Remotely operated underwater vehicle in the form of a quadcopter: features of the design and control system

Автор: D. A. Volkov, A. V. Sayapin, K. V. Safonov, A. A. Kuznetsov

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Informatics, computer technology and management

Статья в выпуске: 2 vol.21, 2020 года.

Бесплатный доступ

Inspection of underwater objects, such as underwater archaeological sites, sunken technical objects, and un-der water located technical structures, requires the use of specially trained divers, manned or unmanned, re-motely operated or autonomous underwater vehicles. A relatively rarely used design for such underwater vehicles is a design in the form of a quadrotor with posi-tive buoyancy. This article discusses the design and the control system of the remotely operated underwater vehicle in the form of a quadrotor. The aim of the work is the selection and justification of the shape of the vehicle, the selection of the optimal structure of the control system with the expectation of the subsequent use of the vehicle as an au-tonomous one. The potential advantages of the selected design in the form of a quadcopter with a cylindrical body are de-scribed, in particular, the large volume of the sealed space of the vehicle, the possibility of installing capacious power sources, the potential for stabilizing the vehicle in a given position if there is a current at the place of work. The sealed case of the device is designed to place control electronics, power electronics and battery power of the device. The selection and justification of the shape of the sealed enclosure were made using a hydrostatic modeling apparatus and theoretical mechanics. A solid cylinder made of polycarbonate was selected as a form of the sealed housing of the vehicle. The advantage of the selected form in comparison with the parallelepiped-shaped case is shown under the condition of the same material parameters. The control system of the device includes software and hardware components. The choice of hardware com-ponents is justified, their key characteristics are described. As the control device of the top level, a single board computer (SBC, Single Board Computer) Orange Pi PC was selected, the direct control of the motor of the vehi-cle is performed using the Cortex-M3 microcontroller. The software architecture of the device is described. The choice of architecture is determined by the requirements of poorly connected components (which makes it easy to replace particular software elements without the need to modify the other elements), the simplicity of the potential replacement of the top-level control modules (which potentially allows switching from a remote control model to an autonomous control model). Some software components are described. The control system is implemented with the high-level lan-guage Python version 3.7, the basis of the control mechanism is message passing, the MQTT protocol maintained by the Mosquitto server is selected as a messaging mechanism. Testing of the vehicle was carried out in pools with standing water and with a simulated current. Testing showed the need to gain experience to control the underwater vehicle. The study will allow us to further develop a new version of the underwater vehicle, taking into account the wishes and identified problems.

Robotics, underwater archaeology, underwater vehicle, quadcopter, control system, hardware-software complex.

Короткий адрес: https://sciup.org/148321733

IDR: 148321733 | УДК: 629.58 | DOI: 10.31772/2587-6066-2020-21-2-163-169

Текст научной статьи Remotely operated underwater vehicle in the form of a quadcopter: features of the design and control system

Introduction. In 2016 Alexander Goncharov and Nikolay Karelin (historians and lecturers at Reshetnev Siberian State University of Science & Technology) went on a research expedition to the north of the Krasnoyarsk Territory in search of the sunken English ship „Thames”. They passed along the Yenisei River and the Yenisei Bay [1]. As a result of the undertaken studies, the location of this ship was determined. It is at the mouth of the Salnaya Kurya River [2].

Alexander Goncharov offered an idea to develop a remotely operated underwater vehicle designed for the exploration of underwater objects that have cultural, historical or other value.

The main purpose of this underwater vehicle is the ability to conduct underwater archaeological research.

The advantage of the proposed design of the vehicle in the form of a quadcopter is the ability to hold a predetermined position and position in moving aquatic environment.

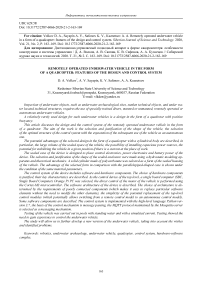

Fig. 1. The developed prototype of the underwater vehicle

Рис. 1. Разработанный прототип подводного аппарата

The originality of this development consists in the whole of the following distinctive features:

– the implementation of the design of the underwater vehicle in the form of a quadcopter and its control system is based on the idea of the implementation of aircraft;

– to control the underwater vehicle special software is used, it is available for use on mobile devices and personal computers;

– the proposed concept of an underwater vehicle combines the advantages of tethered and unmanned underwater vehicles.

Case design. The exoskeletal structure of the underwater vehicle is constructed as a hollow cylinder made of plastic.

This form allows the vehicle to withstand high pressure of the water column, and the calculations show that the maximum immersion depth of the vehicle is not caused by the shape and material of the exoskeletal structure, but by the sealing features of the side flanges.

