Recycling carbonaceous materials by cavitation nanotechnology techniques

Автор: Kashkina Ludmila V., Kulagin Vladimir A., Stebeleva Olesya P., Kulagina Ludmila V.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 5 т.4, 2011 года.

Бесплатный доступ

The purpose of this paper was the studying of hydrodynamic cavitation effect on physical properties of carbonaceous material - heat-treated cellulose. The heat-treated cellulose powders have been investigated by the method of X-ray phase analysis (XPA). Hence it was possible to obtain nanofluid - a water suspension with the features characteristic of weak water suspension of fulleroids as a result of rather short cavitation processing of the weak water suspension of heat-treated cellulose, nanofluid is very perspective for industrial technologies.

Cavitation nanotechnology, activated carbonaceos materials, cement stone, micro constancy, nanostructures

Короткий адрес: https://sciup.org/146114601

IDR: 146114601 | УДК: 533.528+621.74+539.2

Текст научной статьи Recycling carbonaceous materials by cavitation nanotechnology techniques

At present all over the world there is a rapid development of new ideas and experimental approaches to creating efficient technologies on the basis of nanomaterials.

It is considered that there should be no gap or “vacuous” link in the chain of knowledge about biosphere which conservation is the most important problem of ecology. In the new millennium in Russia this gap proved to be the problem of disposal of utilized polymer substances, among them packings, and also combustion products in the form of incineration ashes, carbon-blacks, and the like.

Solid domestic refuse (SDR) is a special danger for environment although industrial waste considerably contributes to pollution as well. Dumping-grounds are a terminal point of empty packaging where it is combined with other solid domestic refuse making up much more than 50 % of the total waste.

According to the “INECO” agency data by the end of 1990s in Russia there had been accumulated more than 55 million tonnes of waste products only at the registered urban dumping grounds. As this takes place, the bulk of SDR has amounted to 250-300 kg per person annually, and the total increase has reached 6 % a year.

The dumping grounds pollute free air, soils and ground waters with various compounds that are harmful and poisonous for humans and habitat: methane, sulfur dioxide, dioxin, high-density

metals salts, vapors of solvents, and other pollutants. They are followed by withdrawal of vast areas from advantageous use and result in arising a great amount of rodents and insects that are an epidemiological threat to the population. Within recent years the sanctioned dumping grounds have been removed further on and on to “green” and residential suburbs. At the same time there are cases of advantageous use of utilization products including waste products under their appropriate structural transformation, e.g. into nano-objects or near to them in size [1, 2]. The research people’s heightened interest in nano-objects is caused by detecting their unusual physical and chemical properties.

A nano-object is a physical object greatly distinguished by properties from the corresponding massive substance and which has as a minimum one size in the nano-range (no more than 100 nanometers). The nanomaterials fall into compact substances and nanodispersions. The former are referred to as so-called “nanostructured” substances, i.e. isotropic substances by their composition, which repetitive structural elements are nano-objects contacting with each other.

Unlike nanostructured substances, nanodispersions consist of a homogeneous medium of dispersion (gas, fluid, or solid) and nanoinclusions distributed in this medium and isolated from each other.

Nanocluster carbon substances are the substances including or consisting of carbon particles of nanoscopic sizes (e.g. fullerenes, fullereniferous and diamond-bearing carbon-blacks).

As of now, research is done on expediency of the application of various superdispersed carbonaceous powders for solid additives to oil lubricants. The application of superdispersed materials for additives has been rather widely used for the past decade when there appeared technological opportunities for industrial-scale production of powders of various nature with particle sizes up to 100 Ǻ.

The addition of a small amount of carbon nanomaterials dramatically changes properties of any material-carrier. At present there are pursued investigations of efficiency of application of various superdispersed carbonaceous powders for solid additives to oil lubricants. At introducing the superdispersed powders of diamond-graphite into grease, the friction coefficient decreases by 14-40% and in particular cases up to 60% depending on a kind of base grease material [4].

