Reducing utility bills through the introduction of energy efficient systems

Автор: Kondrashov Aleksey Vladimirovich, Trinchenko Aleksey Alexandrovich

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 4 (102), 2022 года.

Бесплатный доступ

The object of the study is an improved system for the partial recovery of the condensation heat of refrigeration machines, its development, implementation and study of operational performance, which increases the share of waste heat in the air heating system in order to increase their energy efficiency and optimize operating costs. The purpose of this work is to analyze the costs of using heat to heat the coolant in the air heating system from the heat supply organization, with the costs in case of heating the coolant in the condensation heat recovery system. Method. To analyze the calculated and actual values, the development and implementation of a research stand based on an ultrasonic flow switch and a heat meter was carried out, which made it possible to evaluate the economic effect of the implementation of the proposed solutions. Results. With regard to the air heating system of buildings with artificial freezing of the ice surface, the economic effect in the form of a reduction in utility bills for heating is 2.46 million rubles per year, while reducing the thermal pollution of the environment by at least 1.4 GW.

Energy efficiency, heat recovery, communal payments, air heating, thermal pollution

Короткий адрес: https://sciup.org/143179045

IDR: 143179045 | DOI: 10.4123/CUBS.102.2

Текст научной статьи Reducing utility bills through the introduction of energy efficient systems

The rational use of fuel and energy resources is one of the most important tasks facing the economies of industrialized countries. The relatively low efficiency of energy use in Russia compared to other countries leads to high energy supply costs, an increase in production costs, and contributes to the disruption of sustainable energy supply. The Government of Russia approved the draft Energy Strategy for the period up to 2030, issued Federal Law No. 261-F3 dated November 23, 2009 (as amended on July 20, 2019) “On Energy Saving and Increasing Energy Efficiency ...”, in which, as one of strategic guidelines of the state energy policy formulated the tasks of increasing the energy efficiency of the economy. The current state of affairs can be characterized as a period of transition from the formation of an ideology for increasing energy efficiency to its application in practice [1], [2].

During the operation of heat engines, a significant amount of condensation heat is generated, which in most cases is released into the environment. In order to reduce operating costs and improve the energy efficiency of heat engines (Fig. 1), the development and implementation of special systems for utilizing such low-grade heat has been increasingly proposed [3]–[23]. In this case, in addition to the air condenser, a precondenser (utilizer of the heat of gas compression in the compressor) and a condenser (utilizer of the heat of condensation and heat of oil cooling) are installed. This solution makes it possible to modernize equipment in the direction of reducing thermal pollution of the environment [24]–[26], increase energy efficiency by using low-grade heat by various consumers, and reduce utility bills. With regard to the case of artificial freezing of the ice surface, such consumers can be the ventilation and air conditioning system, as well as the system for heating the coolant used in the snowmelt pit and protecting the soil from freezing [27]–[30].

Fig. 1 – Evaporator-compressor unit Climaveneta BE/SMED-BT (photo taken by the author)

The object of study in this paper is the air heating system of the ice arenas of the figure skating school in St. Petersburg (Russia), where compressor-evaporation units with air-cooled condensers installed on the roof of the building (Fig. 2) are used to freeze the ice surface, through which the heat condensation is released into the atmosphere and is not usefully used.

Fig. 2 – Air condenser ECA12N9P10C2, manufactured by FRIGA-BOHN, France

(photo taken by the author)

The subject of the study was the results of the introduction of a condensation heat recovery system into the air heating system of the ice arena.

The purpose of the work is the development and implementation of highly economical energy supply systems for sports facilities using the analysis of quantitative indicators of energy consumption during their operation.

Tasks to be solved:

-

1. Identification and quantitative analysis of factors that cause excessive energy consumption.

-

2. Analysis of existing heat recovery technologies and the experience of their implementation at sports facilities.

-

3. Development, implementation and study of energy efficiency indicators of an alternative scheme for organizing heating of the ice arena to reduce operating costs.