The first prototype of the device was made in the form of polypropylene pipes connected by means of a socket joint, closed with sealed lids.

We have also considered the case made entirely with the use of 3D printing technology, however, the anisotropy of the case and its relatively low structural strength forced to abandon this approach.

In the future, it is planned to make the case as a single element in the form of a cylinder made of polycarbonate, with an external diameter of 110 mm and a wall thickness of 3 mm.

For this option, we made the calculations of the strength of the case using the methodology published in [4; 5], which showed the structural stability of the case at depth of immersion of up to 100 m.

A perforated metal plate serves as a chassis for the components located inside the body.

The following elements are placed on the plate:

– high-current Li-ion (lithium-ion) battery used as a main power source;

– on-board computer Orange Pi PC;

– MultiWii NanoWii control module based on a microcontroller with an ATmega32U4 processor;

– four electronic speed controllers (ESCs) that control the brushless motors located outside the case.

The metal plate chassis also serves as a heat sink, evenly distributing the heat released during the operation of the speed controllers, which contributes to its removal outside the case.

Two square aluminum profiles are attached to the main part of the case, at the ends of which brushless motors with propellers are installed, designed for the movement of the underwater vehicle in the aquatic environment.

Some elements of the case, including driving propellers, were developed in the OpenSCAD 3D modeling program and printed using a 3D printer. Upon the availability of a 3D printer, this approach makes it possible to get a kit of necessary elements for the purpose of their replacement in case of failure.

The speed controller wires connecting the motors to the on-board control system are routed through sealed lead-ins (seals), which prevent water from entering the case.

An important task is the transmission of video from the underwater vehicle. For these purposes, it is planned to install an on-board camera connected to the main control computer. This will allow using the device distantly as remotely operated. In the future it will be possible to put into operation the system of autonomous control of the device as well.

Two methods of installing a camera on the device are considered: inside the exoskeleton structure (since it is transparent), and in a separate case on the external structures of the device. Each approach has its own advantages and disadvantages. Thus, installing a camera inside the case allows reducing the number of tight joints, which increases the reliability of the device as a whole. However, it causes the need for post-processing of the image from the camera, since the cylindrical body of the device introduces distortions. Installing a camera from the outside will reduce the distortions introduced by the body of the device (or, more precisely, it reduces the requirements for the amount of post-processing of the image from a camera, since a camera is supposed to be placed under a spherical dome), but it creates potential leakage spots.

It is planned to perform optimization of the shape of a driving propeller and the vehicle case as well [6].

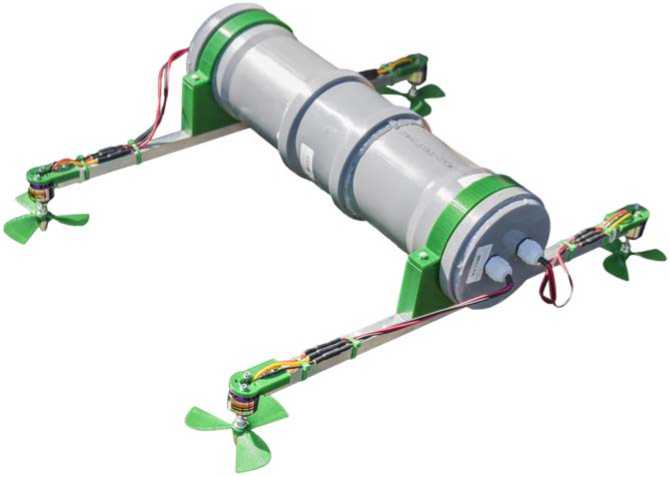

Control system development. The main components of the control system are:

– an operator whose workplace is located on board an expedition escort ship or on shore; the workplace is equipped with the means for displaying the video stream from the board of the underwater vehicle, as well as with controls;

– a top-level control software module receiving operator’s commands (or from an autonomous control system) and translates them into the values of the state space variables of the device;

– software of a low-level controller, ensuring the maintenance of set values of state space variables that controls the operation of electronic speed controllers.

Let us consider the components of the control system of the underwater vehicle in more detail. The control system complex consists of the following components:

– an operator using a device with installed software designed to control the underwater vehicle;

– a control device, which can be used as a smartphone, tablet or personal computer with installed software developed as part of this project, designed to send messages (commands) and receive video from an on-board camera;

– Wi-Fi router, which is used to establish communication between the control device and the on-board computer;

– an on-board computer designed to broadcast video from an on-board camera and receive messages (commands) from a control device, in order to transmit them to the multirotor controller for moving the underwater vehicle;

– a webcam designed to transmit video in order to monitor the environment;

– a multirotor controller used to transmit speed values and the position of the vehicle in space to speed controllers;

– electronic speed controllers (4 pcs.) that allow us to control the motors of an underwater vehicle with a given thrust;

– motors (4 pcs.) that allow us to perform the movement of the underwater vehicle in the aquatic environment.

