Research of the hydraulic resistance coefficient of sunny air heaters with bent pipes during turbulent air flow

Автор: Abdukarimov Bekzod A., Kuchkarov Akmaljon A.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 1 т.15, 2022 года.

Бесплатный доступ

This article examines the issues of hydraulic resistance of solar air heaters with concave tubes and reduction of pressure losses, as well as the determination of the air flow in concave tubes installed in the working chamber of the solar air heater and discusses the reduction of the number of common tubes to reduce pressure losses in the solar air heater and the installation of concave pipes to give air a swirling motion to eliminate a sharp decrease in the heat transfer process.

Solar air heater, pressure, hydraulic resistance, immersion tube, absorber, air, laminar, turbulent, height, dynamic viscosity

Короткий адрес: https://sciup.org/146282418

IDR: 146282418 | УДК: 662.997:66.02

Текст научной статьи Research of the hydraulic resistance coefficient of sunny air heaters with bent pipes during turbulent air flow

Цитирование: Абдукаримов, Б. А. Исследование коэффициента гидравлического сопротивления cолнечных воздухонагревателей с изогнутыми трубками при турбулентном потоке воздуха / Б. А. Абдукаримов, А. А. Кучкаров // Журн. Сиб. федер. ун-та. Техника и технологии, 2022, 15(1). С. 14–23. DOI: 10.17516/1999-494X-0370

design [33] and relatively high efficiency [34].The general direction of work on the creation of air solar collectors is to find ways to reduce heat loss to the environment [35], intensify heat transfer on the absorber [36] and reduce the cost of pumping air through the collector [37, 38] by reducing the hydraulic resistance of the collector.

Device characteristic

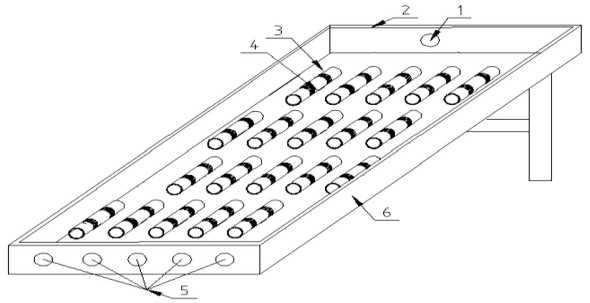

A model of a solar water heater with a concave tube with low hydraulic resistance (Fig. 1) was developed; the device has a length l = 1200 mm, width = 400 mm, height h = 62 mm. This solar air heater has metal tubes in the working chamber with a small heat capacity and concave shape and is built in a checkerboard pattern. The length of each pipe is l = 150 mm. The average duct distance is l = 60 mm. At the base of the duct, a concave shape is given in two rows, this geometric figure has a depth h = 2 mm and a width = 15 mm. The geometric shape attached to the manifold ducts is internally concave along the outer surface of the channel and vice versa. When using a solar air heater, the inlet and outlet pipes are located at d = 15 mm when using a spray gun.

Fig. 1. General schematic view of a solar air heater with concave tubes. Here1-air outlet, 2-window, 3-black metal surface (absorber), 4-air duct, 5-channels for air inlet, 6-case

Pressure loss analysis on the device

This solar air heater works in two ways:

-

– Blowing air into the inside of the collector;

-

– Air intake from the manifold.

During operation by the method of inflating air, diagonal inlet and outlet nozzles of the device are used.

In the case of air intake, each channel uses its own separate channels for air intake.

The channel diagram is a checkerboard shape that covers the entire airflow of the collector through the chamber.

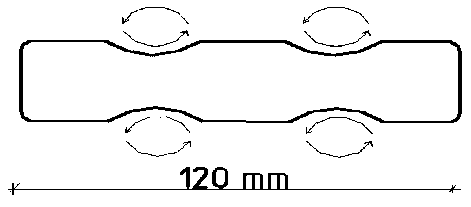

The working chamber of the heater has a concave geometric shape in the air pipes (Fig. 2). air striking these figures forms a vortex motion.

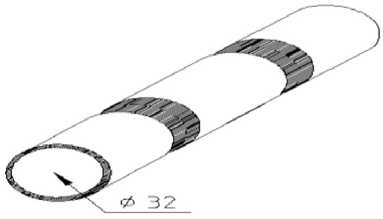

The depth of the concave shape should not exceed h = 2 mm, the diameter of the tube (Fig. 3).