In works [5, 6] there was explored an effect of small additives of С 60 fullerene and fullerene carbon-black on tribological properties of fluid mineral oil. It was shown that cheaper fullerene carbon-black takes practically the same positive effect as pure fullerene does. The following conclusion was made: the role of fullerene is reduced to the triggering of processes of tribopolymerization of the organic components that are in mineral oils and the forming of a protective polymer film on a friction surface.

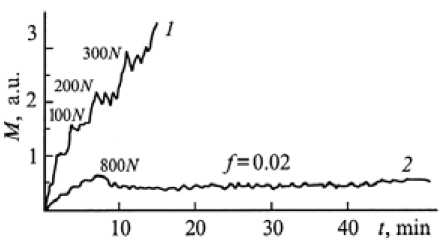

In Fig. 1 are presented two most typical dependences of frictional torque ( М ) on time. Curve 1 is characteristic for pure oil И-40А. The frictional torque increase resulting in a tear, begins at rather low loadings (300-600 N ) whilst the friction assembly with a lubricant containing С 60 (Curve 2), is capable to operate for a long time at loadings over the range of 800-1200 N . In this case the friction coefficient becomes stable on a very low level of 0.015-0.030 which is not attained with using pure oil and the same oil with other carbon additives [5].

There have been developed some methods of forming properties of high-quality concretes with the application of nanomaterials (carbon nanotubes and big multilayer polyhedral nanoparticles of fulleroid type – astralenes) [7].

Fig. 1. Dependence of frictional torque ( М ) on time

а)

b)

-

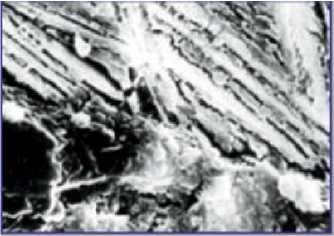

а) ordinary structure of the cement stone showing up as isotropically located flakes

-

b) fibrillar structure of the cement stone in the modified composition including conventional water slurry of ful-leroids

Fig. 2. A photomicrograph of the cement stone structure (magnification 5000х)

Electron shells of fulleroids are characterized by the presence of a great quantity of delocalized π-conjugate electrons. On the bounds the filling compound is the cement stone coming into being in which the fulleroids act the part of centers of oriented crystallization resulting, on the one hand, in emerging cement stone fibrillar structures, and on the other hand, in emerging strain-hardening permolecular structure of polymeric additives. Generating a filiform fibrillar microscopic structure results in strengthening physical and mechanical features of composite concretes. In this process the total number of fulleroids (nanotubes and astralenes in this case) per 1 t of the composition did not exceed 6.5 х 10-6. The application of modification of phase transitions in the composite materials will make it possible to enrich opportunities of building and construction industry when erecting skyscrapers and constructing in regions with higher seismic activity [8].

In Fig.2 is presented a photomicrograph of the cement stone structure in the modified concrete composition.

Research methodologies

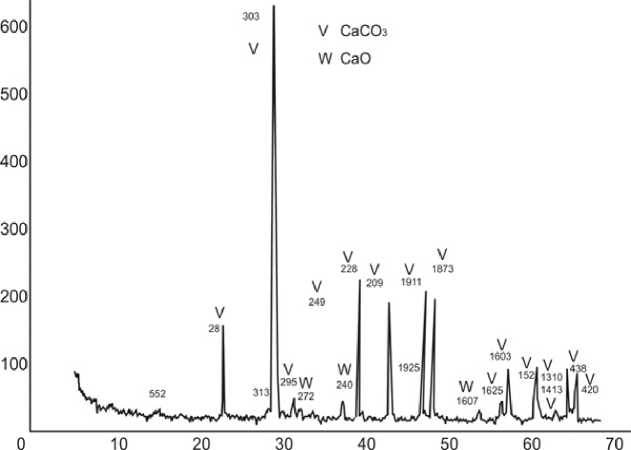

The purpose of this paper was the studying of hydrodynamic cavitation effect on physical properties of carbonaceous material – heat-treated cellulose. The heat-treated cellulose powders have – 467 –

Fig.3. The XPA spectrum of heat-treated cellulose powder been investigated by the method of X-ray phase analysis (XPA) on the X-ray diffractometer SMART APEX II. The XPA spectrum graph is characteristic of a polycrystalline sample (Fig. 3).