-

4. Increasing the energy efficiency of refrigeration machines.

2 Materials and Methods

In the work, for the study, a feasibility study and the introduction of a system for utilizing the heat of condensation of thermal machines into the air heating system of ice arenas were carried out (Fig. 3).

Fig. 3 – Scheme of distribution of air flows of fan heaters over the ice arena

(photo taken by the author)

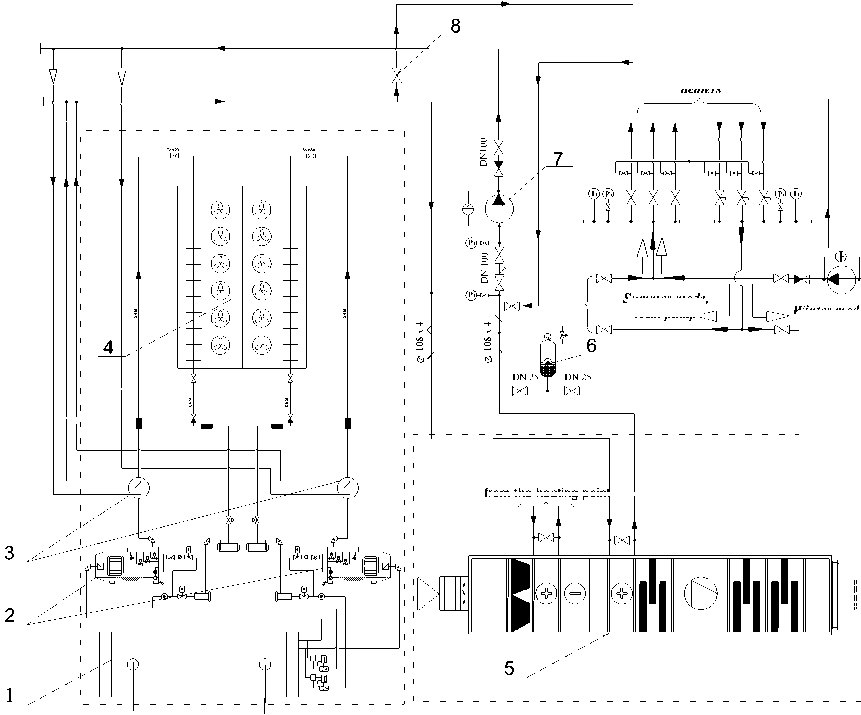

The hydraulic diagram (Fig. 4) shows the main elements of the system under study: 1) Evaporative compressor unit BE/SMED-BT 2402, manufacturer Climaveneta, Italy; 2) Semi-hermetic screw compressors CSH8573-140Y-40D, manufacturer Bitzer, Germany; 3) Precondensers CPS/S145HR, manufacturer Alfa Laval, Italy; 4) Air condensers ECA12N9P10C2, manufacturer Friga-Bohn, France; 5) Air conditioners (K1, K2) manufacturer VTS Clima, Poland; 6) Membrane expansion tank Reflex N200, manufacturer Reflex, Germany; 7) Circulation pump IL50/170-7, manufacturer WILO, Germany; 8) Cast iron gate valve with rubberized wedge BV GGG50, manufacturer HEBEI CENTRAL, China.

Before the modernization of the equipment, the heat carrier from the existing pre-condensers for extracting heat from the hot vapors of the refrigerant entered only into the air conditioning system (into the second heating circuit of the air conditioner K1–K2), where it was not usefully used. After the modernization of the system, the coolant from the precondensers enters through the installed valve (No. 8) and pipelines (Fig. 4) only into the air heating system of three ice arenas, due to which it became possible to completely abandon the use of heat by the heat supply organization.