The coefficient of hydraulic resistance in the air pipes of a solar air heater is determined as follows:

Fig. 2. Circular motion on the concave parts of the air duct

Fig. 3. General view of the air duct

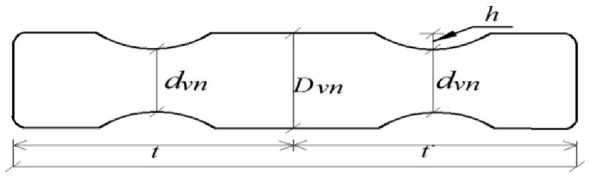

Fig. 4. Schematic view of the steps of a concave air duct

^со=^Г 1 +

100(lgRe-4.6)(l-^1)1-65'

exp C^)0'3

DVn

exp

25(1-^)132" л_^л0.75 - ^Dvn J

Here ξ fl is the hydraulic resistance coefficient of a smooth air pipe; Re is the value characterizing the air flow regime, dvn is the diameter of the smaller part of the pipe, Dvn is the largest diameter of the pipeline, t is the number of steps in the pipe (Fig. 4).

The hydraulic resistance coefficient ξ fl of a smooth air tube, as mentioned above, is determined as follows:

o. 0,316 I M \ ^fl ™ Де0-254 \ji t)

Here Re is the value characterizing the air flow regime, μ is the dynamic viscosity of air at certain temperatures, and μ st is the dynamic viscosity of heated surface air. n – the ratio of dynamic volatility to temperature differences is 1/3.

The Reynolds number is determined as follows:

Re = — . (3)

V

Here is V – speed, d – diameter, ν – kinematic viscosity of air. The dynamic viscosity of air is determined by the following:

Р = р ^^ (— ) . (4)

'О т + С \T0J

Here μ is the dynamic viscosity in (Pa) at a given temperature T ; μ 0-control viscosity in (Pa) at some control temperature T 0; T -set temperature in Kelvin; T 0 control temperature in Kelvin; Sutherland С -constant for the gas whose viscosity is to be determined.

The pressure loss on the device is determined by the following:

Ah = 2 f * . (5)

Here Σξ is the total hydraulic resistance coefficient, v is the average velocity, and 9 is the free fall velocity:

^5=6п+^ . (6)

Theoretical analysis of experimental results

The concave tube solar heater was mainly tested at five different speeds, and at each speed experiment, the main parameters were obtained, including the air speed, the temperature of the heated air from the heater, and the temperature of the absorber and concave tubes (Fig. 5–9, Table 1–5).

Fig. 5. The process of working a solar heater with concave tubes

Table 1. The results were obtained at five different speeds from a concave-tube solar air heater (14.08.2019)

|

Inlet air speed m/s |

Outlet air speed m/s |

Time for experience |

Outdoor temperature oC |

Heated air temperature oC |

Absorber Surface temperature oC |

Tube temperature oC |

|

3.86 |

3.68 |

1330–1400 |

34 |

73 |

84 |

82 |

|

5.2 |

4.78 |

72 |

84 |

81 |

||

|

6.4 |

5.84 |

71 |

83 |

81 |

||

|

7.88 |

6.23 |

70 |

82 |

80 |

||

|

8.2 |

6.55 |

68 |

81 |

79 |

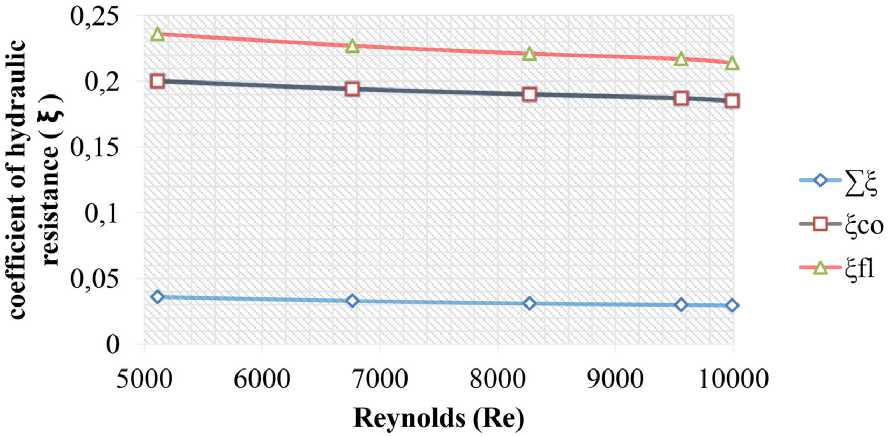

Fig. 6. Reynolds number versus hydraulic resistance coefficient, ^= f(Re)