Fig. 2 shows the scheme of interaction of components of the control system complex.

Four HobbyWing FlyFun 30A speed controllers and four RCX D2830/14 750kv brushless motors connected to them are used to move the device in the aquatic environment.

The electronic components of the underwater vehicle are powered by a high-current Li-ion (lithium-ion) battery with the capacity of 1800 mAh.

As an on-board computer, a single-board computer (microcomputer) with an operating system based on the Linux kernel is used. Initially, the Raspberry Pi Model B+ microcomputer was used in the underwater vehicle prototype, however, later it was replaced by the model Orange Pi PC to make it possible to install and use a webcam designed to monitor the environment and (potentially) recognize objects, since for broadcasting video images of optimal quality and the operation of a computer vision system, higher performance is required.

The software structure of the vehicle is described in [7].

Up to date, the following control mechanisms for the underwater vehicle are developed:

– a web server for using a joystick (gamepad) through the Gamepad API;

– control of the underwater vehicle using a mobile device with the Android operating system.

The connection of the operator’s workstation with the top-level control application is made using wireless and wire technologies, which include a Wi-Fi network to connect the operator’s workplace with a Wi-Fi router, which, in turn, is connected to the on-board computer by an Ethernet cable. The on-board computer and Wi-Fi router use a wire connection to form a single access point. Thus, the necessary flexibility of communication of all system components is provided.

For the exchange of messages (commands) between the control device and the on-board computer, the MQTT protocol is used with the implementation in the form of a Mosquitto server.

To receive messages via the MQTT protocol from the control device and transmit them to the on-board computer, and then send them to the multirotor controller, a program for the use on the on-board computer was developed in the Python programming language.

The control of the vehicle motors is performed using the Arduino-compatible MultiWii NanoWii multirotor controller. The software being used makes it possible to cyclically receive values from the on-board computer and transfer them to speed controllers to operate the motors of the device with preselected thrust. The operation is performed in the fixed coordinate system (roll, pitch, yaw). The program also allows keeping the horizontal position of the device in space, using the values of the gyroscope and accelerometer from the MPU-6050 sensor, embedded into the multirotor controller. When the underwater vehicle deviates from the horizon, the rotation speed of the respective motors changes automatically in order to return the vehicle to a horizontal position. This ability protects the device from tipping over.

To control this underwater vehicle, software for mobile devices with the Android operating system and for personal computers with the Windows operating system are developed and tested [8].

The software for controlling the underwater vehicle allows performing the following tasks:

– control of the movement of the vehicle in the aquatic environment;

– displaying streaming video from an installed camera;

– displaying the information received from installed sensors.

It is possible to control the movement of the device using the program interface or a connected joystick (gamepad).

Testing. This underwater vehicle has been repeatedly tested in pools with standing water, as well as in the water with simulated current. To test the device, two weight plates for a rod weighing 0.2 and 0.5 kg were attached to the case, since at the moment the device design has excessive positive buoyancy. In the future, this will make it possible to equip the underwater vehicle with additional attached implements, such as equipment for sampling water, temperature sensors, salt sensors, etc.

Testing in a pool with standing water showed that to control the underwater vehicle it is necessary to have an experienced operator with control skills. The installed motors had a high speed margin, therefore the speed of the motors was limited by software. When the underwater vehicle was submerged to the depth of 6 meters, there were not any problems. After a few minutes the vehicle was in the aquatic environment, there was no moisture inside the case.

Testing the device in the pool with a simulated current of a depth of 0.5 m showed that it is difficult to control the underwater vehicle in such conditions.