To analyze the actual costs with the results of technical and economic calculations using the fixation of the parameters of the improved system, the development and implementation of a research stand was carried out (Fig. 5). The stand includes a stationary heat meter Streamlux-SLS-720FE and a heat meter SPT-940, the data from which is continuously recorded and stored on a personal computer. Analysis of the data obtained from the indicated metering devices (coolant flow rate, coolant temperature at the inlet and outlet of the system (temperature difference), the amount of heat consumed in the system, etc.) was carried out in the Prolog program. Based on the results of the analysis, the dependence of the temperature of the coolant at the outlet of the condensing heat recovery system of refrigeration machines on the time of day is obtained, and the range of change in the determining parameters that must be maintained to achieve the tasks set in the work is also indicated.

air heating system, fan heaters

from the heating point

Fig. 4 – Hydraulic diagram of the condensation heat recovery system of refrigeration machines

Summer mode, Heat pump

Winter mode

(evaporative compressor unit BE/SMED-BT 2402, manufacturer Climaveneta, Italy – 1; semi- hermetic screw compressors CSH8573-140Y-40D, manufacturer Bitzer, Germany – 2;

precondensers CPS/S145HR, manufacturer Alfa Laval, Italy – 3; air condensers ECA12N9P10C2, manufacturer Friga-Bohn, France – 4; air conditioners (K1, K2), manufacturer VTS Clima, Poland – 5; membrane expansion tank Reflex N200, manufacturer Reflex, Germany – 6; circulation pump IL50/170-7, manufacturer WILO, Germany – 7; cast iron gate valve with rubberized wedge BV

GGG50, manufacturer HEBEI CENTRAL, China – 8

(diagram made by the author)

Fig. 5 – Research stand for fixing the parameters of the improved system (photo taken by the author)

3 Results and Discussion

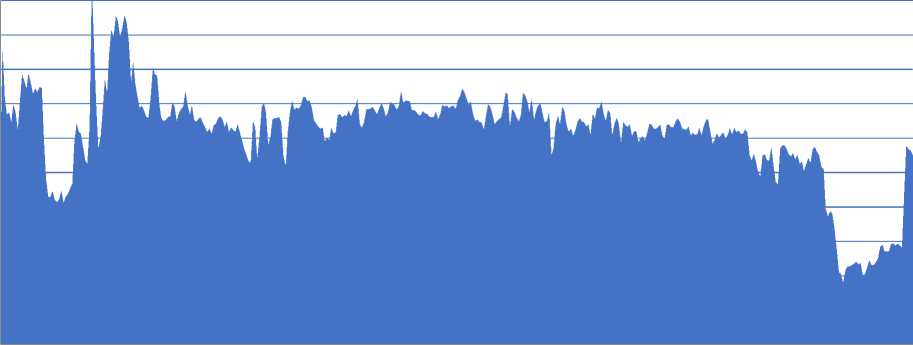

An analysis of the data obtained from the research stand for the period from May 2021 to July 2022 showed that at least 516.23 Gcal was usefully used in the improved air heating system (Fig. 6).

го 5

or

Date of measurement

Fig. 6 – Change in the amount of heat consumption in the air heating system of ice arenas, by months for the period under review Q, Gcal. (diagram made by the author)