Table 2. The dependence of the Reynolds number on the coefficient of hydraulic resistance

|

Re |

5111 |

6766 |

8271 |

9559 |

9993 |

|

5 fl |

0.036 |

0.033 |

0.031 |

0.03 |

0.0295 |

|

^ co |

0.2 |

0.194 |

0.19 |

0.187 |

0.185 |

|

Σξ |

0.236 |

0.227 |

0.221 |

0.217 |

0.214 |

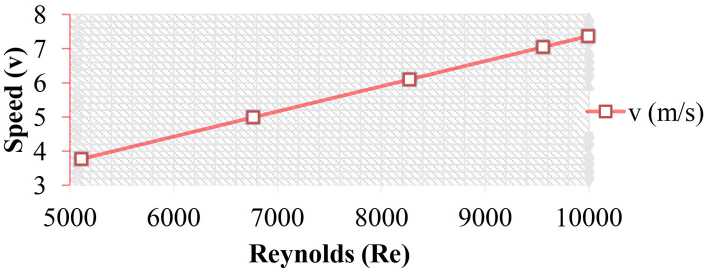

Fig. 7. Reynolds number versus speed, v=f(Re)

Table 3. Reynolds number versus speed

|

Re |

5111 |

6766 |

8271 |

9559 |

9993 |

|

V m/s |

3.77 |

4.99 |

6.1 |

7.05 |

7.37 |

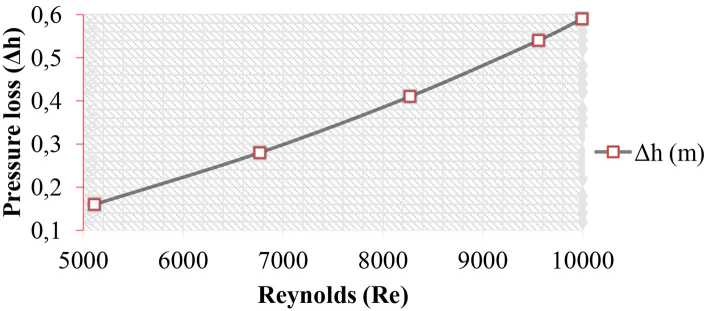

Fig. 8. Reynolds number versus pressure loss ∆h=f(Re)

Table.4 Reynolds number versus pressure loss

|

Re |

5111 |

6766 |

8271 |

9559 |

9993 |

|

Δ h m |

0.16 |

0.28 |

0.41 |

0.54 |

0.59 |

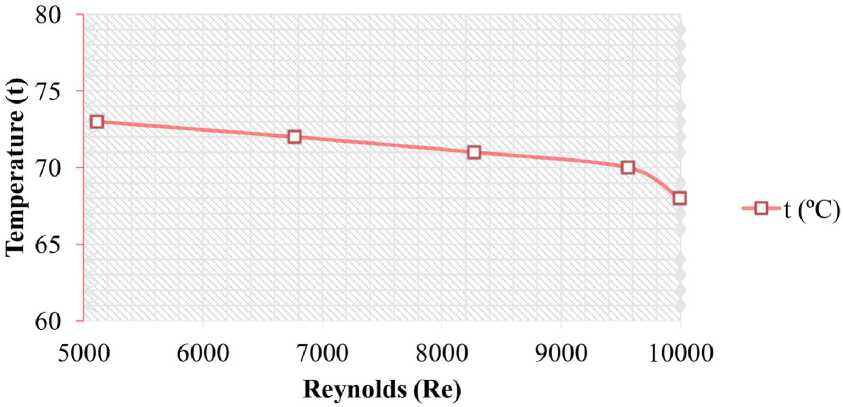

Fig. 9. The dependence of the Reynolds number on the temperature jf the heated air, t = f(Re)

Table 5. Reynolds number versus temperature of heated air

|

Re |

5111 |

6766 |

8271 |

9559 |

9993 |

|

t oC |

73 |

72 |

71 |

70 |

68 |

Conclusion

By replacing common pipes in the working chamber of a solar air heater with pipes with a concave geometric shape, a decrease in the hydraulic resistance coefficient and pressure loss without reducing the heat transfer coefficient of the device was achieved.

