and resource of liquid-propellant engine. (Study of stress and strength of rocket engines). Moscow: Nauka, 2011.

- Makhutov N.A., Gadenin M.M. Technical diagnostics of residual resource and safety studies (series “Safety diagnostics”). Ed. by V.V. Klyuev. Moscow: Publishing house “Spektr”, 2011.

- Sosnovskiy L.A., Makhutov N.A., Gadenin M.M et al. Reliability. Risk. Quality. The Ministry of Education of the Republic of Belarus -Belarusian State University of Transport. Gomel: BelSUT, 2012.

- Makhutov N.A. Analysis of strategic risks in the operation of hydropower and transport systems. Vestnik of the Security Council of The Russian Federation. 2012. No. 4 (22). October. P. 138-141.