Researches of hybrid technology of the noncontact acoustic control

Автор: Geryukov A. Sh., Bogdanov V.V., Nazarov S.V.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Математика, механика, информатика

Статья в выпуске: 7 (33), 2010 года.

Бесплатный доступ

This work is devoted to the results of experimental research concerning noncontact acoustic control of products. An advanced method of ultrasonic vibrations excitation in materials is offered. Design features of an electromagnetic acoustic converter for radiation – acoustic control are described.

Noncontact generation, cathode ray, ultrasonic vibrations, signals record

Короткий адрес: https://sciup.org/148176467

IDR: 148176467

Текст научной статьи Researches of hybrid technology of the noncontact acoustic control

The provision of high and stable quality of special engineering products, including aerospace equipment, is now one of the basic technological problems. Efforts of many scientific-research and design-technological organizations are put into its solution.

One of the primary factors influencing quality of products are defects of internal structure. The majority of refusals arising during tests and exploitation of products are related to manufacturing defects not found out earlier. Therefore a nondestructive test (NT) plays an important role both in the production process and in the process of technological development of products. The form of the construction, the presence of many inaccessible and out-of-the-way places for traditional devices of NT together with the requirement of maximum sensitivity and high resolution as well as special conditions of manufacturing make heavy demands on used methods and devices of NT, and often limit the application of many traditional methods of control. In this connection the creation of essentially new methods and devices of NT is extremely urgent.

One of the most widespread test method in industry is crack detection by means of acoustic waves. The necessity of acoustic contact creation in overwhelming majority of ultrasonic (US) devices makes it practically impossible to carry out NT in vacuum or controllable environment, at considerable levels of radiation and high temperatures which is typical first of all for beam technologies. All this has caused and stimulated the intensive development of researches of new noncontact methods of acoustic control based on optoacoustic and radiation-acoustic (RA) methods of ultrasonic vibrations generation in materials.

Increase of NT reliability is directly connected with the solution of the problem of acoustic contact stabilization. In its turn it has caused the development of noncontact methods of ultrasonic control. In particular, the use of vibrations of pulse compact electron accelerators for excitation of US vibrations provides the formation of short acoustic signals of nanosecond duration with sharp edges, which is extremely important for measurement accuracy increase. Besides, the radiation method of US vibrations generation provides remote excitation of stable acoustic impulses with parameters poorly depending on the quality of controllable product surfaces treatment that is explained by marked subsurface character of ultrasound formation.

To conduct experimental researches on noncontact registration of acoustic vibrations generated by impulse electron beams in current-carrying non-magnetic materials as well as to define defect detecting opportunities of RA quality monitoring a model set of an installation of RA control has been designed and manufactured.

The basic element of an installation is a small-sized electron accelerator, mounted on the basis of the MIRA-2Д impulse X-ray machine.

The accelerator has the following parameters:

-

- maximum electron energy in spectrum is 200 kilo electron volt;

-

- full energy transported by an electron beam for a pulse is about 200 mJ;

-

- duration of current pulse is 10 nsec;

-

- amplitude of beam current is 100 А;

-

- the diameter of beam put into the atmosphere is 6 mm.

The registration of generated acoustic signals was carried out by the electromagnetic-acoustical converter (EMAC) with a magnetic system of one constant magnet of the size 7 × 20 × 30 mm and residual induction 0.6 Tesla. A flat reception coil was made in the form of an ellipse with 12 × 18 mm size made of wire PEV-0.31. Electric pulses from EMAC entered the block of signal amplification, consisting of a preliminary low – noise amplifier and a radio-frequency amplifier UZ-29 with a coefficient of amplification 45 Db, a pass band 20 MHz and a dynamic range 1–200 mV through a parallel diode limiter. The block of amplification by a cable line coordinated on the entry and the exit was connected with the block of visualization made on the basis of the broadband oscilloscope С8-12.

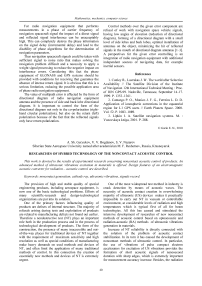

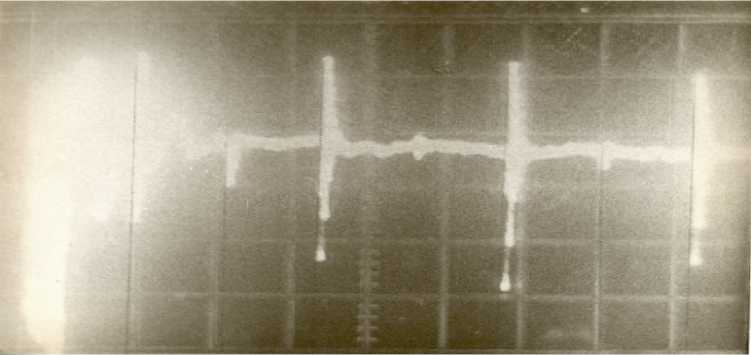

Researches were carried out on samples of АlМg-6 alloy, made in the form of parallelepipeds with 40 × 40 × 60 mm size and plates with the thickness of 18 mm. The sizes of samples were chosen proceeding from the condition of eliminating the effect of lateral faces upon measurement results. Volumetric defects were simulated by flat-bottomed apertures, lateral drilling and rectangular grooves of various sizes. An electron beam was directed on the faultless surface of the sample, the axis of the beam was combined with the axis of defect, as otherwise the characteristics of generated acoustical radiation will depend on the kind and size of an artificial defect. Fig. 1 shows the oscillogram of the audible signals generated by an impulse electron beam in the faultless sample and registered with the help of EMAC.