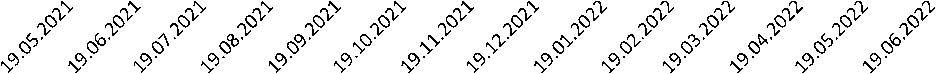

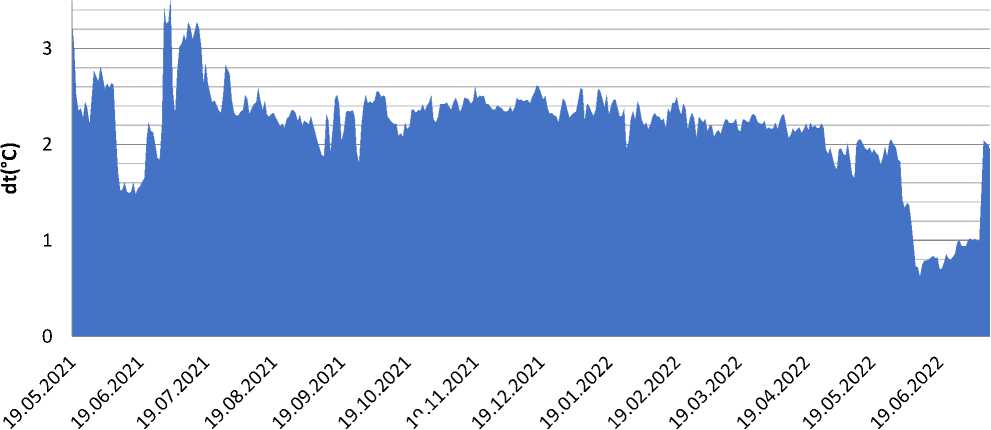

The diagram presented in Fig. 7 illustrates the change in the temperature of the coolant at the inlet to the system, and the diagram Fig. 8 illustrates the temperature difference between the coolant at the inlet and outlet of the system. The change in these parameters over the period under review allows us to conclude that the use of a condensation heat recovery system makes it possible to consistently obtain a coolant with a temperature of 35–40 °C. The data obtained from the research stand, as a result of the study, confirm the possibility of refusing to use the heat of the heat supply organization in the air heating system in favor of the system under study, which made it possible to fully provide the heated premises with the required amount of thermal energy.

g 30

Date of measurement

Fig. 7 – Change in direct water temperature in the condensation heat recovery system, by months for the period under review, t1,°C. (diagram made by the author)

Date of measurement

Fig. 8 – Deviation value of the temperature difference at the inlet and outlet of the system by months for the period under consideration, dt, °C (diagram made by the author)

The values of utility costs before and after the introduction of a heat recovery system in the air heating system of ice arenas during the heating period (payment for heat from the heat supply organization for 7 months) and during the non-heating period (payment for electricity during the operation of the heat pump for 5 months), determined by calculation [31], are shown in Table 1, which compares with the actual costs provided by the chief power engineer of the institution and with the data obtained from the research stand.

Table 1. Utility costs of the air heating system of ice arenas before and after the implementation of the heat recovery system

|

Name of costs |

Costs determined by calculation, rub. |

Actual costs, rub. |

Savings, rub. |

|

|

о JZ ~ Е о о £ §1 2 S та £ С с ф Ф О со Е >. ф о Q. 2 Е |

Heat for the air heating system of ice arenas received from the heat supply organization |

1 650 000 |

1 235 654 |

0 |

|

Electrical energy for heat pump air heating system |

684 064 |

1 225 565 |

0 |

|

|

Electrical energy for the circulation pump of the air heating system |

307 028 |

307 028 |

0 |

|

|

Total: |

2 641 092 |

2 768 247 |

||

|

The difference between the calculated and actual values |

127 155 |

|||

|

" Е Q О V) £ с £ о ,с < -5 У 2 о £ - |

Usefully used in the air heating system 477.75 Gcal per year (data from the research stand) (Cost of 1 Gcal = 3047.67 rubles) |

0 |

0 |

1 456 024 |

|

Electrical energy for the circulation pump of the air heating system |

307 028 |

307 028 |

0 |

|

When studying the operation of the utilization system, an increase in the energy efficiency of refrigeration machines was recorded (due to a reduction in electrical energy consumption due to a smaller number of switching on of axial fans on air condensers), which, in turn, had a positive effect on reducing the pressure and temperature of the refrigerant condensation. In turn, the operation of refrigeration machine compressors at a lower load also leads to a decrease in electrical energy consumption, which increases the useful life of the equipment while reducing the overhaul period.