Список литературы Research of the hydraulic resistance coefficient of sunny air heaters with bent pipes during turbulent air flow

- Duffie J. A. & Beckman W. A. Solar Engineering of Thermal Processes, Fourth Edition. Published by John Wiley & Sons, Inc. New York, 2013, 936 p.

- Abdukarimov B., O'tbosarov S. & Abdurazakov A. Investigation of the use of new solar air heaters for drying agricultural products. E3S Web of Conferences, 2021, 264, 01031. EDP Sciences.

- Abbasov E. S., Abdukarimov B. A. & Abdurazaqov A. M. Use of passive solar heaters in combination with local small boilers in building heating systems. Scientific-Technical Journal, 2021, 3.3, 32-35.

- Abdurakhmanov A. A., Kuchkarov A. A., Mamatkosimov M. A. et al. The optimization of the optical-geometric characteristics of mirror concentrating systems. Appl. Sol. Energy, 2014, 50, 244-251. https://doi.org/10.3103/S0003701X14040033

- Kuchkarov A. A., Kholov S. R., Abdumuminov A. A. et al. Optical energy characteristics of the optimal module of a solar composite parabolic-cylindrical plant. Appl. Sol. Energy, 2018, 54, 293-296. https://doi.org/10.3103/S0003701X18040114

- Abdukarimov B. A., Abbosov Yo.S. & O'tbosarov Sh. R. Hydrodynamic analysis of air solar collectors. International Journal of Advanced Research in Science, Engineering and Technology, 2020, 7(5), 13545-13549.

- Abdukarimov B. A., Abbosov Yo.S. & Mullayev I. I. Optimization of operating parameters of flat solar air heaters. Bulletin of Science and Education, 2019, 19 (73, Part 2), 6-9.

- Abdukarimov B. A. & O'tbosarov Sh. R. Relevance of use of solar energy and optimization of operating parameters of new solar heaters for effective use of solar energy. International Journal of Applied Research, 2020, 6(6), 16-20.

- Abbasov Yo. S., Abdukarimov B. A., Mominov O. A. & Xolikov A. A. Research of the hydraulic resistance coefficient of sunny air heaters with bent pipes during turbulent air flow. Journal of Critical Reviews, 2020, 7(15), 1671-1678.

- Caglayan N. et al. Experimental investigation of various type absorber plates for solar air heaters. Journal of Agricultural Sciences, 2015, 21.

- Uzbekov M. O. & Ismoilov I. K. Research by airflow of metal shavings used in a solar air heater as a heat receiver. International Journal of Advanced Research in Science, Engineering and Technology, 2019, 6(5), 9061-9065.

- Uzbekov M. O. Thermal balance of the solar air heater with a heat sink of metal shavings. International Journal of Advanced Research in Science, Engineering and Technology, 2019, 6(5), 9246-9254.

- Uzbekov M. O. et al. Investigation of the thermal resistance of a solar air heater with metal shavings. Energy Saving and Water Treatment, 2019, 4. 29-33 (in Russian).

- Krasnov N. F. Aerodynamics. Fundamentals of theory. Airfoil and wing aerodynamics. Moscow, 1976, 385 (in Russian).

- Chabane F., Moummi N., Benramache S., Bensahal D. & Belahssen O. Collector efficiency by single pass of solar air heaters with and without using fins. Engineering Journal, 2013, 17(3).

- Chii D.H, Hsuan Ch., Rei Ch.W. & Chun Sh. L. Analytical and experimental study of recycling baffled double-pass solar air heaters with attached fins. Energies, 2013, 6.