The composition of initial powders is obtained by the X-ray spectrum method analysis on the Bruker fluorescent spectrometer S-4 Pioneer. The composition formula is 60% of carbon, 40% of impurities Al, Si, Ca, Mg, Fe, Ni, Cu. The concentrations of paramagnetic impurities are of only sub percent – size (for Cu, Ni – 0.07%, Fe – 0.4%).

In the research process of the initial powder on the OptiTech optical microscope of transmission type XSP-128H (magnification 400х) there have been detected a two-phase composition:

-

1. Black flakes (not completely burned cellulose).

-

2. Fine-dispersed powder of grey color – the grey part (completely burned cellulose).

To perform a cavitation experiment there were prepared water suspensions of powders in distilled water. The concentration of the suspension was determined by the following formula:

C = —m1--100 %, m1 + m 2

where m 1 is the sample mass, m 2 is the water mass. The powders were weighed by the KERN 770 GS/ GL balance to the nearest 10–4gram. The concentrations of the prepared water suspensions were up to 0.1%.

The water suspension was put into a supercavitation mixer with the cuneiform cavitator (the vertex angle at the wedge was 60 degrees) and rotated at room temperature with the rotor fixed velocities from 5000 up to 20000 rpm.

The equipment and experimental technique are described in [3]. With the rotation mode from 15000 до 20000 rpm and the rotation time of 1.5-2 minutes there was observed a water suspension temperature rise from room temperature up to 90 ºС.

Interpretation and discussion of research results

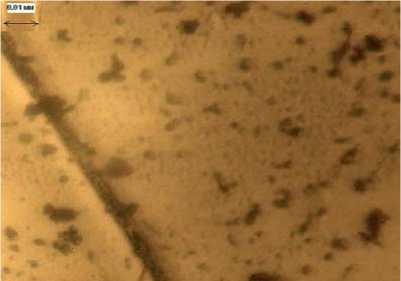

The cavitation experiment having been performed, the water suspensions were settled during 48 hours in closed plastic cups until sediment. The sediment was poured out in Petri dishes and dried in the air at t = 25 ºС (Fig. 4, 5).