4 Conclusions

As a result of comparing the actual costs with the results of technical and economic calculations before and after the implementation of the system, an economic effect was obtained in the form of a reduction in utility bills when the heat supply organization and the heat pump were not used in favor of the condensation heat recovery system, which amounted to 2.46 million rubles in year.

5 Fundings

This work was supported by the Russian Foundation for Basic Research (RFBR Grant No. 20-38-90119\20 dated September 3, 2020).

Список литературы Reducing utility bills through the introduction of energy efficient systems

- Shuravina, D.M., Fokina, N.B., Averyanova, O.V. Vapor compression heat pumps as energy efficient devices. Construction of unique buildings and structures. 2013.. № 10(15). P. 62-76. DOI:10.18720/CUBS.15.6.

- Russian Federation, Laws, «On Energy Saving and Energy Efficiency Improvement and on Amendments to Certain Legislative Acts of the Russian Federation" (with amendments and additions)» dated 23.11.2009 No. 261-FZ.

- Zhang C., Zhou G., Zhao X. and Zhang Z., "The Characteristic Study of the Superheated Vapor Heat Recovery System," 2010 Asia-Pacific Power and Energy Engineering Conference , 2010, pp. 1-4, DOI:10.1109/APPEEC.2010.5448523

- Batukhtin A. G., Batukhtin S. G., Kobylkin M. V. and Baranovskaia M. G., "Application of Heat Pumps in a Centralized heat Supply as the Direction of the Development of District Heating Cogeneration," 2018 International Ural Conference on Green Energy (UralCon) , 2018, pp. 45-50, DOI:10.1109/URALCON.2018.8544378

- Jirinec J. and Rot D., "The Control System for Heating of Small Buildings with Heat Recovery unit and Heat Pump," 2020 21st International Scientific Conference on Electric Power Engineering (EPE) , 2020, pp. 1-4, DOI:10.1109/EPE51172.2020.9269250.

- Huang Feng, Lu Jun, Zheng Jie and Baleynaud J., "Feasibility of heat recovery for district heating based on Cloud Computing Industrial Park," 2015 International Conference on Renewable Energy Research and Applications (ICRERA) , 2015, pp. 287-291, DOI:10.1109/ICRERA.2015.7418711

- Hui Chen, Panpan Qin, Lili Chen, luning Yu and Shikui Liu, "Analysis and determination of the thermal parameters in the waste heat recovery system based on heat pump," 2011 International Conference on Electric Technology and Civil Engineering (ICETCE) , 2011, pp. 1006-1008, DOI:10.1109/ICETCE.2011.5776430.

- Skubienko S. V., Yanchenko I. V. and Babushkin A. Y., "Optimization of a Single-Stage Heat Pump Operation Through Subcooling and Superheating," 2019 International Science and Technology Conference "EastConf" , 2019, pp. 1-3, DOI:10.1109/EastConf.2019.8725401.

- Rusovs D., Jaundālders S. and Stanka P., "PUMPED THERMAL ELECTRICITY STORAGE INTEGRATION IN DISTRICT HEATING SYSTEMS," 2020 IEEE 61th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON) , 2020, pp. 1-4, DOI:10.1109/RTUCON51174.2020.9316560.

- Li Y. et al., "Performance Analysis of Multi-energy Complementary Heating System Based on Photo-voltaic/thermal collectors and Heat Pumps," 2021 4th International Symposium on Traffic Transportation and Civil Architecture (ISTTCA) , 2021, pp. 631-635, DOI:10.1109/ISTTCA53489.2021.9654699

- Robu S., Lupu M. and Daud V., "The Impact of Distributed Heat Pumps on the District Heating System," 2021 9th International Conference on Modern Power Systems (MPS) , 2021, pp. 1-6, DOI:10.1109/MPS52805.2021.9492548.

- Zherlykina, M.N., Kholodov, A.V. Energy saving in air conditioning and refrigeration of buildings. Science Magazine. Engineering systems and structures. – 2011. – № 1(4). – P. 51-57.