- Yeh H.M. & Ho Ch. D. Collector efficiency in downward-type internal-recycle solar air heaters with attached fins. Energies, 2013, 6.

- Bekele A., Mishra M. & Dutta S. Effects of delta-shaped obstacles on the thermal performance of solar air heater. Advances in Mechanical Engineering, 2011, 18 August.

- Chabane F., Moummi N. & Benramache S. Experimental analysis on thermal performance of a solar air collector with longitudinal fins in a region of Biskra, Algeria. Journal of Power Technologies, 2013, 93(1).

- Ho Ch.D. & Yeh H. M. Collector efficiency in downward-type double-pass solar air heaters with attached fins and operated by external recycle. Energies, 2012, 5.

- Chamoli S., Lu R., Xu D. & Yu P. Thermal performance improvement of a solar air heaterfitted with winglet vortex generators. Solar Energy, 2018, 159.

- Singh I. & Singh S. CFD analysis of solar air heater duct having square wave profiled transverse ribs as roughness elements. Solar Energy, 2018, 162.

- Abuska M. Energy and exergy analysis of solar air heater having new design absorber plate with conical surface. Applied Thermal Engineering, 2018, 131.

- Uzbekov M. O. Possibilities of increasing the efficiency of the heat receiver of ics from metal shavings. Computational nanotechnology, 2019, 2, 138-140.

- Abbasov Yo. S. & Uzbekov M. O. Studies efficiency solar air collector. Austrian Journal of Technical and Natural Sciences «East West» Association for Advanced Studies and Higher Education GmbH. Vienna, 2016, 7-8, 13-17.

- Uzbekov M. O. & Abbasov E. S. Technique - economic analysis of the use of solar air collector in the conditions of the Fergana region of the Republic of Uzbekistan. European Science Review, 2019, 1-2, 68-72.

- Ravi R.K. & Saini R. P. Nusselt number and friction factor correlations for forced convective type counter flow solar air heater having discrete multi V-shaped and staggered rib roughness on both sides of the absorber plate. Applied Thermal Engineering, 2018, 129.

- Skullong S., Promthaisong P., Promvonge P., Thianpong Ch. & Pimsarn M. Thermal performance in solar air heater with perforated-winglet-type vortex generator. Solar Energy, 2018, 170.

- Hassan H. & Abo-Elfadl S. Experimental study on the performance of double pass and two inlet ports solar air heater (SAH) at different configurations of the absorber plate. Renewable Energy, 2018, 116.

- Dongxu Jin, Jianguo Zuo, Shenglin Quan, Shiming Xu, Hao Gao. Thermohydraulic performance of solar air heater with staggered multiple V-shaped ribs on the absorber plate. Energy, 2017, 127.

- Fan W., Kokogiannakis G., Ma Zh. & Cooper P. Development of a dynamic model for a hybrid photovoltaic thermal collector solar air heater with fins. Renewable Energy, 2017, 101.

- Khalil A., Shalaby S. M. & Zayed M. E. Improvement of thermal performance of the finned plate solar air heater by using latent heat thermal storage. Applied Thermal Engineering, 2017, 123.

- Srivastava R. K. & Rai A. K. A review on performance enhancement of solar air heater. Department of Mechanical Engineering, Oct 03, 2017.

- Uzbekov M. O. & Nasretdinova F. N. Overview of the main types of solar air heaters. XLI International scientific and practical conference «International scientific review of the problems and prospects of modern science and education». Boston, USA, 2018, 20-23.

- Uzbekov M. O. & Shermatov B. A. Research of absorbers efficiency of solar air heaters. ХXXVII International scientific and practical conference «European research: innovation in science, education and technology». London, United Kingdom, 2018, 21-26.

- Uzbekov M. O. & Sharipov M. S. Methods of discharging the heat from the surface of the heat receiver and improving the efficiency of solar air heater. XXXIVInternational Scientific and Practical Correspondence Conference «Scientific research: key problems of the III millennium». Moscow, 2019, May 5-6, 12-15.

- Kumar A. CFD analysis on the thermal hydraulic performance of an sah duct with multi V-shape roughened ribs. Energies, 2016, 9.

- Kim M. H. Thermal hydraulic performance in a solar air heater channel with multi V-type perforated baffles. Energies, 2016, 9.