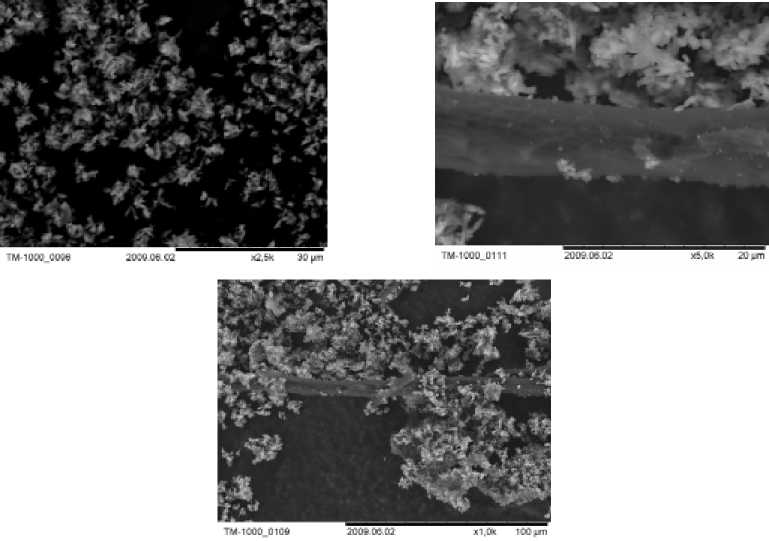

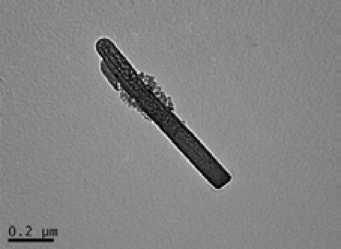

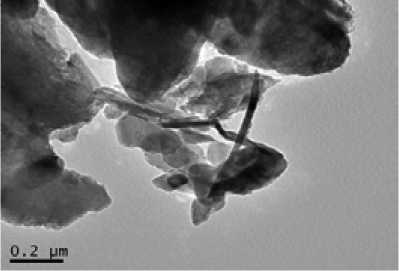

In the performed experiments there was observed self-organization of heat-treated cellulose particles into fine tubes. The tubes were found during electron microscope studies of the samples on the scanning electron microscope Hitachi TM-100 9 (accelerating voltage is 15 kV) (Fig. 6) and on the transmission electron microscope JEOL JEM-2100 (accelerating voltage 200 kV), Fig. 7.

The observable tubes are similar in their shape with carbon nanotubes which have been obtained by various techniques and described in the reference literature and which exceed them in sizes by 3-4 orders of magnitude longer and by 2 orders of magnitude in diameter.

It is known that the velocity of the phase boundary at a cavity microbuble collapse can reach 500 m/s and depends on its radius. The collapse of the bubble goes on within submicroseconds. The temperature in this local spot rises up to 103-104 K as a result of adiabatic compression.

At the cavity bubble collapse in the local volume inside and near to it there are generated fields of high pressure (up to 2000 MPa). The phenomenon is accompanied by intensive turbulent micromixing and mechanical thermolysis of water with the formation of H2, O2, H2O2 and free hydrogen bonds. The pulsation effects of cavitation turn each bubble into a cavitation microreactor in which there are created preconditions for reactions to go. Thus, high local pressures and temperatures make it possible to consider hollow cavitations as an peculiar energy generator which for rather a long time of the cavity expansion from a nucleus, accumulates energy and during the collapse generates it into surrounding fluid [9].

The cause of emergence of self-organizability of heat-treated cellulose particles (atoms, molecules) is the strong energy effect obtained as a result of a hydrodynamic cavitation effect. The vicinity around a cavitation bubble after the «collapse» can be considered as plasma. In this case the mechanism of particles self-organizing is probably similar to that of formation of tubular structures in dust plasma. There have been found tubes of the sizes that are typical for individual carbon multilayer tubes (from several nanometers up to twenty-thirty nanometers), tubular structures with a diameter of 50-100 nanometers which are built from smaller tubes. The tubular units are joined

Fig. 4. View of the cavitation sediment of heat-treated cellulose in the Petri dish

Fig. 5. Photo taken on the OptiTech optical microscope of transmission type XSP-128H (magnification 400х)

Fig. 6. Photo taken on the electron microscope Hitachi TM-100 9 (accelerating voltage is 15 kV)

Fig. 7. Photos taken on the transmission electron microscope JEOL JEM-2100 (accelerating voltage 200 kV)

among themselves due to the forces of magnetic interaction [10]. As samples explored by us contain a great amount of paramagnetic impurities, they should play a major role in the formation of the registered structures.