Identifying signals according to the run time of the acoustical wave in the sample, it is possible to distinguish two types of US waves – longitudinal ones and shift ones.

The amplitude of a longitudinal wave is much bigger than that of a shift wave, which is explained by the design of EMAC used in the experiment and various character of spatial distribution of acoustical radiation of longitudinal and transverse US vibrations. Besides, it is necessary to note, that the second pulse of a shift wave is the result of a longitudinal wave transformation at its reflection from the opposite surface of the sample. The amplitudes of all three registered pulses of a longitudinal wave are practically equal in magnitude which is explained by insignificant losses of acoustical energy in aluminum samples. It is necessary to pay attention to the fact that signals from longitudinal and shift waves are opposite in phase. It confirms the previous conclusion that a longitudinal wave is primary, and a shift wave is the result of its transformation.

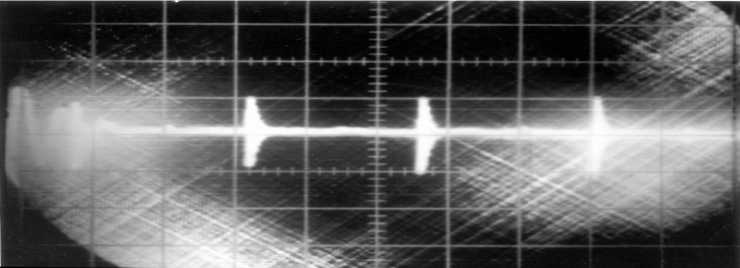

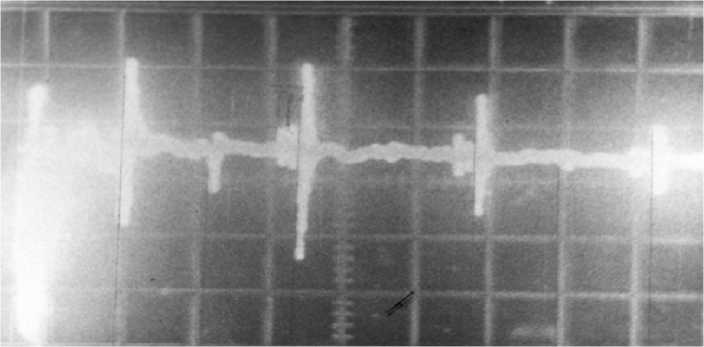

Fig. 2. shows the oscillograms illustrating the opportunities of noncontact radiation-acoustical control in the echo – through variant. The prismatic samples contained defects in the form of rectangular grooves of various depths while their width remained constant – 3 mm. From the comparison of the character of registered ultrasonic signals with the oscillogram of EMAC response while checking the faultless sample it is obvious that the presence of a defect in the product results in the appearance of additional intermediate audible signals and their position on a time base depends on the depth of a defect occurrence. The presence of a double signal from a defect is most likely explained by the character of reflection of the acoustical wave from the groove with flat bottom [1; 2].

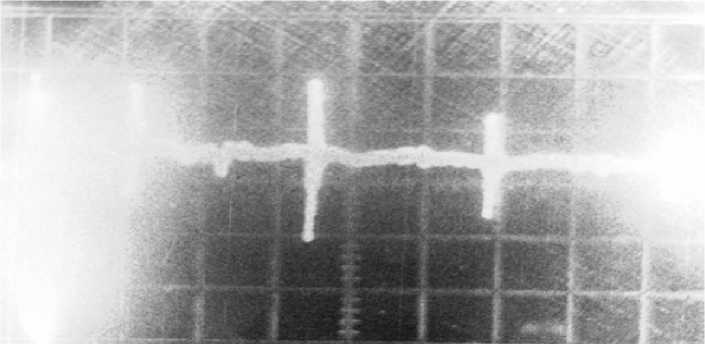

Fig. 3. shows EMAC response oscillogram while checking the sample as a plate with a defect diameter of 3 mm and the depth of 10 mm. It is seen that a series of the first audible signals is lost in noise. However, the second echo-through pulse and the signal from a defect are clearly seen; the third rereflected pulse also gives a stable signal characterizing the defect.