- Tovaras, N.V., Vashanov, V.P., Amelkina, N.M. [et al.] Energy-efficient solutions of NPF "Khimholodservis" for sports facilities. Refrigeration technology. – 2019. – № 12. – P. 20-25.

- Tovaras, N.V., Savkina, N.V. Energy saving and energy efficiency: utilization of thermal emissions. Refrigeration technology. – 2019. – № 2. – P. 6-10.

- Gorshkov A. S. Energy efficiency in construction: issues of regulation and measures to reduce the energy consumption of buildings. Inzhenerno-stroitel'nyi zhurnal.2010. №1. P. 9–13

- Goshka, L.L. On the issue of energy saving and energy efficiency in buildings. Engineering and construction magazine. 2010. № 5. P. 38-42.

- Avsyukevich, A.D. Energy efficiency and energy saving in heat supply systems. Construction of unique buildings and structures. 2013. № 2(7). P. 40-54. DOI:10.18720/CUBS.7.4

- Simbirev O.V. Prospects for the modernization of heating and ventilation systems in buildings. Colloquium-journal. 2019. № 13-2(37).

- Korotkiy, I.A., Neverov, E.N., Korotkikh, P.S., Lonshakov, V.G. Development of a scheme for the utilization of the heat of condensation of refrigeration machines to reduce the dependence of the ice arena on urban heating and hot water supply systems. Bulletin of the International Academy of Refrigeration. – 2021. – № 1. – С. 34-39. – DOI 10.17586/1606-4313-2021-20-1-34-39.

- Buchin, S., Smagin, S. Heat recovery systems in refrigeration plants. Climate world. – 2010. № 62. P. 74–77.

- Denisov-Vinsky, N. D. Heat compressor installations. MegaPascal. 2011. №2. P. 8–16.

- Korotkiy, I.A., Neverov, E.N., Prib, I.A. [et al.] Design solutions for the scheme of a refrigeration machine with the utilization of condensation heat. Refrigeration technology. – 2020. – № 6. – P. 30-33.

- Nemova D.V. Ventilation systems in residential buildings as a means of increasing energy efficiency. Construction of unique buildings and structures. 2012. № 3(3). P. 83–86.

- Israfilov, D.I., Mukhamatdinov, I.A. Ecology of refrigeration units. Science yesterday, today, tomorrow: a collection of articles based on the materials of the XLIX International Scientific and Practical Conference. 2017. № 8 (42). P. 58–62.

- Babaitseva, N. A. Reduction of thermal pollution of the environment. Innovation, technology and business.– 2021. – № 1(9). – P. 10-14.

- Thermal pollution. Great Encyclopedia of Oil and Gas. pp. 1–4. URL https://www.ngpedia.ru/id023994p1.html − (дата обращения 15.07.2022).

- Korotkiy, I.A. Analysis of the energy efficiency of the fast freezing of blackcurrant berries. Foods and Raw Materials. 2014. V. 2, № 2. P. 3–14.

- Korotkiy, I.A., Korotkaya, E.V., Kireev, V.V. Energy efficiency analysis of the sea buckthorn (hippophae rhamnoides) frutts quick freezing. Foods and Raw Materials. 2016. V. 4. № 1. P. 110–120.

- Shakirova, G.G. Recuperation of thermal energy removed by the cooling system of the compressor unit. Modern innovations: fundamental and applied research. – 2015. No. 1 (1). P. 6–7.

- Polyakova, V.Yu., Kalinina, T.O., Kichin, K.V. Analysis of the energy efficiency of heat pumps in heat supply systems on a territorial and climatic basis. Young scientist. - 2016. - No. 27. - P. 142-146.

- Kondrashov, A., Egorov, M. Energy conservation and the use of the heat of refrigeration of ice arenas to heat the school of figure skating of St. Petersburg. Journal of Physics: Conference Series. 2019 DOI:10.1088/1742-6596/1369/1/012063