Fig. 2. Scheme of interaction of components of the control system complex

Рис. 2. Схема взаимодействия компонентов комплекса системы управления

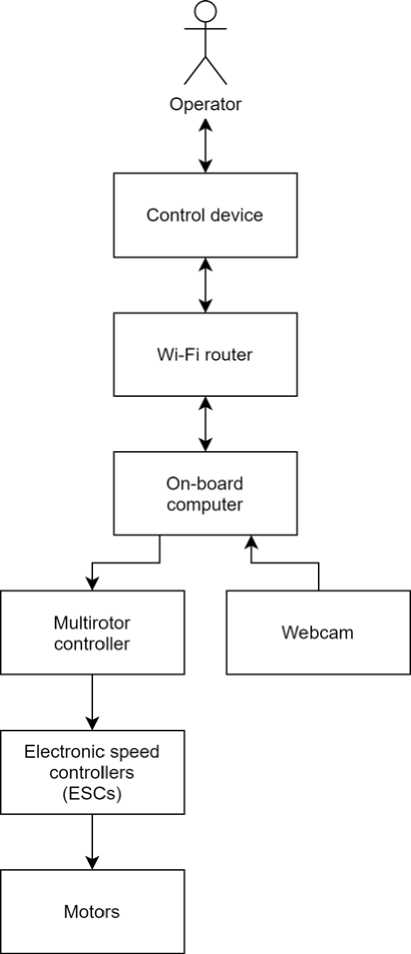

Fig. 3. Testing the underwater vehicle prototype

Рис. 3. Тестирование прототипа подводного аппарата

However, under these conditions, the device stabilizes well and it is able to actively move. After several tests of the underwater vehicle, there were no problems with the penetration of water inside it.

Fig. 3 shows an image of testing the prototype of an underwater vehicle in a pool.

Conclusion. The developed prototype of a remotely operated underwater vehicle in the form of a quadcopter made it possible to determine the viability of the selected device design and the structure of its control system. In the future, it is planned to develop a waterproof case for installing a camera, add some necessary sensors. Is planned to install lighting package as well. In connection with the installation of new components, the underwater vehicle control system and software will be further elaborated. The studies will allow us to develop a new version of the underwater vehicle, taking into account the wishes and identified problems.

Acknowledgment. The participants of this project express their gratitude to the Palace of Water Sports of Re-shetnev Siberian State University of Science and Technology and the Department of Water Use of the Faculty of Forest Engineering of Reshetnev Siberian State University of Science and Technology for their assistance in testing the underwater vehicle.

Список литературы Remotely operated underwater vehicle in the form of a quadcopter: features of the design and control system

- Goncharov A. E., Karelin N. M., Mednikov D. M., Nasyrov I. R. [GIS and satellite remote sensing for archeology: exploring polar history]. Vestnik SibGAU. 2016, Vol. 17, No. 4, P. 956–963 (In Russ.).

- Goncharov A. E., Mednikov D. M., Karelin N. M., Nasyrov I. R. Prospects for using sonar for underwater archeology on the Yenisei: surveying a 19th century shipwreck. IOP Conf. Ser.: Mater. Sci. 2016, Vol. 155. Doi: 10.1088/1757-899X/155/1/012037.

- Volkov D. A., Sayapin A. V. [Remotely operated underwater vehicle for an archaeological survey]. Materialy X Vseros. nauch.-tekhn. konf. s mezhdunar. uchastiem “Robototekhnika i iskusstvennyi intellect” [Materials X All-Russian Scientific-Technical Conf. with Intern. Participation “Robotics and Artificial Intelligence”]. Krasnoyarsk, 2018, P. 21–25 (In Russ.).

- GOST 34233.2–2017. Raschet tsilindricheskikh i konicheskikh obechaek, vypuklykh i ploskikh dnishch i kryshek [State Standard 34233.2–2017. Calculation of cylindrical and conical shells, convex and flat bottoms and covers]. Moscow, Standartinform Publ., 2018. 58 p.

- GOST R 54522–2011. Raschet tsilindricheskikh obechaek, dnishch, flantsev, kryshek. Rekomendatsii po konstruirovaniyu [State Standard R 54522–2011. Calculation of cylindrical shells, bottoms, flanges, covers. Design Recommendations]. Moscow, Standartinform Publ., 2012. 27 p.

- Volkov D. A., Fedotova L. D. [Geometrical and paramateral characteristics of an unmanned underwater vehicle]. Materialy V Mezhdunarodnoy nauchno-prakticheskoy konferentsii “Aktual’nye problemy aviatsii i kosmonavtiki” [Materials V Intern. Scientific-Practical Conf. “Topical Issues in Aeronautics and Astronautics”]. Krasnoyarsk, 2019, Vol. 2, P. 266–267 (In Russ.).

- Sayapin A. V., Volkov D. A. [Software of remotely operated underwater vehicle for an archaeological survey]. Materialy X Vseros. nauch.-tekhn. konf. s mezhdunar. uchastiem “Robototekhnika i iskusstvennyi intellect” [Materials X All-Russian Scientific-Technical Conf. with Intern. Participation “Robotics and Artificial Intelligence”]. Krasnoyarsk, 2018, P. 72–77 (In Russ.).

- Volkov D. A. [Development of the application software for an underwater vehicle control]. Materialy V Mezhdunarodnoy nauchno-prakticheskoy konferentsii “Aktual’nye problemy aviatsii i kosmonavtiki” [Materials V Intern. Scientific-Practical Conf. “Topical Issues in Aeronautics and Astronautics”]. Krasnoyarsk, 2019, Vol. 2, P. 268–270 (In Russ.).