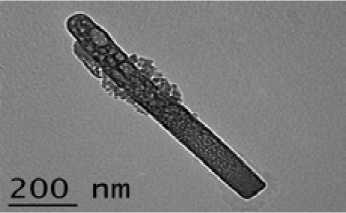

The electron structure of fulleroids especially of rather large sizes (higher fullerenes, tubulenes, multilayer nanotubes, astralenes) is an energy-band structure and enables an efficient excitation energy exchange between excited molecules of the medium and fulleroids [11]. It has been experimentally proved by the strongest cohesion (Fig. 8) of fulleroids in suspensions when it is necessary to have long and intensive external processing (hypersonic treatment) to separate the agglomerates uniting groups of fulleroid clusters [7]. The similar phenomenon (cohesion) is observed in heat-treated cellulose samples after the cavitation processing (Fig. 9).

Fig. 8. Photomicrograph of astralene agglomeration phenomenon on multilayer nanotubes [8]

Fig. 9. Agglomeration of heat-treated cellulose particles after the cavitation processing. Rotating 5000 rpm during 2 min. The electron microscope photo obtained on the JEOL JEM-2100 microscope

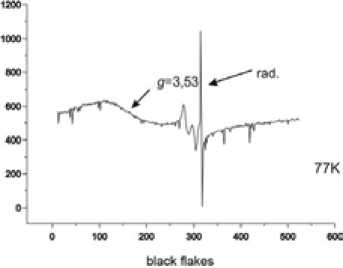

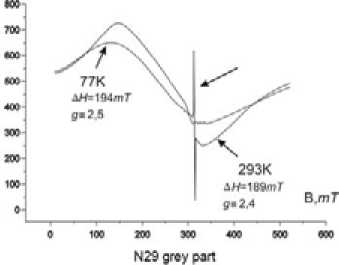

Fig. 10. EPR spectra (black flakes)

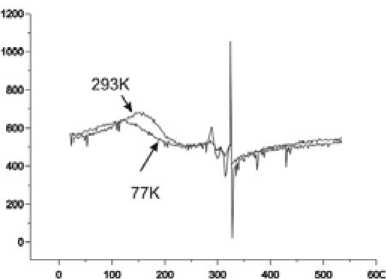

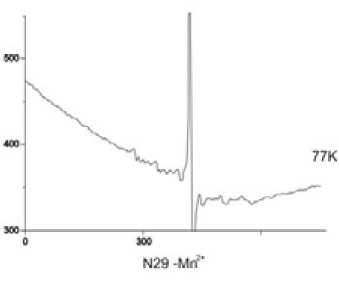

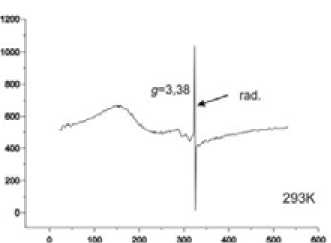

The EPR spectra were taken on the initial samples of heat-treated cellulose. The EPR spectra were taken at temperatures of 300 K, 77 K on the Bruker EPR spectrometer E-500 (Figs. 10, 11).

At 293 K the EPR spectrum will comprise a wide band and a central narrow band. The wide band is caused by the presence of ferric oxide. The narrow band – by a free radical of carbon atom. After the cavitation processing, the shape of the EPR spectra changed and there was observed some broadening of the wide band of the spectrum at 77 K and its intensity decreasing. It may be connected with the presence of superparamagnetic particles in the sample. It is possible that large paramagnetic particles of iron collapse as a result of the cavitation processing, i.e. in the cavitation processing there is an intensive dispersion of the sample, not only the carbon component being crushed but also impurities including paramagnetic impurities. The process goes on a molecular level.

Summary and Conclusions

Hence it was possible to obtain nanofluid – a water suspension with the features characteristic of weak water suspension of fulleroids as a result of rather short cavitation processing of the weak water suspension of heat-treated cellulose. It will probably make it possible to efficiently use the – 471 –

Fig. 11. EPR spectra (grey part)

obtained nanofluid features in solving ecological problems to obtain constructional materials with new operational properties for industrial application.

The article is published with the support of the Program of Development of the Siberian Federal University. Electron-microscopic research has been carried out in the laboratory of electronic microscopy of the Collective Using Center of Siberian Federal University.