Fig. 1. Oscillogram of electric response of EMAC at registration of the acoustical vibrations generated by an electron beam in the sample made of АlМg-6 alloy

а

b

Fig. 2. The oscillograms received during the research of samples with artificial defects in the form of a rectangular groove with a depth: а – 5 mm; b – 15 mm

Fig. 3. The oscillogram received during the research of a sample made of alloy AlМg-6 in the form of a plate t = 18 mm with a flat-bottomed aperture

From the point of view of the requirements made to such detectors which were caused by both peculiarities of a radiating source of acoustical radiation and the character of the problem the analysis of technical characteristics of presently used noncontact receivers of US vibrations has shown that the optimal type of noncontact US detectors is EMAC. Such addition to a radiation-acoustical method provides not only the implementation of noncontact technique of US control of current-carrying non-magnetic materials, but also allows to expand the functionalities of EMAC significantly.

Experimental researches aimed at the optimization of design of EMAC working on longitudinal and shift acoustical waves and allowing to register both types of waves were carried out with the purpose of creation of simple and reliable means of noncontact registration of audible signals. Magnetic EMAC system of all types were made of rare-earth materials (REM) on the basis of intermetallic compounds of cobalt possessing high coercive force and magnetic energy ( Н св = 0.51–0.7 mА/m; W = 120–200 kJ/m3) [3], which allowed maximum miniaturization of converters. As intermetallic bonds of rare-earth metals are included in a group of over critic magnetic materials they possess rather attractive properties. This is the independence of a magnetic moment on a magnet form and the ability to completely restore a magnetic stream during magnetic return even in case when the strength of a foreign degaussing field is commensurable with or exceeds the coercive force. The latter property is especially important at EMAC work in conditions of powerful electromagnetic fields the source of which are impulse electron accelerators. Besides magnets of REM are characterized by high thermal stability (a temperature inductance coefficient for samarium alloys is: cobalt – 0.043 %Сo, samarium– praseodymium–cobalt – 0.056 %Сo, samarium– gadolinium–cobalt – 0.0015 %Сo), which is important during the control directly in a technological process when EMAC characteristics should be constant in a wide temperature span.

EMACs developed on the basis of RE magnets are characterized by simplicity of design and reliability.

Detectors being a component of a cylindrical beam guide of an electron beam were developed for the realization of the control in conditions of unilateral access to the product. Thus, EMAC was made in the form of a ring covering the collimator. In one variant two magnets made in the form of concentric rings separated by a dielectric spacer were set in a case made of ferromagnetic material. Concentric coils were placed under magnet poles. By changing a way of their turning on it is possible to form the optimum diagram of reception orientation.

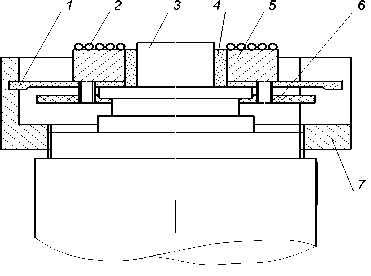

In the second variant (fig. 4), the detector represents a system providing an arrangement of measuring windings 1 EMAC and the face surface of two electron accelerators in one plane, irrespective of changes of the geometrical sizes of used constant magnets 3. It is provided by the mounting of magnetic systems on the steel base 4 with a possibility of coaxial rotation relative to case 5 and the collimator by means of threaded connection. In its turn the case is fixed on the electron accelerator. The design of the detector provides setting up and connecting of a diode limiter and a preliminary amplifier on board 6 as well as the use of several converters with various geometry of magnets and various connection of coils relative to each other. Steel ring 7 screens the magnetic system EMAC made of prismatic magnets.

In practice a signal-to-noise ratio is of major importance in determination of sensitivity limits of EMAC and the efficiency of this or that way of increasing the sensitivity of a detector should be estimated first of all according to this parameter [4].

The way of control with the help of EMAC use was offered, allowing to decrease the influence of an air gap between a converter and a product on the quality of control [5] considerably

К с = ~ с Аg

.

This method is realized as follows. Beforehand an electromagnetic acoustic converter is placed on the neighboring sites of a sample with a defect of a maximum permissible size. Thus, there is set a minimum gap h between surfaces of a sample and an electromagnetic acoustic converter. Echo-signals of each converter are registered and their difference Vg 0 is defined. Then detectors are placed with a minimum gap h on a surface of a sample without defects. Echo-signals of converters are received and their difference V 0 is defined. Then an electromagnetic acoustic converter is placed on a surface of a controlled product with a defect, echo-signals V 1 and V 1 of corresponding electromagnetic acoustic converters are registered and the revealed defect is qualified according to Δ V value:

А V = 11 - Vgl IV - V . (2)

V Vo )

Fig. 4. The design of an acoustic fluctuations detector based on an electromagnetic acoustic converter for realization of noncontact ultrasonic control at unilateral access to a product. 1 – is a steel base; 2 – are inductance coils; 3 – is a collimator;

4 – is a shielding steel ring; 5 – is a magnetic system; 6 – is a board for diode limiter and a preamplifier installation; 7 – is a detector case

When Δ V > 0, a defect is admitted acceptable, when Δ V ≤ 0 it is admitted unacceptable. Thus h gap change, for example, at the expence of controllable product surface pollution, influences Δ V value a little.

The conducted researches allow to conclude that working out of a noncontact method of acoustic control and hardware means for its realization is possible on the basis of ultrasonic vibrations generation in metals by pulse electron bunches of nanosecond duration.